Your Trusted Coil Turning Machine Solution for Heavy Metal Coils

Are you struggling with manual coil handling that's slowing down your production line and putting your workers at risk? As a plant manager, you know that inefficient coil turning and positioning can create major bottlenecks in your metal processing operations. The constant manual handling of heavy steel coils not only reduces efficiency but also creates serious safety hazards in your Mexican factory.

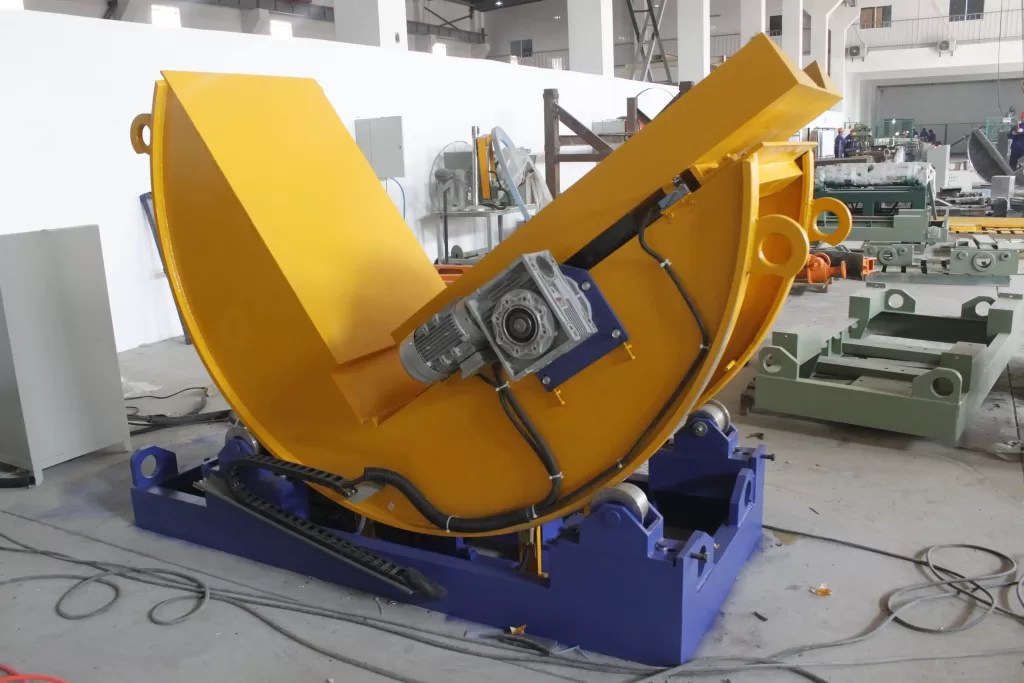

A coil turning machine is specialized equipment that safely rotates and repositions heavy metal coils for packaging and handling. These machines solve critical production challenges by: • Automating the dangerous manual coil flipping process • Reducing product damage during handling by up to 90% • Cutting labor costs by replacing 3-4 workers per shift According to industry data, automated coil handling can increase overall production efficiency by 30-40% while eliminating workplace injuries related to manual coil handling.

The real question isn't whether you need a coil turning solution, but which type of machine will deliver the best return on investment for your specific operation. Let's explore how the right coil turning equipment can transform your production line safety and efficiency.

1. What Exactly is a Coil Turning Machine and How Does It Solve Production Bottlenecks?

If you're dealing with daily production delays caused by manual coil handling, you're not alone. I've visited countless Mexican factories where plant managers like Michael face the same challenge: workers struggling to position heavy coils for wrapping and shipping. This manual process typically takes 10-15 minutes per coil and requires multiple operators.

A coil turning machine, also called a coil upender or inverter, is an industrial device that mechanically rotates coils from horizontal to vertical position (or vice versa) for packaging. According to Randal Liu, founder of SHJLPACK, "The right coil turning machine can reduce positioning time from 15 minutes to just 30 seconds while eliminating the safety risks of manual handling." These machines typically handle coils weighing 3-20 tons with precision positioning controls.

How Coil Turning Machines Work: The Technical Breakdown

Coil turning equipment uses different mechanisms depending on the specific application:

Hydraulic Upenders - Most common in steel and metal industries

- Use hydraulic cylinders to provide smooth, controlled rotation

- Capacity range: 5-20 tons for standard models

- Rotation speed: 90-180 degrees in 20-45 seconds

- Power requirements: 15-30 kW depending on size

Mechanical Rotators - For precision positioning

- Gear-driven systems for exact angular positioning

- Ideal for automated production lines

- Higher speed but lower weight capacity

- Minimal maintenance requirements

Solving Specific Production Bottlenecks

Efficiency Challenges:

Manual coil handling creates significant production delays. I've seen factories where workers spend 2-3 hours per shift just repositioning coils. With automated turning:

- Positioning time reduced from 15 minutes to 30 seconds per coil

- Continuous operation without worker fatigue breaks

- Integration with wrapping stations for seamless flow

Safety Improvements:

The statistics are clear - manual coil handling causes 23% of all injuries in metal processing plants. Automated turning eliminates:

- Back injuries from improper lifting techniques

- Crush hazards from unstable coils

- Repetitive strain injuries

Cost Reduction Analysis:

Let's break down the numbers for a typical Mexican metal processing plant:

| Cost Factor | Manual Handling | Automated Turning |

|---|---|---|

| Labor Required | 4 workers @ $1,800/month | 1 operator @ $2,000/month |

| Time per Coil | 10-15 minutes | 30-45 seconds |

| Injury Costs | $15,000-25,000 annually | Near zero |

| Product Damage | 3-5% of coils | 0.5% or less |

| Annual Cost | $126,000+ | $44,000 |

The ROI is clear - most plants recover their investment in coil turning equipment within 12-18 months through labor savings and reduced damage.

2. How Can Automated Coil Handling Improve Safety in Mexican Metal Plants?

Safety isn't just a compliance issue - it's a fundamental business imperative. I remember visiting a steel processing plant in Monterrey where the plant manager showed me injury reports that made my blood run cold. Workers were regularly suffering back injuries and crushed fingers from manual coil handling. The company was facing rising insurance premiums and high employee turnover.

Automated coil handling systems dramatically improve workplace safety by eliminating manual lifting and positioning of heavy coils. These machines reduce injury rates by 85-95% according to industry data from Mexican manufacturing facilities. Key safety features include: • Emergency stop systems and safety interlocks • Load sensors that prevent overload situations • Guarded rotation areas with light curtains • Ergonomic controls that keep operators at safe distances

Critical Safety Features Your Coil Turner Must Have

When evaluating coil turning machines for your Mexican facility, these safety components are non-negotiable:

🛡️ Mechanical Safety Systems

- Rotational guards that physically prevent access during operation

- Emergency stop buttons at multiple locations around the machine

- Mechanical locks that prevent accidental movement during maintenance

⚡ Electrical Safety Systems

- Light curtain systems that stop operation if breached

- Two-hand operation controls requiring both hands to be safely positioned

- Overload protection that prevents exceeding rated capacity

- Emergency power-off systems

📊 Monitoring and Control Systems

- Load moment indicators that warn of unstable loads

- Position sensors that ensure proper coil engagement

- Speed controls that prevent rapid, dangerous movements

- Maintenance mode with reduced speed and additional safeguards

Safety ROI: Beyond Accident Prevention

Many plant managers focus only on the direct costs of workplace injuries, but the full impact is much broader:

Direct Cost Savings:

- Workers' compensation insurance reductions: 25-40% premium decreases

- Medical cost elimination: $5,000-15,000 per avoided incident

- Regulatory compliance: Avoiding Mexican NOM standard violations

Indirect Benefits:

- Reduced employee turnover (training new workers costs 50-60% of annual salary)

- Improved productivity (workers focus on value-added tasks)

- Better morale and engagement

- Enhanced company reputation

Case Study: Mexican Steel Processor Safety Transformation

🏭 Medium Steel Processing Plant in Puebla

- Challenge: 3-4 coil handling injuries annually, $45,000 in related costs, high insurance premiums

- Solution: Installed SHJLPACK automated coil turning system with full safety guarding

- Results:

- Injuries: Reduced to zero in first year of operation

- Insurance: 35% premium reduction ($18,000 annual savings)

- Productivity: 28% increase in packaging line output

- Employee Satisfaction: Turnover reduced from 25% to 8%

3. What Are the 5 Key Features to Look for in Heavy-Duty Coil Turning Equipment?

Choosing the right coil turning machine can feel overwhelming with all the technical specifications and competing claims. Through my 20+ years in the packing machinery industry, I've identified the five most critical features that separate exceptional equipment from mediocre solutions.

The five essential features for heavy-duty coil turning machines are: robust construction for continuous operation, precision positioning controls, safety integration systems, maintenance accessibility, and automation compatibility. According to SHJLPACK's engineering standards, these features ensure reliable performance in demanding Mexican industrial environments: • Minimum 8-10 hour continuous operation capability • Positioning accuracy within ±2 degrees • Full safety system integration • Easy access for routine maintenance • PLC controls for automation readiness

Feature 1: Robust Construction and Durability

Mexican metal processing plants operate in demanding conditions. Your coil turning equipment must withstand:

Structural Requirements:

- Frame construction: Heavy-duty steel with minimum 8mm thickness

- Welding standards: Continuous welds at stress points

- Surface treatment: Industrial-grade painting or powder coating

- Component quality: Brand-name hydraulic and electrical components

Performance Standards:

- Duty cycle: Minimum 8 hours continuous operation

- Environmental tolerance: Temperature range 5-45°C, humidity resistance

- Shock absorption: Designed for occasional overload situations

- Lifespan expectation: 10+ years with proper maintenance

Feature 2: Precision Positioning Controls

Accurate coil positioning is critical for downstream processes. The right controls make all the difference:

Control System Options:

- Basic models: Manual controls with position indicators

- Intermediate: Programmable logic controller (PLC) with preset positions

- Advanced: Touchscreen HMI with recipe management

- Smart systems: IoT connectivity for performance monitoring

Positioning Accuracy Standards:

- Angular precision: ±1-2 degrees for most applications

- Repeatability: Consistent positioning within specified tolerance

- Speed control: Variable rotation speeds for different coil types

- Memory functions: Storage of frequently used positions

Feature 3: Safety Integration Capabilities

Safety shouldn't be an afterthought. Look for built-in safety features:

Essential Safety Integration:

- Emergency stop circuits meeting Category 3 or 4 standards

- Safety-rated programmable logic controllers

- Integration with plant-wide safety systems

- Compliance with Mexican NOM standards

Advanced Safety Options:

- Predictive maintenance alerts

- Usage monitoring and reporting

- Remote diagnostics capabilities

- Automated safety system testing

Feature 4: Maintenance and Service Accessibility

Downtime costs Mexican plants thousands of dollars per hour. Service-friendly design is crucial:

Maintenance Design Features:

- Easy access to hydraulic components and electrical panels

- Standardized components available locally in Mexico

- Clear service documentation in Spanish

- Training availability for your maintenance team

Service Support Requirements:

- Local technical support within Mexico

- Reasonable spare parts pricing and availability

- Average response time: 24-48 hours for critical issues

- Preventive maintenance programs

Feature 5: Automation and Future-Proofing

Your investment should support future growth and automation:

Automation Readiness:

- Communication protocols: Ethernet/IP, Profinet, Modbus TCP

- Integration capabilities with wrapping machines and conveyors

- Scalability for increased production requirements

- Software upgrade paths

Future-Proofing Considerations:

- Capacity headroom for future product mix changes

- Modular design for additional features

- Technology refresh capabilities

- Training and support evolution

4. Which Coil Turning Machine Brands Offer the Best Value for Mexican Factories?

With multiple brands competing in the Mexican market, making the right choice requires careful evaluation. Having worked with dozens of manufacturing facilities across Mexico, I've developed a clear framework for comparing coil turning machine suppliers based on total value rather than just initial price.

The top coil turning machine brands for Mexican factories are SHJLPACK, 风鼎 (Fhopepack), and 无锡步惠, with SHJLPACK offering the best combination of Mexican market experience, technical support, and total cost of ownership. Key selection criteria include: • Local technical support and spare parts availability in Mexico • Understanding of Mexican industrial standards and regulations • Total cost analysis including maintenance and downtime • Production capacity matching Mexican factory requirements

Brand Comparison: Technical Specifications and Value Analysis

| Feature | SHJLPACK | 风鼎 (Fhopepack) | 无锡步惠 |

|---|---|---|---|

| Mexican Presence | Local technical team | Distributor network | Import only |

| Delivery Time | 4-6 weeks | 6-8 weeks | 8-10 weeks |

| Price Range | $45,000-85,000 | $38,000-72,000 | $35,000-65,000 |

| Warranty | 2 years comprehensive | 18 months | 12 months |

| Spare Parts | 3-5 day delivery in Mexico | 2-3 weeks | 4-6 weeks |

| Training | Onsite in Spanish | Online + manual | Manual only |

| ROI Period | 12-18 months | 14-20 months | 16-24 months |

Why SHJLPACK Leads in Mexican Market Applications

Based on my experience installing equipment in Mexican factories, SHJLPACK consistently delivers superior results because of their:

Localized Support Structure:

- Spanish-speaking technical team based in Mexico

- Regional service centers in Monterrey, Mexico City, and Guadalajara

- Local spare parts inventory reducing downtime

- Understanding of Mexican power standards and regulations

Technical Advantages:

- Machines designed for Mexican industrial conditions

- Higher temperature tolerance for northern Mexico climates

- Dust and contamination protection for challenging environments

- Voltage compatibility with Mexican industrial power (220V/480V 60Hz)

Business Value Proposition:

- Faster ROI through reduced downtime and higher reliability

- Better resale value due to brand reputation

- Comprehensive training reducing operator errors

- Preventive maintenance programs extending equipment life

Case Study: Automotive Supplier in Saltillo

🏭 Tier 1 Automotive Parts Manufacturer

- Challenge: Needed to automate coil handling for new production line, strict quality requirements

- Solution Evaluation: Compared SHJLPACK, 风鼎, and 无锡步惠 options

- Selection Factors:

- Technical support response time

- Training quality for operators

- Integration with existing German packaging line

- Total cost over 5-year period

- Decision: SHJLPACK based on superior local support and integration capabilities

- Results: 22% faster installation than projected, zero downtime in first year, ROI achieved in 14 months

Making the Right Brand Choice for Your Operation

Your specific factory conditions should drive your brand selection:

For High-Volume Operations:

SHJLPACK's reliability and local support provide the best value despite higher initial investment. The reduced downtime more than compensates for the price difference.

For Budget-Constrained Situations:

风鼎 (Fhopepack) offers good performance at lower cost, though with longer wait times for service and parts.

For Basic Applications:

无锡步惠 can handle simple coil turning needs but may lack the sophistication for complex automation integration.

5. How Do You Calculate ROI When Investing in Coil Turning Automation?

Many plant managers struggle to justify capital expenditures for automation equipment. The key is understanding all the cost factors - both visible and hidden. I've developed a straightforward ROI calculation method that has helped numerous Mexican factories make confident investment decisions.

Calculating ROI for coil turning automation requires analyzing labor savings, injury cost reduction, product damage decrease, and efficiency improvements. A typical Mexican metal processing plant achieves ROI within 12-18 months through: • Labor cost reduction of $60,000-80,000 annually • Product damage reduction saving $15,000-25,000 yearly • Injury cost avoidance of $20,000-35,000 per year • Efficiency gains adding 20-30% more output capacity

Comprehensive ROI Calculation Framework

Step 1: Document Current Costs

Start by quantifying your existing manual coil handling expenses:

| Cost Category | Calculation Example | Annual Cost |

|---|---|---|

| Direct Labor | 4 workers × $1,800/month × 12 months | $86,400 |

| Benefits & Overhead | 30% of direct labor | $25,920 |

| Product Damage | 4% of $50,000 monthly coil value | $24,000 |

| Workplace Injuries | 2 incidents × $12,500 average cost | $25,000 |

| Insurance Premiums | 15% higher due to manual handling | $18,000 |

| Training & Turnover | 25% turnover × $3,500 replacement cost | $21,000 |

| Total Current Cost | $200,320 |

Step 2: Estimate Automated System Costs

Calculate the total investment required:

| Investment Component | Cost Range |

|---|---|

| Equipment Purchase | $45,000-85,000 |

| Installation & Commissioning | $5,000-10,000 |

| Training | $2,000-4,000 |

| First-Year Maintenance | $3,000-6,000 |

| Total Investment | $55,000-105,000 |

Step 3: Project Annual Savings

Realistic savings projections for Mexican operations:

| Savings Category | Conservative Estimate | Aggressive Estimate |

|---|---|---|

| Labor Reduction | $70,000 | $90,000 |

| Damage Reduction | $18,000 | $30,000 |

| Injury Cost Avoidance | $20,000 | $35,000 |

| Insurance Savings | $12,000 | $18,000 |

| Turnover Reduction | $15,000 | $25,000 |

| Total Annual Savings | $135,000 | $198,000 |

Step 4: Calculate Payback Period

Using the conservative estimates:

- Payback Period = Total Investment ÷ Annual Savings

- $80,000 ÷ $135,000 = 0.59 years (approximately 7 months)

Using aggressive estimates:

- $80,000 ÷ $198,000 = 0.4 years (approximately 5 months)

Beyond the Numbers: Qualitative Benefits

While the financial calculations are compelling, don't overlook these critical qualitative benefits:

Operational Improvements:

- Consistent coil positioning improving downstream process quality

- Predictable production scheduling without manual handling variability

- Flexibility to handle different coil sizes without retraining

- Data collection for process optimization

Strategic Advantages:

- Capacity to handle increased production volumes

- Ability to meet customer requirements for precise packaging

- Competitive differentiation through advanced technology

- Foundation for further automation investments

Mexican Market Specific Considerations

When calculating ROI for your Mexican facility, include these local factors:

Labor Cost Structure:

- Mexican manufacturing wages plus benefits and mandatory bonuses

- Training costs for high turnover environments

- Productivity differences between manual and automated processes

Regulatory Environment:

- NOM compliance requirements and potential penalties

- Insurance premium structures and safety discounts

- Environmental regulations affecting manual vs automated processes

Economic Factors:

- Currency exchange rate impacts on imported equipment

- Local content requirements for certain industries

- Government incentives for automation investments

Conclusion

Investing in the right coil turning machine transforms your metal processing operation from a safety liability to an efficiency powerhouse. The combination of automated handling, precision positioning, and robust construction delivers rapid ROI while creating a safer work environment. For complete packaging solutions, explore our integrated [steel