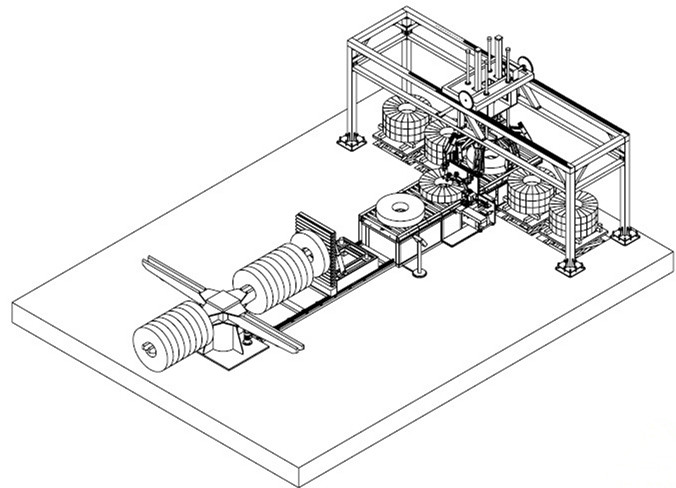

Pallet stretch wrapper JL2100-J

JL2100-J semi-auto pallet wrapping machine working with a rotating turntable can pack the pallet load nicely and tidily by stretch film. The access ramp for pallet jack easy loading & unloading and top plate for pressing down on light and high loads are available for optional requirements.

Stretch film wrapping machine is extremely user-friendly and highly suited to use by smaller-scale film users. The concept of designing a simple and dependable machine is mainly for tackling all your tough applications with the maximum flexibility. Shjlpack’s engineering team emphasizes on safety and reliability of the machine for end users. It aims to cope with a high workload and decrease the risk of maintenance.