Mold flipper: can modular designs support fast growth in the Kingdom?

Rapid industrial growth, like we're seeing in the Kingdom of Saudi Arabia, presents a huge opportunity. But it also creates a massive challenge. You need to scale up your operations quickly to meet demand. This often means investing in new, heavy-duty equipment. The problem is, traditional monolithic machinery is a huge, risky bet. You could invest millions in a machine designed for today's capacity, only to find it's a bottleneck tomorrow. Or worse, your market shifts, and you're left with an oversized, underutilized asset that drains your cash flow. It's a high-stakes decision that keeps many factory owners like you awake at night. The solution lies in a smarter, more flexible approach to equipment design. It involves thinking not in terms of single, giant machines, but in adaptable, scalable systems.

Yes, modular designs for mold flippers can absolutely support fast growth in the Kingdom, or any rapidly expanding industrial market. The core advantage is flexibility. Instead of a single, custom-built unit, a modular system allows you to purchase the capacity you need today and easily add new modules to scale up as your production demands increase. This approach fundamentally de-risks capital investment, shortens delivery times, and creates a more agile manufacturing floor ready for the future.

This might sound like a simple change, but its impact on your business strategy is profound. As an engineer and a factory owner myself, I've seen firsthand how the right equipment philosophy can make or break a company during a growth phase. It’s about more than just flipping molds; it's about building a resilient operation. Let's dig deeper into how this modular approach works in the real world and what it means for a leader like you, who needs to make smart, forward-thinking investments. We'll look at the specific benefits, from initial cost to long-term maintenance and integration with your digital factory goals.

How does modularity in mold flippers reduce initial investment risk?

As a business owner, every major capital expenditure comes under intense scrutiny. You're constantly weighing the potential return against the risk. The biggest fear is sinking a huge amount of capital into a piece of equipment that doesn't deliver. A massive, custom-built mold flipper designed for your peak future capacity is a perfect example of this high-risk scenario. If the market shifts or your growth trajectory changes, you're stuck with an expensive machine that isn't pulling its weight. This is a situation I've seen paralyze even the most successful entrepreneurs. But what if you could align your investment directly with your current, proven needs, while keeping the door open for future expansion? This is the financial power of a modular approach. It allows you to start smaller and grow smarter.

A modular mold flipper significantly reduces initial investment risk by allowing you to purchase only the capacity and features you currently need. This lowers the upfront capital required, leading to a faster return on investment. As your business grows, you can add more modules to increase capacity or add functionality, ensuring your equipment scales precisely with your revenue and production demands. This pay-as-you-grow model transforms a large, risky capital expenditure into a series of smaller, manageable, and justifiable investments.

Breaking Down the Financials

When you, as a CEO like Javier, perform a feasibility analysis, the initial outlay is a critical variable. A monolithic machine forces you to pay for 100% of your projected future capacity on day one. A modular system changes this equation entirely.

Let's imagine you need to handle molds up to 50 tons now, but you project a need for 100-ton capacity in three years.

- Monolithic Approach: You must buy the 100-ton machine today. The structural frame, the power unit, the control system—everything is built for the maximum load. You are paying for capacity that will sit idle for years. Your initial ROI calculation is burdened by this unused potential.

- Modular Approach: You buy a 50-ton base unit. This unit is designed with standardized connection points. The frame, hydraulics, and electrical systems are sufficient for your current needs. The initial cost is substantially lower. Three years later, when your business has grown and you have the contracts to justify it, you purchase a supplementary module. This could be a reinforced support structure or an additional power pack that integrates seamlessly with your existing unit to achieve the 100-ton capacity.

This staged investment has a huge impact on your cash flow and risk profile. I learned this the hard way when I was starting my own factory. Early on, I over-invested in a large machine, and the monthly payments were a heavy burden before we had the sales to support it. It taught me a valuable lesson: preserve cash and invest in line with revenue.

The Hidden Cost of Oversizing

Beyond the initial price tag, an oversized machine carries hidden operational costs. A hydraulic system designed for 100 tons running at 50-ton loads is often less energy-efficient. It's like using a massive truck to deliver a small box; you're burning more fuel than necessary. This directly impacts your challenge with fluctuating energy costs. A modular system, scaled appropriately, operates closer to its peak efficiency range, helping you achieve your goal of reducing unit energy consumption.

| Feature | Monolithic Design | Modular Design |

|---|---|---|

| Initial Investment | High (Pays for future capacity upfront) | Low (Pays for current needs only) |

| ROI Calculation | Slower, burdened by unused capacity | Faster, based on immediate utilization |

| Financial Risk | High (Large single point of failure) | Low (Staged, justifiable investments) |

| Energy Efficiency | Potentially low when underutilized | High (Sized for current workload) |

| Adaptability | Low (Fixed capacity and function) | High (Can be expanded or reconfigured) |

For a leader focused on stability and profitability, the modular approach offers a more rational, defensible investment strategy. It aligns your spending with your success, which is a powerful principle for any business.

Can a modular mold flipper truly scale with unpredictable market demands?

The steel industry is cyclical. You know this better than anyone. One year, the automotive and construction sectors are booming, and you can't produce fast enough. The next, demand softens, and you have to manage capacity carefully. This volatility makes long-term production planning incredibly difficult. If you invest in fixed-capacity equipment, you're constantly caught in a difficult position. In boom times, your machine becomes a bottleneck, limiting your revenue potential. In slow times, it's an underutilized asset, hurting your efficiency metrics. This is a major source of stress for factory owners. The ideal solution would be equipment that can breathe with the market—expanding and contracting as your needs change.

Yes, a modular mold flipper is specifically designed to scale with unpredictable market demands. Its fundamental design principle is adaptability. You can quickly add or even reconfigure modules to increase throughput during peak periods. Conversely, if a specific production line is temporarily idled, a module could potentially be reassigned. This gives you a level of operational elasticity that is impossible to achieve with a single, monolithic machine, helping you maintain balance and profitability through market cycles.

From Bottleneck to Agile Asset

Let's think about your goal to increase产能利用率 (capacity utilization) to 95%. With a traditional, single machine, your entire line's speed is dictated by that one piece of equipment. If your mold flipping and maintenance process is slower than your production line, you have a permanent bottleneck.

A modular system offers a different path.

- Scaling Up: Imagine your smart scheduling platform identifies a sustained increase in demand for a particular product line. With a modular system, you don't have to wait 12-18 months for a whole new machine. You can order a pre-engineered, standardized module. The lead time is shorter, and installation is much faster because it's designed to connect to your existing setup. You could add a second, parallel flipping station or upgrade a component to increase cycle speed. This allows your packaging and handling capacity to grow alongside your production.

- Scaling Down or Reconfiguring: Market demand is not just about volume; it's also about product mix. Let's say demand shifts from large molds to a higher quantity of smaller molds. A large, slow, 150-ton flipper is inefficient for this new workflow. A modular system offers the potential for reconfiguration. You might be able to split a large system into two smaller, independent stations to handle the higher volume of smaller parts, dramatically improving throughput and efficiency. This adaptability ensures your equipment continues to serve your strategy, not dictate it.

A Personal Story of Adaptability

I once worked with a client in the automotive stamping industry. They bought a large, 100-ton die splitter from a competitor. It was a beautiful, massive machine. Two years later, their biggest contract changed, and their new primary product required splitting dies that were only 20 tons, but they had to do it three times as often. Their giant machine was too slow and costly to run for these smaller jobs. It became the single biggest bottleneck in their plant. They eventually had to buy a second, smaller machine, and the big one sat idle most of the time.

This is the exact trap that a modular philosophy helps you avoid. It acknowledges that we cannot predict the future with perfect accuracy. Therefore, we must build systems that allow us to react to the future as it unfolds. For a steel mill owner like Javier, who has to navigate the cycles of global commodity markets, this kind of operational agility is not a luxury; it's a core component of long-term survival and success.

What are the long-term maintenance and operational advantages of a modular system?

As your equipment ages, the problems compound. You know the story well:故障率 (failure rates) climb, finding spare parts for a 15-year-old machine becomes a treasure hunt, and maintenance downtime starts eating into your production schedule. This is a huge issue when your equipment is the heart of a key production line. A single, critical failure on a monolithic machine can shut everything down for days, or even weeks. It hurts your output, damages your reputation with customers, and drives your maintenance team crazy. The goal is to move from this reactive firefighting to a proactive, predictable maintenance strategy. A modular design is a powerful enabler of this shift.

The long-term maintenance and operational advantages of a modular system are significant. Because modules are standardized, spare parts are more readily available and interchangeable, reducing inventory costs and sourcing headaches. Troubleshooting is faster because you can isolate problems to a specific module. It's even possible to swap out a faulty module with a spare for near-zero downtime, repairing the original module offline. This dramatically improves equipment availability and supports predictive maintenance goals.

A Revolution in Maintenance Strategy

Your goal of implementing predictive maintenance and achieving 95% equipment uptime requires a new way of thinking about machine design. Modular systems are inherently more compatible with this goal than their monolithic counterparts.

Standardized Components and Spares

When I design a modular system, I rely on standardized components. The hydraulic power pack for a 50-ton module is the same unit used in other systems. The motors, gearboxes, bearings, and electrical connectors are common parts, not one-of-a-kind custom fabrications.

- For you, the factory owner: This means you don't need a massive, expensive warehouse of unique spare parts for one machine. You can keep a smaller inventory of common spares that service multiple modules, or even multiple machines. This lowers your carrying costs and reduces the financial risk of obsolete inventory.

- For your maintenance team: When a component fails, they know they have the part on hand. They aren't wasting hours or days trying to source a rare part from a supplier who may not even exist anymore. This dramatically reduces Mean Time to Repair (MTTR).

Faster Troubleshooting and Repair

Think about a complex electrical fault in a giant, custom-wired machine. Your technicians might spend a full day just tracing wires to identify the source of the problem. In a modular system, the machine is divided into logical blocks.

| Aspect | Monolithic Machine | Modular Machine |

|---|---|---|

| Troubleshooting | Complex, time-consuming. One fault can hide another. | Simplified. Isolate the problem to a specific module. |

| Repair Strategy | Repair in place. The entire line is down. | Swap module. Repair offline while production continues. |

| Spare Parts | Custom, expensive, long lead times. | Standardized, interchangeable, readily available. |

| Technician Training | Requires deep knowledge of one complex machine. | Simpler. Train on standard modules. |

| Uptime | Lower, vulnerable to single-point failures. | Higher, enabled by redundancy and quick swaps. |

If the drive system on Module B is acting up, you can focus all your diagnostic efforts on that self-contained unit. The inputs and outputs are clearly defined. In the best-case scenario, you can simply disconnect the faulty module, slide in a spare service module, and have the line back up and running in under an hour. This is the holy grail for any plant manager aiming for 95% uptime. It turns a catastrophic line-down event into a scheduled, manageable maintenance task. This is the practical path to achieving your operational stability goals.

How does a modular design integrate with a broader digitalization strategy?

You have an ambitious and very smart goal: deploying MES, IoT sensors, and data analytics to create a fully transparent production environment. This is the future of manufacturing. However, a huge obstacle is often the equipment itself. Older, monolithic machines are "black boxes." They do their job, but they don't communicate. Trying to retrofit them with sensors and connect them to a central system can be a nightmare of custom programming, incompatible protocols, and unreliable data. You might get some information, but it's often incomplete. This can stall your entire digital transformation project. To truly succeed, you need equipment that is designed from the ground up to be part of a connected ecosystem.

A modular design is a natural fit for a digital strategy because each module is a self-contained, intelligent unit. It's designed with standardized data interfaces, making it simple to "plug and play" into your factory's IoT network and MES. Instead of trying to decipher one massive, complex machine, you're collecting clean, targeted data from each module—motor performance, hydraulic pressure, cycle times, and energy use. This granular data is the fuel for the advanced analytics and predictive maintenance you want to implement.

Building the "Digital Twin" Block by Block

The concept of a "digital twin"—a virtual model of your physical operations—is a powerful one. It allows you to simulate changes, predict failures, and optimize performance. Building a digital twin of a monolithic machine is difficult. Building one for a modular system is much more straightforward.

Each module comes with its own well-defined digital profile.

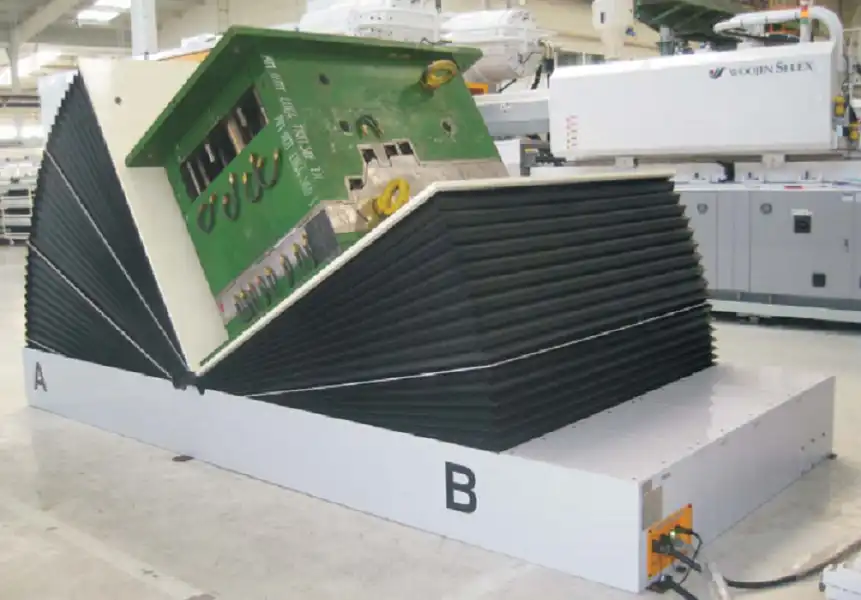

- Module A: The Power Unit. Its digital profile includes data points for motor amperage, oil temperature, pressure levels, and filter status.

- Module B: The Tilting Frame. Its profile includes data from position sensors, load cells to measure weight, and vibration sensors on the main bearings.

- Module C: The Control System. This is the hub that gathers data from other modules and communicates with your factory-level MES.

Because these are standardized, connecting them to your network is not a custom engineering project. It's a configuration task. This drastically lowers the cost and time required for integration. As a supplier, when we provide a modular machine, we can also provide a "digital information packet" for each module. This packet tells your IT and engineering teams exactly what data points are available and how to access them.

From Data Collection to Actionable Intelligence

Your goal isn't just to collect data; it's to use it to lower costs and improve efficiency. With the clean, granular data from a modular system, your analytics platform can start delivering real value.

- Predictive Maintenance: The system can learn the normal vibration signature of a bearing on the tilting frame. When it detects a deviation, it can automatically create a work order in your MES to inspect that specific bearing on that specific module, long before it fails.

- Energy Optimization: By analyzing data from each module's power consumption, you can identify which phases of the operation use the most energy. This allows you to fine-tune the process to meet your goal of a 10% reduction in unit energy consumption.

- Performance Tracking: You can track the cycle time of each module independently. If one starts to slow down, you know exactly where to look. This helps you maintain the high throughput needed to keep your overall capacity utilization above 95%.

In my experience, companies that succeed with digitalization are the ones that choose equipment that is built for it. Trying to force old, analog machines into a digital world is a recipe for frustration. A modular approach provides the smart, connected foundation you need to build the factory of the future.

What's my take as an engineer and factory owner?

You hear a lot of buzzwords in our industry. "Modular," "digital," "smart." It's easy for suppliers to make promises. But as someone who has been on both sides—designing the machines and also paying the bills to run a factory—you learn to separate the marketing hype from the practical reality. You face the real-world pressures of making payroll, managing fluctuating costs, and answering to a board or to yourself about the wisdom of your investments. So you don't need another sales pitch. You need to know if this modular concept actually works when the pressure is on.

My core insight is that modularity is not just a design philosophy; it is a business strategy. It aligns your capital expenditure directly with your operational needs and your revenue growth. This creates a more resilient, flexible, and financially sound manufacturing environment. It's about moving away from making huge, risky bets on the future and instead building the capacity to adapt and win in whatever future comes.

The Journey from Engineer to Owner

When I started as an engineer in a packing machine factory, my job was to solve technical problems. I focused on making the machine strong, reliable, and efficient. I didn't think much about the cost beyond the bill of materials. But when I started my own factory, SHJLPACK, my perspective changed completely. Suddenly, cash flow was king. The money I spent on a new machine was money I couldn't spend on raw materials, marketing, or hiring another salesperson.

I quickly realized that the most "technically perfect" machine could be the wrong business decision if it was too expensive or inflexible. This is where my passion for modular design was born. It came from my own need to grow my business without taking on crippling financial risks. I needed equipment that could grow with me. I needed to be able to start with a solution for my first few customers and then add capacity as my reputation and order book grew. This isn't just a theory for me; it's the story of my own company.

More Than a Supplier, a Partner

This personal journey is why I believe so strongly in being more than just a supplier. A supplier sells you a machine. A partner understands your challenges—like managing energy costs and dealing with aging equipment—and helps you find a strategic solution.

For a leader like you, Javier, who has built a 2-million-ton steel mill from the ground up, you appreciate the difference. You are looking for people who understand the bigger picture. A modular equipment strategy is a conversation about your business goals, not just machine specifications.

- It's a conversation about risk management: How can we structure this investment to protect your cash flow?

- It's a conversation about operational excellence: How will this design help your team achieve 95% uptime and lower energy use?

- It's a conversation about future-proofing: How can we ensure the machine we build today will support your digital transformation goals in three years?

Choosing a modular path is choosing agility. In a world of volatile markets and rapid technological change, the ability to adapt is the single most important competitive advantage.

Conclusion

Modular mold flippers are not just equipment. They are a strategic asset, enabling agile growth and long-term operational stability for ambitious leaders in demanding industries like steel manufacturing.