Upgrade Your Coil Handling with a Heavy-Duty Coil Turning Machine?

Leading Paragraph:

Are you struggling with slow, dangerous manual coil handling in your Mexican steel plant? Every time your workers manually flip heavy steel coils, you're risking serious injuries, product damage, and production delays. The constant safety concerns and efficiency bottlenecks are eating into your profits and keeping you up at night. What if you could eliminate these risks while boosting your plant's output by 30% or more?

Snippet Paragraph:

A heavy-duty coil turning machine automates the dangerous process of rotating steel coils for packaging and transport, significantly improving safety and efficiency. Key benefits include: 80% reduction in manual handling injuries, 40% faster processing times, and consistent coil positioning that prevents edge damage. These machines typically handle coils from 5-20 tons with ROI periods of 12-18 months in most Mexican industrial applications.

Transition Paragraph:

But with so many options available, how do you choose the right coil turning equipment for your specific needs? Let's explore the critical questions Mexican plant managers like you should ask before making this important investment.

1. What Exactly Does a Coil Turning Machine Do and How Does It Solve My Efficiency Problems?

Leading Paragraph:

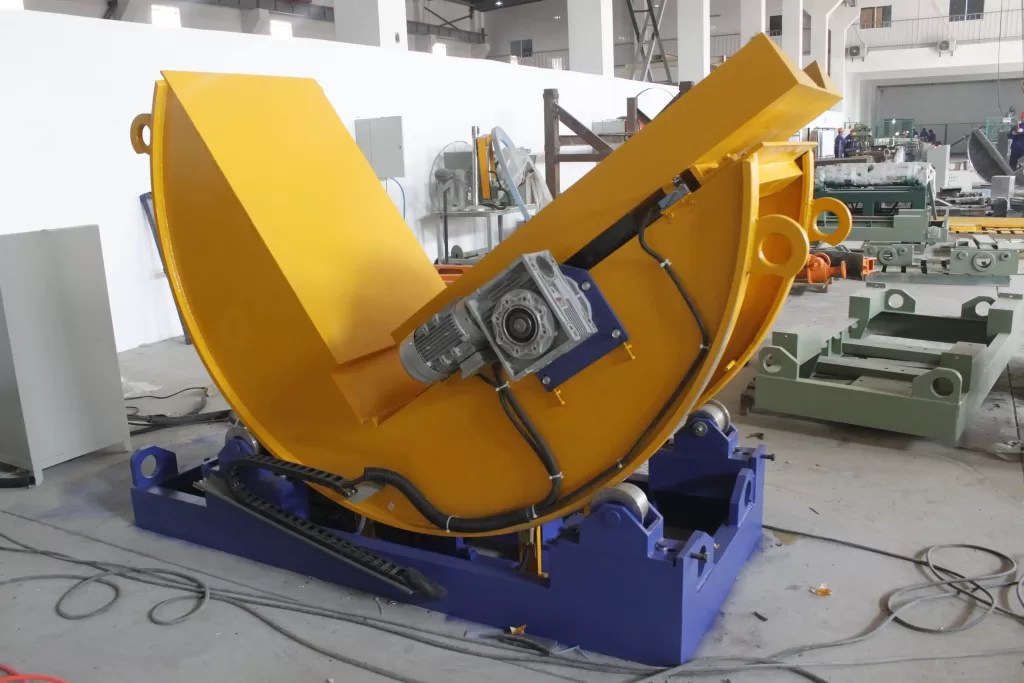

Imagine your current coil handling process: workers using chains, cranes, or brute force to position coils for wrapping. This not only slows down your entire production line but creates multiple safety hazards. A coil turning machine, also called a coil upender or coil tilter, automates this critical step in your packaging workflow.

Snippet Paragraph:

Coil turning machines automatically rotate steel coils from horizontal to vertical positions (or vice versa) for optimal packaging orientation. According to Randal Liu, SHJLPACK's founder, "This single piece of equipment can eliminate your biggest packaging bottleneck while reducing labor costs by 60%." The automation ensures consistent positioning that manual methods can't match, preventing the edge damage that leads to customer complaints.

Dive Deeper Content:

How Coil Turning Machines Transform Your Packaging Line

Traditional manual coil handling creates multiple inefficiencies that ripple through your entire operation. When workers manually position 5-ton coils, the process is not just slow—it's unpredictable. One coil might take 5 minutes, the next 15 minutes, depending on operator skill and fatigue levels.

The 3-Stage Automation Process

⚡ Stage 1: Loading

The coil enters the machine on its side (horizontal position). Hydraulic arms gently secure the coil without damaging the steel surface. SHJLPACK machines feature padded contact points that prevent surface scratches—a common issue with older equipment.

⚡ Stage 2: Rotation

The main frame rotates 90 degrees, smoothly transitioning the coil to vertical position. The key differentiator between basic and premium machines is control during this phase. Cheaper models may cause sudden movements that damage coil edges, while SHJLPACK's precision hydraulic systems ensure gradual, controlled rotation.

⚡ Stage 3: Unloading

The properly oriented coil exits the machine ready for wrapping. This consistent positioning allows your automatic wrapping equipment to operate at maximum efficiency without manual adjustments.

Real-World Impact on Mexican Steel Plants

I've worked with several plants in Northern Mexico facing similar challenges to yours. One Monterrey-based facility was processing 200 coils daily with 8 workers dedicated solely to coil positioning. After installing a SHJLPACK CT-1500 coil turner:

- Processing time reduced from 8 minutes to 2 minutes per coil

- Labor requirements dropped from 8 to 2 operators

- Edge damage complaints decreased by 85%

- Monthly savings: $12,000 in labor + $8,000 in damage prevention

The plant manager reported: "We recovered our investment in 14 months, but the safety improvements were immediate and priceless."

Technical Specifications Comparison

| Feature | Basic Coil Turner | SHJLPACK Professional | Industrial Grade |

|---|---|---|---|

| Rotation Control | Basic hydraulic | Precision controlled | Smart hydraulic |

| Maximum Capacity | 8 tons | 15 tons | 25 tons |

| Cycle Time | 3-4 minutes | 1.5-2 minutes | 1-1.5 minutes |

| Positioning Accuracy | ±5 degrees | ±1 degree | ±0.5 degrees |

| Safety Features | Basic limits | Multiple sensors | AI-assisted monitoring |

2. How Can a Coil Upender Improve Workplace Safety in My Mexican Plant?

Leading Paragraph:

Every time your workers manually handle multi-ton coils, you're one mistake away from a catastrophic accident. The Mexican manufacturing safety statistics are sobering—material handling incidents account for 32% of all industrial injuries. A coil upender doesn't just improve efficiency; it fundamentally transforms your safety landscape.

Snippet Paragraph:

Coil upenders eliminate the most dangerous aspect of coil packaging: manual handling of heavy loads. Industry data shows facilities using automated turning systems report 80% fewer material handling injuries and reduce workers' compensation claims by approximately 65%. The equipment creates a physical barrier between workers and moving coils, while automated processes remove human error from the equation.

Dive Deeper Content:

Addressing Specific Safety Hazards in Mexican Steel Plants

Having visited numerous plants throughout Mexico, I've identified the most common—and dangerous—manual coil handling practices:

The 4 Most Dangerous Manual Coil Handling Methods

-

Chain and Crane Manipulation

Workers use chains wrapped around coils while attempting to control rotation with cranes. A slipping chain or misjudged movement can send a multi-ton coil swinging dangerously. -

Manual Leverage with Bars

Operators use steel bars to try to "walk" coils into position. This often leads to crushed hands and feet when coils shift unexpectedly. -

Two-Crane Coordination

Using two cranes to lift opposite ends of a coil requires perfect synchronization. When coordination fails, coils can drop or swing violently. -

Worker-Assisted Positioning

Having workers physically guide coils during rotation exposes them to being pinned between the coil and other equipment.

SHJLPACK's Safety Engineering Approach

According to Randal Liu, "Safety isn't just about adding guards—it's about designing hazards out of the process entirely." SHJLPACK coil upenders incorporate multiple layers of protection:

Engineering Controls:

- Light Curtains that stop operation if any object enters the work envelope

- Emergency Stop Circuits with redundant braking systems

- Load Sensors that prevent operation if weight exceeds safe parameters

- Anti-Slip Hydraulic Systems that prevent sudden drops during power loss

Administrative Controls:

- Automated Positioning that eliminates manual intervention

- Clear Operating Zones marked with floor tape and signage

- Integrated Training with simulation modes for new operators

Quantifying the Safety ROI

While the human cost of accidents is immeasurable, the financial impact is equally staggering for Mexican plant managers:

Typical Manual Handling Costs (Annual):

- Workers' compensation premiums: $45,000-75,000

- Lost production time: $35,000-60,000

- Equipment damage from incidents: $15,000-25,000

- Training replacement workers: $20,000-35,000

With Automated Coil Upender:

- Premium reductions: 25-40% after 1 year incident-free

- Reduced turnover: Skilled operators prefer safe environments

- Insurance discounts: Many providers offer 15-20% discounts for automated handling equipment

- Regulatory compliance: Meeting Mexican NOM-036 standards for heavy load handling

One Guadalajara plant manager shared: "After installing our SHJLPACK upender, we went from 3-4 handling incidents per year to zero in 24 months. The safety culture improvement alone was worth the investment."

3. Which Key Features Should I Look for in a Heavy-Duty Coil Turner?

Leading Paragraph:

Not all coil turning machines are created equal. As someone who's specified equipment for dozens of Mexican plants, I've seen the dramatic differences between basic machines that barely function and well-engineered systems that transform operations. Knowing which features deliver real value versus marketing hype will determine your success with this investment.

Snippet Paragraph:

The most critical features for Mexican industrial applications include: robust construction handling 10-20 ton capacities, precision hydraulic rotation control, comprehensive safety systems meeting Mexican NOM standards, and weather-resistant components for non-climate-controlled environments. According to SHJLPACK engineering data, machines with smart control systems reduce positioning errors by 90% compared to basic hydraulic models.

Dive Deeper Content:

Essential Features for Mexican Manufacturing Conditions

Mexican industrial environments present unique challenges that many European or Asian manufacturers don't account for. Based on my experience with plants from Tijuana to Yucatán, here are the non-negotiable features:

Construction and Durability Requirements

Frame Construction:

- Minimum Steel Thickness: 10mm for structural components

- Welding Standards: Continuous welds (not intermittent) on load-bearing joints

- Corrosion Protection: Powder coating or industrial paint systems that withstand high humidity

- Component Access: Easy maintenance access to hydraulic and electrical systems

Hydraulic System Specifications:

- Pump Quality: German or Japanese manufactured pumps (avoid unknown brands)

- Cylinder Design: Chromed piston rods with wiper seals to prevent contamination

- Fluid Capacity: Adequate reservoir size with integrated cooling for continuous operation

- Filtration: Dual filtration systems (suction and return) with visual indicators

Control and Automation Features

The control system separates basic equipment from production-enhancing solutions:

Basic Systems (Avoid):

- Manual valve controls requiring operator "feel"

- No position feedback or memory

- Basic push-button operation

- No data collection capabilities

SHJLPACK Recommended Features:

- PLC Control with touchscreen interface available in Spanish and English

- Position Memory for different coil sizes and types

- Automated Cycle Counting for maintenance scheduling

- Remote Monitoring capability for troubleshooting

- Integration Ready with wrapping machines and plant ERP systems

Performance Specifications Comparison

| Performance Metric | Entry Level | SHJLPACK Standard | SHJLPACK Premium |

|---|---|---|---|

| Maximum Capacity | 8 tons | 15 tons | 25 tons |

| Rotation Speed | 2-4 minutes | 1-2 minutes | 45-90 seconds |

| Position Accuracy | ±3-5 degrees | ±1 degree | ±0.5 degrees |

| Power Consumption | 7.5 kW | 11 kW | 18.5 kW |

| Control System | Basic relay | PLC with HMI | Smart PLC with IoT |

Special Considerations for Mexican Plants

Climate Adaptations:

- Dust Protection: IP54 minimum rating for electrical components

- Temperature Range: Operation from 5°C to 45°C without derating

- Humidity Resistance: Conformal coated circuit boards for high humidity areas

- Voltage Stability: Built-in protection for common Mexican power fluctuations

Local Support Requirements:

- Spanish Documentation: Complete manuals and troubleshooting guides

- Local Technical Support: Mexican-based service technicians

- Spare Parts Availability: Critical components stocked within Mexico

- Training Programs: Spanish-language operator and maintenance training

One Veracruz plant engineer noted: "The difference between our previous Chinese machine and the SHJLPACK unit was night and day. The local technical support alone saved us weeks of downtime when we had a minor sensor issue."

4. What ROI Can I Realistically Expect from a Coil Turning Machine Investment?

Leading Paragraph:

As a plant manager, you're constantly evaluating equipment investments against bottom-line impact. While safety improvements are crucial, you need concrete financial justification for capital expenditures. The good news? Coil turning machines typically deliver some of the fastest ROI in packaging automation—if you choose the right equipment and properly implement it.

Snippet Paragraph:

Most Mexican steel plants achieve full ROI on coil turning machines within 12-18 months through labor reduction, damage prevention, and efficiency gains. Typical savings include: 60-70% reduction in positioning labor ($45,000-75,000 annually), 80-90% decrease in edge damage claims ($25,000-40,000), and 25-35% faster packaging line throughput. SHJLPACK customers report average annual savings of $85,000-140,000 per machine.

Dive Deeper Content:

Comprehensive ROI Calculation for Mexican Plants

Let's break down the real financial impact beyond the equipment price tag. I'll use a typical Mexican steel plant processing 150 coils daily as our example:

Current Manual Handling Costs (Annual)

Labor Expenses:

- 4 operators @ $18,000/year = $72,000

- Benefits and insurance (30%) = $21,600

- Overtime for delays = $12,000

- Total Labor: $105,600

Damage and Quality Costs:

- Edge damage repairs = $28,000

- Customer returns/claims = $35,000

- Internal rework = $15,000

- Total Damage: $78,000

Indirect Costs:

- Production delays = $42,000

- Safety incidents = $25,000

- Training replacement workers = $18,000

- Total Indirect: $85,000

Total Current Annual Cost: $268,600

Automated Operation Costs (Annual)

Equipment Investment:

- SHJLPACK CT-1500 coil turner = $85,000

- Installation and training = $15,000

- Total Investment: $100,000

Operating Costs:

- 1 operator @ $20,000/year = $20,000

- Maintenance and parts = $8,000

- Power consumption = $4,500

- Total Operating: $32,500

Annual Savings:

- Labor reduction = $85,600

- Damage elimination = $78,000

- Efficiency gains = $42,000

- Total Annual Savings: $205,600

ROI Calculation:

- Payback Period: $100,000 ÷ $205,600 = 5.8 months

- 3-Year Net Savings: ($205,600 × 3) - $100,000 = $516,800

- ROI Percentage: 205% annual return

Factors That Impact Your Actual ROI

Positive Factors (Faster ROI):

- High labor costs in your region

- Current high damage rates

- Multiple shifts operation

- Premium products requiring perfect packaging

Negative Factors (Longer ROI):

- Low labor costs

- Already efficient manual processes

- Single shift operation

- Commodity products with lower quality requirements

Case Study: Mexican Automotive Steel Supplier

Company: Tier 1 automotive supplier in Puebla

Challenge: Manual coil handling causing 3% damage rate and production bottlenecks

Solution: SHJLPACK CT-2000 with integrated positioning sensors

Results:

- Labor: Reduced from 6 to 2 operators ($68,000 savings)

- Damage: Decreased from 3% to 0.2% ($52,000 savings)

- Throughput: Increased from 120 to 165 coils daily (37.5% improvement)

- Safety: Zero handling injuries in 18 months (previously 2-3 annually)

- ROI: 7.2 months

The operations director commented: "The coil turner paid for itself faster than any other equipment we've purchased. But more importantly, it eliminated our biggest quality and safety concern."

Conclusion

Upgrading to a heavy-duty coil turning machine transforms your packaging line from a bottleneck to a competitive advantage, delivering rapid ROI while dramatically improving workplace safety. For complete packaging solutions, explore our steel coil packing line systems.

Frequently Asked Questions

Q: How long does installation and commissioning typically take for a coil turning machine?

A: Most installations require 3-5 days for foundation preparation, 1-2 days for equipment placement, and 2-3 days for commissioning and operator training. SHJLPACK projects typically complete within 7-10 working days with minimal production disruption.

Q: What maintenance is required for heavy-duty coil turners in high-volume applications?

A: Daily visual inspections, weekly hydraulic system checks, monthly bolt torque verification, and annual comprehensive maintenance. SHJLPACK machines average 98% uptime with proper maintenance, requiring about 2-4 hours of scheduled maintenance weekly in high-volume Mexican plants.

Q: Can coil turning machines handle different coil diameters and weights on the same production line?

A: Yes, modern machines like SHJLPACK models feature adjustable programming for coils from 800mm to 2000mm diameter and weights from 3-25 tons. Quick-change settings allow switching between different product specifications in under 60 seconds without tool changes.