Upender Machine Procurement: What Must Be in Your RFQ and Spec Sheet?

Buying a heavy-duty upender for your steel mill is a major capital investment. Get it right, and you boost efficiency and safety. Get it wrong, and you're stuck with a machine that causes bottlenecks, creates safety hazards, and bleeds money through downtime and maintenance. I've seen companies make this mistake, basing their decision on a vague, one-page request that leaves too much open to interpretation. This often leads to receiving quotes for completely different machines, making a true comparison impossible and increasing the risk of a poor investment.

To create an effective upender machine Request for Quotation (RFQ), you must include detailed technical specifications (load, dimensions, cycle time), comprehensive safety and compliance requirements (local and international standards), clear expectations for after-sales service and support (installation, training, warranty), and questions that evaluate a supplier's capabilities beyond just the price tag, such as their engineering depth and project management experience.

This isn't just about filling out a form. A well-crafted RFQ and specification sheet is your primary tool for risk management. It forces you to think through every aspect of the machine's life in your facility, from how it will receive a steel coil to how your team will maintain it five years from now. It sets clear expectations for suppliers and empowers you to make an informed decision based on value, not just the initial cost. As an engineer who has built a factory from the ground up, I can tell you that the work you put in upfront saves you immense headaches later. Let's walk through the essential elements your RFQ must contain.

What Key Technical Specifications Must Be Defined in an Upender RFQ?

You've identified a need for an upender, but you're worried that a generic request will result in bids that are all over the map. You know that if you don't specify your needs precisely, you could end up with a machine that is either over-engineered and overpriced, or under-powered and unable to handle your actual production demands. The fear is that a small oversight in the technical specs could lead to a large, expensive piece of equipment that doesn't fit your process flow.

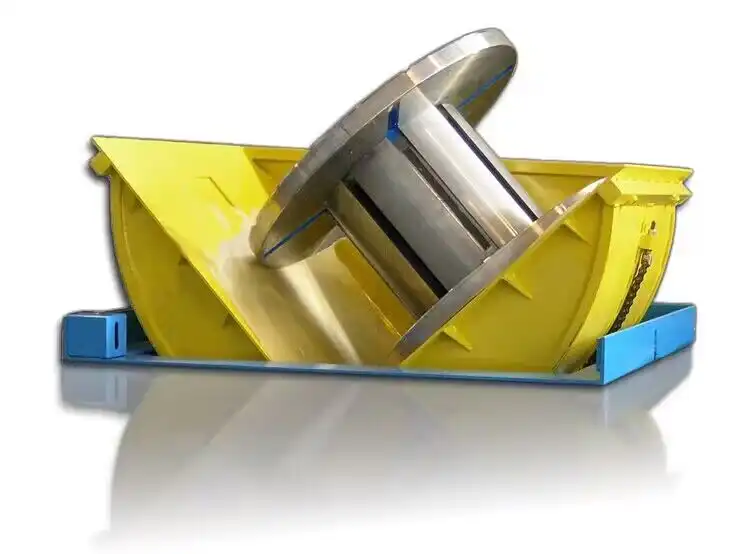

Your RFQ must clearly define the upender's core functions, including maximum load capacity, the full range of product dimensions and weight, required cycle time, the type of drive system (hydraulic or electromechanical), and the specific control system requirements, including preferred PLC brands and HMI functionalities for seamless integration.

Dive Deeper: From Load Capacity to Control Systems

Getting the technical specifications right is the foundation of your entire procurement process. It's about communicating your exact operational reality to the supplier. Let's break this down into critical components.

Load, Dimensions, and Product Type

This seems obvious, but it's where many mistakes happen. Don't just state the maximum weight. Provide the full range.

- Maximum Load Capacity: Specify the heaviest coil or object the machine will ever handle, and add a safety margin (e.g., 20%).

- Product Dimensions: Provide the minimum and maximum for Outer Diameter (OD), Inner Diameter (ID), and Width of your coils. If you're handling other objects like molds or dies, provide their Length x Width x Height. A simple list isn't enough; create a table showing the weight associated with the different dimensions.

- Product Center of Gravity: For non-symmetrical loads, the center of gravity is critical for a safe and stable tilt. If this varies, provide the potential range.

Performance and Drive System

This defines the machine's productivity and its operational characteristics.

- Cycle Time: How fast do you need the 90-degree tilt to happen? Specify the time in seconds for a full up-end or down-end cycle. Be realistic; a faster cycle often means a more powerful, more expensive drive system.

- Drive System: This is a major decision point. You need to choose between hydraulic and electromechanical systems. Neither is universally "better"; the right choice depends on your specific needs, environment, and maintenance capabilities.

| Feature | Hydraulic Upender | Electromechanical Upender |

|---|---|---|

| Power & Capacity | Excellent for very heavy loads (>50 tons). Delivers high torque smoothly. | Best for low to medium loads (<50 tons). Very efficient in its range. |

| Speed Control | Offers smooth, variable speed control through proportional valves. | Speed is generally fixed but can be varied with a VFD (Variable Frequency Drive). |

| Precision | Good positioning, but can have slight "drift." Requires more complex controls for precise stopping. | Excellent, repeatable positioning and stopping accuracy due to motor brakes and gearboxes. |

| Maintenance | Requires regular checks for oil leaks, filter changes, and hose inspections. Prone to oil contamination. | Simpler maintenance. Focuses on gearbox lubrication and motor checks. No oil spills. |

| Environment | Potential for hydraulic oil leaks, making it less suitable for cleanroom or food-grade environments. | Cleaner operation. No risk of oil contamination. Quieter than hydraulic systems. |

| Initial Cost | Often a lower initial purchase price for very high capacities. | Can have a higher initial cost, especially with VFDs, but TCO may be lower. |

Control and Integration

This is about how the machine talks to your operators and your factory's brain. For a CEO like Javier Morales, this is crucial for his digitalization goals.

- Control Panel: Specify if you need onboard controls, a remote pendant, or both. Detail the functions required on the Human-Machine Interface (HMI): start, stop, emergency stop, manual/auto mode, fault diagnostics.

- PLC System: Don't let the supplier choose for you. Specify the PLC brand (e.g., Siemens, Allen-Bradley, Mitsubishi) that matches the standard in your plant. This dramatically simplifies maintenance and spare parts inventory.

- Network Integration: If you plan to connect this machine to your MES or SCADA system, specify the communication protocol required (e.g., EtherNet/IP, PROFINET, Modbus TCP/IP). This is essential for tracking cycle counts, operating hours, and fault codes, which feeds directly into your goal of increasing capacity utilization through data.

How Do You Detail Safety and Compliance Requirements?

Investing in new machinery brings the immense responsibility of ensuring worker safety. You can't afford any incidents. The problem is, safety standards can be a complex web of local, national, and international regulations. Simply stating "must be safe" in an RFQ is a recipe for disaster. It leaves you vulnerable to suppliers who cut corners on safety features to lower their price, putting your people and your company's reputation at risk. An accident could halt production, trigger massive fines, and irreversibly damage morale.

To ensure total safety and compliance, your RFQ must explicitly demand adherence to specific, named standards such as ISO 12100 for risk assessment, IEC 60204 for electrical safety, and any relevant regional standards like OSHA (for the US) or CE marking (for Europe). Furthermore, you must list mandatory physical safety features, including emergency stop circuits, perimeter fencing with interlocked gates, light curtains or area scanners, and mechanical locking pins.

Dive Deeper: Building a Fortress of Safety Specifications

Safety isn't an option; it's a non-negotiable requirement. A detailed safety specification protects your team and your investment. It also separates the serious, responsible suppliers from those who are not.

Mandating Standards Compliance

You must be specific. This removes all ambiguity.

- International Standards: Reference key global standards. ISO 12100 (Safety of machinery - General principles for design) is the cornerstone. IEC 60204-1 (Electrical equipment of machines) is essential.

- Regional Standards: This is critical. If your plant is in Mexico, you should reference the relevant Norma Oficial Mexicana (NOM). If you might export products to Europe, requiring CE marking from the start is a smart move. For a plant in the United States, you'd specify compliance with OSHA 29 CFR 1910. By listing these, you force the supplier to confirm their knowledge and ability to comply. Ask them to provide a Declaration of Conformity with the bid.

Specifying Physical and Electrical Safeguards

Don't assume a supplier will include all the necessary safety hardware. List them as mandatory line items. This creates a clear checklist for you to evaluate each proposal against.

| Safety Feature | Description & Specification Requirement |

|---|---|

| Perimeter Guarding | Must be a physical barrier (e.g., wire mesh fencing) of a specified height (e.g., 2 meters) that prevents personnel from reaching the hazard zone during operation. |

| Interlocked Gates | Any access gates in the perimeter guarding must be equipped with safety interlock switches (e.g., Category 3 or 4). Opening the gate must immediately stop all hazardous motion. |

| Light Curtains | Specify the use of light curtains at the loading and unloading zones. Breaking the light beam must trigger a safe stop. State the required resolution and safety category (e.g., Type 4, PLd). |

| Emergency Stops | E-stop pushbuttons must be located at all operator stations and other strategic points around the machine. They must be hardwired and override all other controls. |

| Mechanical Locking | Require a mechanical locking pin or anti-drop device that automatically engages to prevent the platform from falling in case of a hydraulic or mechanical power failure. |

| Audible & Visual Alarms | A beacon and horn must activate for a few seconds before any machine movement begins, warning nearby personnel. |

| Hydraulic Safety | If hydraulic, the system must include pilot-operated check valves on cylinders to prevent collapse in case of a hose failure. Pressure relief valves are also mandatory. |

By detailing these requirements, you are building a safety case into your procurement document. Ask the supplier to describe how they meet each point in their proposal. This goes beyond a simple "yes/no" and gives you insight into their engineering competence. This level of detail ensures the machine that arrives on your floor is not just productive, but fundamentally safe for your team.

What Service and Support Expectations Should You Include?

You know that the purchase price of an upender is only the beginning of its total cost. The real long-term cost is tied to its uptime. A machine that is difficult to install, has poor documentation, or comes from a supplier who disappears after the check clears can become a massive liability. You worry about extended downtime while waiting for a technician to fly in or for a critical spare part to ship from overseas. This directly threatens your goal of 95% equipment uptime and can quickly erode any initial savings on the purchase.

Your RFQ should clearly outline your expectations for the entire service lifecycle, including detailed requirements for installation supervision, on-site operator and maintenance training, a comprehensive list of recommended spare parts, specific warranty terms (e.g., 24 months), and guaranteed response times for technical support and service calls.

Dive Deeper: Defining a Partnership, Not Just a Purchase

For a forward-thinking leader like Javier, a supplier is a long-term partner. Your RFQ is your first opportunity to define the terms of that partnership. Detailing service and support separates a "box-shover" from a true solution provider.

Installation and Commissioning

Don't leave installation to chance.

- Supplier's Role: Clearly state what you expect. Do you want full turnkey installation, or will your team handle the mechanical and electrical work with the supplier's supervision? Define the roles and responsibilities.

- Timeline: Request a detailed project timeline that includes key milestones: final drawing approval, manufacturing, factory acceptance test (FAT), shipping, installation, and site acceptance test (SAT).

- Acceptance Criteria: Define the specific performance metrics the machine must meet during the SAT before you sign off on the project. This should include cycle time tests, load tests, and verification of all safety functions.

Training and Documentation

A machine is only as good as the team operating and maintaining it.

- Training: Specify the type and duration of training required. It should be broken into two parts: one for operators (daily use, safety procedures, basic troubleshooting) and one for your maintenance team (mechanical adjustments, electrical schematics, PLC program basics, preventive maintenance schedule).

- Documentation: This is critically important. Require at least two sets of complete documentation in your specified language (e.g., English and Spanish).

Here’s a checklist for your documentation requirements:

| Document Type | Minimum Requirements |

|---|---|

| User Manual | Detailed instructions on operation, control panel functions, and safety procedures. |

| Maintenance Manual | Step-by-step guides for preventive maintenance, lubrication schedule, parts replacement, and troubleshooting. |

| Electrical Schematics | Complete, clearly labeled drawings of all electrical and control circuits. |

| Hydraulic/Pneumatic Schematics | Diagrams for all fluid power systems, showing all components. |

| Bill of Materials (BOM) | A complete list of all components with part numbers and original manufacturer details. This is crucial for sourcing parts locally if needed. |

| PLC Program | Request a fully annotated, unlocked copy of the PLC source code. This is non-negotiable for long-term support and integration. |

Warranty and After-Sales Support

This is your insurance policy.

- Warranty Period: Be specific. Instead of "1 year," state "24 months from the date of Site Acceptance Test (SAT)."

- Spare Parts: Ask the supplier to provide a tiered list of recommended spare parts: 1) critical spares to keep on-site, 2) parts recommended for a two-year operational period. Request pricing for this package with the main quote.

- Support Response Time: Define your expectations in a Service Level Agreement (SLA) format. For example: "Telephone/email support response within 4 hours. If remote diagnostics fail, a qualified technician must be on-site within 48 hours." This forces the supplier to think about their support infrastructure in your region.

How Can You Structure Your RFQ to Evaluate Supplier Capabilities Beyond Price?

Every steel mill owner knows the cheapest offer is rarely the best deal. A low price can hide poor build quality, inadequate engineering, or non-existent support. The challenge is creating an RFQ that forces suppliers to reveal their true capabilities, allowing you to compare their substance, not just their price. You need a way to identify a true strategic partner who can contribute to your goals of reliability and digitalization, rather than just a vendor selling a piece of metal.

To evaluate suppliers beyond price, structure your RFQ to demand substantive proof of their expertise. Require them to provide a detailed project reference list, relevant case studies, information on their engineering team's experience, their quality assurance procedures, and their project management methodology. Also, include a commercial questionnaire to assess their financial stability and long-term viability.

Dive Deeper: The RFQ as an Interrogation Tool

Think of your RFQ as a tool to interview the entire company, not just a salesperson. The structure of your questions will reveal their depth and professionalism. This is how you find a partner like SHJLPACK or FHOPEPACK, who focus on total solutions, not just equipment.

Demanding Proof of Experience

Don't just take their word for it.

- Reference List: Ask for a list of at least five similar projects completed in the last three years. Insist on details: client name, location, machine capacity, and contact information for a reference person. A confident supplier will gladly provide this.

- Case Studies: Request one or two detailed case studies for a project similar in scope to yours. This shows their problem-solving ability and how they delivered value to a client. It's a window into their process.

- Factory Tour/Audit: State in the RFQ your intention to visit the manufacturing facility of the shortlisted suppliers. This allows you to see their quality control, manufacturing capacity, and organization firsthand.

Assessing Engineering and Project Management Depth

This is where you separate the assemblers from the true engineers.

- The Team: Ask for an overview of their engineering department. How many mechanical engineers, electrical engineers, and software developers do they have? Who will be your dedicated project manager? Ask for the project manager's resume or qualifications.

- Design & Customization: Describe a unique challenge you have (e.g., limited floor space, a specific integration need) and ask them to propose a conceptual solution. Their response will demonstrate their engineering creativity and willingness to customize.

- Quality Assurance: Ask them to describe their QA process. Do they have ISO 9001 certification? What are their procedures for material inspection, weld testing, and Factory Acceptance Testing (FAT)?

Use a simple scoring matrix in your internal evaluation to keep things objective.

| Evaluation Category | Weighting | Supplier A Score (1-5) | Supplier B Score (1-5) |

|---|---|---|---|

| Technical Compliance | 30% | ||

| Price | 25% | ||

| Service & Support Plan | 20% | ||

| Proven Experience | 15% | ||

| Engineering Depth | 10% | ||

| Total Weighted Score | 100% |

This structured approach forces you to look at the whole picture. The supplier who can provide detailed, confident answers to these questions is the one who understands your needs and has the infrastructure to be a reliable partner, helping you achieve your goals for efficiency and modernization.

My Insights: The One Thing Most People Forget in Their RFQ

I have reviewed hundreds of RFQs and have seen a recurring pattern. People are excellent at specifying the 'what'—the capacity, the speed, the physical machine. They define the steel, the motors, the safety fences. But they almost always forget to specify the 'how'. They forget about the data. In today's industry, a machine that cannot communicate is a liability. It's a black box on your production floor at a time when you're pushing for total production visibility.

The single most overlooked element in an upender RFQ is the detailed specification for data accessibility and the software interface. Most buyers forget to define exactly what data points they need the machine to output, the format of that data, and the communication protocol for seamless integration with their Manufacturing Execution System (MES) or plant-wide data analytics platform.

As someone who built his business on understanding the entire packaging process, I can tell you this: the future of manufacturing efficiency lies in data. Your goal to increase产能利用率 to 95% and deploy a full MES is impossible if your new equipment can't talk to your systems. You need to treat the data interface with the same importance as the main drive motor.

In your RFQ, under the technical specifications, add a section called "Data & MES Integration." Specify things like:

- Required Data Points: List exactly what you want to track. Examples: cycle count, operating hours, motor current, fault codes with timestamps, current load weight (if using load cells).

- Data Format: Specify if you need the data in a simple CSV file, via an OPC UA server, or written directly to an SQL database.

- Communication Protocol: As mentioned before, mandate PROFINET, EtherNet/IP, or whatever your plant standard is.

- Remote Access: Specify your requirements for secure remote access for diagnostics. This allows a supplier's engineer (with your permission) to log in and troubleshoot issues in minutes, not days.

By defining this upfront, you ensure the upender is not just a strong machine, but a smart one. It becomes an active node in your digital factory, feeding you the information you need to optimize production, predict maintenance, and achieve the ambitious efficiency goals you've set for your company. This is the difference between buying a machine and investing in a strategic asset.

Conclusion

A detailed RFQ is your blueprint for a successful upender investment, ensuring reliability, safety, and long-term value for your steel mill's operations.