Mold Flipper: What Are the Must-Have Features for Indian Automotive Suppliers?

As a leader in India's fast-growing automotive industry, you handle heavy and expensive molds every day. I know the feeling. A dropped mold means huge repair bills, production delays, and a serious safety risk. Using old methods like cranes and manual labor to flip these molds is slow, dangerous, and inefficient. Every time a crane lifts a multi-ton mold, you probably hold your breath. One mistake can injure your team, damage equipment, and stop your entire production line. This outdated process is a bottleneck that costs you money and puts your people in danger. A dedicated mold flipper is the clear solution. It offers a secure, controlled, and fast way to handle your molds. But with so many choices, how do you find the right one for the unique demands of the Indian market?

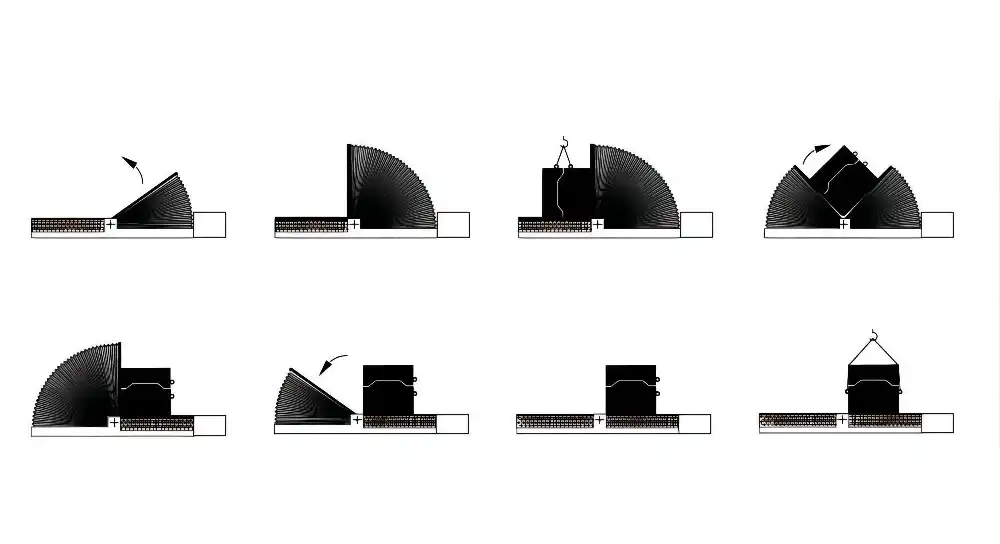

For Indian automotive suppliers, the must-have features for a mold flipper are robust safety mechanisms like hydraulic locking and limit switches, a custom-engineered load capacity to handle diverse mold sizes, a durable and low-maintenance structural design, and an intuitive control system for safe and efficient operation.

Getting the right features is the key to unlocking the full potential of this machine. This is not just about turning a mold over. It is about making your entire operation safer, faster, and more profitable. From my years building these machines and running my own factory, I've learned that the details matter. Let's break down exactly what you need to look for, feature by feature.

How critical is load capacity and size customization for Indian auto parts?

You likely manufacture a wide range of components. These can be small dashboard parts or large body panels. This means your molds vary a lot in size and weight. A standard, off-the-shelf mold flipper might not handle your heaviest molds. Or it could be too big for your smaller ones, which wastes space and money. You need a solution that fits your specific production needs. An investment in equipment must be practical and solve a real problem, not create a new one.

Load capacity and size customization are absolutely critical. An undersized machine is a safety hazard and a liability. An oversized one is a waste of capital and factory floor space. A custom-fit mold flipper ensures you can safely handle your entire range of molds. This maximizes both safety and operational efficiency.

When I first started my own factory, I made a mistake. I tried to save money by buying a standard-size machine for a task that needed a custom solution. I thought, "It's close enough." But "close enough" is not good enough in manufacturing. The machine couldn't handle our largest products safely, and it was inefficient for our smallest ones. This created a bottleneck and constant worry. I learned a valuable lesson: the machine must fit the job perfectly. This is especially true for the Indian automotive sector, which has incredible diversity in its products.

Why "One-Size-Fits-All" Fails in Automotive

The Indian automotive supply chain is complex. One day you might be making molds for scooter headlights, and the next day for SUV doors. A "one-size-fits-all" flipper presents two major problems:

- Safety Risk: If you try to lift a 15-ton mold on a machine rated for 10 tons, you are risking catastrophic failure. The structure, the motor, and the hydraulics are all under stress they were not designed for. This can lead to equipment damage, mold destruction, and serious injury to your team.

- Inefficiency: If you use a massive 50-ton flipper for a 2-ton mold, you are wasting energy on every cycle. The machine's footprint is also larger than necessary, taking up valuable floor space that could be used for production or storage. It's like using a sledgehammer to crack a nut. It works, but it's the wrong tool.

The Engineering Behind Customization

A true partner doesn't just sell you a machine. They work with you to design the right machine. Customization isn't just about changing the color. It's about fundamental engineering. It involves calculating the correct steel thickness for the frame, specifying the right power for the drive system, and designing a table that perfectly supports your mold's unique shape and center of gravity. We analyze your smallest, largest, heaviest, and most awkward molds to design a single machine that handles them all with ease. This detailed approach ensures the machine is a perfect fit for your factory.

| Feature | Standard "Off-the-Shelf" Flipper | Custom SHJLPACK Flipper | Impact on Indian Auto Supplier |

|---|---|---|---|

| Load Capacity | Fixed ratings (e.g., 5T, 10T, 20T) | Engineered to your exact max load + safety factor | Eliminates risk of overload; no wasted capacity. |

| Table Size | Standard dimensions (e.g., 2m x 2m) | Designed to fit your largest and smallest mold footprints | Ensures stable support for all molds; no awkward balancing. |

| Safety Margin | General, may not suit your specific use | Calculated based on dynamic loads of your specific molds | Higher confidence in machine integrity and operator safety. |

| Factory Footprint | Potentially too large or small | Optimized for your available floor space | Maximizes the use of your valuable production area. |

| Initial Cost | May seem lower | Higher than a mismatched standard unit | A smart investment that prevents future costs from accidents or inefficiency. |

What safety features are non-negotiable for a mold flipper in a busy plant?

Your factory floor is a busy place. People and forklifts are always moving around. The last thing you need is a new machine that creates new dangers. A mold flipper is a very powerful piece of equipment. That power needs to be perfectly controlled to prevent any accidents. You cannot afford a single incident that could hurt your team or stop your production lines. Safety is not a feature; it's a foundation.

Non-negotiable safety features for any mold flipper include a robust hydraulic or mechanical locking system to prevent movement during power loss, emergency stop buttons within easy reach, safety railings or light curtains to create a safe zone, and audible and visual alarms during operation.

I will never forget a visit to a potential client's factory years ago. They were using a very old, basic tilter. While I was there, the power flickered for just a second. The machine, which was holding a massive stamping die mid-turn, jolted and started to slip because it had no power-off braking or locking system. Everyone froze. Luckily, the power came back on and the operator regained control. But that moment showed me how quickly things can go wrong. A machine that handles tons of steel must be designed to be safe even when things fail. It must fail safely.

Active vs. Passive Safety Systems

When we talk about safety, we can think of it in two ways: active and passive systems. You need both.

- Active Safety Systems: These are features that require an action to work. This includes the emergency stop (E-stop) button. Operators must be trained to know where these are and how to use them instantly. Other active systems are the controls themselves. A well-designed control panel makes it easy to operate the machine safely and difficult to make a mistake.

- Passive Safety Systems: These features work automatically in the background to keep people safe. This is the most critical category. A hydraulic locking system that engages if power is lost is a passive system. Hard-wired limit switches that prevent the machine from over-rotating are passive. Physical barriers and safety fences are passive. These are the systems that protect your team even if an operator makes a mistake or an external event like a power outage occurs.

The Human Factor: Controls and Training

A machine is only as safe as the person operating it. That is why the control system must be simple and intuitive. Complicated controls can lead to errors, especially in a high-pressure environment. We design our control panels with clear labels, logical layouts, and often use a remote pendant so the operator can stand at a safe distance with a clear view of the entire operation. But the hardware is only half the solution. Proper training is essential. A good supplier will not just install the machine and leave. They will provide comprehensive training for your operators and maintenance staff, ensuring they understand every function and every safety feature.

| Safety Feature | Description | Why It's Non-Negotiable |

|---|---|---|

| Hydraulic/Mechanical Locks | Automatically engages to hold the load if hydraulic pressure or power is lost. | Prevents a mold from crashing down during a power failure. This is the single most important passive safety feature. |

| Emergency Stop Buttons | Large, accessible buttons that immediately cut all power to the machine. | Provides an instant way for anyone to stop the machine in an emergency. Must be located on the panel and around the machine. |

| Limit Switches | Physical or proximity switches that stop rotation at 90 or 180 degrees. | Prevents the machine from over-rotating, which could damage the drive system or the mold itself. |

| Perimeter Guarding | Physical fences, safety railings, or light curtains around the machine. | Creates a "safe zone" and prevents people from accidentally walking into the machine's path while it is moving. |

| Overload Protection | A system that detects if the load exceeds the machine's capacity and prevents operation. | Protects the machine's structure and drive system from damage and prevents a dangerous lifting attempt. |

Why should advanced control systems and automation be a priority?

You are always under pressure to increase production and lower costs. Manual processes are often slow and can lead to mistakes. Your operators are skilled, but they cannot be everywhere at once. You are already looking for ways to use digital solutions, like your smart scheduling platform, to make your factory smarter. Your mold handling process should be part of that digital transformation.

Advanced control systems and automation should be a priority because they significantly reduce cycle times, minimize the risk of operator error, allow for integration with your factory's MES or IoT network, and provide valuable data for predictive maintenance. This ultimately boosts productivity and profitability.

I've seen the change in my own business and in my clients' businesses. In the beginning, a machine with a simple "On/Off" button and a lever was enough. Today, that is not enough. Factory owners like you need data. You need to know how long each cycle takes, how much energy is being used, and when a machine might need service. An advanced control system is not a luxury. It is a necessary tool for modern, competitive manufacturing. It turns a piece of standalone equipment into an intelligent part of your entire production system.

Beyond the Push-Button: What a Modern PLC Offers

The "brain" of a modern mold flipper is the Programmable Logic Controller (PLC). A basic system uses a simple PLC for start, stop, and rotate functions. An advanced system uses a more powerful PLC that unlocks huge potential. You can program variable speeds, so the machine starts and stops smoothly, protecting the mold and the machine's gears. You can add sensors that confirm the mold is seated correctly before the operation begins. The PLC can also track the number of cycles and operating hours, which is vital information for scheduling preventive maintenance.

Integrating Your Flipper into a Smart Factory

The real power comes when you connect the mold flipper's PLC to your larger factory network. This is a key part of Industry 4.0. Through an ethernet connection, the flipper can communicate with your Manufacturing Execution System (MES).

- For Operators: The MES can tell the flipper which mold is coming next, and the PLC can pre-load the correct operating parameters for that specific mold's weight and size. This reduces setup time and prevents errors.

- For Management: You get real-time data on your dashboard. You can see how often the flipper is being used, identify bottlenecks, and track efficiency. The system can send an alert to the maintenance department if it detects a problem, like a motor drawing too much current, which might indicate a future failure. This is predictive maintenance, and it saves you from costly unplanned downtime.

| Control Feature | Basic System | Advanced System (SHJLPACK) | Benefit for a CEO/Owner |

|---|---|---|---|

| Operator Interface | Simple buttons and lights | Touchscreen HMI with graphics and diagnostics | Easier for operators to use correctly; faster troubleshooting of any issues. |

| Speed Control | Fixed speed | Variable speed with soft start/stop | Protects the mold and machine from shock loads, increasing lifespan. |

| Data Logging | None | Records cycle times, hours, motor current, faults | Provides key data for measuring Overall Equipment Effectiveness (OEE). |

| Connectivity | Standalone machine | Ethernet/IP for MES and IoT integration | Enables a fully connected "smart factory," improving scheduling and visibility. |

| Remote Diagnostics | Requires technician on-site | Supplier can access PLC remotely to diagnose issues | Drastically reduces downtime and service costs by allowing for instant support. |

How does robust construction and low maintenance impact long-term ROI?

I am sure you have been burned by equipment that looked good in the sales brochure but broke down all the time. Downtime is the biggest enemy of a factory owner. Every hour a key machine is down for repairs costs you thousands in lost production and idle labor. You are not just buying a machine; you are making a long-term investment in your plant's capability. You need equipment that is built to last in a tough industrial environment like a steel mill or an auto parts factory.

Robust construction and low maintenance directly impact long-term ROI by minimizing unscheduled downtime, reducing repair costs, extending the machine's operational lifespan, and ensuring consistent performance. A well-built machine is a reliable asset, not a constant liability.

When I started my journey as an engineer, and later as a factory owner, I learned this lesson the hard way. Cheaper equipment always costs more in the long run. A machine with a weak frame will flex under load, causing wear on the bearings and drive chain. A machine with low-quality hydraulic components will leak and fail. These small problems add up to a big headache and constant expenses. That is why at SHJLPACK, we build our machines to be tanks. Because I know that a machine that runs reliably for 20 years is a much better investment than one that needs to be replaced in five.

The Hidden Costs of Poor Build Quality

The purchase price is only one part of the total cost of ownership. A poorly built machine has many hidden costs:

- Downtime Costs: The cost of lost production when the machine is broken.

- Repair Costs: The cost of spare parts and labor for frequent repairs.

- Safety Costs: The risk of accidents due to component failure.

- Replacement Costs: The cost of buying a new machine much sooner than you expected.

When you add all these up, the "cheaper" machine is often far more expensive. A machine should be an asset that makes you money, not a drain on your resources.

Materials and Components That Matter

Building a robust machine is about making the right choices in materials and components. It’s not a place to cut corners.

- The Frame: We use heavy-duty, reinforced structural steel (like Q235 or Q345) that is much thicker than necessary. All welds are done by certified welders and inspected. This ensures the frame will not twist or deform, even under the heaviest loads.

- The Drive System: We use a heavy-duty roller chain and a high-quality gear motor from a reputable brand. This provides smooth, reliable turning power for decades.

- The Bearings: We use oversized, sealed bearings that can handle massive radial and axial loads. They are designed for a long life with minimal lubrication.

- The Surface: The table and frame are sandblasted to create a clean, strong surface for paint to adhere to. We then use a high-quality industrial enamel or epoxy paint. This prevents rust and corrosion, even in humid Indian climates.

| Aspect | Low-Quality Build | Robust Build (SHJLPACK) | 10-Year Cost Impact |

|---|---|---|---|

| Steel Frame | Thin steel, minimal reinforcement. | Heavy-gauge structural steel, fully welded and reinforced. | Avoids frame cracking and deformation; no need for costly repairs or early replacement. |

| Bearings | Standard, undersized bearings. | Oversized, sealed, premium-brand bearings. | Prevents frequent bearing failure, which is a major cause of downtime. |

| Hydraulic System | Low-cost seals, hoses, and pumps. | High-quality components from trusted international brands. | Minimizes oil leaks and pump failures; reduces maintenance costs. |

| Paint/Coating | Single layer of cheap paint. | Sandblasted surface with primer and industrial epoxy paint. | Prevents rust and corrosion, extending the machine's life and maintaining its value. |

Conclusion

A mold flipper is more than just equipment. It is a strategic investment in safety, efficiency, and your factory's future. Choose wisely by focusing on these essential features for long-term success.