As a procurement manager in Greece's robust steel and metal industry, you face constant pressure. You need to secure equipment that not only meets today's production demands but also addresses tomorrow's challenges. You see your existing machinery aging, energy costs fluctuating, and the need for greater efficiency becoming more critical every day. Investing in a new coil packing line is a major decision. A wrong choice can lead to production bottlenecks, soaring operational costs, and years of frustration. But the right investment can transform your packaging process from a cost center into a competitive advantage, boosting efficiency and protecting your bottom line.

Before investing in a coil packing line, Greek procurement managers should understand that the decision goes far beyond the initial purchase price. The most critical factors to evaluate are the line's potential for automation to lower labor costs, its energy efficiency to combat price volatility, its capability to integrate with your existing and future digital factory systems (like MES), and the supplier's commitment to being a long-term strategic partner who provides support throughout the entire lifecycle of the machine.

Making this decision can feel overwhelming. You have to balance budget constraints with technical specifications and long-term goals. I understand this because I've spent my entire career in this field, first as an engineer and now as a factory owner. I've worked with hundreds of leaders, like a successful steel mill owner in Mexico named Javier, who treat every equipment purchase as a strategic investment. They ask tough questions to ensure a high return. So, let's walk through the key questions you should be asking to ensure your next investment is a success.

How Can a Modern Coil Packing Line Directly Address Rising Operational Costs?

You see the numbers every month. Labor, energy, and material costs are all climbing, squeezing your profit margins. It's a constant battle to find savings without sacrificing quality or safety. You might feel like these costs are outside your control, but a significant portion of them are directly linked to the efficiency of your production line. An old, inefficient packing line quietly drains money through wasted materials, excessive energy use, and reliance on manual labor. A modern coil packing line is engineered specifically to attack these hidden costs, turning them into measurable savings.

A modern coil packing line directly addresses rising operational costs in three main ways: by automating processes to reduce dependency on manual labor, by using precision controls to optimize the consumption of packing materials like film and paper, and by incorporating energy-efficient motors and smart power-saving modes to significantly lower electricity consumption.

Reducing Labor Dependency

In any industrial setting, labor is a significant and rising cost. Manual or semi-automatic packing processes require multiple operators to handle, wrap, and strap coils. This is not only expensive but also introduces risks of human error and workplace injuries. A fully automated coil packing line performs these tasks consistently and without direct human intervention. The system can automatically convey the coil, position it for wrapping, apply the correct amount of stretch film or VCI paper, strap it, and then move it to the next station. This frees up your skilled workers to focus on more value-added tasks like quality control or machine supervision. For a typical packing station, automation can reduce the required manpower from two or three operators per shift to just one supervisor overseeing the entire process. This directly translates to lower labor costs, reduced risk of injury, and improved consistency in your final product's packaging quality.

Optimizing Material Consumption

Packing materials, like stretch film, VCI paper, and steel or PET straps, are a recurring expense. Older machines often lack the precision to use these materials efficiently. They might over-wrap, leading to waste, or under-wrap, compromising the coil's protection during transit. A modern packing line uses advanced sensors and PLC controls to apply materials with incredible precision. For example, the system knows the exact diameter and width of each coil. It can then calculate the precise number of wraps and the ideal tension needed, ensuring complete protection with minimal material. This level of control can reduce your film or paper consumption by 15-30%. Let’s look at a simple comparison:

| Feature | Old Semi-Auto System | Modern Automated Line |

|---|---|---|

| Material Usage per Coil | ~1.2 kg film | ~0.9 kg film |

| Coils Packed per Day | 100 | 100 |

| Daily Film Savings | 0 kg | 30 kg |

| Annual Film Savings (250 days) | 0 kg | 7,500 kg |

These savings add up quickly and have a direct, positive impact on your operational budget.

Slashing Energy Bills

Energy prices are volatile, making them a major challenge for Greek industries. A packing line that runs 24/7 can be a significant power consumer. I've seen older machines with oversized motors that run at full power continuously, even when idle between coils. Modern machines are designed with energy efficiency as a core principle. They use high-efficiency motors (IE3 or IE4 standards) and are equipped with Variable Frequency Drives (VFDs). A VFD allows the motor to adjust its speed and power consumption based on the real-time need, drastically reducing energy use during acceleration, deceleration, and idle times. Additionally, smart "sleep" or "standby" modes can power down non-essential components when the machine is waiting for the next coil, waking up instantly when needed. This intelligent power management can lower the packing line's energy consumption by up to 40%, providing a hedge against rising electricity costs and contributing to your company's sustainability goals.

Beyond the Machine: What Defines a True Strategic Partnership with a Supplier?

You've probably experienced this before. You buy a piece of equipment based on a great price and impressive specifications. The machine is delivered, but once the final payment is made, the supplier becomes difficult to reach. When you have a technical question or need a spare part urgently, you're met with delays and unhelpful responses. This is the risk of dealing with a simple vendor. A vendor sells you a product. A partner, however, invests in your success. As an entrepreneur who built his factory from the ground up, I learned that the machine itself is only 50% of the solution. The other 50% is the relationship, the expertise, and the support that comes with it.

A true strategic partnership is defined by a supplier's commitment that extends far beyond the sale. It involves in-depth consultation to design a tailored solution, hands-on support during installation and commissioning, comprehensive training for your team, and a long-term commitment to responsive after-sales service, including reliable access to spare parts and ongoing technical guidance.

The Consultation and Design Phase

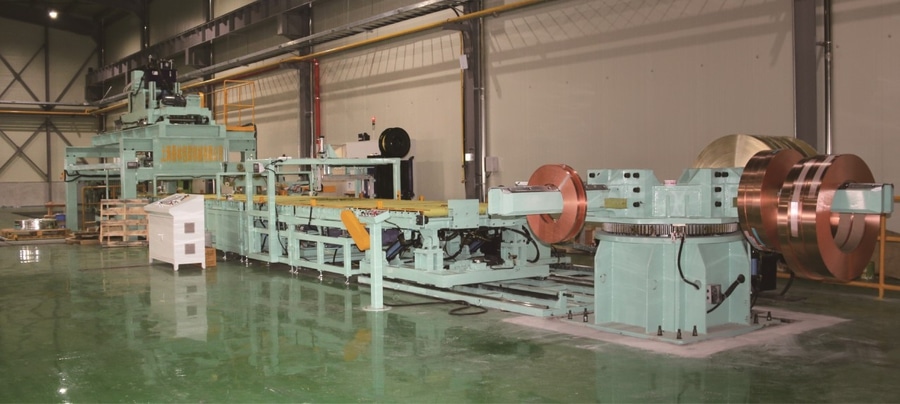

A vendor will send you a catalog and ask you to pick a model. A partner starts by asking questions. They want to understand your entire process. What kind of coils are you packing? Steel, aluminum, copper? What are their dimensions and weights? What is your current factory layout? What are your throughput goals? What are your biggest pain points right now? This initial consultation is crucial. In my company, SHJLPACK, we see ourselves as problem-solvers. We use this information to design a solution that is tailored to your specific needs. This might mean modifying a standard machine to fit into a tight space, integrating it with your existing crane or conveyor systems, or selecting specific packing materials for your product's unique requirements. This collaborative design process ensures that the machine you invest in is not just a machine, but the right machine for you.

Installation, Commissioning, and Training

The difference between a vendor and a partner becomes very clear during installation. A vendor might ship the machine in a crate with a manual and wish you good luck. A strategic partner understands that proper installation and commissioning are key to long-term performance. This means sending experienced engineers to your site. They oversee the unloading, assembly, and connection of the equipment. They work alongside your team to test every function, ensuring the line runs smoothly and integrates perfectly with your production flow. But their job doesn't end there. The most important step is training. A partner provides comprehensive training for both your operators and your maintenance staff. Operators learn how to run the machine safely and efficiently. Your maintenance team learns how to perform routine checks, troubleshoot common issues, and handle preventive maintenance. This knowledge transfer empowers your team and makes you self-sufficient.

Long-Term Support and Maintenance

The machine is running, and production is smooth. What happens a year later when a sensor fails or you need to replace a worn-out part? This is the ultimate test of a partnership. A vendor might be slow to respond or charge exorbitant prices for spare parts. A partner sees long-term support as part of the deal. They maintain a stock of critical spare parts that can be shipped quickly to minimize your downtime. Their technical support team is accessible via phone or email to help your engineers diagnose problems remotely. They might even offer proactive advice based on the machine's age and usage, suggesting preventive maintenance actions before a problem occurs. This ongoing relationship provides peace of mind. It means you have an expert on your side for the entire 15-20 year lifespan of the machine.

| Aspect | A Simple Vendor | A Strategic Partner (SHJLPACK) |

|---|---|---|

| Focus | Making a one-time sale | Building a long-term relationship |

| Design | Offers standard models | Develops a custom-fit solution |

| Installation | Ships a crate with a manual | Sends engineers for on-site support |

| Training | Minimal or none | Comprehensive for operators & maintenance |

| After-Sales | Slow, unresponsive | Fast, proactive, reliable parts supply |

How Does a New Packing Line Fit into a Plant's Digital Transformation Strategy?

Your management team is talking about "Industry 4.0," "Smart Factories," and "Big Data." They want more visibility into the production process. They want to track every coil, monitor machine performance in real-time, and use data to make smarter decisions. But when you look at your factory floor, you see a mix of old and new equipment. Many machines operate as isolated islands, unable to communicate with each other or a central system. Investing in a new piece of equipment that can't speak the language of data is a step backward. It creates another data silo and complicates your digital transformation journey. A modern packing line should not be an isolated island; it should be an intelligent, connected node in your factory's growing digital ecosystem.

A new packing line fits into a digital transformation strategy by being "Industry 4.0 ready." This means it is designed with the hardware and software to connect seamlessly with your plant's Manufacturing Execution System (MES) or ERP. It uses IoT sensors to provide real-time data on production and machine health, and it enables advanced capabilities like remote diagnostics and predictive maintenance.

Data Acquisition and MES Integration

At its core, digital transformation is about data. A smart packing line is designed to both generate and receive data. It needs to integrate with your Manufacturing Execution System (MES). This integration allows for a two-way conversation. The MES can send a work order to the packing line, saying "Pack Coil ID #ABC-123 with packing recipe #2." The packing line, upon completion, sends a message back to the MES: "Coil ID #ABC-123 is packed and weighs X kg. It is ready for dispatch." This simple data exchange has a huge impact. It eliminates manual data entry, which is slow and prone to errors. It provides real-time visibility into your inventory of finished goods. And it helps your production planners make better decisions because they know exactly what is happening on the packing floor at any given moment. When you choose a new line, you must ask the supplier about their experience with MES integration and what communication protocols (like OPC-UA or Profinet) their machines support.

The Role of IoT and Sensors

How do you know if a machine is running efficiently? You measure it. Modern packing lines are equipped with an array of Internet of Things (IoT) sensors that act as the machine's nervous system. These sensors monitor everything. They count the number of cycles, measure the amount of packing material used, track the temperature of motors, and monitor the pressure in pneumatic systems. All this data is collected by the machine's PLC and can be sent to a central dashboard. This allows you and your team to see key performance indicators (KPIs) in real-time. You can track throughput per hour, material consumption per coil, and machine uptime. As I always say, "You cannot improve what you do not measure." This data gives you the power to identify inefficiencies, spot trends, and make targeted improvements to your process.

Enabling Predictive Maintenance

One of the biggest goals of any plant manager is to eliminate unplanned downtime. A breakdown on a critical line like a packing station can bring your entire dispatch process to a halt. This is where predictive maintenance comes in. It's a shift from reactive maintenance (fixing things when they break) to proactive maintenance (fixing things before they break). The data from the IoT sensors is the key. By analyzing trends in data, the system can predict future failures. For example, if a motor's vibration sensor shows a gradual increase in vibration over several weeks, the system can flag it and send an alert: "Motor on strapping unit #1 shows abnormal vibration. Recommend inspection within 48 hours." This allows your maintenance team to schedule a repair during planned downtime, instead of reacting to a catastrophic failure in the middle of a production run. This capability, which would be a top priority for a forward-thinking leader like Javier, directly supports the goal of achieving 95% or higher equipment uptime.

What are the Long-Term ROI Factors Beyond the Initial Purchase Price?

When you present a purchase proposal, the first number everyone looks at is the price. The finance department, naturally, wants to see the lowest possible number. It's tempting to choose the cheapest option on the market. However, from my years of experience helping clients grow their businesses, I can tell you that the cheapest machine is often the most expensive one to own. The initial price tag is just the tip of the iceberg. The real cost of a machine is its Total Cost of Ownership (TCO) over its entire lifespan. A machine that breaks down frequently, consumes a lot of energy and materials, and has a short operational life will cost you far more in the long run than a slightly more expensive but highly reliable and efficient machine.

The most important long-term Return on Investment (ROI) factors are the machine's Total Cost of Ownership (TCO), its reliability and uptime, its production throughput and quality, and its flexibility to adapt to your future business needs. A smart investment prioritizes these factors over the initial purchase price, ensuring sustainable value and a much higher ROI over the machine's life.

Calculating Total Cost of Ownership (TCO)

To make a truly informed decision, you need to look beyond the quote and calculate the TCO. This includes all costs associated with owning and operating the machine for a set period, for example, 5 or 10 years. A simple comparison can be very revealing.

| Cost Factor | Low-Cost Machine | Strategic Investment (e.g., SHJLPACK) |

|---|---|---|

| Initial Purchase Price | €150,000 | €200,000 |

| Annual Energy Costs | €20,000 | €12,000 (VFDs, efficient motors) |

| Annual Material Costs | €50,000 | €42,500 (precision wrapping) |

| Annual Maintenance/Parts | €10,000 (frequent issues) | €3,000 (high-quality parts) |

| Annual Downtime Cost | €25,000 (5% downtime) | €5,000 (1% downtime) |

| 5-Year TCO | €695,000 | €527,500 |

As you can see, the "cheaper" machine ends up costing €167,500 more over five years. A higher initial investment in quality, reliability, and efficiency pays for itself many times over.

The Value of Uptime

In a busy steel or metal processing plant, uptime is everything. Every hour your packing line is down is an hour you are not shipping product. This has a direct financial cost. You can calculate it simply: (Value of products per hour) x (Hours of downtime). But the costs go deeper. You have idle workers you are still paying. You might face financial penalties for late deliveries to your customers. And repeated delays can damage your company's reputation as a reliable supplier. A machine built with high-quality components—robust bearings, reliable PLCs from well-known brands, and durable motors—will have significantly higher uptime. Investing in reliability is not an expense; it is a direct investment in your plant's profitability and your customers' satisfaction.

Future-Proofing Your Investment

The market is always changing. Your customers' needs may change. You might start producing coils of different sizes or need to use new types of packing materials five years from now. A cheaply made, rigid machine might not be able to adapt. A strategically chosen machine is "future-proofed." This means it has a modular design, allowing you to add or modify stations later. For example, you might want to add an automatic label applicator or a stacking system in the future. A good design will accommodate this. It also means the control software can be updated to add new features or improve performance. By choosing a flexible, adaptable machine, you are not just solving today's problem; you are buying a platform that can grow and change with your business. This adaptability is a key part of maximizing your long-term ROI.

My Insight

When I started my career as a young engineer on a factory floor, I saw machines as just metal, motors, and wires. My job was to make them run. But after I took the risk to start my own factory, SHJLPACK, my perspective changed completely. I wasn't just selling machines anymore. My own financial success was directly tied to the success of my clients. If their new packing line helped them reduce costs, increase output, and win more business, they would grow. And when they grew, they would come back to me.

I realized that my mission wasn't to sell a wrapping machine. It was to provide a total solution. This is now our slogan, and it’s the core of everything we do.

A "total solution" means understanding the full picture. It’s what I learned from working with insightful leaders like Javier in Mexico. He didn't just want a machine; he wanted to reduce his energy costs by 10% and increase his equipment uptime to 95%. The machine was simply the tool to achieve those business goals. He needed a partner who understood those goals and could provide the technology, expertise, and support to reach them.

So, for every procurement manager in Greece weighing this decision, my advice is this: look past the machine. Find a partner who is as invested in your operational goals as you are. The right partner won't just sell you a piece of equipment; they will give you the solution that helps you succeed. That is the most valuable investment you can make.

Conclusion

Choosing a coil packing line is a strategic decision. Focus on long-term value, true partnership, and future-readiness. This approach ensures your investment delivers powerful returns for many years to come.