Mold Flipper: Why Are Saudi Manufacturers Prioritizing Safer Mold Handling Now?

Handling massive industrial molds has always been a challenge. I’ve seen it myself in countless factories. Teams use overhead cranes, chains, and a lot of manual effort to flip these heavy, expensive pieces of steel. It’s slow, it’s inefficient, and honestly, it’s dangerous. A single slip, a snapped chain, or a moment of misjudgment can lead to catastrophic failure. This could mean a worker gets seriously injured, a multi-thousand-dollar mold is damaged beyond repair, and your entire production line grinds to a halt. The pressure to avoid these situations is immense, especially in a market that demands constant uptime and reliability. That’s why a simple, powerful solution—the mold flipper—is becoming less of a luxury and more of a necessity.

Saudi manufacturers are prioritizing safer mold handling with equipment like mold flippers now due to a powerful combination of factors. The ambitious goals of Saudi Vision 2030 demand world-class industrial efficiency and safety standards. At the same time, increasing pressure to meet global compliance for export, protect skilled workers, and eliminate costly production downtime from accidents makes investing in modern handling technology a critical strategic decision, not just an operational one.

This shift isn't happening in a vacuum. It’s a calculated response to a changing industrial landscape in the Kingdom. What I'm seeing is that factory owners and managers are moving beyond the traditional mindset of "if it isn't broken, don't fix it." They are now proactively looking for ways to de-risk their operations, boost efficiency, and align their facilities with the country's long-term vision. It's a fascinating change to witness firsthand. Let’s dive deeper into the specific forces driving this trend and what it means for the manufacturing sector in Saudi Arabia.

How does Saudi Vision 2030 drive the demand for safer industrial equipment?

Saudi Vision 2030 is an ambitious blueprint for the future of the Kingdom. Many people think of futuristic cities and economic diversification. But for those of us in the industrial sector, it has a very practical meaning. It means transforming the country's manufacturing base into a global powerhouse. This goal cannot be achieved with old, inefficient, and unsafe practices. An unsafe factory is an unpredictable one, and unpredictability is the enemy of growth and international competitiveness. This is why the demand for modern, safe equipment is no longer just a good idea; it's a core requirement for any manufacturer who wants to be part of this national journey.

Saudi Vision 2030 directly drives demand for safer industrial equipment by establishing a new benchmark for operational excellence. The vision’s focus on localization, creating a high-quality industrial sector, and attracting a skilled workforce necessitates the adoption of modern technologies like mold flippers. These machines ensure a safer working environment, higher efficiency, and the level of quality required to compete on a global stage, making them integral to achieving the vision's industrial goals.

To understand this connection, you have to look beyond the surface. Vision 2030 is about building a sustainable economy. A sustainable industrial sector is one that protects its most valuable assets: its people and its machinery. Outdated handling methods put both at risk. Investing in safety is therefore not a cost but a foundational pillar of this new industrial strategy. It sends a clear message that Saudi manufacturing is serious about quality, reliability, and long-term success. I've spoken with many clients in the region, and this sentiment is shared across the board. They see this investment as part of their contribution to the Vision, and a smart business decision at the same time.

The Push for Industrial Excellence

A key pillar of Saudi Vision 2030 is to increase local content and build a robust domestic manufacturing industry. This isn't just about replacing imports; it's about creating products that can compete with the best in the world. The "Made in Saudi" label must become a symbol of quality, reliability, and safety. You cannot achieve this high standard if your production processes are prone to accidents and inefficiencies. Imagine a potential international partner touring a facility. If they see workers using risky, manual methods to flip a 20-ton mold, it immediately undermines confidence in the entire operation's quality control and reliability. In my experience, building a brand starts on the factory floor. A clean, safe, and organized operation using modern equipment like mold flippers demonstrates a commitment to excellence that is essential for building a strong industrial reputation both locally and internationally.

Attracting and Retaining a Skilled Workforce

Another goal of Vision 2030 is to create jobs and develop a skilled Saudi workforce. Today’s skilled engineers, technicians, and operators have higher expectations for their work environment. They are more aware of occupational hazards and rightfully demand a safe workplace. A company that continues to use outdated and dangerous practices will struggle to attract and retain top talent. People want to work where they feel valued and protected. By investing in equipment that automates dangerous tasks, companies show a clear commitment to their employees' well-being. This not only reduces turnover but also boosts morale and productivity. A happy, safe worker is a focused and productive worker. This creates a positive cycle that directly supports the human capital development goals of the Vision.

Meeting International Standards for Export

To diversify the economy away from oil, Saudi Arabia aims to significantly increase its non-oil exports. To sell products in competitive international markets like Europe or North America, Saudi manufacturers must meet stringent global standards, including ISO and CE safety certifications. These standards cover not just the final product but the entire manufacturing process. A facility with a poor safety record or one that relies on non-compliant processes will face significant barriers to entry. A mold flipper, which is often CE-certified, helps bring a critical part of the production process into compliance. It's a tangible step that shows auditors and international customers that the company takes safety and quality seriously, opening doors to lucrative export markets.

| Aspect | Traditional Approach | Vision 2030-Aligned Approach |

|---|---|---|

| Safety | Accepted as a cost; reactive measures. | A core value; proactive investment in safe technology. |

| Efficiency | Manual processes are "good enough." | Automation of slow/dangerous tasks is essential. |

| Workforce | High tolerance for manual, risky labor. | Focus on attracting/retaining skilled talent with a safe environment. |

| Technology | Use equipment until it fails completely. | Continuous investment in modern, compliant machinery. |

| Market Focus | Primarily domestic. | Geared for both domestic quality and global export standards. |

What are the real costs of unsafe mold handling in a modern factory?

Many factory owners I talk to are very focused on the initial price of a new machine. That makes sense; capital is precious. But they often miss the much larger, hidden costs of not upgrading. Unsafe mold handling isn't just about the risk of an accident. It's a constant drain on resources that quietly eats away at your profit margin. The true cost is a combination of obvious and hidden factors. An accident is the most visible cost, but the daily inefficiencies, the slow damage to equipment, and the low morale of your team are just as damaging over time. Realizing this helps shift the perspective from seeing a mold flipper as an expense to seeing it as a crucial investment in operational health.

The real costs of unsafe mold handling go far beyond the immediate aftermath of an accident. They are a mix of direct costs like medical bills and mold repair, and massive indirect costs like production downtime, which can cost thousands of dollars per hour. Additionally, there are intangible costs such as decreased worker morale, increased insurance premiums, and potential damage to the company's reputation, all of which erode profitability and competitiveness.

I remember a story from a client before he worked with us. His team was using a crane to flip a large injection mold. A chain slipped. The mold, worth over $80,000, crashed to the floor, damaging a critical alignment surface. No one was hurt, thankfully, but the consequences were huge. The mold was out of commission for three weeks for emergency repairs. The production line it served was completely stopped. They missed a major delivery deadline for an automotive client, which resulted in financial penalties and, worse, a serious blow to their reputation. The total cost of that single incident was nearly double the price of the mold flipper they eventually bought from us. This is a perfect example of how the "cost" of doing nothing can be far greater than the cost of investing in the right solution.

The Obvious Costs: Accidents and Damage

These are the costs everyone thinks of first. When a multi-ton mold is handled improperly, two things are at immediate risk: people and the mold itself. A workplace injury leads to direct costs like medical treatment, worker compensation claims, and potentially large fines from safety regulators. The cost of a single serious injury can easily run into the tens of thousands of dollars, or more. Then there is the cost of the mold. These are precision-engineered tools, often made of specialized steel. A drop or impact from a crane can crack the mold, damage its surface, or knock alignment pins out of place. Repairing such damage is extremely expensive and time-consuming. In some cases, the mold may be damaged beyond repair, requiring a complete replacement, which can cost hundreds of thousands of dollars and take months to procure.

The Hidden Costs: Downtime and Inefficiency

This is where the real financial pain often lies, as my client's story showed. Every minute your production line is not running, you are losing money. When a mold needs maintenance or changing, a manual process using cranes is slow and unpredictable. It might take two hours one day, and four the next, depending on who is available and how smoothly things go. A mold flipper turns this into a predictable, repeatable process that takes just a few minutes. This reduction in changeover time is pure profit. Let's say your line generates $2,000 per hour in revenue. If you can save 90 minutes on every mold change, and you do this twice a week, you've just added $6,000 in production capacity every single week. This is not a soft saving; it's real, measurable revenue that goes straight to the bottom line. Unsafe, slow methods are a constant, hidden tax on your productivity.

The Reputational Costs: Morale and Compliance

These costs are harder to quantify but are critically important. A workplace with a poor safety record suffers from low morale. Workers who feel unsafe are less engaged, less productive, and more likely to leave. This increases recruitment and training costs. Furthermore, in today's world, reputation matters more than ever. If your company is known for accidents, it can be difficult to win contracts with major international clients, who conduct rigorous safety audits of their suppliers. In a competitive market like Saudi Arabia, a strong safety record is a powerful differentiator. It builds trust with customers, regulators, and your own employees.

| Cost Category | Specific Items | Potential Financial Impact |

|---|---|---|

| Direct Costs | Medical Bills, Compensation, Fines, Mold Repair/Replacement. | $10,000 - $250,000+ per incident. |

| Indirect Costs | Lost Production (Downtime), Missed Deadlines, Contract Penalties. | $1,000s - $10,000s per hour of downtime. |

| Reputational Costs | Increased Insurance Premiums, Loss of Customer Trust, High Employee Turnover. | Long-term loss of business and increased operating costs. |

How does a mold flipper directly improve operational efficiency beyond just safety?

It’s easy to look at a mold flipper and categorize it solely as a piece of safety equipment. And it is a fantastic safety device. But if that's all you see, you are missing its true potential as a powerful driver of operational efficiency. In my journey from engineer to factory owner, I learned that the best investments are the ones that solve multiple problems at once. A machine that only improves safety can be seen as a "cost center." But a machine that improves safety and makes you faster, more predictable, and protects your assets becomes a "profit center." The mold flipper is one of those machines. It fundamentally changes the workflow around mold handling for the better.

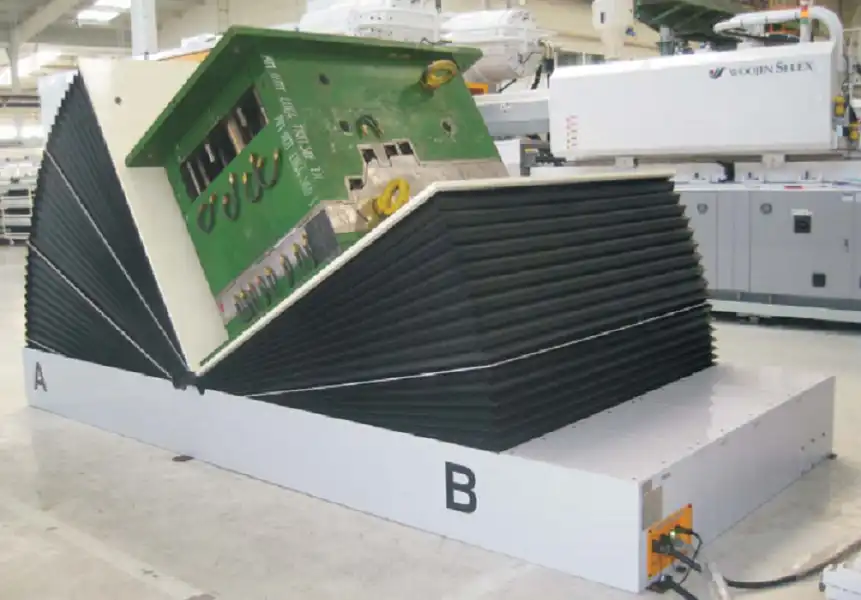

Beyond its primary role in preventing accidents, a mold flipper directly boosts operational efficiency by dramatically cutting down the time required to turn a mold from hours to minutes. This speed enables faster production line changeovers, allows for more frequent and predictable maintenance cycles, and protects expensive molds from the damage often caused by chains and cranes, ensuring greater asset longevity and uptime.

Think about the traditional process. You need a certified crane operator. You need at least one or two other people on the ground to rig the chains and guide the load. The process is slow and requires careful coordination. The entire area has to be cleared for safety. A mold flipper, by contrast, is a one-person, push-button operation. The operator can safely and quickly turn the mold in a fraction of the time, without needing a crane or extra personnel. This isn't just a marginal improvement; it's a complete transformation of the process. The time saved can be immediately reallocated to value-added activities, like running the production line. This is how safety and efficiency become two sides of the same coin.

Speeding Up Mold Maintenance and Changeovers

In any manufacturing plant, especially in industries like automotive or plastics, time is money. The faster you can change a mold, the faster you can start the next production run. The old method with a crane can take anywhere from one to several hours. It’s an "event." A mold flipper can accomplish the same 90-degree or 180-degree turn in under five minutes. This drastic reduction in changeover time has a massive impact on Overall Equipment Effectiveness (OEE). It directly increases the 'Availability' component of OEE. When maintenance is quick and easy, it gets done more regularly. Teams are more likely to perform preventative checks when it doesn't require a major production stoppage. This leads to better-maintained molds, fewer unexpected breakdowns, and higher quality parts.

Protecting Your Most Valuable Assets

Molds are not just chunks of steel; they are highly precise, expensive assets. A single large mold for a car bumper or a large container can cost hundreds ofthousands of dollars. Using cranes and chains to flip them puts them at constant risk. The chains can scratch or dent critical parting line surfaces. An unbalanced lift can cause the mold to swing and impact other equipment. A mold flipper eliminates all of these risks. It holds the mold securely on a stable platform and uses smooth, controlled hydraulic or electromechanical power to turn it. There are no chains, no swinging, no impacts. By protecting the mold from damage, the flipper extends its operational life and ensures the quality of the parts it produces. This is a direct protection of a significant capital investment.

Creating a Predictable and Standardized Workflow

One of the biggest enemies of efficiency is variability. When a task takes a different amount of time every time it's performed, it's impossible to plan effectively. Crane-based mold flipping is highly variable. A mold flipper standardizes the process. It takes the same amount of time, every time. This predictability is a huge advantage for production planners like my friend Javier Morales. They can schedule maintenance and changeovers with precision, knowing exactly how long the machine will be down. This allows for tighter scheduling, better labor allocation, and a much smoother overall production flow. It removes the guesswork and replaces it with reliable, repeatable performance.

| Process Step | Manual Method (Crane & Chains) | Mold Flipper Method |

|---|---|---|

| Setup | Requires crane operator, riggers; clearing the area. (15-30 min) | One operator positions the mold on the table. (5 min) |

| Turning | Slow, careful lifting, manual turning, risk of swing. (30-90 min) | Smooth, automated, controlled rotation. (2-5 min) |

| Securing | Lowering carefully, unhooking chains. (15-30 min) | Mold is already stable on the table, ready for work. (1 min) |

| Total Time | 60 - 150+ minutes | ~10 minutes |

| Risk Factor | High (Personnel injury, mold damage) | Very Low |

What should Saudi buyers look for when choosing a mold flipper supplier?

Okay, so you're convinced. A mold flipper is the right choice for your factory in Saudi Arabia. You see the benefits for safety, efficiency, and aligning with Vision 2030. Now comes the important part: choosing the right supplier. All machines are not created equal, and the supplier you partner with is just as important as the equipment itself. A bad choice can lead to a machine that doesn't fit your needs, constant breakdowns, and a lack of support when you need it most. From my experience building SHJLPACK, I've learned that our most successful clients are the ones who look for a long-term partner, not just the cheapest price tag.

When choosing a mold flipper supplier, Saudi buyers should look beyond the initial price and evaluate the supplier's ability to be a strategic partner. Key factors include their engineering capability to customize the machine for specific mold sizes and weights, a strong and responsive after-sales support system with available spare parts, a proven track record with case studies in heavy industry, and clear proof of compliance with international safety certifications like CE and ISO.

You are not just buying a piece of steel; you are investing in a critical part of your production process. You need to be confident that the machine will perform reliably for years to come and that the supplier will be there to support you. Think of it like hiring a key employee. You want someone with the right skills, a good track record, and who is committed to your company's success. Applying this same logic to choosing an equipment supplier will help you make a much better long-term decision. Here are the things I always advise my clients to look for.

Technical Expertise and Customization

Your molds are unique to your products. They have specific dimensions, weights, and centers of gravity. A one-size-fits-all mold flipper is rarely the best solution. A good supplier will start by asking for the details of your molds. They will have engineers who can analyze your needs and recommend or design a machine with the right table size, load capacity, and features. This is where my own background as an engineer becomes so important. I understand the technical details. Can the supplier offer different control options? Can they integrate the machine with your existing workflow? The ability to customize is a clear sign of a knowledgeable and capable supplier. Don't settle for an off-the-shelf solution if it's not a perfect fit for your operation.

After-Sales Support and Spare Parts

What happens a year or five years down the line when a hydraulic hose wears out or a sensor fails? This is one of the most critical questions you can ask. A cheap machine with no support is a future headache. A quality supplier will have a clear after-sales support plan. They should be able to provide you with a list of critical spare parts to keep on hand. They should have technical support available via phone or email to help your maintenance team troubleshoot problems. For a market like Saudi Arabia, ask about their ability to provide on-site support if needed. A supplier who is invested in your uptime will have a robust support system in place.

Proven Track Record and Certifications

Don't be the test case for a new supplier. Ask for references and case studies. A reputable company will be proud to share examples of their work with other clients, especially in heavy industries like steel or automotive. Ask to see their certifications. Is the machine built to recognized international standards like CE (for Europe) or ISO? These certifications are not just pieces of paper; they are independent verification that the machine is designed and built with safety and quality in mind. This is especially important for companies in Saudi Arabia looking to align with global best practices and export their products.

| Criteria | Key Questions to Ask the Supplier | What a Good Answer Looks Like |

|---|---|---|

| Customization | Can you adapt the machine for my specific mold weight and dimensions? | "Yes, let's see your drawings. Our engineers will design the right table size and capacity." |

| After-Sales Support | What is your support process? How quickly can I get spare parts? | "We offer 24/7 technical support and have a recommended spare parts list. We can ship critical parts within 48 hours." |

| Certifications | Is your equipment CE or ISO certified? Can you provide the documentation? | "Absolutely. All our machines are CE certified. We will provide all necessary documentation with the delivery." |

| Industry Experience | Can you share case studies or references from companies in my industry? | "Certainly. We have worked with several steel mills/auto parts makers. Here are some examples of our solutions for them." |

| Price vs. Value | Why is your machine priced this way? What is included? | "Our price includes a robust design, high-quality components, full certification, and comprehensive support. It's an investment in reliability." |

Conclusion

Prioritizing safe mold handling with a flipper is not a cost for Saudi manufacturers. It's a strategic investment in efficiency, compliance, and future growth aligned with Saudi Vision 2030.