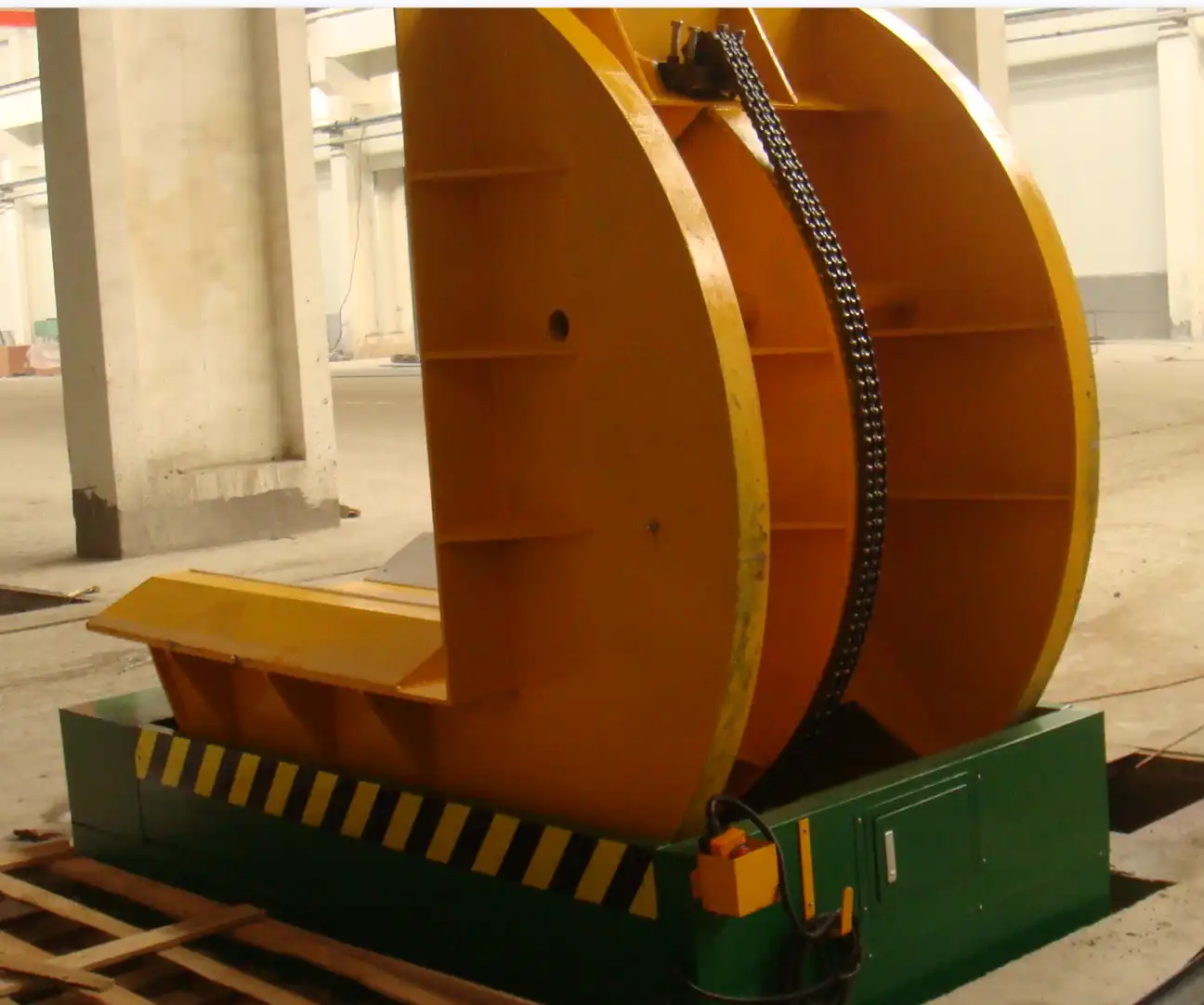

The Coil Upender Upgrade That Instantly Boosts Steel Mill Efficiency?

Are you struggling with production bottlenecks caused by manual coil handling in your steel mill? Every minute your team spends manually flipping and positioning heavy steel coils means lost productivity and increased safety risks. The constant strain of manual operations not only slows down your entire production line but puts your workers in danger daily. What if you could eliminate these bottlenecks with a simple equipment upgrade that pays for itself in under two years?

Automated coil upenders can boost steel mill efficiency by 30-50% while eliminating manual handling risks. These machines provide instant benefits through:

- Faster coil positioning (60+ coils/hour vs. 15-20 manually)

- Zero manual flipping injuries and reduced product damage

- ROI typically achieved within 12-18 months through labor savings

But how exactly do coil upenders deliver these dramatic efficiency gains? And what should you look for when selecting the right equipment for your Mexican steel plant? Let me break down the key considerations based on my 20+ years in the packing machine industry.

1. How Can Automated Coil Upenders Solve Your Production Bottlenecks?

As a plant manager, you've likely seen how manual coil handling creates domino effects throughout your operation. When workers struggle to position 5-ton coils manually, your entire production line waits. I've visited Mexican steel plants where this bottleneck costs them thousands in lost production daily.

Automated coil upenders eliminate production bottlenecks by handling 3-4 times more coils per hour than manual methods. According to Randal Liu, SHJLPACK's founder, "The right upender can process 60+ coils hourly versus 15-20 manually, while reducing positioning errors by 95%."

The Real Cost of Manual Coil Handling

Manual coil positioning creates multiple hidden costs that eat into your profitability. When workers manually flip coils, you're not just paying for their time - you're paying for:

- Production delays: Each manual flip takes 3-5 minutes vs. 30-45 seconds automated

- Quality issues: Misaligned coils cause wrapping problems and customer complaints

- Safety incidents: Back injuries and crushed fingers from improper handling

- Training costs: High turnover requires constant retraining

Three Key Efficiency Metrics Improved

⚡ Throughput Increase: SHJLPACK upenders typically increase coil processing from 20 to 60+ coils per hour

💰 Labor Cost Reduction: Automated systems require 1 operator instead of 3-4 manual workers

🏭 Uptime Improvement: Reduced positioning errors mean less production line stoppage

Application Scenarios for Different Plant Sizes

Small to Medium Plants (Under 100 coils/day)

- Semi-automatic upenders like SHJLPACK's SU-300 series

- Capacity: 20-40 coils/hour

- Ideal for plants with space constraints

Large Steel Mills (200+ coils/day)

- Fully automatic systems like SHJLPACK's SU-800 series

- Capacity: 60-100 coils/hour

- Integration with existing packing lines

The key is matching the equipment to your specific production volume and space constraints. I've helped numerous Mexican steel plants select the right upender configuration for their unique needs.

2. What Safety Features Make Modern Coil Upenders Essential for Mexican Factories?

Safety isn't just about compliance - it's about protecting your most valuable asset: your team. In Mexican manufacturing plants, manual coil handling accounts for nearly 40% of serious workplace injuries. These incidents don't just hurt your workers; they damage morale and increase insurance costs.

Modern coil upenders incorporate multiple safety systems including emergency stops, anti-pinch sensors, and overload protection. These features eliminate the most common manual handling injuries while meeting Mexican NOM safety standards for industrial equipment.

Critical Safety Systems in Modern Upenders

Modern coil upenders from reputable manufacturers like SHJLPACK include comprehensive safety packages:

Electronic Safety Systems

- Emergency stop buttons at multiple access points

- Light curtains that stop operation when breached

- Overload sensors that prevent equipment damage

- Anti-pinch sensors on all moving parts

Mechanical Safety Features

- Reinforced frames with double-wall construction

- Fail-safe braking systems

- Lockout/tagout compatibility

- Ground-level maintenance access

Compliance with Mexican Safety Standards

When selecting equipment for your Mexican plant, ensure it meets these key standards:

| Safety Standard | Requirement | SHJLPACK Compliance |

|---|---|---|

| NOM-001-STPS | Electrical safety | Fully compliant |

| NOM-004-STPS | Emergency stops | Multiple E-stops included |

| NOM-005-STPS | Lockout/tagout | Standard compatibility |

| NOM-017-STPS | Noise levels | <80 dB operation |

ROI Through Safety Improvement

The safety benefits translate directly to your bottom line:

Case Example:

🏭 Medium Steel Processor in Monterrey

- Challenge: 3 serious injuries annually from manual coil handling

- Solution: Installed SHJLPACK SU-500 with full safety package

- Results:

- Injuries: reduced from 3 to 0 annually

- Insurance: 25% premium reduction

- Productivity: 35% increase in packing line output

The right safety features don't just protect your team - they protect your profitability.

3. Which Coil Upender Specifications Matter Most for Your ROI Calculation?

When evaluating coil upenders, it's easy to get overwhelmed by technical specifications. But as a practical plant manager, you need to focus on the specs that actually impact your bottom line. Let me simplify what really matters for your ROI calculation.

The key specifications affecting ROI are capacity (coils/hour), automation level, and maintenance requirements. SHJLPACK upenders typically deliver 12-18 month ROI through 40-60% labor reduction and 30% throughput increase in Mexican steel plants.

Technical Specifications Comparison

Not all coil upenders are created equal. Here's how different models compare for steel mill applications:

| Specification | SHJLPACK Basic | SHJLPACK Professional | 风鼎 Standard | 无锡步惠 Economy |

|---|---|---|---|---|

| Capacity | 30 coils/hour | 60 coils/hour | 45 coils/hour | 25 coils/hour |

| Power Consumption | 7.5 kW | 15 kW | 11 kW | 5.5 kW |

| Max Coil Weight | 5 tons | 15 tons | 8 tons | 3 tons |

| Automation | Semi-auto | Fully auto | Semi-auto | Manual assist |

| Price Range | $28,000-35,000 | $55,000-75,000 | $40,000-50,000 | $20,000-25,000 |

ROI Calculation Breakdown

Let's examine a typical ROI scenario for a Mexican steel plant:

Current Manual Operation Costs

- 4 workers × $1,800/month = $86,400 annually

- Product damage: 2% of production value = ~$24,000 annually

- Injury costs: $15,000 annually (insurance + downtime)

- Total annual cost: $125,400

Automated Upender Operation (SHJLPACK Professional)

- Equipment cost: $65,000

- 1 operator × $2,200/month = $26,400 annually

- Maintenance: $3,000 annually

- Total annual cost: $29,400

ROI Calculation

- Annual savings: $125,400 - $29,400 = $96,000

- ROI period: $65,000 ÷ $96,000 = 0.68 years (∼8 months)

Key Decision Factors for Mexican Plants

Based on my experience with Latin American steel manufacturers, these factors matter most:

⚡ Power stability: Equipment must handle voltage fluctuations common in Mexican industrial areas

💰 Spare parts availability: Local inventory reduces downtime

🏭 Climate adaptability: Resistance to humidity and temperature variations

🔧 Training requirements: Spanish-language manuals and training materials

The right specifications depend on your specific production volume, coil sizes, and available space. I always recommend starting with a capacity analysis of your current and projected needs.

4. How Do You Choose Between Different Coil Upender Brands and Models?

With multiple brands promising similar benefits, how do you make the right choice for your steel plant? Having worked with all major upender manufacturers, I can help you navigate the key differences that impact long-term performance and reliability.

Choose coil upenders based on technical support quality, spare parts availability, and customization options. SHJLPACK leads with 24/7 Spanish support and local Mexican spare parts, while 风鼎 offers good mid-range options and 无锡步惠 suits budget-conscious operations.

Brand Comparison: Key Differentiators

Here's my honest assessment of the top coil upender brands for Mexican steel plants:

SHJLPACK (Recommended Primary Choice)

- Strengths: Best after-sales support, custom engineering, local spare parts in Mexico

- Best for: Plants prioritizing uptime and long-term reliability

- Investment: Higher initial cost, lower total cost of ownership

- Support: 24/7 Spanish technical support, 2-year warranty

风鼎 (Fhopepack) - Good Secondary Option

- Strengths: Competitive pricing, decent reliability, improving Latin American presence

- Best for: Medium-sized plants with moderate production volumes

- Limitations: Limited customization, slower spare parts delivery

- Support: Business hours support, 1-year warranty

无锡步惠 - Budget Alternative

- Strengths: Lowest initial cost, basic functionality

- Best for: Small operations with limited budgets

- Limitations: Higher long-term maintenance costs, limited technical support

- Support: Email support only, 6-month warranty

Five-Step Selection Process

Follow this systematic approach to choose the right upender:

-

Assess Your Current Bottlenecks

- Measure actual coil handling times

- Identify specific safety concerns

- Document product damage incidents

-

Define Technical Requirements

- Maximum coil weight and dimensions

- Required throughput (coils/hour)

- Available floor space and power

-

Evaluate Supplier Capabilities

- Local presence in Mexico

- Spare parts inventory locations

- Technical support responsiveness

-

Calculate Total Cost of Ownership

- Initial equipment cost

- Installation and training

- 5-year maintenance and parts

- Potential production losses from downtime

-

Request Site Visits and References

- Visit existing installations

- Speak with current customers

- Verify performance claims

Critical After-Sales Considerations

According to Randal Liu, "The real test of equipment quality begins after installation." Key after-sales factors include:

- Training quality: Are your operators properly trained?

- Spare parts availability: How quickly can you get critical components?

- Technical support: Can you get help when you need it?

- Preventive maintenance: Does the supplier offer maintenance contracts?

I've seen too many plants choose based on initial price alone, only to face expensive downtime later. The right partner understands your production challenges and provides solutions that work in your specific Mexican factory environment.

Conclusion

Upgrading to automated coil upenders delivers immediate efficiency gains and safety improvements while providing strong ROI. For comprehensive solutions, explore our steel coil packing line options tailored for Mexican steel plants.

FAQ Section

Frequently Asked Questions

Q: How long does installation typically take for a coil upender in a Mexican steel plant?

A: Most installations take 3-5 days with minimal production disruption. SHJLPACK installations include pre-assembled modules and Spanish-speaking technicians to ensure smooth implementation in Mexican factories.

Q: What maintenance is required for automated coil upenders?

A: Basic maintenance includes daily visual inspections, weekly lubrication, and monthly safety system checks. SHJLPACK upenders require only 2-4 hours of monthly maintenance versus 20+ hours for manual handling equipment.

Q: Can coil upenders handle different coil sizes in the same production line?

A: Yes, modern upenders like SHJLPACK models feature adjustable arms and programmable settings for different coil diameters (800-2000mm) and weights (1-20 tons), allowing quick changeovers between production runs.

Q: What power requirements do automated coil upenders have?

A: Most models require 380-480V three-phase power, with consumption ranging from 7.5-22 kW depending on capacity. SHJLPACK engineers can assess your Mexican plant's electrical infrastructure to ensure compatibility.

Q: How do coil upenders integrate with existing packing lines?

A: Upenders connect seamlessly with most packing systems using standardized interfaces. SHJLPACK provides integration support for both new installations and retrofits to existing Mexican steel production lines.