6 TYPES COIL WRAPPING MACHINE BEST PRACTICES WITH COIL PACKAGE

6 TYPES COIL WRAPPING MACHINE

BEST PRACTICES WITH COIL PACKAGE

The coil wrapping machine is used for packaging of the steel coils, rods coil, hose ciol, steel wires with different application. The packages are well protected from the external factors like pressure, moisture and so on by the coil packages. The machine is available in different types with diverse features in coil size, packing material. This helps in various applications to load the coils with different handling way and wrap it to protect it from external impact. In this article we will discuss more about the coil wrapping machine and its best practices with coil package.

Following description helps to find a easy way to understanding all the coil packaging form and designing avaiable.

Chapter 2. Ring side up for coil loading from top

By head crane coil loading

Chapter 3. Trolley for heavy coil loading & packing

Chapter 4. Semiauto coil wrapper in horizontal coil loading

Chapter 5. Automatic solution for coil packing

Chapter 6. Customized solution for special coil packaging

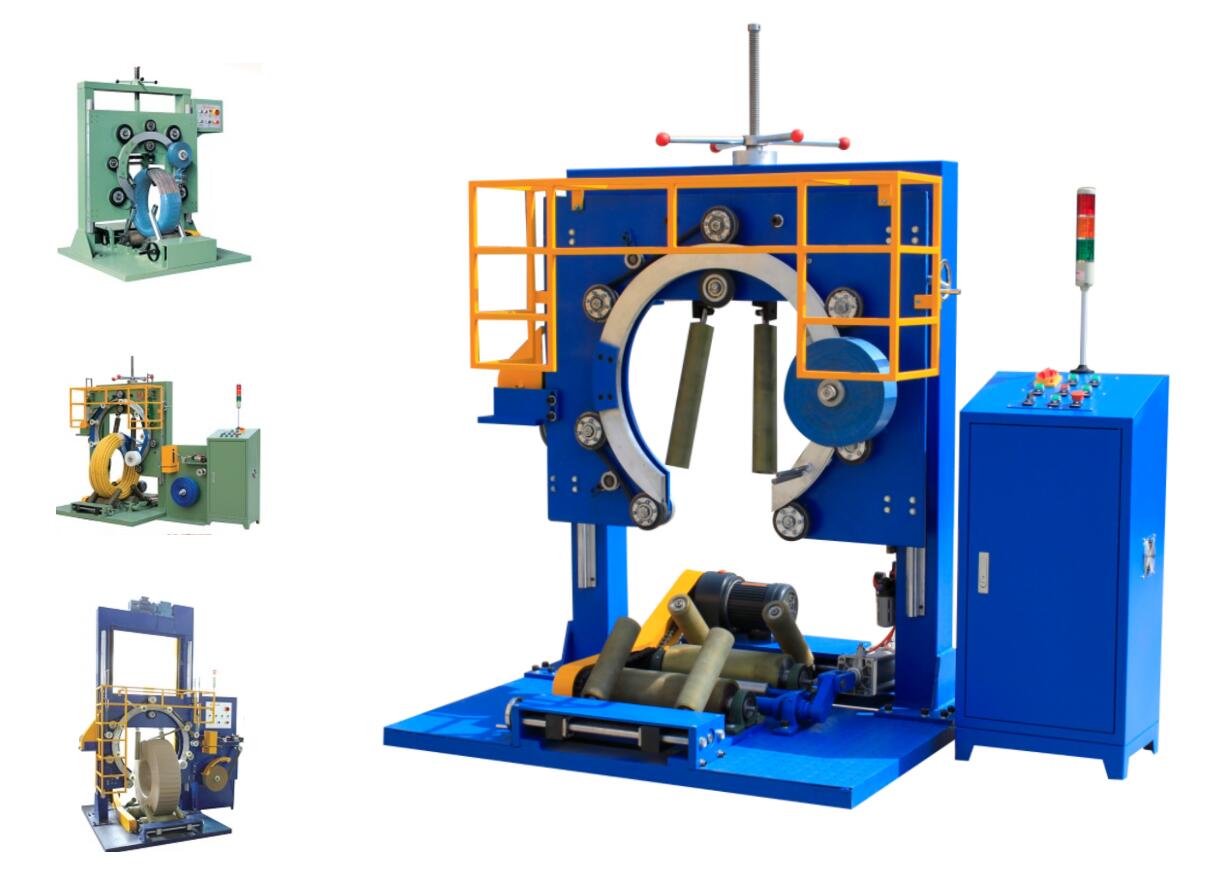

Chapter 1. Vertical Ring side down for easy coil loading by manually

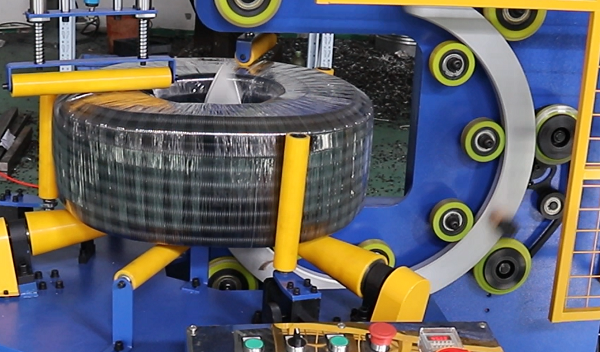

This is a initial designing way for the coil packing, the ring toward to the floor, so that the packing can be well loding by rolling in and out. So it is a basic wrapping equipment used for coil rolling and packaging in a long time. This coil wrapping machines first stop the product flow on the control panel, then take the coil in its hand and automatically turn it into a package with a coil package machine.

Coil loading by manually with wrapping station fixed

In the packing process, before using the coil wrapping machine, only power connection and air connection required. So of the customer will dig a pit and installed the machine into so that the roller level same as the floor for easy coil rolling in & out.

Coil loading by tool with wrapping station movement:

This is a solution with special designing that the wrapping station is movable. This kind of ring side down machine is for easy loading and unloading from the top by crane or forklifter. As you know, there is a problem for heavy coil handling by crane with belt or C-hook that the coil is swaying when the coil was lifting and moving. The swaying is denger for the wrapping machine. Because of any "connecting" would deform the machine structure or shape of the heavy coil. So there is need a enough space on the top side of the roller station. So that it is easy for coil handling throught manul loading and unloading procession.

Chapter 2. Ring side up for loading from top side

This kind of designing also fit for bigger packing range in the coil OD as long as the height of the facility is enough.

By head crane coil loading

The most of user choosing this version is for resovling the probilem caused by crane handling and manual packaging. Since the top sides is opening, the machine allows more safety operation space.With the update device, the machine can do automatic coil supprotive from top and bottom. So that the coil would be well wrapping without shaking.

By the way, the main board of the wrapper is able up and down adjustment that is a way to resove the packing problem caused by different coil OD.

By manually coil loading

This is a machine asking the standing opeartion way because of the wrapping position in rolls is app. 600-800mm. So the people no need bow for handling the coil packing procession from packing material fixing, cutting, reloading... The coil load have to be light and easy to lifting, The heavy coil packaging by this machine is not a good choice when the coil loading and unloading by manually. For example, the coil weight upto 20Kg coil lifting and down in 8 hours that is a high strength work for many staff.Chapter 3. Coil wrapping with trolley for heavy coil

It is one of importation coil packing solution that designed for heavy load, such as steel coil, wire oil, aluminum coil...The trolley includes the roller rotaion for coil 360 degree turning. And it includes the motor driven track system for ajduting the trolley position for wrapping and coil unloading.

In the safety opeartion, the safety fence, light barrer can be using for safety working area.

Chapter 4. Semiauto coil wrapper for horizontal coil loading

Chapter 5. Automatic solution for coil packing

Basic: Conveyor loading automatic coil packaging

This is an basic soltuion for coil packing, because of the it just relate to the packaging procession. Only coil strapping, coil wrapping and stacking was included into the soltuion. It is a traditional automatic solution.that is for replace man power from the packing procession by machine.