Mold flipper: is now the right time to standardize handling across Saudi facilities?

Are your production lines in Saudi Arabia feeling the pressure? You might have state-of-the-art machinery in one area, but in another, you're still relying on decades-old methods for critical tasks like mold handling. I see this a lot. A facility will invest millions in a new production line but overlook the supporting processes. This creates a bottleneck. Using cranes and chains to flip heavy molds is slow, inconsistent, and frankly, dangerous. Every time this happens, you are losing precious minutes, risking damage to expensive molds, and putting your team's safety on the line. These small inefficiencies add up, slowly eating away at your productivity and profits, making it impossible to meet the demanding goals of a modern industrial operation. It's a hidden problem that needs a modern solution.

Yes, now is absolutely the right time for industrial facilities across Saudi Arabia to standardize their mold handling processes with dedicated mold flippers. The strategic push towards industrial modernization under Saudi Vision 2030, combined with the clear and immediate return on investment from improved safety, efficiency, and equipment longevity, makes this a critical upgrade. It is a strategic decision that aligns operational reality with national ambition.

This is more than just buying a new piece of equipment. It is about changing the way you think about your workflow. It is about removing variables and risks from a critical process. When you standardize how you handle molds, you create a ripple effect of positive changes across your entire operation, from the factory floor to the balance sheet. I have seen this transformation happen many times. Let’s break down the specific challenges and benefits, so you can see why this is such a powerful move for any forward-thinking facility in the region.

You see the obvious costs on a report. A maintenance invoice for a damaged mold. The logged hours of downtime when a production line stops. But what about the costs that never make it onto a spreadsheet? These are the ones that truly hurt your business. Think about the extra minutes your team spends struggling with chains and an overhead crane for every single mold turnover. Think about the constant, low-level stress on the mold from uneven lifting, which slowly leads to micro-cracks and a much shorter lifespan. This is a quiet drain, a ghost in your operational budget. The real problem is that these hidden costs are accepted as "the cost of doing business." But they don't have to be.

The hidden costs of non-standardized mold handling extend far beyond simple repair bills. They include reduced production uptime from slow changeovers, inflated labor costs due to inefficient manual processes, a shortened lifespan for expensive molds due to handling-induced stress, and significant, unquantifiable financial risk from potential safety incidents.

Dive Deeper: Uncovering the Invisible Drains

Let's look at this with an engineer's eye. Non-standardized handling, usually involving overhead cranes, is a process full of variables. Each lift is slightly different. This variability is where the hidden costs live. We can break them down into a few key areas.

The Cost of Time and Inefficiency

The most direct hidden cost is wasted time. A manual turnover with a crane might take two skilled operators 60 to 90 minutes. They have to clear the area, attach chains, perform the slow, careful lift, and then position the mold. A dedicated mold flipper can do the same job with one operator in under 15 minutes.

Let's do some simple math. If you change molds just three times a week, the difference is stark.

- Crane Method: 75 minutes/change x 3 changes/week = 225 minutes/week of handling time.

- Mold Flipper Method: 15 minutes/change x 3 changes/week = 45 minutes/week.

That is a saving of 180 minutes, or 3 hours, every single week. Over a 50-week year, that is 150 hours of recovered production time. For a steel plant owner like Javier Morales, whose time is measured in tons per hour, those 150 hours represent a massive amount of lost revenue.

The Cost of Premature Equipment Failure

Molds are precision tools, and they are expensive. When you lift a multi-ton mold with chains, the forces are concentrated at the attachment points. This creates stress. Over time, this repeated stress causes microscopic damage and fatigue, leading to a shorter operational life. A mold flipper supports the entire surface of the mold on a stable platform. It turns the mold smoothly, distributing the load evenly. This gentle handling can significantly extend the life of your molds, delaying the huge capital expense of replacing them.

Here is a table to make it clearer:

| Cost Factor | Non-Standardized Method (Crane & Chains) | Standardized Method (Mold Flipper) | Impact on the Business |

|---|---|---|---|

| Labor | High skill, 2+ operators, long duration | Low skill, 1 operator, short duration | Reduces direct labor cost per changeover. |

| Downtime | 60-90 minutes per changeover | < 15 minutes per changeover | Increases available production time (OEE). |

| Mold Lifespan | Reduced due to stress and impact risk | Maximized due to even support and gentle handling | Lowers capital expenditure on mold replacement. |

| Safety Risk | High risk of load drop, pinch points, human error | Very low risk, engineered and controlled process | Prevents catastrophic accidents and associated costs. |

| Process Control | Highly variable, depends on operator skill | Highly repeatable and predictable | Enables better planning and scheduling (MES integration). |

When I started my own factory, I had to watch every penny. I learned early on that the things that seem "free," like using existing cranes for jobs they weren't designed for, are often the most expensive in the long run. The invisible costs of inefficiency and risk are what separate a struggling plant from a highly profitable one.

How does a standardized mold flipper system improve safety and efficiency?

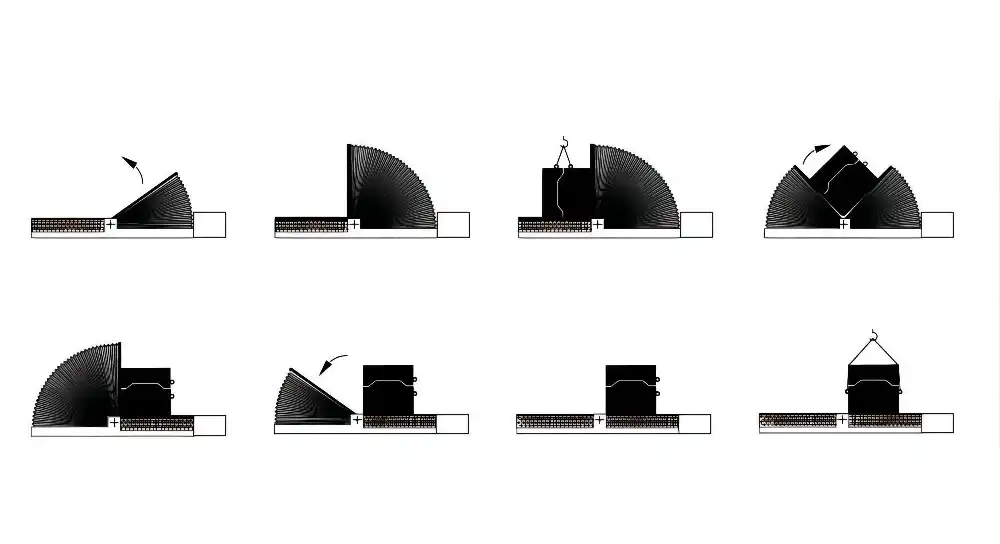

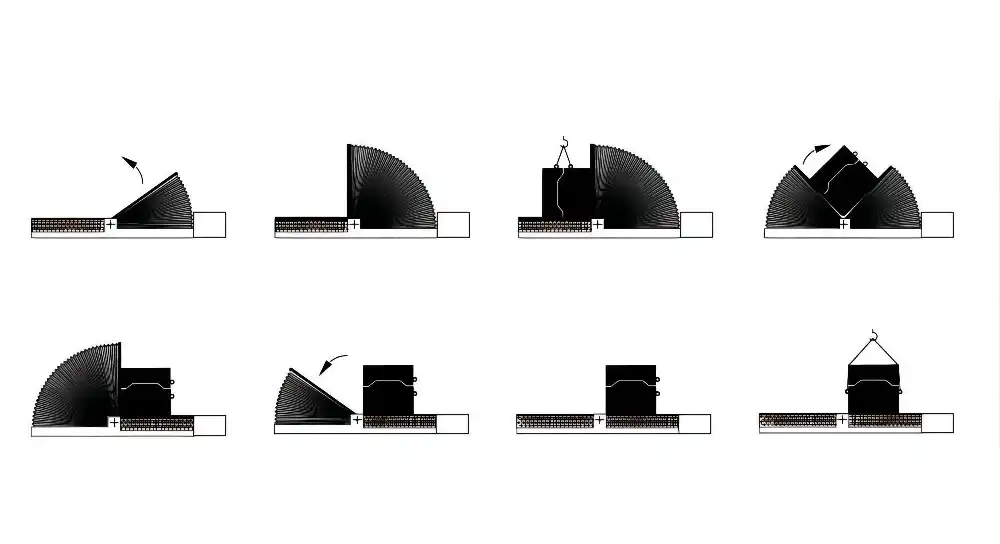

Every plant manager knows the feeling. You walk the floor and see a massive mold suspended in mid-air from chains. It is a moment of high risk. Everyone in the area has to stop what they are doing. The crane operator must be perfectly focused. The riggers must be certain of their connections. Any small mistake—a moment of inattention, a weak link in a chain—can lead to disaster. This inherent danger naturally slows the whole process down. Efficiency is sacrificed for safety, and even then, the risk is never zero.

A standardized mold flipper system improves safety by replacing a high-risk manual task with a controlled, engineered, and predictable machine process. It secures the workpiece on a stable platform, eliminating the danger of suspended loads. This newfound safety directly fuels efficiency, as it allows for rapid, repeatable changeovers without the delays and precautions required by hazardous manual methods.

Dive Deeper: The Twin Pillars of Safety and Speed

Safety and efficiency are not opposing forces. In a well-designed system, they support each other. A safer process is almost always a more efficient one. A mold flipper is a perfect example of this principle.

Engineering a Safer Environment

The fundamental safety improvement comes from one simple change: the load is never uncontrollably suspended.

- With a Crane: The mold's center of gravity is constantly shifting. The load is held by chains under tension. It can swing or twist unexpectedly. The safety of the operation depends entirely on the equipment's condition and the operator's skill.

- With a Mold Flipper: The mold rests on a solid, wide table. It is clamped securely. The entire system is designed for one purpose: to turn the object in a smooth, controlled arc. The risk of a sudden drop is virtually eliminated.

This change has a huge psychological impact on the workforce. When operators know a process is safe, they can perform it confidently and without hesitation. This reduces stress and improves morale. I remember a client who manufactured large components for the automotive industry. Their safety record was decent, but they had a few near-misses with their crane-based handling. After we installed a mold flipper system across their facilities, the plant manager told me the biggest change wasn't just the time saved; it was the "calm" on the factory floor during changeovers. That calm is the sound of a safe, efficient process.

Unleashing Operational Efficiency

Once the safety question is solved, efficiency follows naturally. The speed of a mold flipper is not about moving recklessly; it is about removing unnecessary steps and delays.

Consider the workflow:

| Step | Crane & Chain Method | Mold Flipper Method | Efficiency Gain |

|---|---|---|---|

| 1. Preparation | Clear a large safety zone. Inspect chains and rigging. | Move the mold to the flipper. | Faster, smaller footprint required. |

| 2. Attachment | Manually attach heavy chains, ensuring balance. | Place mold on the table and press a button to clamp. | Drastically reduces manual labor and time. |

| 3. The Turn | Slow, careful lift and turn, requires constant adjustment. | Smooth, automated 90° or 180° turn in seconds. | Predictable and fast cycle time. |

| 4. Placement | Carefully lower and position the mold. | Unclamp and remove the mold. | Simple and quick. |

This streamlined process directly addresses the goals of a forward-thinking leader like Javier. His objective to raise equipment uptime to 95% is simply not achievable when a basic process like mold changing is a long, risky, and unpredictable event. By standardizing with mold flippers, you make changeovers a small, predictable part of the schedule, not a major production stoppage. This predictability is the foundation of a truly efficient factory.

Can standardization with mold flippers support Saudi Vision 2030's industrial goals?

Saudi Vision 2030 is one of the most ambitious national transformation plans in the world. At its heart is a goal to build a robust, diversified, and globally competitive industrial sector. This isn't just about building new factories; it's about making existing ones smarter, safer, and more productive. So, how does a piece of equipment like a mold flipper fit into such a grand vision? It might seem small, but it is fundamental. You cannot build a world-class industrial economy on top of outdated, inefficient, and unsafe operational practices.

Yes, absolutely. Standardizing with mold flippers directly advances the core tenets of Saudi Vision 2030. It boosts manufacturing efficiency, elevates workplace safety standards to global levels, and provides a crucial hardware foundation for the digital transformation and Industry 4.0 initiatives that are central to the vision's goal of creating a technologically advanced and competitive industrial base.

Dive Deeper: From Factory Floor to National Ambition

The goals of Vision 2030 are big, but they are achieved through thousands of small, practical improvements on the ground. Standardizing mold handling is one of those critical improvements that has an outsized impact.

Aligning with the Pillars of Vision 2030

Let's connect this specific technology to the high-level goals:

- A Thriving Economy & Increased Competitiveness: Vision 2030 aims to increase non-oil exports. To do that, Saudi products must compete on price and quality in the global market. Every riyal saved through increased efficiency, reduced downtime, and lower maintenance costs makes a Saudi factory more competitive. A mold flipper is a cost-reduction tool. It cuts labor costs, extends the life of capital assets (molds), and maximizes the output of production lines.

- An Ambitious Nation & Human Capital Development: A core goal is to create safe, high-quality jobs for Saudi citizens. A factory that relies on dangerous manual handling is not an attractive workplace. By investing in safer, modern equipment like mold flippers, companies show a commitment to their employees' well-being. This helps attract and retain skilled talent. It shifts the nature of the job from risky manual labor to skilled machine operation, which is a key part of upskilling the national workforce.

The Gateway to Industry 4.0

Perhaps the most important link to Vision 2030 is digitalization. The vision calls for the adoption of Fourth Industrial Revolution (Industry 4.0) technologies. A "smart factory" relies on data from every part of the process.

An old-fashioned crane and chain process is a "black box"—it generates no useful data. A modern mold flipper is different. It can be a node in your digital factory.

| Digital Capability | How a Mold Flipper Enables It | Relevance to Vision 2030 |

|---|---|---|

| IoT Integration | Can be equipped with sensors to track cycles, runtime, and faults. | Provides real-time data for a "digital twin" of the factory. |

| MES Connectivity | Can be linked to the Manufacturing Execution System to automate work orders. | Enables intelligent scheduling and resource management. |

| Predictive Maintenance | Data from the flipper can predict when it needs service, preventing unexpected breakdowns. | Increases overall equipment effectiveness (OEE) and reliability. |

| Data Analytics | Analyzing turnover times can identify further optimization opportunities. | Supports data-driven decision-making for continuous improvement. |

For a leader like Javier, who has a goal to deploy MES, IoT, and big data platforms, this is crucial. You cannot have a smart factory if your core equipment is "dumb." Upgrading to a connectable mold flipper isn't just a mechanical upgrade; it is a digital one. It is a practical, tangible step on the path to building the kind of advanced, efficient, and data-rich industrial facilities that will define the success of Saudi Vision 2030.

What does the ROI look like for a facility-wide mold flipper upgrade?

This is the most important question for any business owner or CEO. As an engineer who became a factory owner, I understand this better than anyone. A new machine is not just a piece of steel; it is an investment that must pay for itself. The initial cost of upgrading an entire facility's mold handling process can seem large. It's easy to look at the quote and decide to "make do" with the old way for another year. But that is a mistake. The old way is not free. It is actively costing you money every day in lost time, risk, and inefficiency. The real question is not "Can we afford to do this?" but "Can we afford not to?"

The Return on Investment (ROI) for a facility-wide mold flipper upgrade is typically strong and fast, often paying for itself in 12 to 24 months. The calculation must go beyond the purchase price and include the significant savings from reduced labor hours, increased production uptime, lower mold repair and replacement costs, and the financial mitigation of safety risks.

Dive Deeper: A Clear-Eyed Calculation for Leaders

Calculating the ROI for a mold flipper is straightforward. It is about comparing the total cost of ownership of your current method with the new, standardized method. Let's build a business case that a practical leader like Javier Morales would appreciate. We will use conservative numbers for a hypothetical steel facility.

Assumptions:

- Cost of one heavy-duty mold flipper: $100,000 USD

- Number of mold changes per week: 4

- Time saved per changeover: 60 minutes (1 hour)

- Labor rate (2 operators for old way, 1 for new): saving 1 operator @ $30/hr

- Value of lost production time (downtime cost): $1,500/hour

- Annual mold repair cost from handling damage: $25,000

- Reduction in repair costs with flipper: 80%

Let's break down the annual savings.

Hard Savings (Tangible and Measurable)

These are the numbers you can easily track on a balance sheet.

-

Uptime Gain:

- Time saved per week: 1 hour/change x 4 changes/week = 4 hours

- Annual time saved: 4 hours/week x 50 weeks = 200 hours

- Annual Uptime Value: 200 hours x $1,500/hour = $300,000

-

Labor Savings:

- Labor saved per change: 1 operator x 1 hour x $30/hour = $30

- Annual labor savings: $30/change x 4 changes/week x 50 weeks = $6,000

-

Mold Maintenance Savings:

- Annual repair reduction: $25,000 x 80% = $20,000

Here is the ROI table:

| ROI Component | Calculation | Annual Savings |

|---|---|---|

| Uptime Value Recaptured | (4 changes/wk) x (1 hr saved/change) x (50 wks) x ($1,500/hr) | $300,000 |

| Direct Labor Savings | (1 operator saved) x ($30/hr) x (200 changes/yr) | $6,000 |

| Reduced Mold Repair | $25,000 (annual cost) x 80% (reduction) | $20,000 |

| Total Annual Hard Savings | $326,000 |

Payback Period = Investment Cost / Total Annual Savings

$100,000 / $326,000 = 0.31 years, or approximately 4 months.

Soft Savings (Critical but Harder to Quantify)

- Safety: The cost of a single major accident can easily exceed $1,000,000 in direct costs, fines, and lost production. Mitigating this risk has immense value.

- Employee Morale: A safer, more modern workplace leads to happier, more productive employees and lower turnover.

- Process Predictability: Being able to schedule maintenance with confidence is a huge strategic advantage that enables lean manufacturing.

When I talk to clients, I always emphasize this point. The hard savings alone usually justify the investment in under a year. The soft savings—the safety, the morale, the predictability—are the bonus that transforms a good investment into a brilliant one. My own success was built on making these kinds of data-backed decisions, moving from just being an engineer to owning a factory. This is how strong, resilient businesses are built.

Conclusion

Standardizing mold flippers in Saudi facilities is a powerful, data-driven move for enhancing safety, boosting efficiency, and securing future growth. The time to invest is now.