Pallet Changing Machine: How Do Pharma Plants Ensure GMP Compliance During Pallet Swaps?

In my years in the industrial machinery business, I've seen how one small detail can bring a massive operation to a halt. In a pharmaceutical plant, that small detail could be a simple wooden pallet. It arrives from a warehouse, seemingly harmless. But it can carry dust, mold, or bacteria directly into a sterile cleanroom. This is a massive risk. A single contamination event can force a recall of life-saving medicine, trigger huge regulatory fines, and destroy a company's reputation. The manual process of moving goods off these pallets is slow, dangerous, and full of opportunities for human error. You need a better way.

Pharma plants ensure Good Manufacturing Practice (GMP) compliance during pallet swaps by using specialized pallet changing machines. These machines are designed with hygienic materials, like stainless steel, and have smooth, easy-to-clean surfaces. They operate using a validated, automated process that minimizes human contact with the product. This creates a critical barrier, preventing cross-contamination between the non-sterile warehouse environment and the sterile production zone.

This might sound straightforward, but the engineering and processes behind it are very precise. The principles of clean design and process validation are critical. I've spent my career helping clients in demanding industries like steel and coil packing solve similar challenges. The need for reliability and precision is universal. Let’s explore the specific requirements that make a pallet changer truly GMP compliant. The lessons here apply to any industry that values quality and safety.

What are the key GMP requirements for pallet changing in pharmaceutical manufacturing?

You know you must follow GMP regulations, but the official documents can be dense and confusing. When you look at a new piece of equipment like a pallet changer, it's hard to know exactly what an auditor will focus on. Where do you begin?

If you choose the wrong machine, you risk failing a critical audit. This can lead to expensive modifications, or worse, needing to replace the equipment entirely. The pressure to make the right decision from the start is very high. It's a significant capital investment, and you need to be sure it will perform and comply for years to come.

The solution is to focus on the core pillars of GMP as they apply to equipment. This means focusing on three main areas. First, the machine must be designed to actively prevent contamination. Second, its operation must be traceable and repeatable. Third, it must be easy to clean, maintain, and validate.

A pallet changer must meet key GMP requirements to be used in pharmaceutical settings. The equipment must be built from materials that are non-reactive and do not shed particles, such as 304 or 316L stainless steel. The machine's design must be smooth and free of crevices or sharp corners to allow for easy and effective cleaning and sanitization. Finally, the pallet-swapping process itself must be validated to prove it is repeatable, traceable, and effectively prevents cross-contamination.

Dive Deeper: From General Rules to Specific Features

Understanding the high-level GMP rules is one thing. Translating them into specific machine features is what truly matters during procurement and installation. As an engineer, I always look at the practical details. It's the same whether I'm designing a machine for a heavy steel coil or for a pallet of delicate vials. The machine must protect the product. In pharma, this protection is focused on purity.

Material and Surface Finish: The First Line of Defense

The choice of material is fundamental. GMP guidelines demand materials that won't react with, add to, or be absorbed by the products. This is why stainless steel is the industry standard. It's durable, corrosion-resistant, and non-porous. But not all stainless steel is the same. Type 304 is common, but for processes involving corrosive cleaning agents, Type 316L offers superior resistance. The "L" stands for low carbon, which improves weldability and reduces corrosion risk at the welds.

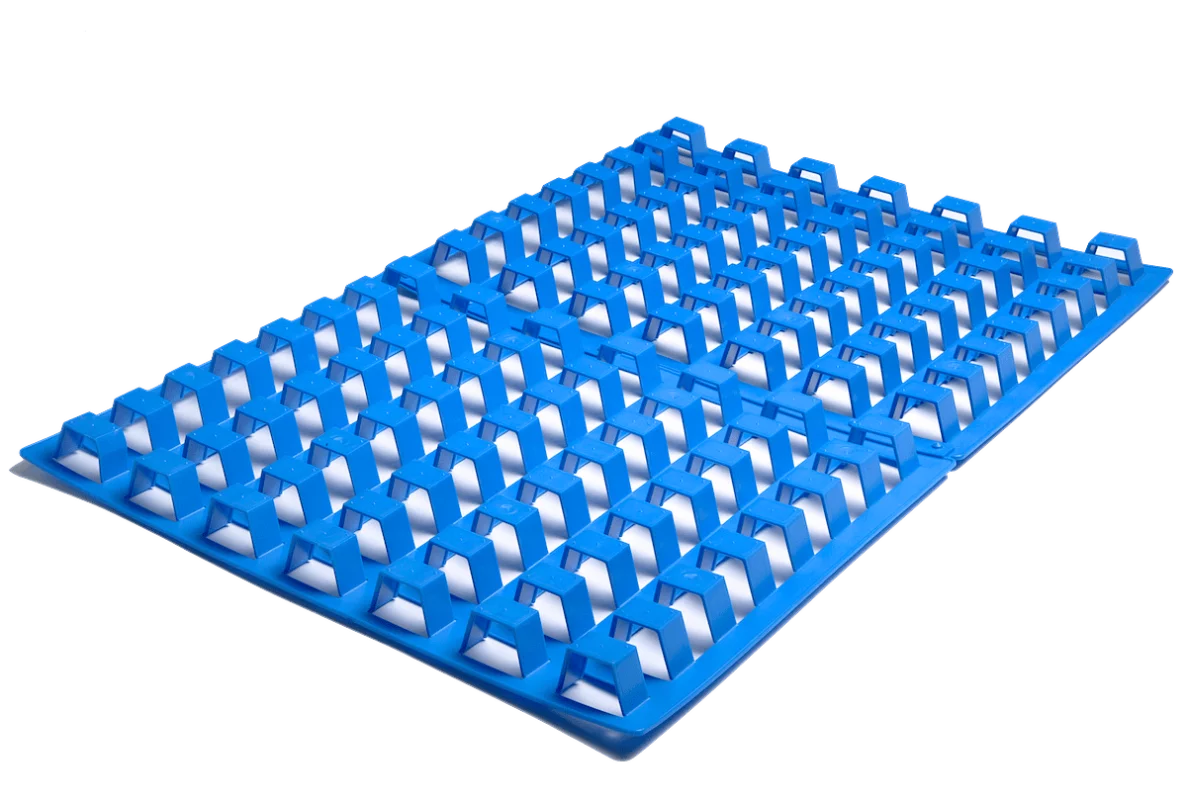

Beyond the material itself, the surface finish is critical. A pharmaceutical machine must have smooth, polished surfaces. This is measured by surface roughness (Ra). A lower Ra value means a smoother surface with fewer microscopic peaks and valleys where bacteria can hide. This is a stark contrast to a standard industrial environment. A wooden pallet is a perfect breeding ground for microbes, and even standard plastic pallets can get scratched, creating hiding spots for contaminants. A GMP-compliant pallet changer surface is designed to be defenseless against cleaning protocols.

Cleanability and Hygienic Design

A machine can be made of the right material, but if it's designed poorly, it's impossible to clean effectively. This is where hygienic design principles come in.

- No Crevices or Pockets: Every surface should be self-draining. There should be no sharp corners, exposed threads, or tiny gaps where moisture and contaminants can collect.

- Welds: All welds must be continuous, smooth, and ground flush with the surrounding material. A rough weld is a contamination risk.

- Enclosed Components: Motors, bearings, and electronic components should be sealed and enclosed to protect them from cleaning solutions and to prevent them from shedding particles (like grease) into the environment.

Comparing GMP vs. Standard Industrial Requirements

To make it clearer, here is how requirements differ between a GMP environment and a standard warehouse.

| Feature | GMP Requirement (Pharmaceutical) | Standard Industrial Practice | Why it Matters for GMP |

|---|---|---|---|

| Material | 304/316L Stainless Steel | Painted Carbon Steel, Aluminum, or Plastic | Prevents corrosion, leaching, and microbial growth. Ensures product purity. |

| Surface Finish | Smooth, polished, low Ra value | Standard mill finish, may be rough or textured | Eliminates hiding spots for bacteria and makes cleaning 100% effective. |

| Design | Hygienic design: no crevices, sloped surfaces, continuous welds | Functional design: focus on strength and cost, not cleanability | Prevents build-up of contaminants and ensures the machine can be properly sanitized. |

| Process Control | Validated, automated process with strict segregation of zones | Often manual or semi-automated, with less focus on segregation | Guarantees repeatability and minimizes human error, which is a major contamination source. |

How does a pallet changing machine's design contribute to maintaining a sterile environment?

You see a shiny, stainless-steel machine and assume it's clean. But how can you be certain that its design actually maintains sterility during operation? It’s not just about looking clean.

It is easy to be impressed by a polished surface. However, a machine with a poor design can be a hidden source of contamination. It might have internal areas that are hard to clean, or its movements could create air turbulence, spreading particles throughout your cleanroom. This would completely undermine its purpose and put your entire production at risk.

The real contribution to sterility comes from the specific details of the machine's construction and its mechanical action. The most effective designs are fully enclosed and use gentle clamping, pushing, or inverting mechanisms. These methods secure the product load while minimizing any disturbance that could dislodge and spread particles.

A pallet changing machine's design is critical for maintaining a sterile environment. It achieves this through its construction with hygienic materials and smooth, easily cleanable surfaces. More importantly, its enclosed mechanisms physically separate the incoming "dirty" pallet from the cleanroom area. The machine swaps it for a sanitized, cleanroom-safe pallet, often without any direct human handling of the product load itself.

Dive Deeper: Mechanics of a Sterile Transfer

The way a machine handles a load is just as important as the materials it's made from. In the pharmaceutical world, the goal is to transfer the product from a "dirty" pallet to a "clean" one with zero added contamination. This requires clever engineering. The machine is not just moving a box; it's protecting the integrity of what's inside.

In-Wall vs. Freestanding Models

The location of the pallet changer is a key part of the contamination control strategy.

- In-Wall (or Through-Wall) Systems: This is the most common setup for cleanroom applications. The pallet changer is physically built into the wall that separates the lower-grade warehouse area from the high-grade cleanroom. The "dirty" pallet is loaded on the warehouse side. The machine performs the swap, and the product load on a clean pallet exits on the cleanroom side. The machine itself acts as an airlock and a physical barrier, ensuring materials pass through without compromising the cleanroom's integrity.

- Freestanding Systems: These are used within a single classified area. For example, a company might use specific plastic pallets in one part of the production process and different stainless-steel pallets in another. A freestanding changer manages this internal transfer without needing to be built into a wall.

Comparing Hygienic Handling Mechanisms

Different pallet changers use different methods to transfer the load. Each has implications for sterility and product safety.

- Pusher Type: This is a simple mechanism. A flat plate, or platen, pushes the entire product load horizontally from the old pallet onto the new one. While simple, this creates friction between the bottom layer of cases and the surface they slide on. This can create particles or damage sensitive packaging. The mechanism needs to be designed carefully to ensure the pushing plate itself is perfectly clean.

- Inverter Type: This machine clamps the top and bottom of the load securely. It then rotates the entire load by 180 degrees. The original pallet is now on top and can be easily removed. A new, clean pallet is placed on the load, and the machine rotates back. This method is very secure, but it is not suitable for all products, such as liquids or unstable items that cannot be inverted.

- Clamping Type: This is often the most gentle and hygienic method. The machine uses side clamps to gently squeeze and lift the entire product load. With the load suspended, the old pallet is removed from below, and a new pallet is moved into position. The machine then lowers the load onto the new pallet. This "contactless" method avoids pressure on the top and bottom of the load and minimizes product disturbance.

From my experience in heavy industry, I learned a similar lesson. When we move a 5-ton steel coil, we use specialized equipment that lifts from the core. We never squeeze it from the sides, as that would damage the outer layers of steel. The principle is identical: the handling mechanism must be designed to protect the product's value. In pharma, that value is its purity.

What validation processes are necessary for a new pallet changer in a GMP facility?

You’ve done the research, selected the right machine, and had it installed. The job isn't over. Now comes the most critical phase for GMP compliance: validation. This process of testing and documentation can feel overwhelming.

If your validation records are incomplete or your testing protocols are weak, a regulatory auditor can declare your equipment non-compliant. This could mean shutting down the production line until you can provide the necessary proof. All the time and money invested in the machine hangs in the balance, waiting for you to prove it works exactly as intended, every single time.

The best way to manage this is with a structured, methodical approach. The industry standard for this is the "V-model" of validation. It breaks the process down into manageable stages: Installation Qualification (IQ), Operational Qualification (OQ), and Performance Qualification (PQ). Following this structure ensures you don't miss any steps.

A new pallet changer in a GMP facility must undergo a strict, multi-stage validation process. This begins with an Installation Qualification (IQ) to verify that the machine is installed correctly and matches all design specifications. It is followed by an Operational Qualification (OQ), which tests every function of the machine to ensure it operates within pre-defined limits. Finally, a Performance Qualification (PQ) proves that the machine consistently and reliably performs its task under real production conditions while preventing contamination.

Dive Deeper: The Three Pillars of Validation

Validation is not just about testing; it's about creating documented evidence. You must be able to prove to an auditor, years after installation, that the machine was installed correctly and operates reliably. Let's break down the three key stages.

Installation Qualification (IQ)

The IQ phase confirms that you got what you paid for and that it’s installed correctly. It's a static check of the machine before it’s even powered on.

- Key Activities: You will check the machine against the purchase order and design specifications. You will verify that all components, manuals, and drawings have been delivered. A critical step is checking material certifications to prove that the stainless steel is the correct grade (e.g., 316L). You'll also confirm that all utility connections (electrical, pneumatic) match the machine's requirements and that it is installed in the correct location according to the facility layout drawings.

Operational Qualification (OQ)

The OQ phase is where you turn the machine on and test its functions. This is typically done without any real product, or using a "dummy" load of empty boxes. The goal is to prove the machine operates according to its functional specifications.

- Key Activities: You will follow a pre-approved test script. This script will have you test every button, switch, and sensor. Does the emergency stop work? Do the safety light curtains stop the machine when the beam is broken? You will measure operational parameters like clamping pressure and cycle time to ensure they are within the specified ranges. Every test is documented: what was tested, what was the expected result, and what was the actual result.

Performance Qualification (PQ)

The PQ phase is the final test. Here, you prove that the machine works reliably and effectively under real-world conditions with actual product. This is where you confirm that the machine achieves its primary goal: enabling a sterile transfer.

- Key Activities: You will run the machine for a set number of cycles or a specific period to demonstrate consistency and reliability. The most important part of the PQ is testing for contamination. This often involves a scientific study. For example, you might take microbial swabs from the clean pallet and the product load before and after the transfer process. The results must show that the pallet changer does not add any contaminants to the product or the cleanroom environment.

| Stage | Purpose | Key Activities & Checks | Example Document |

|---|---|---|---|

| IQ | To verify the machine is installed correctly per design specs. | Check material certificates, verify part numbers, confirm utility connections, check calibration of instruments. | IQ Protocol & Report |

| OQ | To test that the machine's functions work as intended. | Test alarms, sensor functions, emergency stops, operational ranges (speed, pressure). | OQ Test Script & Report |

| PQ | To prove the machine performs consistently under real conditions. | Run with actual product, conduct microbial swab testing, challenge the process at its limits. | PQ Protocol with acceptance criteria & Report |

My Insights: Beyond the Machine, It's About the Partnership

Javier, when I look at your background, I see a journey very similar to my own. You started on the factory floor and built a successful steel company. I started as an engineer and built my own packing machinery factory. We both understand that equipment is more than just steel and motors. It is the heart of the operation. Whether you are producing 2 million tons of steel or I am designing a machine to wrap a coil, the principles of reliability, efficiency, and smart investment are the same.

The topic today is about pharmaceutical machines, but the core lesson is universal. When you face challenges like aging equipment, rising energy costs, and the need to digitalize, you are not just buying a machine. You are looking for a solution. You are looking for a partner.

From my own journey of achieving financial independence through this industry, I feel a deep need to give back. I do that by sharing what I’ve learned. So, let me share what I believe is most important when making a decision like this.

First, look for a partner who understands your entire process. A supplier who only knows their one machine is not enough. You need someone who asks about what happens before and after their machine. How will it integrate with your MES system? How will it communicate with your automated guided vehicles? How does it fit into your goal of reducing overall operational costs by 8%? This is why our slogan at SHJLPACK is "TOTAL SOLUTION FOR WRAPPING MACHINE." We believe in looking at the whole picture.

Second, the best partners help you prepare for the future. The machine you buy today must solve the problems of tomorrow. You are focused on digitalization, IoT sensors, and predictive maintenance. That’s exactly right. A good partner will already be building these features into their equipment. They should be able to show you how collecting data from their machine can help you increase your equipment uptime to your goal of 95%. They should be able to explain how their design helps you reduce energy consumption.

Finally, remember that the expertise behind the machine is often more valuable than the machine itself. When I was starting out, I relied on mentors who had been in the business for decades. Now, I try to be that person for my clients. A true partner doesn’t just sell you a machine and walk away. They provide support through installation, commissioning, and maintenance. They offer their knowledge to help you solve problems. They become part of your team. This is the kind of relationship that turns a simple equipment purchase into a strategic advantage that helps you grow your business.

Conclusion

Ensuring GMP compliance in pallet changing requires smart machine design, strict validation, and a strong partnership. Get these right, and you protect your product, your process, and your business.