As a factory manager, you are under constant pressure to improve efficiency and cut costs. Now, people are also telling you to be "eco-friendly." It can feel like just another demand, another expense on your already tight budget. You might think that sustainable packaging means weaker materials or processes that slow down your production line. This concern is valid, especially when any downtime means a significant loss. But what if I told you that the path to becoming more environmentally friendly is the same path to becoming more profitable and efficient?

The environmental benefits of using eco-friendly steel wire packaging come from reducing material consumption, lowering energy use, and preventing product waste. By optimizing your packaging process with modern solutions, you not only decrease your carbon footprint but also directly cut operational costs, improve safety, and boost your bottom line.

This might sound too good to be true. I understand the skepticism. I’ve spent my entire career in the packing machine industry, first on the factory floor and then building my own company, SHJLPACK. I’ve seen firsthand how a small change in packaging can have a huge ripple effect on an entire operation. In this article, I’ll break down exactly how sustainable packaging practices deliver real-world environmental and financial returns. We will explore how you can meet your green targets not as an added burden, but as a direct result of making your factory work smarter.

How Does Eco-Friendly Packaging Reduce Material Waste in Steel Wire Operations?

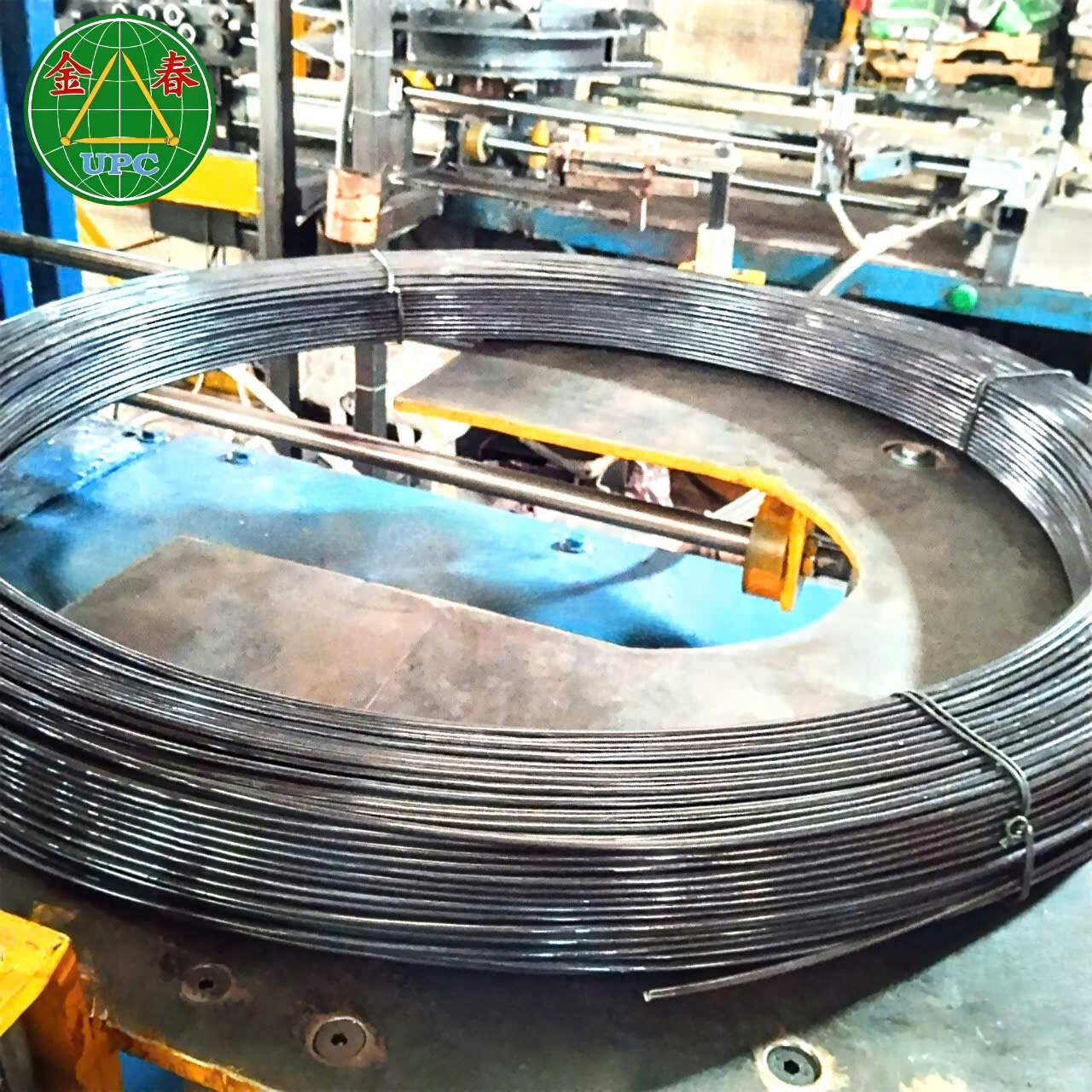

You look at your warehouse and see pallet after pallet of stretch film and strapping. You know that a lot of it ends up in the trash. Every time a worker wraps a coil by hand, they might use a little extra "just to be safe." This small amount, multiplied by hundreds of coils a day, adds up to a mountain of waste and a significant, unnecessary cost. This over-consumption of materials is a drain on your resources and a direct hit to your profitability. You know there has to be a more controlled, more efficient way to do it.

Eco-friendly packaging reduces material waste by using automated systems that apply the precise amount of wrapping material needed for secure packaging, and nothing more. High-performance machines with features like pre-stretching can significantly increase the yield of each roll of film, cutting your material consumption by 50-70% while providing a stronger, more reliable wrap.

Diving Deeper into Material Reduction

When we talk about reducing material waste, we are really talking about two things: precision and optimization. Manual wrapping is the enemy of both. An automated system, on the other hand, is built for them.

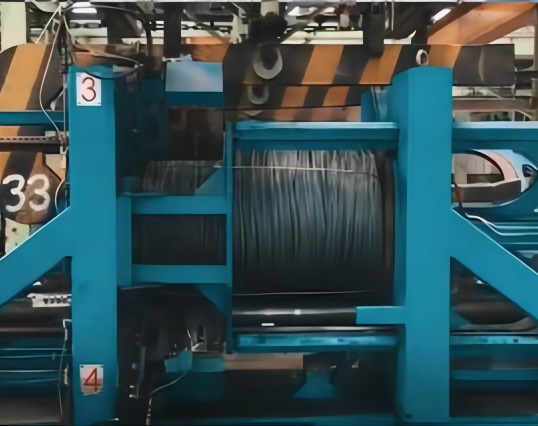

The Power of Pre-Stretch

The most important feature for reducing film waste is the powered pre-stretch system on an automatic wrapping machine. Here’s how it works:

- Inside the machine, a set of rollers pulls the stretch film and stretches it before it gets applied to the wire coil.

- A standard machine can stretch the film by 200% to 300%. This means one meter of film from the roll becomes three or four meters of film applied to your product.

- Manual wrapping, by comparison, achieves maybe 50-60% stretch at best. A worker simply cannot physically stretch the film to the same degree as a machine.

The result is a drastic reduction in the amount of plastic you use. Let's look at a simple comparison.

| Feature | Manual Wrapping | Automated Wrapping | Impact |

|---|---|---|---|

| Film Stretch Ratio | 50-60% | 250-300% | Use 50-70% less film per coil |

| Wrap Consistency | Varies by worker | Perfectly uniform every time | Less film needed for a secure wrap |

| Material Cost | High | Significantly Lower | Direct savings on purchasing consumables |

| Disposal Cost | High | Significantly Lower | Less plastic waste for landfills |

This isn't just a theory. I've helped clients implement these systems and the results are immediate. The savings on stretch film alone often pay for the machine in a surprisingly short amount of time. You use less plastic, which is great for the environment, but you also spend far less money on that plastic.

Eliminating Guesswork and Error

Automated systems also bring a level of precision that is impossible to achieve manually. You can program the machine for the exact number of wraps, the ideal wrapping tension, and the perfect overlap for each specific product type. This means every single coil is packaged to the same high standard using the minimum amount of material required for safe transit. No more "just a little extra" wrap. No more wasted material from inconsistent application. This is how you systematically attack waste and cost in your packaging process.

Can Sustainable Packaging Materials Lower Your Carbon Footprint?

Many managers hear "sustainable materials" and immediately think of expensive, unproven bioplastics that might not be strong enough for heavy industrial products like steel wire. They worry that making a "green" choice on materials could compromise the safety of their product during shipping. This fear can lead to inaction, causing them to stick with old, wasteful methods because they are familiar. The truth is, a bigger environmental impact comes from the sheer volume of traditional material used and the energy wasted to produce and transport it.

Yes, choosing sustainable packaging materials can significantly lower your carbon footprint, but it’s not always about switching to a new "green" material. The biggest impact often comes from using less of a high-performance, recyclable material like LLDPE stretch film. By using automated machinery to apply a thinner, stronger film more efficiently, you reduce the total mass of plastic needed. This lowers the carbon emissions associated with material production, transportation, and disposal.

Diving Deeper into Carbon Footprint Analysis

To truly understand the environmental impact, we need to think about the entire lifecycle of the packaging material. This includes its creation, its use, and its end-of-life.

The Lifecycle of Packaging Material

- Production: Manufacturing any material, including plastic film, requires energy and raw resources. The more material you use, the larger this initial carbon footprint is. Using a machine that can stretch film 300% means you cut the production-related emissions for your packaging by two-thirds.

- Transportation: Packaging materials have to be shipped to your factory. Heavier, bulkier materials require more fuel to transport. By using less material, you are also reducing the number of trucks on the road bringing supplies to your plant.

- Application: An automated wrapper uses electricity. However, its energy consumption is consistent and efficient, often less than the total energy wasted through the inefficiencies of a manual process, including compressed air for tools and the physical energy of multiple workers.

- End-of-Life: What happens to the packaging after it reaches your customer? Modern stretch films are highly recyclable (Category 4 - LDPE). The less material you use, the less material needs to be collected, transported, and reprocessed.

Let's compare the carbon impact of inefficient versus efficient packaging strategies.

| Packaging Stage | Inefficient Strategy (Manual/Heavy Film) | Efficient Strategy (Automated/Thin Film) | Carbon Footprint Reduction |

|---|---|---|---|

| Material Production | High volume of thick film produced | Low volume of thin, strong film produced | Significant reduction in manufacturing emissions |

| Transport to Factory | More frequent, heavier shipments | Fewer, lighter shipments | Lower fuel consumption and transport emissions |

| Waste Generation | High volume of plastic waste sent to landfill | Low volume of recyclable plastic waste | Reduced landfill burden and disposal emissions |

| Overall Impact | Large Carbon Footprint | Small Carbon Footprint | A clear path to meeting sustainability targets |

It's About Being Smart, Not Just "Green"

The key insight here is that the most sustainable material is the one you don't have to use. The goal isn't necessarily to find some magical, zero-impact material. For heavy-duty applications like steel wire, you need strength and reliability. The smartest environmental and business strategy is to use technology that allows you to get that required strength and reliability while consuming the absolute minimum amount of proven, effective, and recyclable material. This approach reduces your carbon footprint at every single stage of the lifecycle.

What Is the Link Between Automation and Eco-Friendly Packaging?

You see your workers manually wrapping heavy coils. It's slow, physically demanding, and creates a bottleneck at the end of your production line. You also know it's a safety risk. This entire process feels inefficient and outdated. You want to automate, but you see it mainly as a way to increase speed. You might not realize that the decision to automate is also one of the most significant environmental decisions you can make.

Automation is the critical link to eco-friendly packaging because automated machines are inherently more efficient with both materials and energy. They replace inconsistent, wasteful manual labor with a precise, repeatable, and optimized process that reduces plastic consumption, lowers energy usage per package, and minimizes the risk of product damage, which itself is a major source of environmental waste.

Diving Deeper into Automation's Green Impact

The connection between automation and sustainability is direct and measurable. A machine is designed by engineers to perform a task with maximum efficiency. Let's break down how this translates into environmental benefits.

Unlocking Efficiency Gains

An automated packaging line does more than just wrap coils faster. It fundamentally changes how you use resources.

- Energy Efficiency: Think about the energy used in manual packaging. It's not just the worker's physical effort. It might involve forklifts idling, multiple trips back and forth, and the use of inefficient handheld tools. An integrated automated system is designed to perform its task using a minimal amount of electricity in a smooth, continuous process. It does one job, and it does it with engineering precision.

- Material Efficiency: As we've discussed, this is the most obvious benefit. A machine's pre-stretch capability and programmable wrapping patterns ensure not a single inch of film is wasted. This consistency is something manual labor can never replicate. Over a year, this precision translates into tons of plastic that you never have to buy, ship, or dispose of.

- Space Efficiency: A well-designed automated line can have a smaller physical footprint than an area cluttered with manual wrapping stations, pallets of materials, and workers moving around. This allows for a more streamlined and efficient factory layout, which reduces internal transport distances and associated energy use.

Automation as a Safety and Sustainability Tool

A key concern for any factory manager, like Michael, is worker safety. High injury rates are not only a human tragedy but also a source of massive costs and operational disruption.

- Reducing Injury Risk: Automating the lifting, turning, and wrapping of heavy steel coils eliminates the most dangerous manual handling tasks. This drastically reduces the risk of back injuries, strains, and other common industrial accidents.

- The Environmental Link to Safety: A safer workplace is a more stable and efficient workplace. Fewer accidents mean less downtime, less disruption, and a more consistent production flow. This operational stability allows the efficiency benefits of the automated system to be fully realized. When your line is running smoothly, you are operating at peak resource efficiency.

The table below shows how automation directly addresses both operational and environmental goals.

| Challenge | Manual Process Problem | Automated Solution | Environmental Benefit |

|---|---|---|---|

| Material Use | Inconsistent, wasteful over-wrapping | Precise, programmed wrapping with pre-stretch | Drastic reduction in plastic consumption |

| Energy Use | Inefficient use of labor and tools | Optimized, low-energy machine cycle | Lower electricity consumption per unit |

| Worker Safety | High risk of manual handling injuries | Eliminates heavy lifting and repetitive strain | Prevents disruptions that lead to inefficient stops/starts |

| Process Speed | Slow, creates production bottlenecks | Fast, consistent, and predictable output | Smoother production flow, maximizing resource use |

By investing in automation, you are not making a choice between productivity and sustainability. You are choosing a single solution that delivers both.

How Does Better Packaging Protect Products and Prevent Environmental Waste?

You’ve had a customer call to complain about a shipment. The steel coils arrived with damaged edges from shifting around in transit. Now you have to deal with the cost of the return, the replacement product, and a damaged client relationship. But the waste is much bigger than that. That entire coil, which took immense energy and resources to produce, is now scrap. This is a huge financial loss, but it's also a massive environmental waste.

Better packaging directly prevents environmental waste by ensuring product integrity from your factory to the customer. A securely wrapped coil is protected from damage, corrosion, and contamination. This eliminates the need to scrap and remanufacture damaged goods, which saves the enormous amount of energy, water, and raw materials that were invested in the original product. Preventing product loss is one of the most impactful forms of environmental stewardship.

Diving Deeper into the Cost of Waste

When a product is damaged, we often only think about the immediate financial loss. But the environmental cost is staggering. Let's look at what is truly lost when a steel coil is scrapped due to poor packaging.

The Hidden Environmental Price Tag of a Damaged Coil

- Wasted Energy: Think of the entire production process. The immense heat of the furnace to melt the steel. The energy to run the rolling mills. The power for the drawing process to create the wire. All of that energy is completely wasted.

- Wasted Raw Materials: The iron ore, coal, and alloys used to create that specific batch of steel are lost. While the steel might be recycled, the recycling process itself requires significant energy. It's far more sustainable to protect the original product.

- Wasted Water: Steel production is a water-intensive process, used for cooling and processing. This water, now spent, has to be treated. A scrapped coil means all that water was used for nothing.

- Wasted Logistics: The fuel used to transport the raw materials to the mill, and then to transport the finished coil to the customer, is now completely wasted. The return shipment of the damaged product adds even more unnecessary emissions.

How Secure Packaging Creates Environmental Value

An automated wrapping machine provides a level of protection that manual wrapping cannot match.

- Load Containment: The high, consistent tension from a pre-stretch system creates a tight, unified load. The layers of the coil are bound together, preventing them from shifting and causing edge damage.

- Edge Protection: Machines can be programmed to apply extra wraps at the top and bottom edges of the coil, which are the most vulnerable areas. This "cocoon" of film acts as a durable bumper during handling and transport.

- Barrier from Elements: A properly wrapped coil is sealed against moisture, dust, and other contaminants that can lead to rust and corrosion, another common reason for product rejection.

Let's quantify the value. It's not just about saving a coil; it's about saving everything that went into it.

| Consequence of Poor Packaging | Financial Cost | Environmental Cost |

|---|---|---|

| Product Damage | Cost of scrap, replacement product | Wasted energy, water, raw materials from production |

| Customer Complaint | Loss of future business, reputation damage | N/A |

| Return Logistics | Cost of return shipping and handling | Additional, unnecessary carbon emissions |

| Increased Insurance | Higher premiums due to frequent claims | N/A |

Investing in a proper packaging solution is like buying an insurance policy against this massive, multi-layered waste. Protecting your product is not just good business; it is a fundamental principle of industrial sustainability.

My Insight: Stop Chasing "Green," Start Chasing "Efficient"

I remember a conversation I had a few years ago with a factory manager in Mexico. Let's call him Carlos. He was a lot like Michael Chen—experienced, practical, and under a lot of pressure to increase output while keeping costs down. When I first brought up the environmental benefits of our wrapping machines, he almost laughed.

He said, "Vincent, I appreciate the thought, but all this 'eco-friendly' talk just sounds expensive to me. My main problems are line stoppages and the rising cost of stretch film. My guys are wrapping by hand, and it's slow and sloppy. If I can't solve that, saving the planet is the last thing on my mind."

He was facing the exact same supplier trust crisis that so many managers face. He'd been sold equipment before that didn't deliver on its promises. So, I changed my approach. We didn't talk about the environment again. Instead, we pulled out a calculator.

I asked him, "Carlos, how much do you spend on stretch film a month?" We figured out the number. Then, I showed him the specs for our orbital wrapper's pre-stretch system. I explained, "This machine will stretch one foot of your film into three feet. It will use at least 50% less film per coil. Let's calculate what that saves you per month."

The number was significant. Then we talked about labor. He could move two workers from the slow, manual wrapping station to more productive roles elsewhere in the plant. We added those labor savings. Then we talked about his damaged product numbers. By providing a more secure, consistent wrap, we estimated we could cut his product damage in half.

By the end of our conversation, we had calculated a clear Return on Investment (ROI) for the machine based only on his biggest pain points: material cost, labor cost, and product loss. He made the investment.

About six months later, he called me. He was thrilled with the machine's performance. His costs were down, and his throughput was up, just as we had calculated. But then he said something that stuck with me. "You know, Vincent, the funny thing is, my boss just praised me for our new sustainability initiative. Our plastic waste is down by more than half, and because we're not scrapping damaged coils, our total waste output has plummeted. I achieved our green targets without even trying. I was just trying to run a better factory."

That is the secret. The most powerful environmental benefits are a direct byproduct of a relentless pursuit of efficiency. When you reduce waste, you reduce cost. When you use less energy, you reduce cost. When you protect your product, you protect your profit. Eco-friendly operation isn't a separate goal you chase. It's the result you get when you make your operation as smart, lean, and efficient as possible.

Conclusion

Ultimately, eco-friendly packaging is not a cost center. It is the outcome of a more efficient, profitable, and safer operation. Smart business is, by its very nature, sustainable business.