Upender Machine 101: What Is It and How Does It Work for Steel Coils?

Handling multi-ton steel coils is one of the most demanding tasks in any steel mill. Using an overhead crane with chains or C-hooks to flip a coil is slow, requires a lot of space, and puts your team in a potentially dangerous situation. A single moment of imbalance can lead to a dropped coil, causing catastrophic damage to your product, your equipment, and worse, your people. This inefficiency is a hidden cost that eats into your profits and a safety risk that keeps plant managers up at night. As an engineer who has spent his life in this industry, I've seen firsthand how these traditional methods create bottlenecks and liabilities. The solution is a specialized piece of equipment designed specifically for this job: the upender machine.

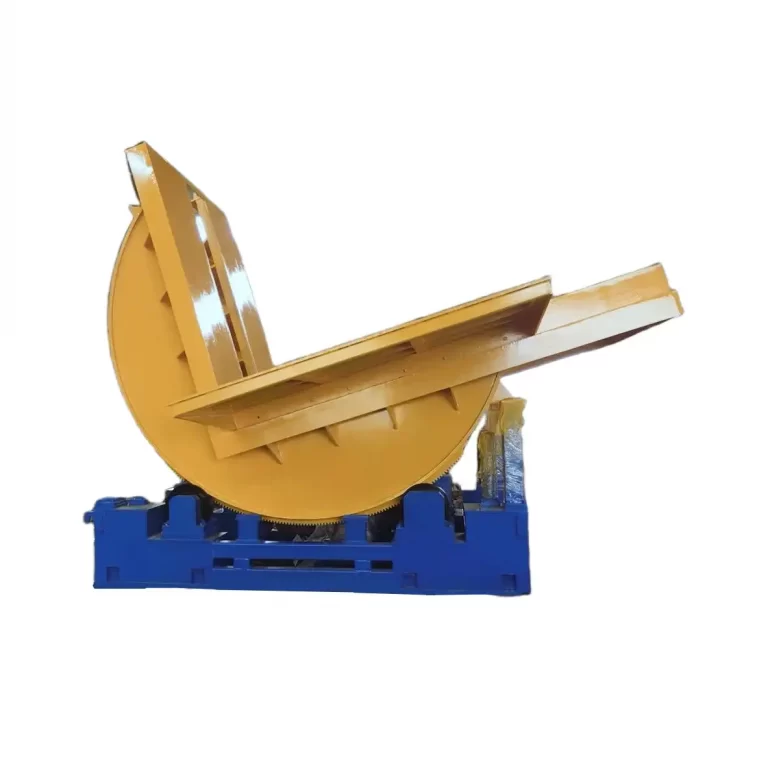

An upender, also known as a coil tilter or upender machine, is a piece of industrial equipment designed to safely and efficiently rotate heavy objects like steel coils by 90 degrees. Its core function is to take a coil from a "bore vertical" (eye-to-sky) position and lay it down to a "bore horizontal" (eye-to-the-wall) position, or vice versa. It does this on a stable, powered platform, eliminating the risks and inefficiencies of using cranes for tilting operations.

This simple-sounding task is fundamental to the entire logistics chain in a steel mill. From the end of the rolling line to the wrapping station, and finally to loading for transport, coils need to be reoriented. Making this step fast, reliable, and safe is not just an improvement; it’s a strategic advantage. It directly impacts your operational efficiency, product quality, and workplace safety. In this article, I'll draw on my years of experience designing and building these machines to walk you through how they work, the different types available, and what you, as a steel mill owner, should look for.

How Does a Mechanical Upender Differ from a Hydraulic One?

When you decide to invest in an upender, one of the first technical questions you'll face is about the drive system. Choosing between a mechanical and a hydraulic upender feels like a major decision, because it is. Picking the wrong one for your specific operation can lead to years of maintenance headaches, unexpected downtime, and performance that doesn't quite match your production rhythm. As a hands-on owner like Javier, you know that the "wrong" equipment choice shows up directly in your operational costs and can compromise your ambitious uptime goals. You need a machine that is reliable and fits your maintenance team's capabilities. Understanding the fundamental differences between these two workhorses is the first step to making a smart investment that pays for itself.

A mechanical upender uses an electric motor connected to gears or a screw jack system to perform the tilting motion, offering high precision and clean, oil-free operation. In contrast, a hydraulic upender uses a hydraulic power unit (HPU) to pump fluid into cylinders that push the platform, providing immense power and speed, especially for extremely heavy loads.

The choice between them isn't about which one is "better" overall, but which one is better for your steel mill. Both are proven technologies, but they excel in different areas. Your decision will depend on factors like the weight of your coils, your required cycle time, your plant's environmental policies, and your maintenance team's expertise. Let's break down the mechanics, pros, and cons of each system so you can analyze them like an engineer.

Mechanical Upenders: Precision and Cleanliness

A mechanical upender is driven by a straightforward and reliable system. An electric motor turns a gearbox, which in turn drives either a heavy-duty roller chain or a large screw jack mechanism. This direct mechanical linkage is what moves the tilting platform.

The primary advantage here is precision and control. The movement is smooth and highly repeatable, which is excellent for integration into automated lines where exact positioning is critical. Because there's no hydraulic fluid, you completely eliminate the risk of oil leaks. This is a significant benefit for plants with strict environmental standards or those handling products that cannot be contaminated, like food-grade steel or materials with sensitive surface finishes.

Maintenance is also simpler in many ways. It typically involves routine lubrication of gears, chains, and bearings. There are no hoses to replace, no seals to fail, and no hydraulic fluid to filter or change. Troubleshooting is often more direct, focusing on the electrical motor, the gearbox, and the mechanical linkages. I remember a client in the automotive supply chain who chose a mechanical system for this very reason. They were running a "clean floor" policy, and the risk of a hydraulic leak near their stamping line was unacceptable. The predictability of the mechanical system also helped them sync the upender's cycle time perfectly with their robotic arms.

Hydraulic Upenders: Raw Power and Speed

Hydraulic systems are the titans of heavy lifting. An electric motor drives a pump, creating immense pressure in hydraulic fluid. This fluid is directed through valves into large cylinders that act like powerful muscles, pushing the upender's platform with incredible force.

This is the go-to solution for extremely heavy loads. If your mill is handling coils that are 30, 40, or even 50 tons and beyond, hydraulics often provide the most cost-effective power. The systems are robust and can deliver very fast cycle times, which is a major advantage in high-throughput environments. The components are generally standard, and most industrial maintenance teams have experience working with hydraulic cylinders, pumps, and valves.

However, this power comes with its own set of responsibilities. Hydraulic systems require a dedicated hydraulic power unit (HPU), which takes up floor space. The system contains a large volume of oil that needs to be kept clean and periodically replaced. The biggest operational concern is the potential for leaks from hoses, fittings, or cylinder seals. While a well-maintained system is very reliable, a leak can be messy, create a slip hazard, and require immediate downtime for repairs.

A Comparison for Decision-Making

To help you make a data-driven choice that aligns with your goals for efficiency and cost control, here’s a direct comparison:

| Feature | Mechanical Upender | Hydraulic Upender |

|---|---|---|

| Load Capacity | Good for light to heavy loads (up to ~30 tons) | Excellent for very heavy to extreme loads (20+ tons) |

| Speed | Moderate and consistent | Can be very fast |

| Precision | High, very repeatable positioning | Good, but can have slight variations |

| Maintenance | Simpler; lubrication, gear/chain checks | More complex; fluid filtering, seal/hose replacement |

| Environmental | Excellent; no risk of oil leaks | Fair; potential for leaks requires management |

| Initial Cost | Can be higher for very heavy capacities | Often more cost-effective for extreme capacities |

| Integration | Excellent; easy to control with PLC logic | Good; requires controlling valves and pump |

For a CEO like Javier, the choice might come down to a long-term cost-of-ownership analysis. A mechanical system may have a slightly higher initial cost for a 25-ton coil, but it could offer lower maintenance costs and zero environmental risk over a 15-year lifespan. A hydraulic system might be cheaper upfront but requires a budget for consumables and potential cleanup.

What Are the Key Safety and Efficiency Benefits for a Steel Mill?

In a high-volume steel mill, every process is under pressure to be safer and more efficient. The traditional method of tilting a coil using an overhead crane and chains is a perfect example of a process filled with hidden risks and inefficiencies. It’s slow, it requires a skilled operator and ground crew working in close proximity to a suspended multi-ton load, and it often results in minor but costly damage to the coil edges. When you're trying to hit a 95% equipment uptime goal and reduce operating costs, these seemingly small issues add up to a major liability. They represent a weak link in your production chain. An upender directly attacks this weak link, turning a hazardous, variable process into a controlled, predictable, and safe operation.

The key benefits of an upender for a steel mill are a dramatic increase in workplace safety by eliminating manual handling of suspended loads, and a significant boost in operational efficiency through faster, more consistent cycle times and the reduction of product damage. It transforms a high-risk manual task into a simple, automated machine cycle.

These benefits aren't just theoretical; they translate directly into tangible results on your factory floor and on your balance sheet. By replacing an outdated, risky method with a purpose-built machine, you are making a direct investment in the stability, safety, and profitability of your entire operation. Let's dive deeper into how these benefits play out in a real-world steel mill environment.

A Fundamental Shift in Workplace Safety

The most important benefit is always safety. When a crane tilts a coil, several things have to go perfectly. The chains or clamps must be attached correctly, the crane operator must lift and turn with perfect smoothness, and ground personnel must stay clear. There are too many variables. An upender removes nearly all of them.

- Eliminating Suspended Loads: The coil is loaded onto a stable, ground-level platform. It is never freely suspended during the tilting motion. This single change eliminates the primary risk of a catastrophic drop.

- Creating Exclusion Zones: The machine's operation can be integrated with safety fencing and light curtains. This creates a fully enclosed work cell, ensuring no personnel can enter the area while the machine is in motion. This aligns perfectly with modern industrial safety standards.

- Reducing Manual Strain: Your crew is no longer manually pushing, pulling, or positioning heavy chains and clamps on the coil. The machine does the work. This reduces the risk of strains, sprains, and other common industrial injuries.

I once visited a client's plant where they had a "near-miss" incident. A 15-ton coil shifted in its chains during a tilt. Nobody was hurt, but it shut down that part of the plant for half a day and was a huge wake-up call for the management. We installed an upender a few months later. The plant manager told me the biggest change wasn't the speed, but the "calm" in that area of the plant. The stress and risk were simply gone.

Driving Measurable Gains in Efficiency

For a CEO focused on metrics like uptime and cost reduction, the efficiency gains are just as compelling as the safety improvements.

- Faster Cycle Times: A crane tilt can take several minutes, depending on operator skill and plant congestion. An upender performs the same task in a predictable cycle, often in 60-90 seconds. When you multiply that time saving by hundreds of coils per day, it adds up to hours of reclaimed production time.

- Reduced Product Damage: Crane chains and C-hooks can easily dent or scratch the edges and outer wraps of a steel coil. This damage often leads to the material being downgraded or scrapped. An upender's platform is designed with smooth steel or can be fitted with protective padding (like polyurethane) to handle the coil gently. This directly reduces scrap rates and improves the quality of the final product you deliver to customers.

- Freed-Up Crane Capacity: Your valuable overhead crane is a critical piece of equipment. When it's busy performing slow tilting operations, it's not available for its primary job: moving coils from one major process area to another. By delegating the tilting task to a dedicated upender, you free up your crane to do more value-added work, reducing bottlenecks across the entire plant.

One of my customers did a simple ROI calculation. They found that by reducing coil edge damage by just 1%, the upender would pay for itself in under two years. When they added in the increased throughput from faster cycle times, the payback period dropped to just over 12 months. This is the kind of hard data that justifies capital investment.

How Can an Upender Be Integrated into an Automated Production Line?

You're investing heavily in a digital future for your plant—implementing an MES to track production, using IoT sensors to monitor equipment health, and aiming for comprehensive visualization. In this connected environment, a standalone machine is an island. It’s a dead end in your data and material flow. If an upender can't talk to the rest of your line, it becomes a manual transfer point, a bottleneck that disrupts the very automation you're trying to build. This completely undermines your goal of a seamless, data-driven operation. The value of a modern upender isn't just in its ability to tilt steel; it's in its ability to become a smart, communicative part of your larger automated system.

An upender is integrated into an automated production line through its Programmable Logic Controller (PLC). This PLC acts as the machine's brain, communicating with the main line's control system and MES via industrial protocols. It uses signals from sensors to receive a coil from an infeed conveyor, perform the tilt, and then transfer it to an outfeed conveyor, all without manual intervention.

Thinking of an upender as an "intelligent node" in your production line is the right approach. It's a machine that doesn't just perform a physical task but also sends and receives data, enabling the kind of smart scheduling and predictive maintenance you're aiming for. Let's break down how this integration actually works on a technical level.

The Core of Communication: The PLC

Every modern, automated upender is controlled by a PLC. This is a rugged industrial computer that runs the machine's logic. The key to integration is ensuring this PLC can "speak the same language" as the rest of your factory.

- Control Handshakes: The integration works through a series of "handshake" signals. The infeed conveyor's PLC tells the upender's PLC, "I have a coil ready for you." The upender's PLC confirms, "I am ready to receive." Once the coil is in place, the upender's PLC takes over, performs the tilt, and then signals the outfeed conveyor's PLC, "I have a tilted coil ready for pickup." The outfeed conveyor then responds, "I am ready to receive," and activates to move the coil away.

- Industrial Protocols: This communication happens over standard industrial networks like PROFINET, EtherNet/IP, or Modbus TCP. When you specify a machine, you need to tell the manufacturer what protocol your plant uses. This ensures the equipment arrives ready to be plugged into your existing network, minimizing engineering time during installation. As a partner, this is one of the first questions we ask—we want our machine to be a simple "plug-and-play" addition to your line.

The Eyes and Ears: Sensors and Data Feedback

To operate automatically, the upender needs to sense its environment. This is where IoT-enabled sensors come into play, feeding crucial data back to the PLC and, by extension, your MES.

- Presence and Position Sensors: Photoelectric sensors at the entry and exit points detect when a coil has arrived and when it has cleared the machine. Proximity sensors on the tilting platform can confirm that the coil is seated correctly before the cycle begins. These sensors prevent crashes and ensure the process only runs when conditions are right.

- Data for Your MES: This is where you achieve the "comprehensive production visualization" you're aiming for. The upender's PLC can send a wealth of data to your MES:

- Cycle start and stop times

- Total cycle count for the shift or day

- Fault codes if an error occurs

- Motor current draw (which can be used for predictive maintenance)

This data allows your MES to have a real-time, accurate picture of where every coil is in the process.

A Practical Integration Scenario

Imagine a coil leaving your wrapping machine and heading to the warehouse.

- The coil travels down a powered roller conveyor and stops at the upender's infeed position, tripping a sensor.

- The sensor signal goes to the upender's PLC. The PLC communicates its status ("Ready with Coil") to your plant's MES.

- The MES, knowing the warehouse shuttle is approaching, sends a "Start Cycle" command to the upender's PLC.

- The upender automatically tilts the coil from eye-to-sky to eye-to-the-wall. Internal sensors confirm the 90-degree tilt is complete.

- The upender's PLC signals the MES: "Cycle Complete."

- The MES commands the outfeed conveyor to activate, moving the now correctly oriented coil to the pickup point for the warehouse shuttle.

In this scenario, no operator touched the coil or a control panel. The process was efficient, safe, and fully tracked. This is the power of true integration.

What Should You Consider When Choosing an Upender for Steel Coils?

Purchasing a heavy-duty machine like an upender is a major capital investment. It's not something you buy from a catalog. A hasty decision based only on price can leave you with a machine that is undersized, unsafe, or wears out far too quickly. For a detail-oriented leader like yourself, who conducts rigorous feasibility analysis for every investment, the stakes are high. Choosing the wrong machine means wasted capital, production disruptions, and a failure to meet your cost-reduction and efficiency goals. You are not just buying a piece of equipment; you are choosing a long-term production asset. As an engineer who has designed, built, and repaired these machines, I want to share the critical factors you must consider. This is the checklist I use to ensure a client gets a machine that is a true solution, not a new problem.

When choosing an upender for steel coils, you must look beyond the price tag and evaluate four key areas: core technical specifications (capacity, size), structural integrity and build quality, the comprehensiveness of its safety features, and the reliability of the manufacturer's after-sales support and partnership commitment.

This is about moving from a supplier mindset to a strategic partner mindset. A supplier sells you a machine. A partner works with you to understand your unique operational needs—your coil dimensions, your line speed, your safety protocols—and delivers a machine that is perfectly tailored to your mill. Let's break down what to look for in each of these areas.

Core Technical Specifications: The Non-Negotiables

This is the foundational data. If you get this wrong, nothing else matters.

- Load Capacity: This is the most critical number. Identify the absolute maximum weight of any coil you produce or plan to produce. Then, add a safety margin of at least 25%. If your heaviest coil is 20 tons, you need a machine rated for a minimum of 25 tons. This ensures the motors, structure, and components are not constantly operating at their breaking point, which is key to longevity.

- Platform (Table) Size: The platform must accommodate your largest coil. You need two measurements: the maximum coil outer diameter (OD) and the maximum coil width. Provide these to the manufacturer. Also, discuss the platform surface. A V-shaped saddle is standard for coils to keep them centered and stable. For sensitive surfaces, a polyurethane or rubber coating is essential to prevent damage.

- Tilting Angle and Speed: The standard is a 90-degree tilt. If you have unique process needs, custom angles are possible. The cycle time (tilting speed) must match or be faster than your production line's takt time to avoid creating a bottleneck.

- Duty Cycle: Be clear about how you will use the machine. Will it run five cycles per hour, or thirty? A high duty cycle requires more robust motors, gearboxes, and bearings to handle the heat and wear.

Beyond the Spec Sheet: The Engineer's View

This is where you separate a well-built machine from a cheap one. I always tell my clients to look at the "bones" of the machine.

- Structural Integrity: Ask about the thickness of the steel plate used in the frame and platform. Look at the welding quality. Are the welds clean and continuous? A heavily reinforced frame with gussets in high-stress areas is a sign of quality engineering. This is what ensures the machine will withstand decades of heavy use.

- Component Quality: The best machine in the world will fail if it uses poor-quality components. Ask what brands are used for critical parts: the motor (e.g., Siemens, ABB), the gearbox (e.g., SEW-Eurodrive), and the bearings (e.g., SKF, FAG). Using well-known, reputable brands means better reliability and easier access to spare parts down the road.

Safety and Support: The Partnership Test

This is what defines the long-term value of your investment.

- Comprehensive Safety Features: Don't settle for just an emergency stop button. A safe, modern machine should include:

- Perimeter safety fencing with interlocked gates.

- Light curtains at the entry/exit points to stop the machine if an object or person crosses the beam.

- Warning lights and an audible horn that activate before and during motion.

- Mechanical locking pins for safe maintenance access.

- After-Sales Support: This is where a true partner proves their worth. Before you buy, ask these questions: What does your warranty cover? Do you provide installation supervision and operator training? How quickly can you provide critical spare parts? Do you offer remote diagnostic support?

I remember a client in Mexico who had an issue. We were able to log in to their machine's PLC remotely from our office, diagnose the sensor fault, and guide their local maintenance team through the fix in under an hour. That is the kind of support that prevents a minor issue from becoming a costly shutdown and is the core of our philosophy at SHJLPACK.

Conclusion

An upender is more than steel and motors; it’s a key to safer, more efficient, and automated steel coil handling, directly supporting the strategic goals of a modern steel mill.