Introduction

A slitting coil packing line is a crucial piece of equipment for any company in the metal processing industry. However, the process of purchasing one can be daunting, especially if it's your first time. To help you make an informed decision and avoid common pitfalls, we've compiled a list of the top mistakes to avoid when buying a slitting coil packing line.

Understanding a Slitting Coil Packing Line

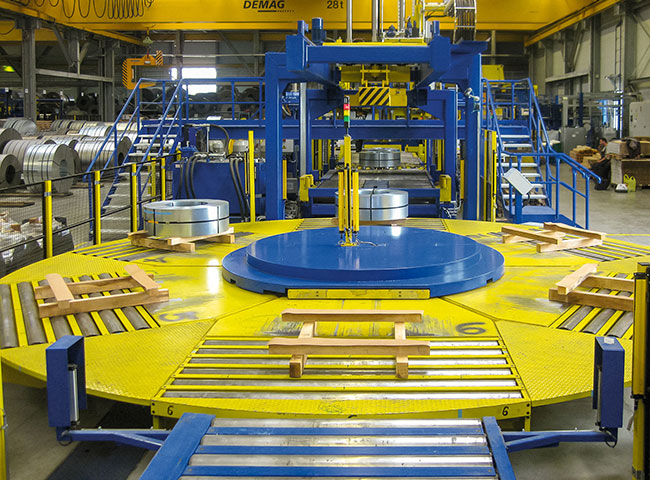

Before diving into the mistakes, let's quickly understand what a slitting coil packing line is. It's an integrated system that slits, recoils, and packs metal coils, making them ready for transport and further processing. This equipment is essential for ensuring high-quality, precise cuts and efficient packaging of metal coils.

Mistake 1: Failing to Determine Your Needs Properly

1. Assessing Production Volume

When purchasing a slitting coil packing line, one of the most common mistakes is not accurately determining your production needs. You should consider factors such as production volume, material specifications, and desired processing speed. This information will help you choose the right equipment for your business.

2. Evaluating Material Specifications

On top of production volume, it's essential to evaluate the material specifications you'll be working with. Different materials require different slitting and packing equipment, so understanding your requirements is crucial.

Mistake 2: Not Researching the Market and Suppliers

1. Importance of Comparing Suppliers

Another mistake is failing to research the market and compare different suppliers thoroughly. You should evaluate various manufacturers and their offerings to ensure you're getting the best value for your money. Don't forget to check their industry experience and reputation.

2. Checking Reviews and Testimonials

Don't underestimate the power of reviews and testimonials. They can give you valuable insights into the supplier's product quality, customer service, and overall reliability.

Mistake 3: Overlooking the Importance of Automation

1. Benefits of Automation

Automation is an essential aspect of modern slitting coil packing lines. It increases efficiency, reduces manual labor, and minimizes human errors. Not considering automation when purchasing your equipment is a significant oversight.

2. Cost and Time Savings

With automation, you'll save time and money in the long run, as your production line will run more smoothly, and your employees can focus on other tasks.

Mistake 4: Ignoring the Need for Customization

1. Adapting to Specific Requirements

No two businesses are the same, and neither are their slitting coil packing line requirements. Therefore, it's crucial to consider customization options when selecting your equipment, ensuring it meets your specific needs.

2. Enhancing Efficiency and Productivity

Customization can lead to increased efficiency and productivity, as your equipment will be tailored to your unique processes and requirements.

Mistake 5: Not Considering Maintenance and Support

1. The Role of Proper Maintenance

Maintenance is critical forthe longevity and performance of your slitting coil packing line. Neglecting the importance of proper maintenance and support can lead to costly downtime and reduced efficiency.

2. Importance of Reliable Support

Choosing a supplier that offers reliable support and after-sales service is crucial. This ensures that you have access to expert help when needed, minimizing potential disruptions in your operations.

Mistake 6: Compromising on Quality for Price

1. The Long-term Costs of Low-Quality Equipment

While it may be tempting to choose the cheapest option available, compromising on quality for price can lead to long-term costs. Low-quality equipment may require more frequent repairs and replacements, ultimately costing more in the long run.

2. Investing in Durability and Performance

Invest in high-quality, durable equipment that offers excellent performance. This investment will pay off over time, as it will require less maintenance and last longer.

Mistake 7: Disregarding Safety Features

1. Ensuring Operator Safety

Operator safety should be a top priority when purchasing a slitting coil packing line. Look for equipment that includes safety features such as guards, emergency stops, and interlock systems to minimize the risk of accidents.

2. Meeting Industry Standards

Ensure that the equipment you choose meets industry safety standards and regulations to protect your employees and maintain compliance.

Mistake 8: Neglecting Training and Skill Development

1. Importance of Staff Training

Proper training and skill development are essential for achieving optimal performance from your slitting coil packing line. Failing to invest in staff training can lead to operational inefficiencies and even accidents.

2. Achieving Optimal Performance

Choose a supplier that offers comprehensive training and support for your employees, ensuring they can operate the equipment effectively and safely.

Mistake 9: Failing to Plan for Future Expansion

1. Scalability and Growth

As your business grows, so too will your production requirements. Failing to plan for future expansion can limit your company's growth potential and result in costly equipment upgrades.

2. Adapting to Changing Market Demands

Choose equipment that is scalable and can adapt to changing market demands, allowing you to remain competitive and efficient as your business expands.

Mistake 10: Not Assessing the Environmental Impact

1. Energy Efficiency and Waste Reduction

In today's environmentally conscious world, it's essential to consider the environmental impact of your slitting coil packing line. Choose equipment that is energy-efficient and reduces waste to minimize your company's carbon footprint.

2. Sustainable Business Practices

Investing in environmentally friendly equipment can also contribute to a more sustainable business model, improving your company's image and attracting environmentally conscious customers.

Conclusion

Avoiding the mistakes outlined in this article can help you make an informed decision when purchasing a slitting coil packing line. By carefully considering your needs, researching suppliers, focusing on automation and customization, and prioritizing maintenance, safety, and environmental factors, you can invest in equipment that will serve your company well for years to come.

FAQs

1. What is a slitting coil packing line?

A slitting coil packing line is an integrated system that slits, recoils, and packs metal coils, making them ready for transport and further processing.

2. Why is automation important for a slitting coil packing line?

Automation increases efficiency, reduces manual labor, and minimizes human errors, leading to cost and time savings.

- What should I consider when choosing a supplier for my slitting coil packing line?

Consider factors such as industry experience, reputation, product quality, customer service, and after-sales support.

4. Why is customization important for a slitting coil packing line?

Customization ensures that your equipment meets your specific needs, leading to increased efficiency and productivity.

5. How can I ensure the safety of my employees when operating a slitting coil packing line?

Choose equipment with safety features such as guards, emergency stops, and interlock systems, and ensure it meets industry safety standards and regulations. Additionally, invest in proper staff training to minimize the risk of accidents.