Mold Flipper: Which Key Features Deliver Value for Saudi Industrial Projects?

Handling massive, multi-ton molds is one of the most critical and dangerous tasks in any heavy industrial facility. I've seen it myself many times. A small mistake, a moment of imbalance, can lead to disaster. The mold can be damaged, costing hundreds of thousands in repairs and lost production. Worse, people can get hurt. For ambitious industrial projects in Saudi Arabia, where speed and safety are paramount, relying on outdated or inadequate handling methods is a risk you cannot afford. This is where a specialized mold flipper becomes not just a piece of equipment, but a core part of your operational strategy. It’s an investment in safety, efficiency, and the long-term health of your entire production line.

The key features of a mold flipper that deliver real value for Saudi industrial projects are robust construction designed for harsh climates, non-negotiable multi-layered safety systems, deep customisation to match specific operational workflows, and an intelligent, easily integrated control system. Together, these features maximize uptime, protect personnel and assets, and ensure the equipment is a seamless, value-adding part of a modern, efficient factory.

I believe that buying a machine is just the first step. Understanding how it creates value is what truly matters. As an engineer who has built these machines and run a factory, I want to share what I've learned. We will look at each of these key features. I will break them down, show you what to look for, and explain how they directly impact your bottom line. Let’s explore why these details are so crucial for success in demanding environments like those in Saudi Arabia.

How does robust construction ensure long-term reliability in harsh Saudi environments?

Imagine your factory floor. The air is hot, and fine dust seems to get into everything. This is a daily reality for many industrial sites in Saudi Arabia. Now, picture a new piece of equipment failing after just a few years because it wasn't built for these conditions. The downtime, the repair costs, the frustration—it's a scenario every plant owner dreads. You need equipment that is not just strong, but engineered to survive and thrive in your specific environment.

Robust construction ensures long-term reliability in Saudi Arabia by using high-grade steel, heavy-duty components, and superior welding techniques. These elements resist wear from extreme heat and abrasive dust, prevent structural fatigue under continuous heavy loads, and minimize maintenance, guaranteeing consistent performance and a longer operational life.

When I started my journey in this industry, I learned a simple lesson: the quality of the materials and the build defines the life of the machine. It’s not about how it looks on day one, but how it performs on day one thousand. Let's dive deeper into the specific elements of robust construction that make a real difference.

The Foundation: Steel Grade and Thickness

The frame of a mold flipper is its skeleton. If the skeleton is weak, the entire machine is compromised. We typically use high-tensile steel, like Q345, instead of standard Q235 steel for the main structural parts. Q345 steel has a higher yield strength. This means it can handle greater stress before it deforms. For a machine that will be flipping molds weighing 50, 100, or even 200 tons, this is not a small detail. It's the difference between a machine that lasts for decades and one that develops structural issues. We also insist on using thicker steel plates than what might be considered "standard." A thicker plate provides more rigidity and resistance to bending. This stability is critical during the tilting motion, ensuring the movement is smooth and controlled, which protects both the mold and the machine itself. For a plant manager in Saudi Arabia, this means fewer worries about equipment failure and more predictable production schedules.

Critical Components: Motors, Bearings, and Hydraulics

A strong frame is just the start. The components that create movement are just as important. In a hot climate, electric motors can overheat easily. That's why we often specify motors with a higher service factor or a better insulation class. This allows them to run cooler and more reliably, even when the ambient temperature in the factory is high. The same logic applies to bearings and hydraulic systems. We use oversized, sealed bearings from reputable brands like SKF or FAG. These are designed to keep dust out and operate smoothly under heavy loads for years. The hydraulic system, which provides the immense force needed to tilt the mold, must be protected from heat. We use high-quality hydraulic oil and seals that are rated for higher temperatures. This prevents leaks and loss of performance, which are common failure points in lesser machines.

The Unsung Hero: Welding and Surface Treatment

You can have the best steel and components, but if they are not joined together properly, the machine will fail. The quality of the welding is paramount. We employ certified welders and use inspection methods like ultrasonic testing to ensure every weld is free of defects. After assembly, the surface treatment provides the final layer of protection. In a dusty, and sometimes coastal, Saudi environment, corrosion is a real threat. Our process involves sandblasting the entire structure to create a clean, rough surface. This helps the paint adhere properly. Then, we apply a thick layer of zinc-rich epoxy primer, followed by a durable polyurethane topcoat. This multi-layer system creates a tough barrier that resists abrasion from sand and dust, and prevents corrosion from humidity. It keeps the machine looking and performing its best for a very long time.

| Feature | Standard Construction | Robust SHJLPACK Construction | Value for Saudi Projects |

|---|---|---|---|

| Steel Grade | Q235 Carbon Steel | Q345 High-Tensile Steel | Higher strength, resists deformation under heavy loads. |

| Component Sizing | Standard duty | Oversized motors, bearings, hydraulic pumps | Better heat dissipation, longer life, lower failure rate. |

| Welding | Basic visual inspection | Certified welders, NDT inspection (e.g., UT) | Ensures structural integrity, prevents cracks and failures. |

| Surface Coat | Single layer of paint | Sandblasting, epoxy primer, polyurethane topcoat | Superior resistance to dust abrasion and corrosion. |

What safety features are non-negotiable for a mold flipper in modern industrial settings?

I remember a conversation with a plant manager who witnessed a chain sling snap while lifting a large die. The die crashed to the floor, narrowly missing several workers. The plant was shut down for a week. The financial cost was huge, but the impact on team morale was even worse. When you are moving an object that weighs as much as a house, you cannot leave safety to chance. A single failure can have devastating consequences for your people and your business.

Non-negotiable safety features for a mold flipper include a combination of mechanical locks, hydraulic safety valves, electronic interlocks with light curtains or area scanners, and a clear, audible alarm system. These features work together as a layered defense system to prevent accidental movement, protect operators from entering dangerous areas, and ensure the machine fails in a safe state if any problem occurs.

Building a safe machine is a moral obligation for an engineer. It's the most important part of my job. A modern mold flipper must have multiple, redundant safety systems. One system might fail, but it's extremely unlikely that three or four will fail at the same time. Let's look at what these essential layers of protection are.

Mechanical and Hydraulic Safeguards

These are the physical systems that provide the first line of defense. Think of them as the machine's muscle. For example, some designs include heavy-duty mechanical locking pins. These pins can be engaged to physically block the machine from moving, which is essential when operators need to perform maintenance on the mold. They provide a positive lock that doesn't rely on hydraulic or electric power. In the hydraulic system itself, we always install pilot-operated check valves on the cylinders. If a hydraulic hose were to burst—a rare but possible event—these valves would instantly lock the cylinder in place, preventing the platform from crashing down. This is a simple, purely mechanical safety feature that can prevent a catastrophe. These systems are robust, reliable, and provide peace of mind that even in the event of a power loss or component failure, the load will remain secure.

Electronic and Sensor-Based Protection

This is the machine's brain and eyes. We use modern sensor technology to create an intelligent safety perimeter. A common feature is a light curtain. This projects an invisible barrier of infrared beams around the hazardous area. If an operator's hand or body breaks any of these beams while the machine is in motion, the system instantly stops. It’s much more effective than just a physical guardrail. For larger areas, we can use laser area scanners that map out a "danger zone" on the floor. Anyone stepping into this zone will trigger an immediate halt. We also use limit switches to control the machine's range of motion. These switches prevent the flipper from tilting too far, which could cause instability. These electronic systems work with the machine’s PLC to create a smart, responsive safety environment that protects people without hindering the workflow.

Operator-Focused Safety

Ultimately, the machine is controlled by a person. So, the interface must be designed for safety. We place large, red Emergency Stop (E-Stop) buttons in easily accessible locations on the control panel and sometimes on the machine itself. Hitting this button kills all power to the motors and hydraulics. For the main operation, we often use a "hold-to-run" control system. This means the operator must keep the button pressed for the machine to move. If they let go for any reason, the machine stops. This prevents accidental activation. We also include a loud buzzer and a flashing beacon light that activate a few seconds before the machine starts to move. This simple audio-visual warning alerts everyone in the area that the flipper is about to operate, giving them time to move to a safe distance.

| Safety Layer | Feature | Function | Why It's Non-Negotiable |

|---|---|---|---|

| Mechanical | Mechanical Locking Pins | Physically blocks movement for maintenance. | Provides a positive, fail-safe lock independent of power. |

| Hydraulic | Pilot-Operated Check Valves | Prevents platform from falling if a hydraulic hose fails. | Averts catastrophic load drops due to pressure loss. |

| Electronic | Light Curtains / Area Scanners | Creates an invisible safety barrier; stops machine if breached. | Protects operators from entering the motion zone during use. |

| Operator Interface | E-Stops and Hold-to-Run Controls | Provides immediate shutdown and prevents accidental activation. | Gives the operator direct control over stopping the machine. |

Can customisation options truly enhance a mold flipper's operational efficiency?

I once visited a client who had bought a standard mold flipper from another supplier. It was a good machine, but it wasn't right for them. Their molds were an unusual shape, so loading them onto the standard-sized table was awkward and slow. They had to use extra rigging and two workers to guide it into place. The machine was supposed to save time, but it was actually creating a new bottleneck in their production line. This is a perfect example of why a one-size-fits-all approach doesn't work for specialized industrial equipment.

Yes, customisation options significantly enhance a mold flipper's operational efficiency. By tailoring the table size, load capacity, tilting angle, and integration features like conveyor systems, the machine fits perfectly into a specific production workflow. This directly reduces material handling time, minimizes manual labor, eliminates wasted motion, and boosts overall factory throughput.

A machine should adapt to your process, not the other way around. My philosophy has always been to start with the customer's problem. What is your mold size? How do you move it? Where does it need to go next? The answers to these questions define the machine. Let's look at how specific customisations can deliver a huge return on investment.

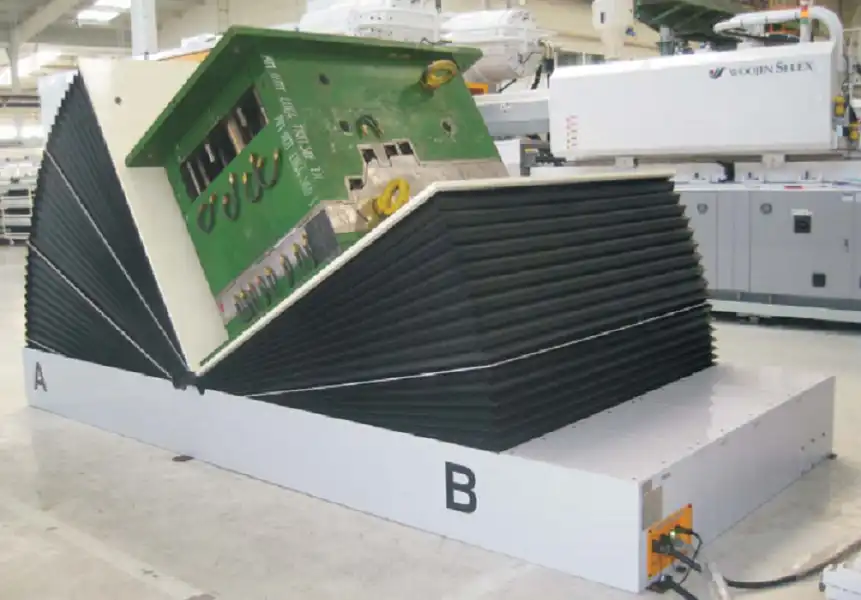

Tailoring the Physical Dimensions and Capacity

This is the most fundamental level of customisation. The working table of the flipper must match the footprint of your molds. If the table is too small, the mold is unstable. If it's too large, it wastes valuable floor space and can be difficult to access. We design the table dimensions specifically for the client's range of molds. We can even add custom fixtures or V-blocks to securely hold cylindrical objects or irregularly shaped tools. The load capacity is another critical factor. We don't just offer a few standard capacities. We calculate the required capacity based on your heaviest mold plus a generous safety margin. We can also customize the tilting angle. While 90 degrees is standard, some processes, like die-splitting, may require a full 180-degree rotation. Getting these basic physical parameters right is the first step to creating a truly efficient machine.

Integrating with Your Workflow

A standalone machine can still create islands of inefficiency. True efficiency comes from flow. We can integrate the mold flipper directly into your production line. For example, we can equip the flipper’s table with powered chain or roller conveyors. This allows a mold to be moved onto the flipper automatically from a mold transport cart. After being flipped, it can then be conveyed automatically to the next station, such as a maintenance area or a coordinate measuring machine (CMM). This level of integration drastically reduces the need for overhead cranes and forklifts to handle the mold at this stage. It cuts down on handling time, reduces the risk of damage, and frees up your crane for other critical tasks. For a large-scale Saudi project aiming for high efficiency, this seamless integration is a game-changer.

Adapting for Special Requirements

Every factory has unique needs. We can add features to solve specific problems. For example, we can integrate a hydraulic lifting function, turning the mold flipper into a combination flipper-lift table. This allows you to flip the mold and also adjust its height for ergonomic access during maintenance. For facilities with very heavy molds, we can design the flipper to be installed in a pit, so the working table is flush with the factory floor. This makes loading and unloading much easier and safer. We can even add features like integrated weighing scales or special electrical connections for mold heaters. By listening to your challenges, we can build a multi-functional machine that solves several problems at once, delivering far more value than a standard piece of equipment.

| Customisation Area | Standard Flipper | Customised SHJLPACK Flipper | Efficiency Gain |

|---|---|---|---|

| Table Size | Fixed, generic dimensions | Sized precisely for the client's molds | Faster, safer loading; optimal use of floor space. |

| Workflow | Standalone operation | Integrated conveyors, connects to carts/other stations | Eliminates crane use, reduces handling time, automates flow. |

| Functionality | Tilting only | Can include lifting, pit installation, custom fixtures | Solves multiple problems with one machine, improves ergonomics. |

| Capacity | A few standard options (e.g., 10T, 20T) | Engineered specifically for the required load + safety factor | Ensures safety and longevity without over-engineering. |

How does the control system impact the integration and ease of use in a Saudi factory?

A powerful machine with a bad control system is like a genius who can't communicate. The potential is there, but you can't access it. I've seen operators struggle with confusing controls, leading to slow performance and mistakes. I've also seen maintenance teams spend days trying to connect a new machine to the factory's central network because it used an obscure control platform. In a modern industrial project, especially in a forward-looking region like Saudi Arabia, the control system is not an afterthought. It is the heart of the machine's intelligence and its ability to work as part of a larger, connected system.

The control system is critical because it defines the machine's usability for operators and its compatibility with the factory's digital ecosystem. A system with a well-designed HMI, a reputable PLC like Siemens or Allen-Bradley, and modern communication protocols allows for simple operation, seamless integration with MES/SCADA systems, and powerful remote diagnostics, which are essential for a smart factory.

When we design a machine, we think about two users: the operator who uses it every day, and the engineer who needs it to communicate with the rest of the plant. A great control system serves both of them perfectly.

The Operator's Experience: HMI and Controls

The day-to-day user interacts with the machine through the Human-Machine Interface (HMI). A simple box with buttons and lights is no longer good enough. We use modern, color touch-screen HMIs. This allows us to create a graphical, intuitive interface. We can show a picture of the machine and its current status. We can provide step-by-step instructions for different operations. We can display alarms in clear text, not confusing codes. For a project in Saudi Arabia, we can easily program the HMI to operate in both English and Arabic. This reduces the learning curve for operators, minimizes the chance of errors, and makes the machine much faster and more pleasant to use. The result is higher productivity and a safer work environment.

The Engineer's Perspective: PLC and Connectivity

The brain of the control system is the Programmable Logic Controller (PLC). The choice of PLC brand is very important for integration. We build our systems using globally recognized and supported platforms like Siemens, Allen-Bradley (Rockwell), or Schneider Electric. Why? Because most modern factories have standardized on one of these brands. Using the same brand means the client's in-house maintenance team is already familiar with the programming software and hardware. It also makes communication simple. We can easily connect the mold flipper to the plant's Manufacturing Execution System (MES) or SCADA system using standard industrial protocols like PROFINET or EtherNet/IP. This allows the central system to monitor the flipper's status, track its usage, and collect data for performance analysis. This is a fundamental requirement for any factory pursuing digital transformation or Industry 4.0 initiatives.

Future-Proofing with Remote Access

One of the most valuable features a modern control system can offer is remote access. We can install a secure industrial VPN router in the control panel. This allows our engineers, with the client's permission, to remotely log into the machine's PLC and HMI from our office. If there is a problem, we can diagnose it in minutes instead of days. We can help the local maintenance team troubleshoot the issue over the phone or video call. For a facility in Saudi Arabia, this is incredibly valuable. It can mean the difference between a few hours of downtime and waiting several days for a service engineer to travel to the site. This feature turns a supplier into a true partner, providing instant support to keep your production running.

| Control System Aspect | Basic System | Advanced SHJLPACK System | Impact on Integration and Use |

|---|---|---|---|

| Operator Interface | Push buttons and indicator lights | Color touch-screen HMI with graphics and multiple languages | Intuitive, easy to learn, reduces operator error, faster operation. |

| PLC | Obscure or proprietary brand | Siemens, Allen-Bradley, or other major global brand | Easy for local teams to maintain, simplifies spare parts management. |

| Connectivity | Hardwired signals only | Industrial Ethernet (PROFINET, EtherNet/IP) | Seamless integration with factory MES/SCADA for data collection. |

| Support | On-site service only | Secure remote access for diagnostics and support | Drastically reduces downtime, provides instant expert support. |

My Insights

When I first started my career as an engineer on a factory floor, I saw firsthand how a single piece of equipment could define the rhythm of an entire production line. A good machine makes everything run smoothly. A bad one causes constant headaches and drains resources. Later, when I built my own factory, I learned the other side of the story. I felt the pressure of making large capital investments. I understood that every dollar had to deliver a return.

These experiences taught me that for a business owner or a plant manager like Javier Morales, buying a machine like a mold flipper is not just a technical decision. It's a strategic one. For a major industrial project in Saudi Arabia, with its ambitious goals for growth and efficiency, this is even more true.

You aren't just buying steel and hydraulic parts. You are investing in operational continuity. The real value isn't in the machine itself, but in the problems it solves and the goals it helps you achieve.

- A robustly constructed machine solves the problem of premature failure in a harsh climate, helping you achieve your goal of stable production.

- A machine with non-negotiable safety features solves the problem of workplace hazards, protecting your people and your business.

- A customised machine solves the problem of inefficiency, helping you reduce costs and maximize throughput.

- An intelligent control system solves the problem of integration, helping you achieve your goal of building a smart, data-driven factory.

My mission with SHJLPACK is built on this understanding. It's not just to sell equipment. It's to be a partner who shares knowledge and provides a total solution. It’s about listening to your unique challenges—whether it's fluctuating energy costs or the need to digitize your operations—and engineering a machine that directly addresses those challenges. The best mold flipper for a Saudi industrial project is one that is built not just with steel, but with a deep understanding of your business.

Conclusion

Choosing a mold flipper with robust construction, top-tier safety, deep customisation, and a smart control system is a strategic investment in the long-term productivity and safety of your project.