Mold Flipper: How Can Malaysian Plants Lower Changeover Time Without New Presses?

Are you watching your production schedule slip while your team struggles with a slow, cumbersome mold changeover? You see the press sitting idle, a silent monument to lost revenue. Every minute it's not running, you're not just losing output; you're losing money and falling behind competitors. You might even be thinking the only solution is a massive, expensive investment in a new, faster press. That's a huge capital commitment, and in today's volatile market, it's a risk that keeps many plant owners like you up at night.

Malaysian plants can dramatically lower changeover time without buying new presses by integrating a dedicated mold flipper into their process. This machine is designed to safely and efficiently turn heavy molds and dies, which is often the biggest bottleneck. By automating this single, critical step, you reduce manual labor, enhance safety, and get your press back online in a fraction of the time.

This might seem like a simple fix, but its impact ripples through your entire operation. I've seen it firsthand in facilities across Asia. Investing in a new press is a monumental decision, but what if you could achieve a significant boost in productivity for a fraction of the cost and disruption? A mold flipper isn't just a piece of equipment; it's a strategic tool that unlocks hidden capacity in the machinery you already own. Let's explore how this works and why it’s a game-changer for any plant focused on efficiency and profitability.

What exactly is a mold flipper and how does it slash downtime?

Do you find that your skilled technicians spend more time wrestling with cranes and chains to flip a mold than they do actually setting it up in the press? This manual process is not only slow but also incredibly risky. Every time a heavy mold is suspended in the air, you are one slip away from a catastrophic failure that could damage the mold, the press, or worse, injure an employee. This constant, low-level stress and inefficiency eats away at your plant's overall equipment effectiveness (OEE).

A mold flipper, also known as a mold tipper or upender, is a mechanical device that securely grips a mold and rotates it 90 or 180 degrees. It replaces the hazardous and time-consuming manual method of using cranes and slings. By automating the turning process, it reduces the core changeover task from hours to mere minutes, directly slashing press downtime and boosting available production time.

The Mechanics of Efficiency

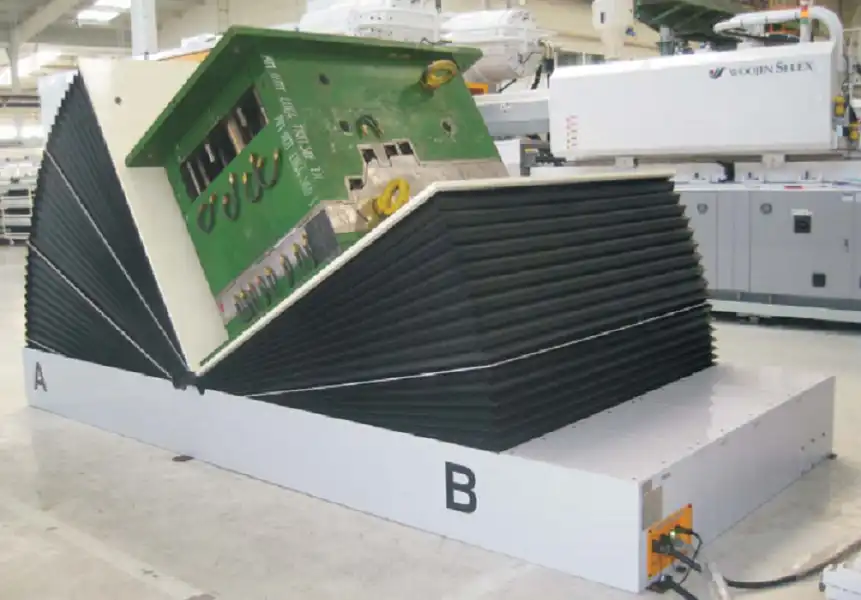

A mold flipper is deceptively simple in its function but brilliant in its design. It typically consists of two robust platforms, or tables, connected by a powerful rotating mechanism, often driven by a hydraulic or electromechanical system. The operation is straightforward:

- Loading: The mold is placed on one of the flipper's tables using a forklift or overhead crane.

- Securing: The mold is secured to the table. Some advanced systems use hydraulic clamps for faster and safer gripping.

- Flipping: The operator, standing at a safe distance, uses a control panel to initiate the flip. The machine smoothly and steadily rotates the mold to the desired orientation (typically 90° for maintenance or 180° for a complete turnover).

- Unloading: The flipped mold is then ready to be moved to the press or a maintenance station.

The entire process takes only a few minutes. Let's compare this with the traditional method.

Traditional vs. Mold Flipper Method

| Task | Traditional Method (with Crane) | Method with Mold Flipper | Time Savings & Benefits |

|---|---|---|---|

| Preparation | Clear large area, rig complex slings and chains. | Place mold on the flipper table. | Minimal prep needed. Reduced labor. |

| Lifting & Turning | Multiple crane lifts, careful manual guidance. | Single push-button operation. | Eliminates >90% of turning time. |

| Risk Profile | High risk of load slipping, swinging, or dropping. | Extremely low risk. Load is secured. | Drastically improves personnel safety. |

| Labor Required | 2-3 skilled riggers and a crane operator. | 1 operator. | Frees up skilled labor for value-added tasks. |

| Typical Time | 45 - 90 minutes. | 3 - 5 minutes. | Huge reduction in press downtime. |

As you can see, the difference is not just incremental; it is transformative. I remember a client at a stamping plant in Malaysia who was struggling to meet demands from the automotive sector. Their changeovers were taking nearly two hours. They thought they needed another press line. After we analyzed their process, we realized that 70 minutes of that time was spent just flipping and positioning the die. By installing a 180-degree mold flipper, they cut their total changeover time to under 40 minutes. They didn't need a new press; they just needed to unlock the capacity of their existing one. This is the power of targeted automation.

How does a mold flipper improve safety and reduce labor costs?

Think about the most dangerous moments on your factory floor. For many plants using heavy dies or molds, it's the moment a multi-ton piece of steel is hanging from a crane, slowly being turned by technicians using pry bars and their own strength. It's a high-stakes, high-risk procedure. An accident can lead to devastating injuries, expensive equipment damage, and a complete halt in production. You carry the financial and emotional weight of that risk every single day.

A mold flipper improves safety by creating a controlled, predictable, and fully mechanized process for turning heavy molds. It eliminates the need for personnel to work directly under or near a suspended load, drastically reducing the risk of crushing injuries. This automation, in turn, reduces the number of specialized riggers required for a changeover, directly lowering associated labor costs.

A Paradigm Shift in Workplace Safety

In my early days as an engineer, I witnessed a near-miss that I'll never forget. A sling slipped while turning a large die. The die swung violently, missing a worker by inches but crashing into a nearby support column. The cost of the die repair and structural inspection was significant, but the impact on team morale was even greater. That incident highlighted a fundamental problem: we were relying on human skill to manage an inherently unstable physical process.

A mold flipper removes this instability. The mold is securely fastened to a stable platform before any movement begins. The rotation is smooth, controlled by a system with built-in safety features like limit switches, emergency stops, and hydraulic safety valves.

Key Safety and Labor Benefits

- Elimination of Suspended Load Hazards: This is the single most important safety improvement. The risk of a dropped load, the number one cause of fatalities in crane operations, is completely removed from the turning process.

- Ergonomic Improvements: Technicians no longer need to manually push, pull, or pry heavy molds into position. This reduces the risk of strains, sprains, and other musculoskeletal injuries that accumulate over time and lead to lost workdays and compensation claims.

- Reduced Labor Dependency: A typical manual changeover requires a team: a crane operator and at least two skilled riggers on the ground. A mold flipper can be operated by a single person, often the same technician who is preparing the mold. This leads to direct cost savings.

| Cost Center | Without Mold Flipper | With Mold Flipper | Financial Impact |

|---|---|---|---|

| Direct Labor | 3 operators x 1.5 hours = 4.5 man-hours | 1 operator x 0.25 hours = 0.25 man-hours | 94% Reduction in Man-Hours per Changeover |

| Insurance Premiums | Higher premiums due to high-risk activities. | Potential for lower premiums with demonstrated risk reduction. | Long-term operational savings. |

| Accident Costs | High potential cost (medical, legal, downtime, repairs). | Negligible risk of turning-related accidents. | Mitigates huge, unpredictable financial risk. |

| Training | Requires extensive, ongoing rigger and crane safety training. | Requires minimal, one-time operator training. | Reduced training overhead and complexity. |

By investing in a mold flipper, you are not just buying a machine. You are investing in a safer work environment. This boosts morale, reduces employee turnover, and demonstrates a commitment to your team's well-being. For a leader like Javier, who understands that people are his greatest asset, this is a powerful statement. The resulting reduction in labor costs is a tangible financial benefit that makes the investment even more compelling.

What is the ROI of a mold flipper compared to a new press?

As a business owner, every investment decision comes down to the numbers. You're constantly weighing capital expenditure against potential returns. When faced with a production bottleneck, the default option often seems to be adding capacity, which in this case means a new press. But a new press is a multi-million dollar investment with a long lead time and significant installation costs. You need a solution that delivers results faster and provides a much clearer, quicker return on investment (ROI).

The ROI of a mold flipper is exceptionally high and realized much faster than that of a new press. It achieves this by unlocking productivity from an existing asset (your press) at a fraction of the cost. The payback period for a mold flipper is often measured in months, not years, driven by direct savings from reduced downtime and lower labor costs.

A Pragmatic Financial Analysis

Let's do a simplified, back-of-the-napkin calculation. This is the kind of rigorous analysis that leaders like Javier must perform for any capital request. We'll make some conservative assumptions for a typical stamping operation in a Malaysian plant.

Assumptions:

- Press Hourly Rate (Revenue + Margin): $500/hour

- Number of Changeovers per Week: 10

- Time Saved per Changeover with Flipper: 1 hour (a conservative estimate)

- Labor Savings per Changeover: 2 technicians x $20/hour x 1 hour = $40

- Cost of a Mold Flipper (installed): $50,000

- Cost of a New Press (installed): $2,000,000+

Calculating the Payback

Weekly Savings from Reduced Downtime:

10 changeovers/week 1 hour/changeover $500/hour = $5,000/week

Weekly Savings from Labor:

10 changeovers/week * $40/changeover = $400/week

Total Weekly Savings:

$5,000 + $400 = $5,400/week

Payback Period for Mold Flipper:

$50,000 (Cost) / $5,400 (Weekly Savings) = 9.25 weeks

In this scenario, the mold flipper pays for itself in less than three months. After that, it generates over $280,000 in additional profit or unlocked capacity value annually, year after year.

The Strategic Comparison

Now, let's contrast this with the investment in a new press.

| Metric | Investment in Mold Flipper | Investment in New Press |

|---|---|---|

| Capital Outlay | ~$50,000 | ~$2,000,000+ |

| Payback Period | ~3 Months | 5-10+ Years |

| Implementation Time | 1-2 weeks | 6-12 months |

| Operational Disruption | Minimal | Significant (foundation, electrical, etc.) |

| Impact | Unlocks capacity in existing asset | Adds new capacity (but doesn't fix old inefficiency) |

| Risk | Low financial and operational risk | High financial risk |

From a purely financial standpoint, the choice is clear. The mold flipper is a low-risk, high-return investment that solves a core operational problem directly. A new press is a high-risk, long-term strategic bet. For a pragmatic leader focused on optimizing current assets and controlling costs, especially in a cyclical industry like steel and manufacturing, the mold flipper is the smarter first step. It addresses the immediate challenge of improving capacity utilization and boosts the bottom line almost immediately. This is the kind of lean, intelligent investment that separates good operators from great ones.

How do you integrate a mold flipper into an existing production line?

You've seen the numbers and the safety benefits. The idea of a mold flipper makes sense. But now comes the practical question: How does this piece of equipment actually fit into my factory? Your floor space is already optimized, and your workflow is established. The thought of disrupting this delicate balance can be a major source of hesitation. You need a solution that integrates smoothly, not one that creates new problems.

Integrating a mold flipper into an existing production line is a straightforward process that involves strategic placement and workflow adjustment. It is typically installed in a dedicated mold maintenance or staging area, away from the immediate press area, to create a seamless flow: from storage, to the flipper, to the press. This minimizes disruption and requires no modification to the press itself.

A Step-by-Step Integration Plan

From my experience helping numerous plants, including many in Malaysia, the key is planning. This isn't just about dropping a machine on the floor. It's about rethinking a small part of your process to achieve a large gain. A good supplier won't just sell you a machine; they will act as a partner to ensure it works for you.

Stage 1: Layout and Flow Analysis

The first step is to map out your current mold changeover process. Where do molds come from? Where do they go for maintenance? Where are they staged before being loaded into the press? We look for a logical spot to insert the flipping process. Often, the ideal location is in the tool room or a designated mold prep area. This creates a "flipper station." The goal is to ensure that by the time a mold arrives at the press, it is already in the correct orientation and ready for installation. This decouples the time-consuming flipping process from the critical-path press downtime.

Stage 2: Siting and Installation

Mold flippers have a relatively small footprint. They require a solid, level concrete floor and an electrical connection. Unlike a new press, they don't require deep foundations or massive structural changes.

- Location: Placed near the mold storage racks.

- Foundation: Standard reinforced concrete floor is usually sufficient.

- Power: Requires a standard industrial power supply.

- Installation: Can typically be installed and commissioned in one or two days, often over a weekend to avoid any production stoppage.

Stage 3: Workflow Redesign and Training

This is the most critical part. The new workflow looks something like this:

| Old Workflow | New, Optimized Workflow |

|---|---|

| 1. Crane moves old mold from press to floor. | 1. Crane moves old mold from press to maintenance area. |

| 2. Team rigs and flips old mold (time-intensive). | 2. While press is running, new mold is moved from storage to flipper. |

| 3. Old mold moved to storage/maintenance. | 3. New mold is flipped and prepared at the flipper station. |

| 4. Team retrieves and rigs new mold. | 4. When press stops, old mold is removed. |

| 5. Team flips new mold near press (downtime). | 5. Pre-flipped new mold is moved directly into the press. |

| 6. New mold moved into the press. | 6. Press is back online. |

Notice the key difference: the flipping of the next mold happens while the press is still running the current job. This concept, known as external setup (part of the SMED - Single-Minute Exchange of Die methodology), is the secret to massive downtime reduction. Operator training is simple and focuses on the safe operation of the control panel. This is a partnership. At SHJLPACK, we don't just deliver a machine. We provide the expertise to help you analyze your layout, define the new workflow, and train your team to ensure you get the maximum benefit from day one.

Why is targeted automation the key to future-proofing your plant?

I’ve spent my entire career in the packing and machinery industry. I started on the factory floor, worked my way up to engineer, and eventually built my own company. That journey taught me a vital lesson: the most successful companies are not always the ones that make the biggest, boldest investments. They are the ones that make the smartest, most targeted improvements. In a world of tight margins and global competition, you can't afford to replace every aging machine. You have to find ways to make what you have better, faster, and safer.

Targeted automation, like using a mold flipper, is the key to future-proofing your plant because it directly attacks a specific bottleneck with a high-ROI solution. Instead of a massive, high-risk overhaul, it delivers immediate efficiency gains, improves safety, and frees up capital for other strategic initiatives like digitalization and data analysis. This philosophy of incremental, intelligent investment builds a more resilient and profitable operation.

This is more than just a business strategy; it's a mindset. When I started my own factory, SHJLPACK, I didn't have unlimited funds. I had to be strategic. I looked for the 20% of my process that was causing 80% of my problems. For many manufacturing plants, whether in Malaysia or Mexico, mold and die changeover is exactly that kind of problem.

The Modern Approach to Industrial Growth

For a leader like Javier, who has already embraced innovation by implementing a cogeneration system and a smart scheduling platform, this idea should resonate deeply. It aligns perfectly with a modern, data-driven approach to manufacturing.

- Solving the Right Problem: A new press doesn't solve the problem of an inefficient changeover process. In fact, it can amplify it, as the pressure to keep the more expensive machine running is even higher. A mold flipper solves the actual problem: the time and risk associated with turning the mold.

- Alignment with Lean Principles: This approach is the essence of Lean Manufacturing. It's about identifying and eliminating "muda" (waste). The time your press sits idle during a manual flip is pure waste. The excess motion and risk are waste. A mold flipper surgically removes that waste.

- Enabling Digital Transformation: Every dollar you don't spend on a new press is a dollar you can invest in your digital future. Think MES implementation, IoT sensors for predictive maintenance, or big data analytics to optimize your entire supply chain. Targeted automation clears the path for these higher-level, future-proofing investments.

I built my business and achieved financial independence by applying this principle. I helped my clients grow by showing them how to find these high-impact opportunities. Now, through SHJLPACK, my mission is to share this knowledge. Don't get trapped in the thinking that bigger is always better. The future belongs to the operators who are smart, lean, and targeted in how they deploy their capital and technology. A mold flipper is a perfect example of this philosophy in action.

Conclusion

Stop focusing on massive press overhauls. A mold flipper is a smarter investment that offers a faster, safer, and more profitable way to boost your plant's operational efficiency.