Mold Flipper: What Maintenance Basics Keep Uptime High in Indonesia?

Your production line is humming along smoothly. Suddenly, a crucial mold flipper grinds to a halt. The entire workflow stops. Deadlines are now at risk, and the costs of unplanned downtime start piling up with every passing minute. This isn't just a small problem. In the competitive steel and manufacturing sectors of Indonesia, or anywhere else for that matter, every second of downtime erodes your hard-earned profit margins. It can feel like you're constantly fighting fires instead of focusing on growing your business. I've heard this story from countless plant managers and owners over the years. But what if I told you that a few simple, consistent maintenance basics could virtually eliminate these unexpected shutdowns? It’s not about spending more money; it’s about being smarter and more strategic with your maintenance.

To keep mold flipper uptime high, especially in demanding environments like those in Indonesia, you must implement a strict regimen of daily visual checks, scheduled lubrication, regular hydraulic and electrical system inspections, and comprehensive operator training. These four pillars form the unbreakable foundation of reliable, long-term performance.

This might sound simple, almost too simple. But I can tell you from my journey, from engineer to factory owner, that the devil is always in the details. I have personally seen factories with brand-new, top-of-the-line equipment fail because they neglected these fundamental basics. A machine is only as reliable as the care it receives. Let's break down each of these pillars one by one. I will share what I've learned from my years on the factory floor and in the design office to help you build a maintenance plan that actually works and protects your investment.

How can a routine inspection schedule prevent unexpected breakdowns?

You trust your maintenance team. You believe they have everything under control. Then, out of nowhere, a critical bolt shears off, or a hairline crack in the frame goes unnoticed until it becomes a catastrophic failure. The line stops, and the blame game begins. The truth is, an "unexpected" failure is rarely a surprise. It's almost always the result of small, overlooked issues that have been allowed to snowball into a major problem. This reactive approach, where you only fix things when they break, is incredibly expensive. It costs you in emergency repair fees, overnight shipping for parts, and, most significantly, in lost production hours. A structured, routine inspection schedule is your best early warning system. It transforms maintenance from a reactive firefight into a proactive strategy, allowing you to catch problems when they are small, simple, and cheap to fix.

A routine inspection schedule prevents breakdowns by creating a disciplined system for early detection. Daily checks by operators and more thorough weekly or monthly checks by the maintenance team are designed to identify wear, leaks, loose components, and other potential issues before they can cause a catastrophic failure, ensuring your equipment runs continuously.

The Two Tiers of Inspection

Not all inspections are created equal. To be effective, you need a two-tiered approach. I’ve implemented this in my own factory and for clients across Asia with great success. It’s about creating layers of defense against downtime.

-

Tier 1: The Operator's Daily Check (The 5-Minute Pre-Flight)

This is the first line of defense. The person who uses the machine every day is in the best position to notice small changes. This check should be mandatory before every shift begins. It’s not technical. It’s about using one's senses. The operator should visually check for any hydraulic fluid drips on the floor, look for loose guards or bolts, and listen for any new or unusual noises during the first cycle. It takes less than five minutes, but it can prevent 80% of common issues. -

Tier 2: The Technician's Weekly/Monthly Check (The Deeper Dive)

This is a more formal, documented inspection done by your maintenance staff. They use tools and follow a detailed checklist. This is where you look for issues that an operator might not spot. This includes checking the torque on critical bolts, inspecting welds for any signs of stress or cracking, and checking the tension and condition of drive chains or belts. This scheduled check finds problems that develop slowly over time.

Building a Practical Checklist

A vague instruction like "check the machine" is useless. Your checklist needs to be specific and actionable. I always recommend using a simple table format that can be printed and placed in a binder near the machine or digitized for your MES system.

| Component | Check Point | Frequency | Status (OK/Action) | Technician/Date |

|---|---|---|---|---|

| Structure | Inspect frame welds for cracks | Monthly | ||

| Check all structural bolts for tightness | Weekly | |||

| Hydraulics | Check oil level in reservoir | Daily | ||

| Inspect hoses and fittings for leaks/wear | Weekly | |||

| Electrical | Ensure E-stop buttons function correctly | Daily | ||

| Check limit switch alignment and cleanliness | Weekly | |||

| Mechanical | Listen for unusual noise from bearings/motor | Daily | ||

| Check lubrication points (see lube chart) | Weekly |

One important factor for my clients in Indonesia is the climate. The high humidity can accelerate corrosion and wreak havoc on electrical components. Your checklist must account for this. Specifically instruct technicians to look for early signs of rust on the frame and to ensure all electrical cabinets have tight seals to keep moisture out. These small, region-specific details make a huge difference.

What role do hydraulic and electrical systems play in mold flipper reliability?

Your mold flipper starts to stutter during its tilting motion. Or perhaps it feels weak, struggling to lift a load it handled easily just a few months ago. Maybe its movements are jerky and unpredictable. It's easy to blame the machine's age or brand. But often, the real culprit is a neglected hydraulic or electrical system. Think of these systems as the machine's muscles and nerves. The hydraulic system provides the brute force, while the electrical system provides the intelligent control. If either one is unhealthy, the entire machine's performance will suffer, no matter how strong its steel frame is. You can restore your machine's power and ensure smooth, predictable, and safe performance by focusing on the health of your hydraulic fluid, filters, and electrical connections.

The hydraulic system provides the raw power for tilting and lifting, while the electrical system controls the precision, speed, and safety interlocks of those movements. Therefore, maintaining clean, high-quality hydraulic fluid and secure, clean electrical connections is absolutely critical for preventing sluggish performance, erratic behavior, and sudden, costly failures.

Hydraulic System Health 101

The hydraulic system is the heart of your mold flipper's power. Treating it well is non-negotiable. I’ve seen expensive hydraulic pumps destroyed by simple neglect. Here’s where to focus:

- Fluid is its Lifeblood: Hydraulic oil does more than just transmit force. It also lubricates components and helps dissipate heat. The level is important, but the quality is even more so. Contaminated oil—whether with water from humidity or fine metal particles from internal wear—is like poison. It acts as an abrasive, grinding down the tight tolerances inside your pumps and valves, leading to pressure loss and eventual failure. Implement a regular oil analysis program. It’s cheap and tells you exactly what’s happening inside your system.

- Filters are the Kidneys: Clogged filters are a common cause of sluggish performance. When a filter is clogged, it starves the pump of oil, a condition called cavitation, which is incredibly destructive. Don't just wait for the clog indicator. Follow the manufacturer's replacement schedule for filters. In a dusty environment like a steel mill, I often advise clients to cut that replacement interval in half. It’s a cheap preventative measure.

- Inspect Hoses and Fittings: A burst hydraulic hose is a production stopper and a serious safety hazard. High-pressure oil can inject itself into the skin, causing severe injury. On a weekly basis, have your team visually inspect all hoses for signs of cracking, blistering, or rubbing. Pay close attention to the crimped fittings, as this is where failures often begin.

Electrical System Integrity

If the hydraulics are the muscles, the electrical system is the brain and nervous system. Its failure often leads to problems that are difficult to diagnose.

- Vibration is the Enemy of Connections: Your factory floor is full of vibration. Over time, this constant shaking can loosen terminal screw connections inside the main control cabinet and on components like motors and solenoids. A loose connection can cause intermittent faults—the machine works one minute and stops the next. This can drive your maintenance team crazy. A simple monthly task of opening the panel (with power off!) and checking critical connections with a screwdriver can prevent these phantom problems.

- Sensors and Switches are the Eyes: The limit switches and proximity sensors tell the machine’s control system where it is in its cycle. If a sensor is dirty, covered in grime or oil, or has been knocked out of alignment, the machine may fail to stop at the correct position or may not start a cycle at all. Make "clean and check all sensors" a part of your weekly checklist. It’s a simple task that prevents complex problems.

Why is proper lubrication the most direct way to impact mold flipper longevity?

You start to hear it. A faint grinding noise at first, then a loud screech as the mold flipper begins its tilt. You notice that pivot pins and bearings are wearing out much faster than the manual says they should. Your budget for spare mechanical parts is climbing higher and higher each year. What you're experiencing is the sound and cost of your multi-thousand-dollar investment slowly grinding itself into dust. Every metallic squeal is the sound of money being wasted and the machine's operational lifespan getting shorter. I've seen it happen time and again. The solution is remarkably simple and cost-effective: a consistent, correct lubrication schedule is the best and cheapest insurance policy for your machine's mechanical health. It is the number one secret to making heavy industrial equipment last not just for years, but for decades.

Proper lubrication directly impacts longevity by creating a microscopic, high-pressure protective film between moving metal-on-metal surfaces. This crucial film drastically reduces friction, which in turn minimizes abrasive wear, lowers operating temperatures, prevents corrosion, and stops the seizure of critical components like bearings, bushings, and pivot pins.

More Than Just Squirting Grease

Effective lubrication is a science, not just a task. I've seen well-meaning maintenance staff cause damage by getting the details wrong.

- The Right Lubricant for the Right Job: All grease is not the same. Using a general-purpose grease on a high-temperature bearing near a motor is a recipe for failure. The grease will break down, liquefy, and run out, leaving the bearing unprotected. The machine's manual is your bible here. It will specify the exact type of lubricant needed for each point, often with a specific viscosity (for oil) or NLGI grade (for grease). Factors like temperature, load, speed, and exposure to water (a big issue in humid climates like Indonesia's) determine the correct choice.

- The Right Amount at the Right Time: More is not better. Over-lubricating a bearing can blow out its seals. The excess grease then becomes a magnet for dust and dirt, creating a grinding paste that accelerates wear. Too little grease, obviously, provides no protection. Your team needs to be trained on the correct amount for each point. For a sealed bearing, it might be just a few pumps from a grease gun until you see a tiny bit of old grease purged.

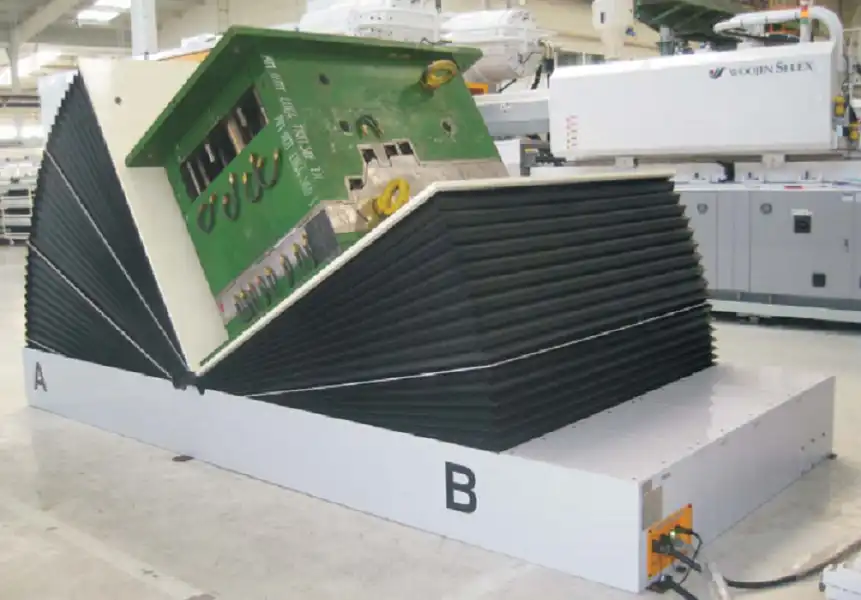

The Lubrication Map: A Visual Guide to Success

One of the most effective tools I've implemented with my clients is a "lubrication map." This is a simple diagram or a photograph of the machine with all lubrication points clearly marked.

| Lube Point ID | Location Description | Lubricant Type | Frequency | Notes |

|---|---|---|---|---|

| A1 | Main Drive-Side Pivot Pin | High-Load EP2 Grease | Weekly | 3 pumps from grease gun |

| A2 | Main Idle-Side Pivot Pin | High-Load EP2 Grease | Weekly | 3 pumps from grease gun |

| B1 | Hydraulic Cylinder Clevis | Moly EP Grease | Monthly | Clean fitting before applying |

| C1 | Drive Chain | Chain Lubricant Spray | Weekly | Apply while chain is moving slowly |

You can even use color-coded stickers on the machine itself that correspond to the chart and the type of grease gun to use. This makes the process fast, simple, and nearly impossible to get wrong. It takes the guesswork out of the equation and ensures consistency, even if you have staff turnover. This simple system directly fights equipment aging, one of your key challenges.

Why is operator training the most overlooked aspect of maintenance?

Your expensive mold flipper is being misused. You see operators slamming it into position, using it to nudge heavy objects, ignoring warning lights, or attempting to lift loads that are clearly over its specified capacity. The machine breaks down again, and you blame the equipment. But the real problem is that you have a powerful tool in the hands of an untrained user. This kind of abuse leads directly to premature wear, frequent failures, and, most importantly, serious safety risks. You can buy the best machine in the world and hire a fantastic maintenance team, but a single untrained or careless operator can destroy all that value in one shift. The solution is to invest in thorough, continuous operator training. This simple act transforms your machine users from "button pushers" into the first and most important line of defense for your equipment.

Operator training is often overlooked because it is viewed as a time-consuming cost rather than a profit-driving investment. However, properly trained operators prevent the vast majority of breakdowns by using the machine correctly, performing vital daily checks, and accurately reporting abnormalities immediately, making them the most crucial and cost-effective part of any proactive maintenance strategy.

From Button Pusher to Machine Guardian

The entire goal of operator training is to shift their mindset. They are not just running a machine; they are the guardians of a valuable company asset that is critical to their job and the company's success. This is a culture shift.

To achieve this, training must go beyond just showing them the "start" and "stop" buttons. I always insist that training includes a basic overview of how the machine works. They don't need to be engineers, but explaining what the hydraulic pump does, why the limit switches are important, and what happens when you overload the machine gives them a newfound respect for the equipment. When an operator understands that slamming the controls sends a damaging shockwave through the hydraulic system, they are far less likely to do it.

What Effective Training Must Cover

A comprehensive training program isn't a one-time lecture. It's an ongoing process. Here are the core components:

- Correct & Safe Operation: This is the foundation. It includes the proper startup and shutdown sequence, how to use the controls smoothly, and a deep understanding of the machine's load capacity and center of gravity. I’ve seen accidents happen because an operator didn’t understand how the load's balance affects the flipper's stability.

- The Daily Pre-Flight Check: As discussed earlier, the operator must be trained to perform the 5-minute daily inspection. They need a simple checklist and must know what they are looking and listening for.

- Emergency Procedures: What should they do if the machine behaves erratically? Who do they call? Where are all the emergency stop buttons? Seconds matter in an emergency, and training builds the muscle memory to react correctly.

- Effective Reporting: This is a huge, often-missed detail. An operator needs to know how to report a problem accurately. "It's making a funny noise" is not a helpful report. "There's a high-pitched whine coming from the main hydraulic pump, and it gets louder when I tilt a heavy mold" is an incredibly valuable report that allows a technician to diagnose the problem in minutes, not hours.

When I ran my factory, I made this training and the daily sign-off sheet mandatory. It created a culture of accountability and ownership that dramatically reduced our downtime and repair costs. It helps you achieve your goal of 95% uptime more than almost any other single activity.

My Insights: A Message to Fellow Factory Owners

I've laid out the technical basics for maintaining a mold flipper. The checklists, the schedules, the lubrication charts—these are the "what" and the "how." But now, I want to talk directly to you, the owner, the CEO, the person like Javier Morales who carries the weight of the entire operation on your shoulders. I want to talk about the "why." I’ve been in your shoes. I started as an engineer on the floor, and I built my own factory. I know the pressure of meeting payroll, the sting of rising energy costs, and the constant challenge of aging equipment.

The ultimate secret to achieving high uptime and lowering your operating costs isn't found on a checklist; it's forged in a culture of ownership. When your maintenance team and your machine operators feel like true partners in the success and health of the equipment, proactive care becomes second nature. This transforms your maintenance budget from a recurring expense into a powerful, profit-driving investment.

I see you have a challenge with aging equipment. Many people see an old machine and think only of the replacement cost. I look at a 15-year-old machine that is still running well, and I see a testament to excellent maintenance. The goal isn't always to buy new; it's to maximize the life and value of the assets you already own. This philosophy saved me crucial capital in my early days as a factory owner, allowing me to invest in growth instead of just replacement. Every ringgit or dollar you save on an emergency repair is a dollar that goes straight to your bottom line. It's a dollar you can reinvest to achieve your strategic goals, like implementing a new MES system or other digital transformation projects.

This brings me to my final point, and it’s the reason I started SHJLPACK. You are looking for more than a supplier; you are looking for a strategic partner. This is the key. When you are looking to purchase your next wrapping machine or handling system, don't just ask about the price tag. Ask the hard questions. Ask to see their recommended maintenance schedule. Ask for their critical spare parts list. Ask them what kind of training they provide for operators and technicians. Ask them how they support their machines that are 10 or 15 years old.

Their answers will tell you everything you need to know. They will tell you if you are talking to a simple vendor who just wants to make a sale, or a true partner who is invested in your long-term success. A partner understands that their success is tied to your ability to run their machine profitably for years to come. This is the core of my mission. I achieved my success because of the knowledge I gained in this industry. Now, at SHJLPACK, we are dedicated to sharing that knowledge to help you succeed.

Conclusion

Consistent maintenance is not a cost center. It is your best strategy for ensuring high uptime, extending equipment life, and protecting your bottom line in a competitive industrial world.