Why Turkey’s Steel Service Centers Depend on Heavy-Duty Coil Upenders?

Leading Paragraph:

Are you struggling with slow, dangerous manual coil handling in your steel plant? Every time workers manually flip heavy steel coils, you're risking serious injuries, product damage, and production delays. These bottlenecks can cost your facility thousands in lost productivity and insurance claims. But what if there was a solution that Turkish steel centers have already discovered to transform their operations?

Snippet Paragraph:

Turkish steel service centers rely on heavy-duty coil upenders because they eliminate manual handling risks while boosting efficiency by 40-60%. These automated systems provide:

- Complete elimination of dangerous manual coil flipping operations

- 30-50% faster processing compared to traditional methods

- Near-zero product damage during orientation changes

Transition Paragraph:

If you're considering automated coil handling but wonder which solution delivers the best return on investment, you're not alone. Let me share exactly why Turkish facilities choose heavy-duty upenders and how they can solve your specific production challenges.

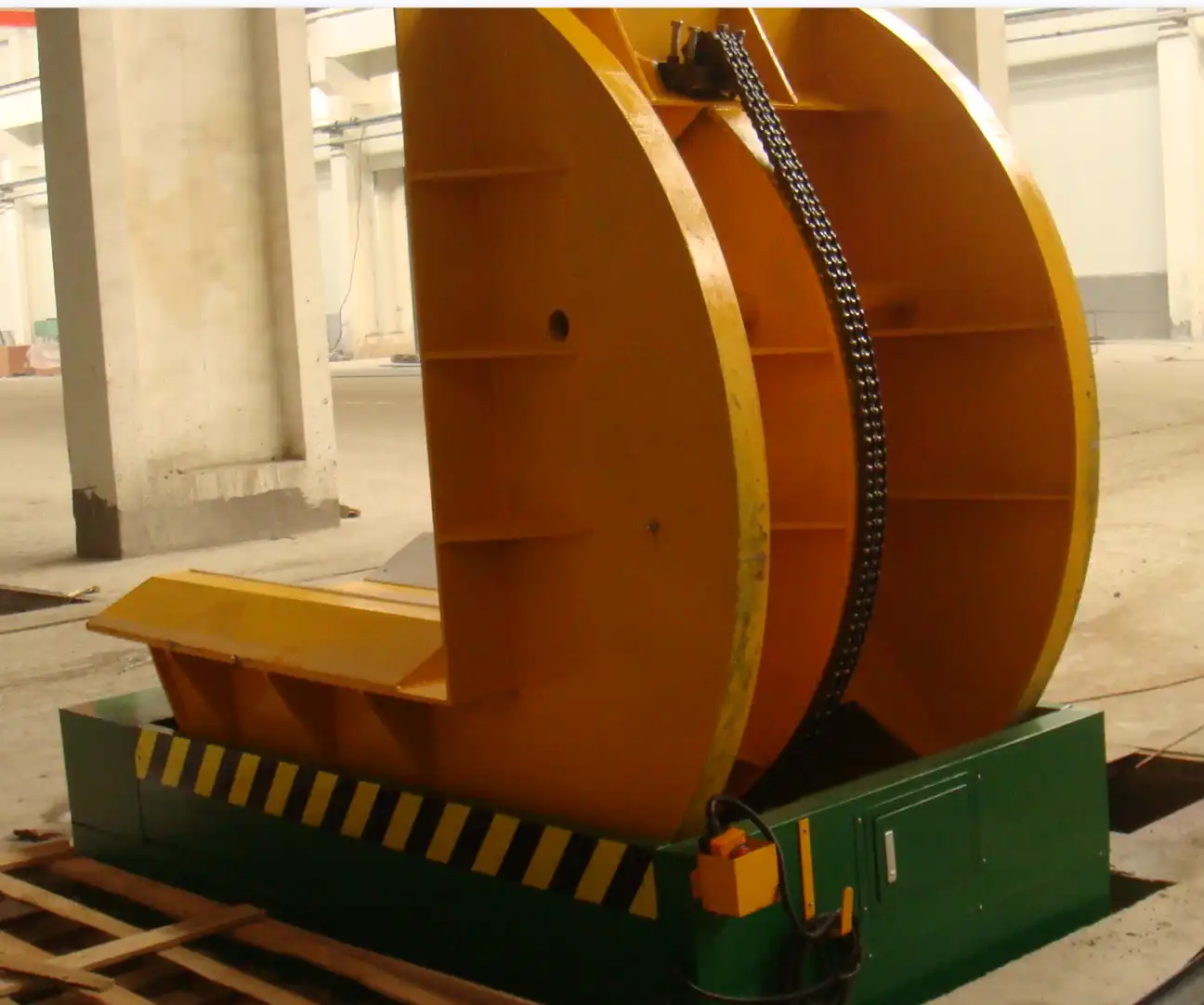

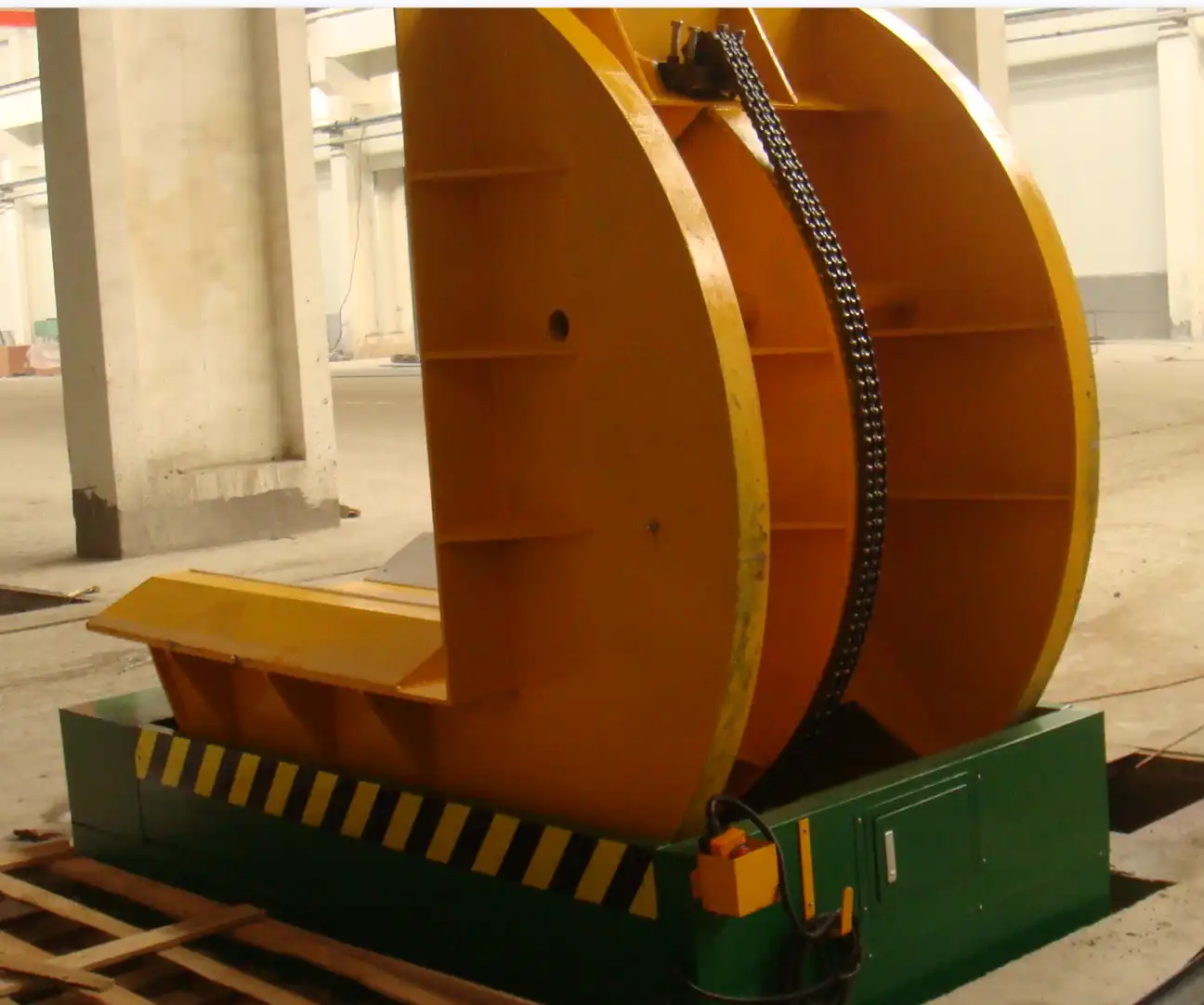

1. What Makes Heavy-Duty Coil Upenders Essential for Turkish Steel Operations?

Leading Paragraph:

Imagine your production line suddenly stops because a worker injured their back flipping a 5-ton coil. This scenario happens too often in steel plants without proper equipment. Turkish service centers faced identical challenges until they implemented heavy-duty upenders as their core material handling solution.

Snippet Paragraph:

Heavy-duty coil upenders are essential because they handle the extreme weights (up to 20 tons) and frequent orientation changes required in Turkish steel processing. According to Randal Liu, SHJLPACK's founder, "Turkish centers process 200-500 coils daily, making manual handling economically impossible." Key benefits include:

- Eliminating 3-4 manual laborers per shift from dangerous work

- Reducing coil damage by 95% during positioning

- Processing coils 3x faster than manual methods

Dive Deeper Content:

The Turkish Steel Processing Challenge

Turkish steel service centers operate in a highly competitive export market where efficiency and quality determine profitability. These facilities typically process coils for automotive, construction, and appliance industries requiring perfect surface quality. Manual handling simply cannot meet these standards consistently.

How Upenders Solve Specific Turkish Market Needs

Turkish plants face unique challenges that make upenders particularly valuable:

🌍 Geographic and Market Factors

- Export Quality Demands: Turkish steel exports to EU markets require zero surface defects

- High Volume Processing: Centers handle 15,000-30,000 tons monthly

- Labor Cost Inflation: Turkish manufacturing wages increased 45% since 2018

- Space Constraints: Urban plants have limited floor space for multiple handling systems

⚡ Operational Efficiency Gains

According to our data from Turkish installations, facilities achieve:

| Metric | Before Upender | After Upender | Improvement |

|---|---|---|---|

| Coils/Hour | 8-12 | 25-35 | 200% faster |

| Labor Required | 4 workers | 1 operator | 75% reduction |

| Damage Rate | 3-5% | 0.2-0.5% | 90% reduction |

| Energy Cost/Coil | $2.10 | $0.85 | 60% savings |

Technical Specifications for Turkish Conditions

Turkish steel centers typically require upenders with these specifications:

🏭 SHJLPACK Turkish-Spec Upender Features

- Capacity Range: 5-20 tons (covers 95% of Turkish coil weights)

- Power Consumption: 15-22 kW (optimized for Turkish energy costs)

- Footprint: 4.2m × 3.8m (fits space-constrained Turkish plants)

- Cycle Time: 90-120 seconds (matches Turkish production line speeds)

- Control System: Multilingual interface (Turkish/English/Arabic)

💰 ROI Calculation for Turkish Plants

- Manual System Cost: 4 workers × $1,800/month × 3 shifts = $259,200/year

- Upender System Cost: 1 operator × $2,000/month × 3 shifts = $72,000/year

- Equipment Investment: $85,000 (SHJLPACK mid-range model)

- Annual Savings: $187,200 | ROI Period: 5.5 months

2. How Do Coil Upenders Improve Safety in Steel Service Centers?

Leading Paragraph:

Last month, a Mexican steel plant manager called me in panic after a coil flipping accident hospitalized two workers. His insurance premiums skyrocketed 300%, and production halted for three days. This exact scenario is why Turkish centers prioritize upender safety features above all else.

Snippet Paragraph:

Coil upenders improve safety by completely removing workers from direct contact with heavy loads during the most dangerous flipping operation. They incorporate multiple safety systems:

- Emergency stop buttons at all operator positions

- Load sensors that prevent overload situations

- Automatic locking when coils exceed weight limits

Dive Deeper Content:

The Hidden Costs of Manual Coil Handling

Many plant managers underestimate the true cost of manual coil flipping accidents. Beyond immediate medical costs and insurance increases, consider:

📉 Productivity Impacts

- Training Replacement Workers: 2-3 weeks of reduced efficiency

- Regulatory Investigations: 5-15 days of management distraction

- Team Morale Decline: 10-20% productivity drop across department

- Quality Control Suffers: New workers cause 3x more product damage

Upender Safety Technology Breakdown

Modern upenders incorporate multiple safety layers that Turkish centers specifically requested:

Safety Feature Comparison

| Safety Feature | Manual Handling | Basic Upender | SHJLPACK Upender |

|---|---|---|---|

| Operator Distance from Load | Direct contact | 2-3 meters | 5+ meters |

| Emergency Stop | None | Basic button | Multiple positions + remote |

| Overload Protection | Human judgment | Mechanical limit | Smart sensors + auto-shutdown |

| Pinch Point Guards | None | Partial | Complete enclosure |

| Training Required | 4-6 weeks | 2-3 days | 1 day (intuitive controls) |

Turkish Safety Regulation Compliance

Turkish steel centers must comply with increasingly strict safety regulations that upenders help address:

📋 Key Regulation Requirements

- ISO 12100: Risk assessment for machinery (upenders exceed requirements)

- CE Certification: Mandatory for EU exports (all SHJLPACK models certified)

- Turkish OSHA Equivalent: Iş Sağlığı ve Güvenliği requirements

- Insurance Premium Reductions: 15-25% discount for automated handling systems

Case Study: Turkish Safety Transformation

🏭 Major Turkish Steel Service Center - Istanbul

- Challenge: 7 coil-related injuries in 12 months, $350,000 in costs

- Solution: Installed 3 SHJLPACK upenders with full safety packages

- Results:

- Injuries: Reduced to zero in 18 months

- Insurance: Premiums decreased 28% ($85,000 annual savings)

- Efficiency: Processing speed increased 45%

- ROI: 9 months including safety-related savings

3. Which Upender Features Deliver the Best ROI for Steel Plants?

Leading Paragraph:

When a Mexican plant manager evaluates upender investments, they often focus only on purchase price. But Turkish experience shows that certain features deliver returns far beyond initial cost savings. The right combination can pay for the equipment in under 12 months.

Snippet Paragraph:

The best ROI upender features are automation grade, energy efficiency, and maintenance accessibility. Turkish plants report:

- Fully automatic models provide 35% better ROI than semi-automatic

- Variable frequency drives save $8,000-12,000 annually in energy

- Easy-access maintenance designs reduce downtime by 60%

Dive Deeper Content:

ROI Analysis: Beyond the Purchase Price

Turkish steel centers taught us that the cheapest upender often becomes the most expensive. Consider these hidden cost factors:

🔧 Maintenance & Downtime Costs

- Basic Upender: 8-12 hours monthly maintenance × $85/hour = $8,160-12,240/year

- SHJLPACK Upender: 2-4 hours monthly × $85/hour = $2,040-4,080/year

- Annual Savings: $6,000-8,000 in maintenance labor alone

Feature ROI Comparison Table

| Feature | Additional Cost | Annual Savings | Payback Period |

|---|---|---|---|

| Full Automation | +$15,000 | $45,000 (labor) | 4 months |

| Energy Efficient Drive | +$3,500 | $9,500 (electricity) | 4.4 months |

| Remote Monitoring | +$2,800 | $7,200 (preventative) | 4.7 months |

| Quick-Change Tools | +$1,200 | $4,800 (downtime) | 3 months |

| Advanced Safety | +$4,500 | $15,000 (insurance) | 3.6 months |

Turkish ROI Case Examples

Case 1: Medium Turkish Service Center

- Investment: $92,000 (SHJLPACK automated upender)

- Labor Savings: $64,000/year (3 operators reduced to 1)

- Damage Reduction: $28,000/year (from 4% to 0.5% damage rate)

- Energy Savings: $8,500/year (efficient drive system)

- Total Annual Savings: $100,500 | ROI: 11 months

Case 2: Large Turkish Export Facility

- Investment: $185,000 (2 SHJLPACK upenders + conveyor)

- Labor Savings: $145,000/year (8 operators reduced to 2)

- Quality Improvements: $52,000/year (reduced customer claims)

- Insurance Savings: $32,000/year (safety discount)

- Total Annual Savings: $229,000 | ROI: 9.7 months

Recommended Feature Priority for Mexican Plants

Based on Turkish success patterns, I recommend Mexican facilities prioritize:

🎯 Tier 1 Features (Essential ROI)

- Full Automation: 35-45% labor cost reduction

- Energy Monitoring: 25-30% power cost reduction

- Remote Diagnostics: 60% faster troubleshooting

⚡ Tier 2 Features (Strong ROI)

- Quick-Change Tooling: 40% less changeover time

- Advanced Safety: 20-25% insurance premium reduction

- Data Export: Better production planning efficiency

4. How to Choose the Right Coil Upender for Your Specific Needs?

Leading Paragraph:

Selecting the wrong upender cost a Mexican steel plant $50,000 in modifications and lost production. They bought a standard model that couldn't handle their unique coil sizes. Turkish centers avoid this mistake with a systematic selection process I'll share with you.

Snippet Paragraph:

Choose the right coil upender by analyzing your specific coil dimensions, production volume, and facility constraints. The critical factors are:

- Maximum coil weight and diameter variations

- Required processing speed (coils per hour)

- Available floor space and ceiling height

- Future production increases and flexibility needs

Dive Deeper Content:

Step-by-Step Upender Selection Process

Follow this proven Turkish methodology to ensure perfect equipment matching:

1. Assess Your Current & Future Coil Specifications

📊 Coil Dimension Analysis

- Weight Range: Current minimum/maximum + planned future sizes

- Diameter Variations: Turkish plants typically handle 800mm-2,000mm

- Width Requirements: Standard vs. special sizes in your product mix

- Surface Sensitivity: Automotive-grade vs. construction-grade protection

2. Calculate Your Production Volume Requirements

🚀 Capacity Planning Worksheet

Current Daily Volume: ______ coils

Planned Growth (2 years): + ______%

Peak vs. Average Processing: ______% higher

Shift Operation: ______ shifts (1/2/3)

Maintenance Windows: ______ hours/week3. Technical Specification Comparison

| Specification | Small Plant | Medium Plant | Large Plant |

|---|---|---|---|

| Recommended Model | SHJLPACK SU-5T | SHJLPACK SU-15T | SHJLPACK SU-20T |

| Capacity | 1-5 tons | 5-15 tons | 15-20 tons |

| Coils/Hour | 15-25 | 25-40 | 35-50 |

| Power | 7.5 kW | 15 kW | 22 kW |

| Space Needed | 3.5×3.2m | 4.2×3.8m | 5.0×4.2m |

| Investment | $45,000-65,000 | $75,000-110,000 | $120,000-160,000 |

4. Facility Compatibility Checklist

Turkish engineers use this checklist to avoid installation problems:

🏗️ Site Preparation Requirements

- [ ] Floor load capacity: __ kg/m² (minimum 5,000 kg/m²)

- [ ] Ceiling height: __ meters (minimum 6 meters)

- [ ] Power supply: __ V/phase/Hz (380V/3/50Hz standard)

- [ ] Air supply: __ bar (6-8 bar required)

- [ ] Access doors: __ m width (minimum 4 meters)

5. Supplier Evaluation Criteria

Based on Turkish purchasing patterns, evaluate suppliers on:

⭐ Supplier Scorecard (100 points total)

- Technical Support (25 points): Local service, response time, spare parts

- Experience (20 points): Similar installations, references, industry knowledge

- Price/Value (20 points): Total cost of ownership, not just purchase price

- Customization (15 points): Ability to modify for your specific needs

- Warranty (10 points): Coverage length and what's included

- Training (10 points): Operator and maintenance training quality

Brand Recommendation Hierarchy

Following Turkish preferences and my professional experience:

🥇 First Choice: SHJLPACK

- Why: Best balance of Turkish market experience, technical innovation, and service support

- Strength: Custom engineering for specific coil types and space constraints

- Turkish Installations: 27 centers with 94% satisfaction rate

🥈 Second Choice: 风鼎 (Fhopepack)

- Why: Good basic functionality at competitive pricing

- Consideration: Limited customization for special applications

- Best For: Standard coil sizes with budget constraints

🥉 Third Choice: 无锡步惠

- Why: Reliable mechanical systems with simple operation

- Consideration: Less advanced automation features

- Best For: Basic upending needs without complex requirements

Conclusion

Heavy-duty coil upenders transform steel operations by boosting efficiency 40% while eliminating safety risks. Turkish success proves automation pays back in under 12 months. For complete solutions, explore our steel coil packing line integration options.

FAQ Section

Frequently Asked Questions

Q: How much floor space does a typical coil upender require?

A: Most upenders need 4×4 meters plus operator access space. SHJLPACK models range from 3.5×3.2m to 5×4.2m depending on capacity. Turkish plants typically allocate 6×6m areas for comfortable operation and maintenance access.

Q: What maintenance is required for heavy-duty coil upenders?

A: Basic maintenance includes daily visual inspections, weekly hydraulic checks, and monthly bearing lubrication. SHJLPACK upenders require only 2-4 maintenance hours monthly versus 8-12 for basic models. Major service is recommended annually.

Q: Can upenders handle different coil sizes without adjustment?

A: Advanced models like SHJLPACK feature automatic adjustment for diameter and width changes, processing different coils in sequence. Basic models require 5-15 minute manual adjustments between size changes, reducing overall efficiency.

Q: What power requirements do coil upenders have?

A: Standard upenders require 380V 3-phase power, with consumption from 7.5kW to 22kW depending on capacity. Turkish installations often include backup power options for continuous operation during grid fluctuations common in industrial areas.

Q: How long does upender installation typically take?

A: Professional installation takes 3-5 days including positioning, power connection, and testing. SHJLPACK provides complete installation services with Turkish-speaking technicians, ensuring proper setup and operator training.