Mold Flipper: What Benefits Matter Most to Malaysian Manufacturers in 2025?

Handling large, heavy molds is a daily reality in many Malaysian manufacturing plants. You might be using an overhead crane and chains, the same way it's been done for decades. But you also know the feeling in your gut every time that massive piece of steel swings in the air. You worry about the safety of your people, the risk of damaging a mold worth thousands of ringgits, and the production delays that a single mistake can cause. This old method is a weak link in your production chain, exposing you to unnecessary risks and inefficiencies that you simply can't afford in today's competitive market.

The most crucial benefits of a mold flipper for Malaysian manufacturers in 2025 are drastically improved workplace safety, a clear and calculable return on investment (ROI) through reduced operational costs, and the ability to perform faster, more effective maintenance on valuable molds. These factors directly lead to higher production uptime and a more stable, predictable manufacturing environment.

As an engineer who has spent his entire career on factory floors, I've seen how a single piece of equipment can change everything. The conversation about a mold flipper isn't just about a new machine. It's about a new way of thinking about your workflow. It's about moving from a position of risk to a position of control. Let's dig deeper into the specific benefits that will give you a competitive edge in Malaysia's evolving industrial landscape. We'll look at safety, ROI, and maintenance to see why this investment makes perfect sense for 2025 and beyond.

How can a mold flipper directly improve operational safety and reduce liability?

You've probably seen it happen. A team gathers around a heavy mold, hooking it up to an overhead crane. Chains are adjusted, people shout instructions, and everyone holds their breath as the mold is slowly, carefully lifted and turned. It’s a moment of high tension. One slip, one snapped chain, or one moment of misjudgment, and the result could be a severe injury or a destroyed mold. This constant, underlying risk creates stress for your operators and a significant potential liability for your company. What if you could eliminate that moment of tension entirely?

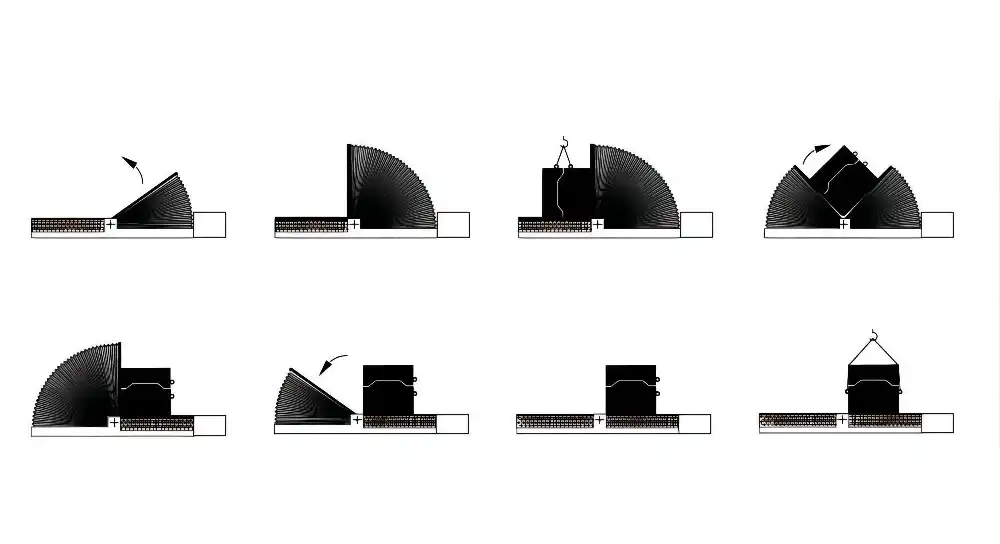

A mold flipper improves safety by creating a controlled, predictable, and stable process for turning heavy molds. This drastically reduces the risk of accidents, worker injuries, and costly damages compared to traditional crane methods. It transforms a dangerous manual task into a simple, automated machine operation.

The Dangers of Traditional Methods

Let's be honest about the risks of using a crane and chains. The center of gravity shifts as the mold turns. The load can swing unexpectedly. Chains are subject to wear and tear that might not be visible to the naked eye. The entire operation relies heavily on the skill and communication of the crane operator and the ground crew. This introduces a huge variable: human error. Even with the best team, fatigue or a momentary distraction can lead to disaster. I’ve personally visited factories where a dropped mold not only cost them the tool itself but also damaged the factory floor and put the entire production line out of commission for days. The potential for accidents is always present with this method.

How a Mold Flipper Creates a Safe Zone

A mold flipper, or mold upender, fundamentally changes the physics of the operation. The mold is placed securely on a stable platform. It is then rotated by a powerful and reliable hydraulic or mechanical system. The entire process happens within a defined, predictable path of motion. There are no swinging loads. There are no chains under immense, shifting tension. The operator is typically standing at a control panel, a safe distance away from the machine. The task is reduced to pushing a button. This level of control removes the guesswork and the danger. It creates a 'safe zone' around what was once one of the most hazardous tasks in the workshop.

The Financial Impact of Safety

Improved safety isn't just about peace of mind; it has a direct financial benefit. Fewer accidents mean fewer worker compensation claims, which can lead to lower insurance premiums. You avoid the massive costs associated with production downtime, emergency repairs, and replacing a damaged mold, which can run into tens or even hundreds of thousands of ringgits. Furthermore, in Malaysia, as in many countries, workplace safety regulations are becoming stricter. Demonstrating a commitment to safety with modern equipment like a mold flipper can protect you from fines and legal liabilities. A safer workplace also improves employee morale and makes your company a more attractive place to work.

| Feature | Crane & Chain Method | Mold Flipper Method |

|---|---|---|

| Control Level | Low (relies on operator skill) | High (machine-controlled) |

| Primary Risk | Dropped/swinging load, chain failure | Machine malfunction (low probability) |

| Worker Position | Close proximity to suspended load | At a safe distance (control panel) |

| Potential for Injury | High (crushing, impact) | Very Low |

| Potential for Damage | High (mold, floor, other equipment) | Very Low |

What is the real ROI of a mold flipper beyond just speed?

When you look at the price of a mold flipper, it's easy to see it as a major capital expense. Your mind immediately goes to the budget. You might think, "My crane works just fine. Why should I spend this money?" This is a common reaction. But focusing only on the initial cost ignores the significant, ongoing expenses of your current method. The true financial picture isn't about what a mold flipper costs; it's about what it saves you every single day. The real ROI is found in the problems you no longer have.

The real ROI of a mold flipper comes from a combination of direct and indirect savings. These include significantly reduced labor costs, prevention of damage to expensive molds, minimized production downtime, and improved overall workflow efficiency. It’s an investment that pays for itself by eliminating hidden and unpredictable expenses.

Calculating the Tangible Returns

Let's break down the real numbers. First, consider labor. Flipping a mold with a crane often requires two or three people: a skilled crane operator and one or two riggers on the floor. The process can take anywhere from 15 to 30 minutes, sometimes longer. A mold flipper reduces this to one operator, and the entire cycle takes less than five minutes. Calculate the hourly wages of those employees and the time saved per flip, then multiply that by the number of flips per year. The savings add up quickly.

Second, think about the cost of your molds. For industries like automotive or electronics manufacturing in Malaysia, a complex mold is a huge investment. What is the cost if one is damaged or destroyed? A single accident can wipe out the profits of many production runs. A mold flipper nearly eliminates this risk. This isn't a saving you see every day, but it's a catastrophic cost you are preventing.

Third, consider downtime. When a mold needs maintenance or changing, production stops. The longer the changeover takes, the more money you lose. By cutting the mold flipping time from 30 minutes to 5 minutes, you gain 25 minutes of valuable production time. This increased uptime goes directly to your bottom line.

The Intangible, Yet Powerful, Gains

Beyond the hard numbers, there are other returns that are just as important. When your workers don't have to perform a dangerous task, morale improves. They can focus on quality and productivity instead of worrying about safety. The process becomes simple and repeatable, which makes training new employees much easier. Your entire operation becomes more predictable. You can schedule maintenance and changeovers with confidence, knowing exactly how long they will take. This predictability is the foundation of a lean and efficient manufacturing system. It also enhances your reputation. A clean, safe, modern facility is more impressive to potential clients and partners.

A Malaysian Context: Labor and Competition

In Malaysia, the manufacturing sector is highly competitive, and skilled labor costs are rising. Relying on labor-intensive, high-skill processes for simple tasks like flipping a mold is no longer a sustainable strategy. Automation isn't a luxury; it's a necessity to stay competitive. By investing in a mold flipper, you are reducing your dependence on specialized labor for this task, lowering your operational costs, and positioning your company as a modern, efficient leader in the Malaysian market.

| Cost Category | Crane & Chain Method (Annual Cost) | Mold Flipper Method (Annual Cost) | Annual Savings |

|---|---|---|---|

| Labor | 2-3 staff x 20 min/flip x 200 flips/yr | 1 staff x 5 min/flip x 200 flips/yr | Significant |

| Mold Damage Risk | 1% chance of RM 100,000 mold damage | <0.1% chance of damage | RM 990 (risk reduction value) |

| Downtime | 25 extra min/flip x 200 flips/yr | 0 | 83 hours of production time |

| Insurance/Liability | Higher premium due to known risk | Potential for lower premium | Variable |

How does a modern mold flipper support maintenance on aging equipment?

Your molds and dies are some of the most valuable assets on your factory floor. As they age, they require more frequent inspection, cleaning, and repair to maintain quality and prevent failures. But performing this maintenance can be a huge challenge. Accessing every surface of a multi-ton mold hanging from a crane is difficult, unsafe, and time-consuming. Because it's such a hassle, maintenance checks are often rushed or skipped altogether. This neglect accelerates the aging process and leads to unexpected breakdowns and poor part quality.

A modern mold flipper supports maintenance by providing safe, quick, and precise 90-degree or 180-degree access to all sides of a mold. This allows technicians to perform inspections, cleaning, and repairs efficiently and thoroughly, which extends the life of aging equipment and improves the quality of your products.

The Challenge of Mold Maintenance

Imagine your maintenance team trying to work on a mold. If it's suspended by a crane, it's never perfectly stable. They can't easily reach the top or bottom surfaces. They might have to build temporary, unsafe platforms to get access. The whole process is inefficient and risky. It discourages the kind of detailed, careful work that proper maintenance requires. As a result, small problems like minor cracks, wear on guide pins, or blockages in cooling channels are missed. These small problems eventually grow into big failures that stop production. This is especially true for older molds that need more care.

Enabling Proactive and Predictive Maintenance

This is where a mold flipper becomes a critical maintenance tool. By placing the mold on the flipper, your team can rotate it to the perfect angle and hold it there, stable and secure. They can open the mold and have complete, safe access to both halves. This ease of access makes it possible to implement a truly proactive maintenance schedule. Instead of waiting for a mold to fail (reactive maintenance), your team can perform regular, detailed inspections. They can spot wear and tear early and schedule repairs before a failure occurs. This is the first step toward predictive maintenance, a key goal for any modern manufacturer looking to maximize uptime. When maintenance is easy, it gets done right.

Extending the Lifespan of Your Most Valuable Assets

I started my career as an engineer, and I know that proper maintenance is everything. A well-maintained mold will produce high-quality parts for years longer than one that is neglected. By using a mold flipper, you make it easy for your team to do their best work. They can clean every channel, polish every surface, and repair every minor issue. This consistent care directly translates to a longer operational life for your molds. In an environment with aging equipment, you can't afford to let your assets degrade due to difficult maintenance procedures. A mold flipper protects your investment and ensures you get the maximum value out of every single mold in your facility.

| Maintenance Task | Using Crane & Chains | Using Mold Flipper |

|---|---|---|

| Access to Mold Cavity | Difficult and limited | Easy and complete |

| Time for Inspection | 30-45 minutes (includes setup) | 10-15 minutes (includes flip) |

| Safety during Task | Low (unstable load) | High (stable platform) |

| Thoroughness of Cleaning | Compromised | Excellent |

| Likelihood of Proactive Checks | Low (due to hassle) | High (due to ease) |

We have discussed the big three benefits: safety, ROI, and maintenance. These are logical, easy-to-measure advantages that make sense on any spreadsheet. Most factory owners in Malaysia will stop there when considering a mold flipper. But after spending more than 25 years building and running packing machine factories, I've learned to look for the less obvious, "ripple effect" benefits of new technology. There is one powerful, hidden benefit of a mold flipper that goes beyond the machine itself and can change the culture of your entire operation.

The most overlooked benefit of a mold flipper is its role as a 'Process Standardizer.' It forces a structured, repeatable, and documented workflow for mold handling. This eliminates guesswork and individual variations, creating a foundation for true operational excellence and continuous improvement across your plant.

Moving Beyond 'The Way We've Always Done It'

I remember my early days working as an engineer in a factory. When it was time to change a mold, it was chaotic. The senior operator had his own "special" way of rigging the chains. Another operator preferred a different method. There was no single, correct way; it was all based on individual habits and experience. This created inconsistency and risk. A new employee had a steep learning curve and a high chance of making a mistake. This "way we've always done it" mentality is the enemy of efficiency and quality control. A mold flipper destroys this mentality.

The Flipper as a Workflow Anchor

A mold flipper doesn't allow for improvisation. There is only one way to use it correctly. The workflow becomes a clear, non-negotiable sequence:

- Bring the mold to the flipper with a forklift or crane.

- Position the mold correctly on the platform.

- The operator steps back to the control panel and activates the machine.

- The machine performs the rotation.

- Remove the mold.

This simple, rigid process becomes the standard. It's easy to document, easy to teach, and easy to follow. It removes the variability and tribal knowledge that cause so many problems on the factory floor. The machine itself becomes the anchor for a standardized operating procedure (SOP).

The Ripple Effect of Standardization

This is where the magic happens. When your team sees the benefit of a standardized process in one area, they start to ask, "Where else can we do this?" The success of the mold flipper becomes a catalyst for change. It encourages a mindset of continuous improvement. The team might then look at standardizing tool setup, raw material delivery, or quality checks. This single investment in one machine can kickstart a wider cultural shift toward lean manufacturing principles. For a CEO or factory owner like you, who is aiming for higher efficiency and digitalization, this cultural shift is invaluable. It’s the foundation upon which you can build a truly world-class operation, ready to compete not just in Malaysia, but globally.

| Operational Area | Pre-Flipper (Variable Process) | Post-Flipper (Standardized Process) | Result |

|---|---|---|---|

| Mold Handling | Relies on individual operator skill | Machine-defined, repeatable sequence | Reduced Errors & Risk |

| Training | Long, apprenticeship-style | Fast, SOP-based | Faster Onboarding |

| Time Tracking | Unpredictable duration | Consistent, predictable cycle time | Improved Scheduling |

| Mindset | "This is just how we do it." | "What's the best, standard way?" | Continuous Improvement |

Conclusion

For Malaysian manufacturers, a mold flipper is not just equipment. It is a strategic investment in safety, efficiency, and a standardized, future-ready production process that delivers measurable returns.