Mold Flipper: How Do You Choose Capacity (5–20T) for Thailand Operations?

Choosing the right equipment for your factory floor is a decision that has long-term consequences. When it comes to a mold flipper, selecting the wrong capacity can be a costly and dangerous mistake. You might end up with a machine that can't handle your future projects, creating a production bottleneck that costs you time and money. Or worse, an undersized machine could pose a serious safety risk to your team. On the other hand, overspending on a machine with capacity you'll never use is a waste of capital that could have been invested elsewhere in your business. These are the real-world pressures I faced when I was managing a factory, and they are the challenges my clients work to solve every day.

To choose the right mold flipper capacity (5-20T) for your Thailand operations, you must analyze your current and future mold weights, consider your production frequency, and factor in a safety margin of at least 20-30%. For Thailand, you must also consider the hot, humid climate's impact on components like electrical systems and motors when assessing the machine's long-term reliability and design.

This simple rule is a great starting point. But a critical investment like this requires more than a rule of thumb. As an engineer and a factory owner myself, I know that a thorough analysis is what separates a good investment from a bad one. We need to break down this decision into smaller, manageable parts. Let's dig deeper into the factors that will help you build a solid business case for your purchase, ensuring it supports your goals for efficiency, safety, and profitability for years to come.

What are the key factors influencing mold flipper capacity selection?

You have a budget, and you have an immediate need for a mold flipper. But when you start looking, you're faced with dozens of technical specifications and persuasive sales pitches. It’s easy to feel pulled in different directions, and the path to a clear decision can seem complicated. Many people fall into the trap of focusing only on the heaviest mold they have right now. This is a critical mistake. What about the larger molds your sales team is trying to win contracts for? What about the speed and frequency of your operations? A short-sighted decision here means you could be shopping for another machine in just a few years, repeating the same costly process.

The key factors influencing mold flipper capacity are: the maximum and average weight of your molds, the physical dimensions of your molds (length, width, and height), the frequency of mold flipping in your workflow, and most importantly, your projected business growth and future mold requirements.

Diving Deeper into Capacity Factors

Making the right choice goes beyond just one number. A strategic approach requires a holistic view of your operations, both now and in the future. I always advise my clients to think of it as creating a "machine profile" that is perfectly tailored to their needs.

Analyzing Your Mold Inventory

First, look at your entire collection of molds. Don't just identify the single heaviest one. Create a simple spreadsheet listing the weights of all your molds. This will give you not just a maximum weight, but also an average weight and a weight distribution. Why does this matter? Your maximum weight determines the absolute minimum capacity you must have. But your average weight and flipping frequency determine the machine's duty cycle. If you are constantly flipping molds close to the machine's maximum capacity, you need a more robust, heavy-duty machine than if you only flip the heaviest mold once a month. The maximum weight defines the machine's strength; the average weight and frequency define its endurance.

Workflow Integration and Mold Dimensions

Next, consider how the mold flipper fits into your production flow. Is it for the maintenance bay, where molds are turned for cleaning and repair? Or is it part of a rapid changeover process on the production line? For maintenance, speed might be less critical than precision and safety. For production, cycle time is everything. A faster flipping speed could shave valuable minutes off every changeover, adding up to significant gains in Overall Equipment Effectiveness (OEE). Also, think about the physical size and shape of your molds. A long, narrow mold has a very different center of gravity than a compact, square one. You need to ensure the flipper's table is large enough to support the entire mold base securely. An off-center load can put immense stress on the machine's structure and drive system, leading to premature wear and safety risks.

Future-Proofing Your Investment

Finally, and perhaps most importantly for a forward-thinking leader, you must look ahead. Where will your business be in five years? Are you planning to enter new markets, produce larger parts, or take on more complex projects? If your business is growing, your molds will likely get bigger and heavier. Buying a machine that only meets today's needs is planning for stagnation. I always recommend building in a capacity buffer of at least 20-30% above your current maximum mold weight. This "growth buffer" is a smart investment. It ensures your new equipment can support your ambitions, not limit them.

To help you with this, here's a simple checklist I use with clients:

| Factor | Question to Ask Yourself | My Recommendation |

|---|---|---|

| Max Mold Weight | What is the absolute heaviest mold we have or plan to acquire in the next 5 years? | Your flipper's rated capacity must exceed this number. |

| Average Mold Weight | What is the weight of the molds we flip most often (e.g., 80% of the time)? | This informs the required duty cycle and energy efficiency of the motor. |

| Mold Dimensions | Are our molds unusually long, wide, or tall? Is the center of gravity off-center? | Ensure the machine's table size and structural design can handle the footprint. |

| Flipping Frequency | How many times per hour, shift, or day will we use this machine? | High frequency demands more robust components, especially in the drive system. |

| Growth Plans | Are we expanding our product lines or taking on larger projects in the near future? | Add a 20-30% capacity buffer to your maximum expected weight. |

How do Thailand's specific operational conditions affect your choice?

A machine is not an isolated piece of technology. It operates within an environment, and that environment can have a huge impact on its performance and lifespan. A mold flipper that works perfectly in a dry, temperate climate in Europe might face serious challenges in Southeast Asia. Ignoring these local conditions is a common oversight that can lead to unexpected and costly problems. Imagine your production line halting because a key electrical component has failed due to humidity, or discovering that the machine's structure is corroding much faster than the manufacturer promised. These are not hypothetical problems; they are expensive realities I have helped clients navigate.

For your Thailand operations, you must account for the high ambient humidity and temperature. This means selecting a mold flipper that is built with IP-rated electrical cabinets, high-quality corrosion-resistant coatings, and a robust cooling system for the hydraulic or electric motors to prevent overheating and premature failure.

Diving Deeper into Thailand's Environmental Challenges

I have supplied packing and handling equipment to many factories across Southeast Asia, including several in Thailand's industrial estates. Through this experience, I've learned that a "tropicalized" or "Thailand-ready" specification is not a luxury; it's a necessity for ensuring reliability and achieving a good return on your investment.

The Humidity and Heat Challenge

Thailand's climate is characterized by high heat and humidity year-round. This combination is tough on industrial machinery. Humidity is the enemy of electronics. Moisture can seep into standard electrical cabinets, causing corrosion on terminals, short circuits on printed circuit boards (PCBs), and phantom faults that are incredibly difficult to diagnose. This is why a higher Ingress Protection (IP) rating is crucial. An IP65-rated cabinet is designed to be dust-tight and protect against water jets, making it far more resilient in a humid environment than a standard IP54 cabinet. Heat is another major factor. High ambient temperatures mean that motors and hydraulic systems have to work harder to stay cool. An overworked cooling system can lead to motor burnout or the degradation of hydraulic fluid, causing sluggish performance and eventual failure. Look for machines with oversized cooling fans, larger oil reservoirs, and even dedicated oil coolers for hydraulic systems.

Power Grid and Local Skills

In some industrial areas, the power grid may not be as stable as in other parts of the world. Voltage sags, spikes, and brownouts can damage sensitive electronic components like PLCs and VFDs. It's a wise precaution to ask potential suppliers about built-in power conditioning or to plan for an external voltage stabilizer. Another practical consideration is the local skill base. While Thailand has many skilled technicians, complex, proprietary systems can be difficult to service. I always advocate for machines that use widely available components from brands like Siemens, Schneider, or Omron. A control system with a clear, user-friendly HMI (Human-Machine Interface) that includes self-diagnostic functions can empower your local team to resolve minor issues quickly without having to wait for a specialist.

Here is a comparison of standard vs. "Thailand-Ready" specifications:

| Component | Standard Specification | Recommended for Thailand | Why It Matters for Your Operations |

|---|---|---|---|

| Electrical Cabinet | IP54 | IP65 or higher | Prevents moisture and dust ingress, avoiding costly electrical failures. |

| Surface Finish | Standard industrial paint | Two-part marine-grade epoxy paint or hot-dip galvanizing | Fights accelerated corrosion from constant high humidity. |

| Motor & Hydraulics | Standard fan cooling | Oversized cooling fans, auxiliary oil cooler for hydraulics | Prevents overheating in ambient temperatures that often exceed 35°C. |

| Control System | Standard PLC/HMI | PLC with advanced diagnostics and remote access capability | Simplifies troubleshooting for your local team and enables fast remote support from the supplier. |

When should you choose a 5T, 10T, or 20T mold flipper?

You've analyzed your needs and considered the local environment. Now you arrive at the specific decision on the table: should you invest in a 5-ton, 10-ton, or 20-ton capacity machine? Each of these options comes with a significantly different price tag, physical footprint, and energy consumption profile. Choosing a model that's too small might save you some money on the initial invoice, but it will create a ceiling on your production capabilities and introduce unnecessary safety risks. On the other hand, choosing a massive 20-ton machine when your heaviest mold is only 7 tons means you are wasting capital and valuable factory floor space. It can feel like a high-stakes gamble.

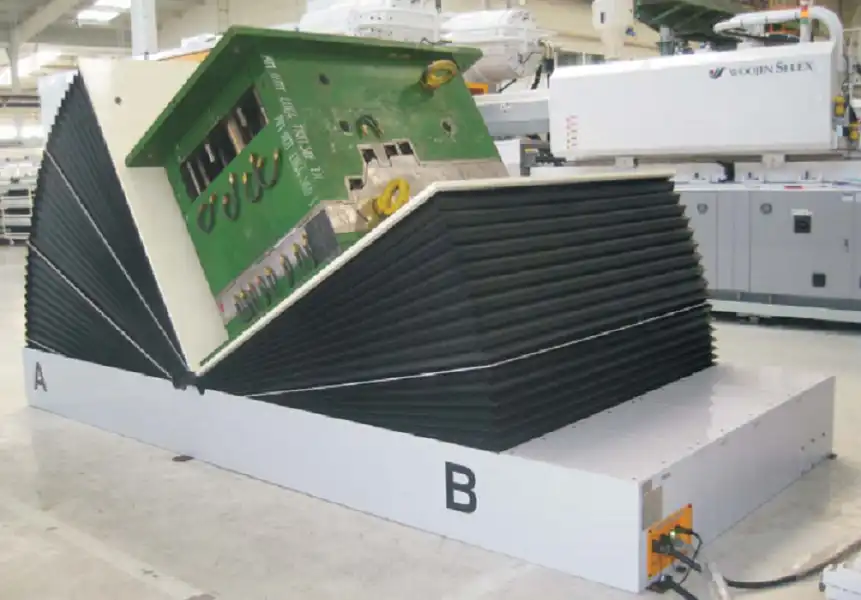

You should choose a 5T mold flipper for smaller, dedicated production lines like those in plastic injection molding. A 10T flipper is a versatile, all-around choice for medium-sized tool and die shops or mixed manufacturing environments. You should opt for a 20T or larger flipper for heavy industrial applications, such as automotive stamping dies or large-scale molds used in steel mill operations.

Diving Deeper into Specific Capacity Scenarios

Let's move away from guesswork and use practical, scenario-based thinking. By matching your operational profile to the right machine capacity, you can make a confident, data-driven decision. From my experience helping clients in various industries, here’s how I see the roles of these different capacity machines.

The Case for a 5-Ton Flipper: Speed and Precision

A 5-ton mold flipper is a specialist. It's the perfect solution for factories with a high volume of relatively lightweight molds. Think of a facility in Thailand that produces plastic components for consumer electronics or medical devices. Their molds might weigh between 1 and 4 tons, but they might need to change them several times a shift to meet diverse orders. In this environment, the key performance indicator is not raw power, but cycle time. A smaller, nimbler 5-ton machine can often be engineered for faster rotation, and its lower energy consumption reduces the operational cost per flip. The focus here is on maximizing throughput and efficiency for a known, consistent range of mold sizes. It's an excellent choice for a dedicated, high-speed production line.

The 10-Ton "Sweet Spot": The Versatile Workhorse

For many businesses, the 10-ton mold flipper represents the ideal balance of capability and cost. It's the most versatile option, a true workhorse. I often recommend this capacity to general machine shops, tool and die makers, and factories with a mixed portfolio of products. Consider a Tier 2 automotive supplier in the Rayong industrial corridor. They might produce a variety of parts, with molds ranging from 3 tons to 8 tons. A 10-ton flipper gives them the capacity to handle everything in their current inventory with a comfortable safety margin. It also provides the flexibility to bid on new projects with slightly heavier tooling without needing a new machine. It's a future-proof investment for a business that needs to stay agile and responsive to market demands.

Stepping Up to 20 Tons: The Heavy-Duty Specialist

When you enter the 20-ton category, you are dealing with serious industrial power. These machines are built for the most demanding applications. This is the realm of large automotive stamping plants producing body panels, forging operations, or maintenance shops in heavy industries like the steel mills that you, Javier, know so well. When your molds consistently weigh 12, 15, or 18 tons, your primary concerns shift. While speed is still a factor, it is secondary to absolute structural integrity and safety. These machines feature reinforced frames, powerful drive systems (often hydraulic for smooth control of massive loads), and multiple, redundant safety features like mechanical locking pins and hydraulic load-holding valves. The investment is significant, not just in price but also in the foundation and floor space required. Therefore, the decision to buy a 20-ton flipper must be justified by a clear and consistent need to handle these heavy loads safely and reliably.

| Capacity | Ideal Application Scenario (in Thailand) | Key Consideration | Potential Pitfall to Avoid |

|---|---|---|---|

| 5 Ton | A factory producing plastic casings for consumer goods. Molds are 1-4 tons. | Speed, cycle time, and energy efficiency are top priorities. | Limits your ability to take on larger, more lucrative jobs. |

| 10 Ton | A general tool & die shop servicing automotive and appliance industries. Molds are 3-8 tons. | Versatility is key. It must be a reliable "all-rounder." | May be slightly oversized and less efficient for very small jobs. |

| 20 Ton | A large stamping plant for automotive parts. Molds are consistently 12-18 tons. | Safety systems and structural rigidity are non-negotiable. | High capital cost. Underutilization is a major waste of resources. |

Beyond capacity, what other features are critical for long-term ROI?

It is natural to focus on the headline number—the lifting capacity—and the purchase price. These are the easiest metrics to compare. But my journey from an engineer on the factory floor to a business owner has taught me that the real value of a machine is revealed over its years of operation, not on the day it's delivered. A machine that is cheap to buy but breaks down frequently, is difficult for your team to operate, or lacks modern safety features will ultimately cost you far more in downtime, repairs, and risk than you ever saved on the initial purchase. As someone who appreciates technology and smart investments, I know you understand this. A true strategic supplier doesn't just sell you a machine; they help you identify the features that will deliver lasting value and a strong return on investment (ROI).

Beyond capacity, the most critical features for long-term ROI are robust safety systems like hydraulic locks and safety fences, energy-efficient drives such as variable frequency drives (VFDs), user-friendly controls with built-in diagnostics, and features that support your digital transformation goals, like IoT sensors for predictive maintenance.

Diving Deeper into Value-Adding Features

Let's look past the spec sheet and talk about the features that directly address your goals of improving efficiency, lowering costs, and advancing your digital strategy. This is how you turn a capital expenditure into a competitive advantage.

Safety is Not an Option, It's a Prerequisite

In a modern factory, safety is paramount. An accident doesn't just harm your people; it can halt production for days, lead to investigations, and damage your company's reputation. A well-designed mold flipper should have multiple layers of safety. This includes physical barriers like safety fences with interlocked gates that stop the machine if someone enters the operating area. It also includes technologies like light curtains that create an invisible safety field. Most importantly, for heavy loads, look for redundant locking systems. A hydraulic system should have load-holding valves that prevent the table from moving even if a hose fails, backed up by a robust, automatic mechanical locking system. This isn't just about compliance; it's about protecting your team and ensuring stable, predictable operations.

The Hidden Costs of Energy

Your challenge with fluctuating energy costs is something I hear from factory owners all over the world. This is where modern drive technology can make a huge difference. A standard motor runs at full speed the moment it's turned on, causing a large inrush of current and high mechanical stress. A Variable Frequency Drive (VFD), however, allows the motor to ramp up and down smoothly. This simple change can reduce a machine's energy consumption by 20-30% or more, especially in applications with frequent starts and stops. The VFD also reduces wear and tear on gearboxes, chains, and motors, extending their service life. The small additional upfront cost for a VFD pays for itself quickly through lower electricity bills and reduced maintenance.

Embracing Industry 4.0 for Higher Uptime

Your goal to achieve 95% uptime and implement a digital strategy is exactly the right way to think. Your new mold flipper can be an active part of this strategy. Ask your supplier about adding simple, inexpensive IoT sensors to critical components. A vibration sensor on the main drive motor or a temperature sensor on the hydraulic power pack can provide a constant stream of health data. By analyzing this data, your maintenance team can move from a reactive "fix it when it breaks" model to a predictive one. They can spot a failing bearing or an overheating system weeks before it causes a catastrophic failure, allowing them to schedule maintenance during planned downtime. This is a practical, low-cost way to boost reliability and get real-time visibility into the health of your equipment.

| Feature | Initial Cost Impact | Long-Term ROI Benefit | How It Addresses Your Goals |

|---|---|---|---|

| VFD Electric Drive | +5-10% | Reduces energy cost by 20-30%; lowers mechanical stress. | Directly supports "Lower unit energy cost" (Goal 2). |

| Integrated Safety PLC | +5% | Prevents accidents, reduces risk, ensures regulatory compliance. | Protects assets and people, leading to stable production. |

| IoT-enabled Sensors | +3-7% | Enables predictive maintenance, drastically reduces unplanned downtime. | Directly supports "Improve uptime to 95%" (Goal 1) and "Digitalization" (Goal 3). |

| Remote Diagnostics | Low (often software) | Enables faster troubleshooting and reduces need for on-site service calls. | Directly supports "Reduce overall operating costs" (Goal 4). |

What are my personal insights on avoiding common purchasing mistakes?

The process of buying major industrial equipment can be a minefield. You have your engineers providing technical requirements, your finance department applying pressure on the budget, and a dozen suppliers all promising that their machine is the best. It's a difficult balancing act. Over the years, I have seen many good, smart leaders make mistakes in this process. They get lured in by an unbelievably low price, they forget to consider the total cost of ownership over the machine's life, or they fail to properly investigate the supplier they are about to partner with. These are the kinds of mistakes that can haunt a business for a decade. Because I started on the factory floor and eventually built my own successful company, I have been on both sides of this transaction. Let me share some personal insights with you—the kind of direct advice I give to my most valued clients to help them avoid these common traps.

My key insight is this: don't just buy a machine, invest in a partnership. The most common and costly mistakes are choosing a supplier based only on the initial price, failing to insist on a live demonstration with a load similar to your own, and neglecting to confirm the availability of local service and spare parts in your region.

Diving Deeper into My Personal Advice

This isn't theoretical knowledge from a textbook. This is what I learned from my own successes and failures, and from helping hundreds of clients like you.

The "Lowest Price" Trap

I remember a client who came to me after a terrible experience. He had purchased a large wrapping machine from a supplier who offered a price that was 20% lower than everyone else's. He felt like he got a great deal. But the machine was unreliable from day one. It broke down twice in the first six months, halting his entire production line for a total of five days. The cost of that lost production and the emergency repairs was more than three times what he had "saved" on the purchase price. The lesson is clear: you must look at the Total Cost of Ownership (TCO), not just the sticker price. TCO includes the purchase price, but also energy consumption, maintenance costs, spare parts, and most importantly, the cost of potential downtime. A slightly more expensive machine from a reputable manufacturer is almost always the cheaper option in the long run.

"Seeing is Believing": The Power of a Factory Acceptance Test (FAT)

You would never buy a car without test-driving it first. Why would you spend tens or hundreds of thousands of dollars on a machine without seeing it perform? I strongly urge all my clients to conduct a Factory Acceptance Test (FAT) before the machine is shipped. This means visiting the supplier's factory or arranging a detailed live video call to see your exact machine in action. Don't just let them flip a test block. If possible, ask them to use a weight and size that is similar to your own molds. Pay close attention. Does the machine run smoothly and quietly? Is there any visible vibration or straining? Are the movements precise? A FAT is your best opportunity to catch any potential issues before the machine is on a ship halfway across the world.

The After-Sales Lifeline

For an operation in Thailand, this is perhaps my most important piece of advice. The machine you buy is only as good as the support that comes with it. Before you sign any contract, you need to ask tough questions about after-sales service. Does the supplier have a local partner or service agent in Thailand or at least in the ASEAN region? How large is their spare parts inventory, and where is it located? What is their guaranteed response time if you have a critical failure? Is the machine's documentation, including electrical and hydraulic schematics, available in clear English or even Thai? A supplier who gives you vague answers to these questions is a major red flag. You are not just buying a piece of steel; you are buying a decade or more of operational uptime. You need a partner who will be there to support you.

| Vetting Criteria | What to Look For | A Major Red Flag |

|---|---|---|

| Technical Expertise | Do their salespeople listen to your needs and ask smart questions? Can they offer custom solutions? | They only push a standard catalog model without understanding your application. |

| Reference Checks | Can they provide you with contacts for other clients in your industry or region? | They are hesitant to provide references or only give you one "perfect" one. |

| After-Sales Support | Do they have a clear, documented process for service and spare parts in Thailand? | Vague promises like, "Don't worry, we'll ship parts quickly from our factory." |

| Factory Acceptance Test | Are they enthusiastic and open about you performing a FAT before shipment? | Any refusal or attempt to make it difficult for you to see your machine run. |

Conclusion

Choosing the right mold flipper is about balancing today's needs with tomorrow's growth. Focus on Total Cost of Ownership, robust safety, and a strong supplier partnership to ensure your investment pays off.