HOW TO CHOOSE THE COIL WRAPPING MACHINE FOR COILS

A machine that wraps coils with wrapping material, consisting of an annular frame with a track encircling an opening, and a carriage assembly that moves along the track, dispensing the wrapping material onto the coil. The coil wrapping machine wad designed and produced by the best engineers and designers of SHJLPACK, which is mostly suitable for many coil package, especially for ssteel coil, wire coil, plasitc pipe coils. A coil wrapping machine is a machine used to wrap coils with insulation or other protective materials, as well as to make the coils easier to handle.

A coil wrapping machine, also known as a coil packing machine, is a type of machinery used for packaging steel coils, plastic pipe coils, and steel wire coils. The main function of the machine is to wrap these coils with protective materials, such as stretch film, shrink film, or paper, to protect the coils during transportation and storage.

The process of wrapping a coil with a coil wrapping machine typically involves the following steps:

1. Loading the coil: The coil is loaded onto the machine's mandrel, which holds the coil in place during the wrapping process.

2. Applying the wrapping material: The machine applies the wrapping material, such as stretch film, shrink film, or paper, to the coil. The wrapping material can be applied manually or automatically.

3. Wrapping the coil: The mandrel rotates, and the wrapping material is wrapped around the coil. The wrapping pattern can be programmed to be tailored to the specific needs of the product

4. Securing the wrap: The wrapping material is secured with heat, adhesive, or mechanical means.

5. Unloading the wrapped coil: The wrapped coil is then unloaded from the machine for transportation or storage.

There are different types of coil wrapping machines available on the market, including semi-automatic and fully automatic machines. Some machines are designed to wrap a single coil at a time, while others can handle multiple coils simultaneously. The choice of a machine depends on the specific needs of the application, such as the size of the coils, the type of wrapping material, and the required wrapping pattern.

Following is the tipical coil wrapping machine available from market per different coil package.

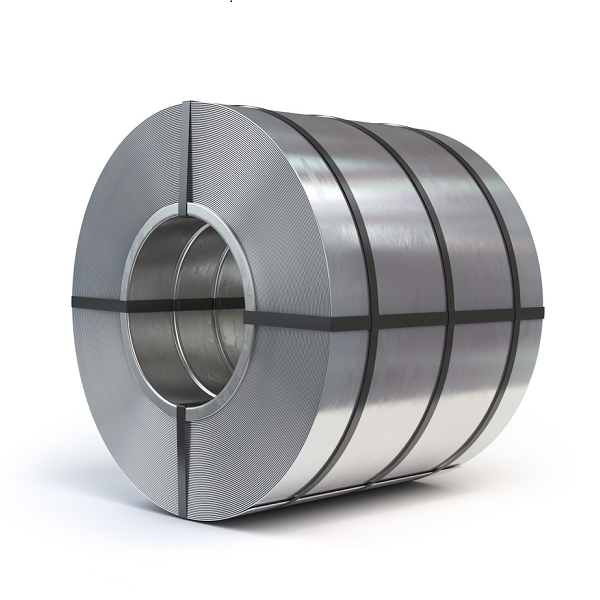

A. STEEL COIL WRAPPING MACHINE

Steel coil wrapping machines are designed to handle metal steel coils of different sizes, widths, and weights. They can also be programmed to wrap the steel coils with different wrapping patterns, depending on the specific needs of the application. Some steel coil wrapping machines are semi-automatic, while others are fully automatic, with the ability to program different wrapping patterns and sequences.

It is important to note that steel coil wrapping machine is not only protect steel coils during transportation and storage but also make the steel coils easy to handle, stack and take up less space.

Packing material: Stretch film, Paper, Woven...

1. ECOMOMIC VERSION

An economic version of a steel coil packing machine is a cost-effective option for packaging steel coils.The steel coil loading and unloading by semiauto which using crane or forklifter. It may not have as many features or capabilities as a more expensive steel coil wrapping machine, but it can still effectively pack and secure steel coils for transport. The specific features and capabilities of an economic version of a steel coil packing machine will vary depending on the manufacturer and model.

After loading the steel coil on the wrapping station, the paper packing material will be feeding and utomatic length checking and cutting.

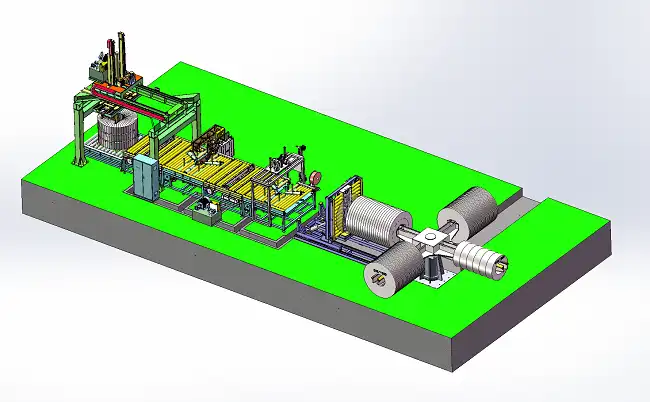

2. AUTOMAITC COIL WRAPPING MACHINE:

An automatic steel coil wrapping and packing line is a system that is used to package and secure steel coils for transport. The line typically includes a series of machines and equipment that work together to efficiently and effectively pack the steel coils. Some of the key components of an automatic steel coil packing line may include:

-A decoiler machine to uncoil the steel coils and prepare them for packing

-A straightener machine to ensure the steel coils are straight and free of any defects before packing

-A coil wrapping machine to wrap the steel coils with protective materials such as stretch film, paper or wovon

-A strapping machine to secure the wrapped steel coils with steel straps or plastic straps

-A palletizer machine to stack the packaged steel coils on pallets for easy handling and transport

The specific components and features of an automatic steel coil packing line will depend on the manufacturer and the specific needs of the customer.

Automatic steel coil packing line

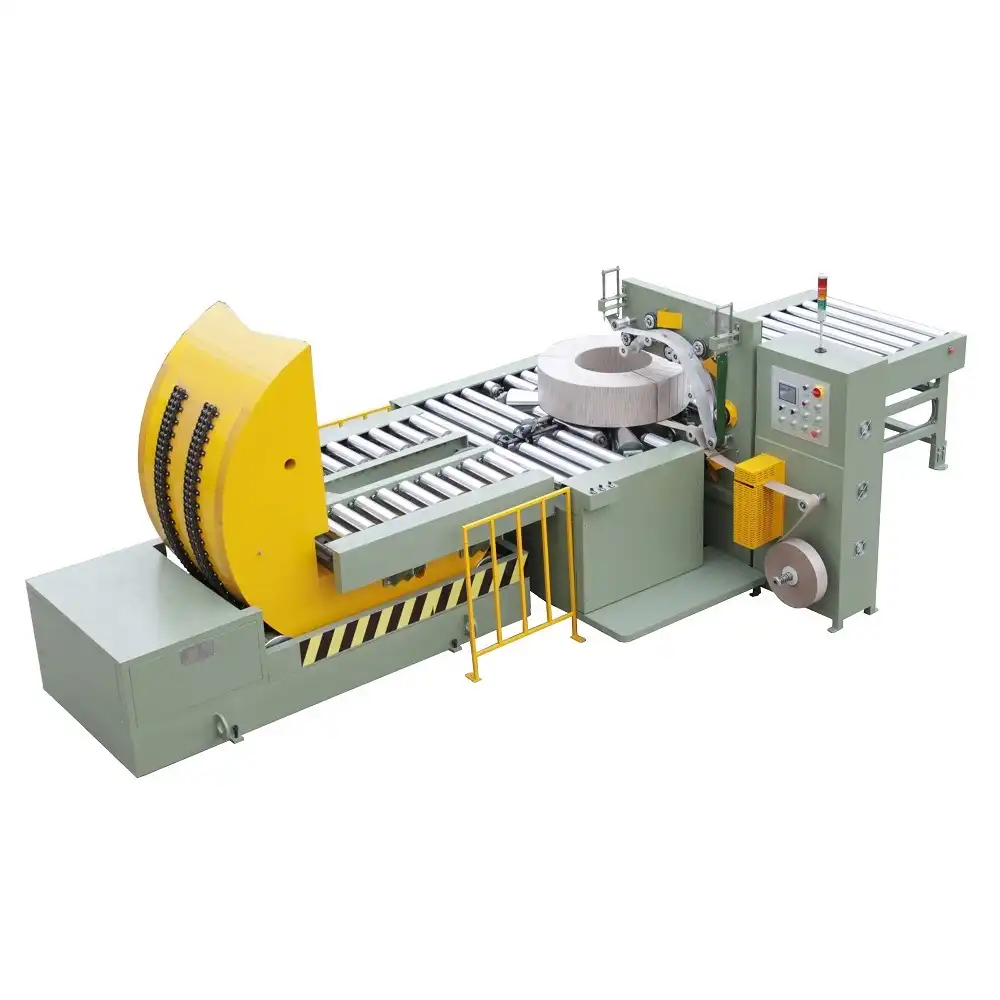

B. STEEL WIRE COIL WRAPPING MACHINE

A steel wire coil wrapping machine is a type of packaging equipment used for wrapping steel wire coils with protective materials to secure them for transport and storage. The machine can be used to wrap steel wire coils of different sizes and shapes, and typically includes the following components:

A wrie coil support system to hold the steel wire coil in place

A wrapping material dispenser to apply the protective wrapping material such as stretch film, paper, or woven fabric

A ring wrapping head that rotating through the coi eyel to apply the wrapping material

A tension control system to ensure the wrapping material is applied with the correct tension and overlap

A cutting mechanism to trim and cutting the wrapping material after it has been applied

1. ECONOMIC VERSION

The economic wire coil wrapping machine inclues the ring wrapper and supportive rotation roller that coil loading and unloading by manually or crnae.

It is able to work for different steel wire coil packaging. No matter what wire coil size, weight and packaging goal, Our team makes solutions as your need.

Some of the features that a steel wire coil wrapping machine may have include:

-

Adjustable steel wire coil wrapping parameters such as ring speed, wrapping tension, and wrapping overlap

-

Automatic or semi-automatic operation with packing material feeding and cutting

-

Automatic end-of-roll detection and splicing

-

PLC control system for easy operation

-

Safety guard to protect the operator

-

The specific features and capabilities of a steel wire coil wrapping machine will vary depending on the manufacturer and model.

2. HORIZONTAL STEEL WIRE COIL WRAPPING MACHINE

The bubble fim packing machine for door includes the film covering and sealing device with wrapping machine,out feeding conveyor and control panel

This is a sealed packaging way by bubble film and stretch film which can protecting every corner of the goods which is good for transportation to avoide damge.

PE film and bubble film are used in the film coating device. Then, the film is cut with sealant.

Beside, there is vertial type steel wire wrapping machine, the horizontal version wie coil wrapping machine designed for on-line handling and packing.

The horiozntal packaging solution can be connects with in-feeding and out-feeding conveyor.

By horizontal wire coil handling and wrapping, the packing machine can be connected with automatic wire coil rewinding and stacking machine. So it makes the whole system automation in the wire packaging and storage.

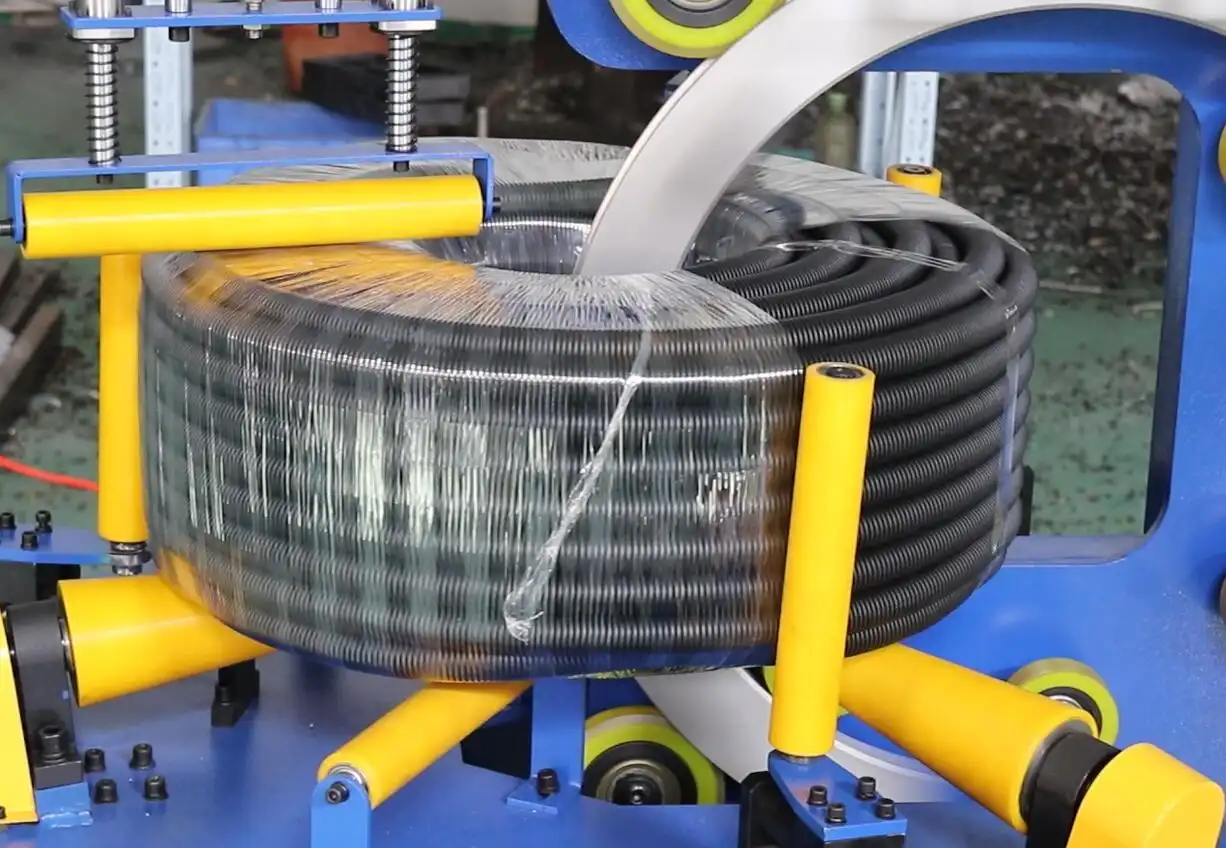

C. PLASTIC PIPE AND HOSE COIL WRAPPING MACHINE

Plastic Pipe and Hose Coil Wrapping Machinery is designed for the efficient and convenient packaging of garden hose coils, HDPE Pipe, PVC pipe coil... This machine is specifically designed for plastic coils from small OD to big OD. The high efficiency makes it a good equipment for saving on both material and labor costs. It features a hose reel with an eye-wrap design and has various functions such as being suitable for multiple packaging materials, manual and automatic modes, adjustable speed and overlapping rate, safety guardrails, and automatic alarms for faults. Additionally, it includes support rollers for the plasitc coils, adjustable packing tension, special brake devices to prevent material folding, and a high level of efficiency for packaging.

2. VERTIAL PLASITC COIL WRAPPING MACHINE

Vertical plastic coil wrapping for light coil packing with manually coil loading. Packing material usually fixs on the ring for coil packing. Packing speed is app. 20-35 sec per coil

2. HORIZONTAL HOSE WRAPPING MACHINE

Choosing the horizontal versino hose coil wrapping machine is mainly for two factors: 1. The coil too light to wrapping by vertical wrapping. 2. For automatic coil packing.

By horizontal wrapping, the light coil can be holding with proper force to avoid the coil shaking and deforming.

D. CABLE COIL WRAPPING MACHINE

1. SEMIAUTO CABLE COIL WRAPPING MACHINE

2. AUTOMATIC CABLE COIL WRAPPING MACHINE

E. CONCLUSION

When choosing a coil wrapping machine, there are several factors to consider to ensure that the machine is well suited to your specific needs and requirements. Some of the key factors to consider include:

1. Production Volume: Consider the number of product coils you need to wrap on a daily, weekly or monthly basis. This will help you determine the size and capacity of the machine you need.

2. Coil size: Make sure that the machine can handle the size and weight of the hose coils you will be wrapping.

3. Wrapping Material: Consider the type of wrapping material you will be using, as well as the width and thickness of the material, to ensure that the machine is compatible.

4. Automation level: Consider the level of automation that you need. Fully automatic machines can handle the entire wrapping process with minimal operator input, while semi-automatic machines may require more operator involvement.

5. Safety: Make sure the machine has a safety guard to protect the operator and the machine from accidents.

6. Maintenance and Support: Consider the availability of maintenance and support services from the manufacturer, and the ease of access to spare parts.

7. Price: Consider the budget you have allocated for the machine and compare the cost of different models.

8. Flexibility: Consider the flexibility of the machine, if you need to wrap different size of coils.

It's important to ensure that the col wrapping machine you choose is well suited to your specific needs and requirements. Some of the semiauto wrapper is a fool style operation equipment, some automatic wrapper needs the necessary resources and expertise to operate and maintain it properly.

More coil wrapping machine: JUST HERE

Referenec: https://patents.google.com/patent/US6520445

https://patents.google.com/patent/US8037661