Mold Flipper: How Can Vietnam Factories Stabilize Quality During Tool Changes?

In Vietnam's booming manufacturing landscape, the pressure is on. You need to produce faster and better to stay competitive. But a hidden problem often sabotages your efforts: the tool change process. Handling heavy molds with cranes or manual force is slow and risky. It can easily cause tiny, unseen damage to your expensive tools. This damage leads directly to inconsistent product quality, frustrating production delays, and a growing pile of scrap material. This single, recurring issue can silently eat away at your profits and reputation. The solution is simpler than you think. A specialized mold flipper gives you a controlled, precise, and safe way to handle these critical assets. It eliminates the guesswork and risk, ensuring your molds are perfectly prepared every time. This leads to the stable, predictable quality your customers demand.

A mold flipper helps Vietnamese factories stabilize quality by providing a safe, controlled, and precise method for turning and positioning heavy molds. This prevents accidental damage to the mold's critical surfaces during tool changes, which is a common cause of defects and inconsistencies in the final product. It ensures the mold is always handled correctly, leading to repeatable and reliable production outcomes.

This might sound like a simple fix, but its positive impact spreads through your entire operation. It is not just about preventing a few scratches on a mold. The benefits touch everything from worker safety to your bottom line. Let's explore exactly how this equipment solves some of the most persistent challenges on the factory floor. We will look at how it improves quality, safety, and overall efficiency, which are critical for any growing factory in Vietnam.

How does a mold flipper directly prevent product defects?

You invest a lot of money in high-precision molds to make perfect parts for your customers. Yet, you still find yourself dealing with quality issues, especially right after a mold change. It is a frustrating cycle. You inspect the faulty parts and find small problems like warping, flash, or surface blemishes. The cause is often a mystery, but it frequently traces back to the mold handling process. A small knock from a crane or an unbalanced lift can be enough to damage the mold's delicate surfaces. A mold flipper is designed to solve this exact problem. It supports the mold's weight and geometry perfectly. It prevents the impacts and stresses that lead to these expensive and time-consuming product defects.

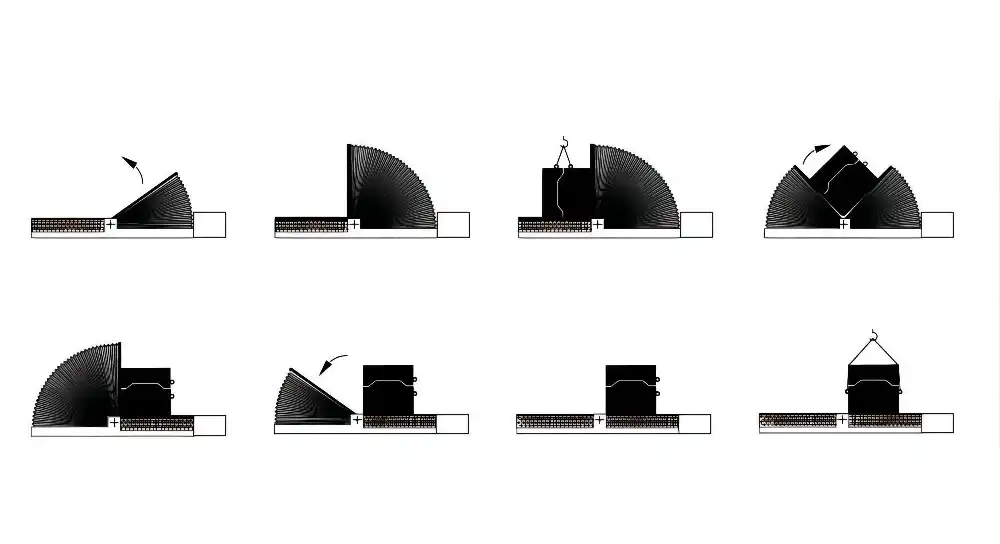

A mold flipper directly prevents product defects by eliminating the primary cause of mold damage: improper manual or crane-based handling. It ensures a smooth, stable 90-degree or 180-degree turn, protecting the delicate sealing edges, cavity surfaces, and alignment pins. This guarantees the mold maintains its precise geometry, which is essential for producing high-quality, defect-free parts consistently.

Understanding the Root Causes of Mold-Related Defects

When we talk about mold damage, we are not always talking about a catastrophic crack. The most common issues are subtle and hard to spot with the naked eye. But they have a big impact on the final product. Traditional handling methods, like using an overhead crane with chains, create multiple opportunities for this kind of damage. The swinging motion, the concentrated stress from lifting chains, and the potential for human error all contribute to the problem.

For example, a slight bump can misalign the guide pins. This prevents the two halves of the mold from closing perfectly. The result is often "flash," where excess material seeps out of the parting line, creating extra cleanup work and wasting material. Or, a chain could scratch the highly polished cavity surface. This scratch will then be transferred to every single part produced, leading to unacceptable surface finish and a high rejection rate. These are not one-time problems. They are recurring headaches that disrupt production schedules and erode profitability.

The Controlled Environment of a Mold Flipper

A mold flipper changes the entire dynamic of mold handling. Instead of lifting and swinging a heavy, unbalanced load through the air, the mold is securely placed on a stable platform. The machine then performs a smooth, controlled rotation. This process protects the most vulnerable parts of the mold.

| Feature | Crane & Chain Method | Mold Flipper Method |

|---|---|---|

| Control | Low. Relies entirely on operator skill. | High. Automated, stable, and repeatable. |

| Stress Points | Concentrated on lifting lugs or chains. | Distributed evenly across the mold's base. |

| Risk of Impact | High. Swinging loads can bump into other equipment or columns. | Virtually zero. The mold is contained within the machine's footprint. |

| Parting Line Protection | Poor. Prone to damage from uneven forces. | Excellent. The smooth rotation prevents stress on sealing edges. |

| Resulting Quality | Inconsistent. High risk of defects after each change. | Consistent. Drastically reduces mold-related defects. |

By distributing the load and controlling the movement, the flipper ensures that the mold’s precision is maintained. The alignment pins stay true, the parting lines remain crisp, and the cavity surfaces stay flawless. This directly translates to better, more consistent product quality from the very first part after a changeover. It turns a high-risk procedure into a standard, reliable operation.

Safety must be the number one priority on any factory floor. But the old way of flipping heavy molds using cranes, straps, and chains is full of risks. It is an accident waiting to happen. Every time a multi-ton mold is suspended in the air, you are counting on a chain not to break and a worker not to make a mistake. The thought of a heavy mold slipping, or an operator getting caught in a pinch point, is a constant worry for any responsible manager. A serious accident can cause devastating harm to your team. It also leads to huge production downtime, potential legal problems, and lasting damage to your company’s reputation. A mold flipper is designed to prevent these exact scenarios. It contains the entire flipping process within a robust, purpose-built machine. This removes the operator from the immediate danger zone and dramatically reduces the risk of a catastrophic accident.

The hidden safety risks of traditional mold handling in Vietnamese factories include catastrophic failure from chain or strap breakage, crush injuries from swinging or dropped molds, and operator strain from manual positioning. These methods rely heavily on operator skill and judgment, creating unpredictable and high-risk situations that a dedicated mold flipper is specifically designed to eliminate.

The "Danger Zone" and Human Element

When a mold is handled with a crane, a large "danger zone" is created around and under the suspended load. Everyone in the area is at risk. A mechanical failure, like a frayed strap snapping, can have immediate and tragic consequences. Even without equipment failure, human error is a major factor. A crane operator might misjudge the speed or path of the swing. A rigger might not secure the chains properly. The process requires several people to work in close coordination under immense pressure, which is a recipe for potential mistakes.

Furthermore, the process often requires workers to manually push or guide the mold into its final position. This puts them at high risk for crush injuries between the heavy mold and other machinery. In Vietnam, where manufacturing is growing quickly, training and safety protocols can sometimes struggle to keep pace. Relying on such a manual, high-risk process is a liability that modern factories cannot afford.

Upgrading to Modern Safety Standards

A mold flipper fundamentally changes this safety equation. It is an engineered solution that replaces improvisation with a predictable, safe process. The mold is loaded at ground level and secured to the machine's table. The operator then steps back to a safe distance and activates the machine with a simple push of a button. The entire rotation happens within the machine's strong steel frame.

This type of equipment helps Vietnamese factories meet international safety standards, such as those outlined by CE or OSHA. As Vietnam continues to integrate into the global supply chain, customers and partners will increasingly expect these high safety standards.

| Safety Factor | Crane & Chain Method | Mold Flipper Method |

|---|---|---|

| Operator Position | In the danger zone, often in direct contact with the load. | At a safe distance, using a control panel. |

| Load Security | Relies on chains/straps and balance. Prone to slipping. | Secured mechanically to a stable platform. |

| Failure Mode | Catastrophic. Dropped or swinging load. | Controlled. Mechanical or hydraulic locks prevent movement. |

| Required Personnel | Multiple workers (crane operator, riggers). | Typically one operator. |

| Compliance | Difficult to document and standardize. | Easily meets international safety regulations. |

Investing in a mold flipper is not just about protecting your employees. It is also about protecting your business. A single serious accident can lead to crippling financial costs from fines, legal fees, and lost production. By adopting safer technology, you create a more stable and secure working environment for everyone.

How does a mold flipper boost overall operational efficiency?

In any factory, time is money. Every minute that a machine is not producing is a minute of lost revenue. Mold changes are often one of the biggest production bottlenecks. The process can take much longer than necessary, tying up valuable equipment and personnel. You see your skilled technicians spending an hour or more carefully maneuvering a heavy mold with an overhead crane. This process is not only slow but also stressful and risky. This is valuable time that your team could be spending on other important tasks, like preventative maintenance or quality control. A mold flipper can solve this problem by reducing the mold changeover time by over 70%. It turns a complex, multi-person job into a quick, predictable, one-person operation. This gets your production line back up and running in a fraction of the time.

A mold flipper boosts overall operational efficiency by drastically reducing mold changeover time. It transforms a slow, labor-intensive process requiring multiple skilled workers into a fast, automated, and often one-person task. This reduction in downtime directly increases machine uptime and overall production capacity.

A Direct Comparison: Minutes vs. Hours

Let's look at the real-world difference. A traditional mold change using a crane involves many steps. You have to clear the area, fetch the right chains and straps, carefully attach them, slowly lift and flip the mold, and then meticulously position it. Each step is deliberate and slow to ensure safety. The entire process can easily take an hour or more, and it requires at least two or three skilled people.

A mold flipper streamlines this entire workflow. The mold is brought to the flipper, placed on the table, and the machine does the rest. The flip itself takes only a minute or two. The total time from start to finish is dramatically reduced.

| Task | Crane & Chains Method (Minutes) | Mold Flipper Method (Minutes) |

|---|---|---|

| Preparation | 10-15 (Clear area, find gear) | 2-3 (Move mold to flipper) |

| Lifting & Securing | 10-15 (Attach chains, check balance) | 2-3 (Secure on table) |

| The Flip/Turn | 10-20 (Slow, careful movement) | 1-2 (Automated rotation) |

| Positioning | 10-15 (Manual guidance) | 3-5 (Remove and transport) |

| Total Time | 40-65+ minutes | 8-13 minutes |

This time savings is not just a one-time benefit. It happens every single time you change a mold. If your factory performs several mold changes a day, the cumulative time saved adds up to hours of extra production capacity each week.

Unlocking Lean Manufacturing Potential

The benefits go beyond just speed. This efficiency gain is a cornerstone of lean manufacturing principles like SMED (Single-Minute Exchange of Die). The goal of SMED is to reduce changeover times to under 10 minutes. Achieving this with a crane is nearly impossible. A mold flipper is a key piece of enabling technology that makes SMED a realistic goal for factories in Vietnam.

By automating the flip, you also free up your skilled labor. The crane operator and riggers are no longer tied up for an hour on a simple mold change. They can be reallocated to more value-added activities, like performing preventative maintenance on other machines or setting up the next job. This improves your overall labor efficiency and helps you get more out of your expert team. It transforms the mold change from a major disruption into a routine, predictable part of your daily operations.

What should a Vietnamese factory owner look for when choosing a mold flipper?

You are convinced that a mold flipper is the right investment for your factory. That is a great first step. But now you face another question: how do you choose the right one? There are different models, different features, and different suppliers. Making the wrong choice can be a costly mistake. You could end up with a machine that is too small for your molds, lacks critical safety features, or comes with poor after-sales support. This can turn a potential solution into a brand new problem. To avoid this, you should focus on a few key criteria. By carefully considering capacity, safety, control systems, and supplier reliability, you can confidently select a mold flipper that will be a valuable and dependable asset for your factory for many years.

When choosing a mold flipper, a Vietnamese factory owner should prioritize four key factors: 1) Load Capacity and Table Size to safely handle their largest molds; 2) Robust Safety Features like locking mechanisms and E-stops; 3) Precise Control Systems for smooth operation; and 4) a reliable supplier offering strong local or regional support for installation, training, and maintenance.

Key Technical Specifications

First, look beyond the basic weight capacity. While you must ensure the machine can handle your heaviest mold with a safety margin, other technical details are just as important.

- Table Size and Construction: The platform, or table, must be large enough to fully support the base of your largest mold. A mold overhanging the edge is unstable and unsafe. Look for a table made from thick, heavy-duty steel plate to prevent flexing under load.

- Drive Mechanism: Mold flippers are typically powered by either a hydraulic system or an electromechanical (motor and gearbox) system. Hydraulic systems are powerful and smooth, ideal for very heavy loads. Electromechanical systems can offer excellent precision and may require less maintenance. The choice depends on your specific needs and a good supplier can advise you.

- Control System: The controls should be simple and intuitive for your operators. A basic push-button pendant is often sufficient. However, for integration into an automated line, you might need a more advanced PLC (Programmable Logic Controller) interface.

- Safety Features: This is non-negotiable. Look for features like a robust mechanical locking system that prevents the table from moving in case of a power failure. An easily accessible emergency stop (E-stop) button is essential. Physical guarding or light curtains may also be necessary depending on your factory layout and local regulations.

The Supplier as a Strategic Partner

The machine itself is only half of the equation. The supplier you choose is just as important, especially in a market like Vietnam. You are not just buying a piece of equipment; you are investing in a long-term solution.

| Criteria | What to Look For | Why It's Important for Vietnam |

|---|---|---|

| Local or Regional Support | Technicians based in Vietnam or the ASEAN region. Readily available spare parts. | Reduces downtime significantly. Overcomes language barriers and time zone differences for faster service. |

| Technical Expertise | Deep experience in your specific industry (e.g., plastic injection, die casting). Ability to customize. | They understand your challenges and can recommend the best machine configuration, not just a standard model. |

| Training & Documentation | Offers comprehensive on-site training for your operators and maintenance staff. Provides clear manuals, preferably in Vietnamese. | Ensures your team can use the machine safely and effectively from day one. Empowers your staff to handle basic troubleshooting. |

| Proven Track Record | Can provide case studies or references from other factories in the region. | Gives you confidence in their product quality and service reliability. |

A good supplier acts as a partner. They will ask questions to understand your entire process. They will help you choose the right machine and may even suggest customizations, like conveyor integration or specific table surfaces, to perfectly fit your workflow. This partnership is what turns a good machine into a great investment.

My Final Thoughts: It's Not Just a Machine, It's a Mindset

I remember my early days as an engineer working on the floor of a busy packing machine factory. I once saw a near-miss that I will never forget. A five-ton mold, swinging from an overhead crane, slipped slightly in its chains. It missed a worker by just a few inches. The silence that fell over the factory floor in that moment was deafening. That image has never left me.

When I started my own company, SHJLPACK, I didn't just want to build and sell machines. I wanted to sell real solutions to problems like the one I witnessed that day. A mold flipper is more than just a piece of fabricated steel. It represents an investment in a different way of thinking. It's about adopting a mindset that puts safety first. It's about committing to precision and operational excellence.

Vietnam's manufacturing sector is at a pivotal moment. The world is watching, and competition is fierce. To succeed on the global stage, you can no longer afford the hidden costs that come from outdated practices, poor quality, and unsafe working conditions. Installing modern equipment like a mold flipper is a powerful statement. It tells your employees that you value their safety. It tells your customers that you are serious about quality.

This is the kind of forward-thinking that helped me on my journey, allowing me to build a business and help my clients grow theirs. It's not just about the machine; it's about building a more stable, more profitable, and safer factory. And that is the knowledge I am dedicated to sharing with partners like you.

Conclusion

A mold flipper is a crucial investment for Vietnamese factories, enhancing quality, safety, and efficiency. It paves the way for sustainable growth and a strong competitive edge in the global market.