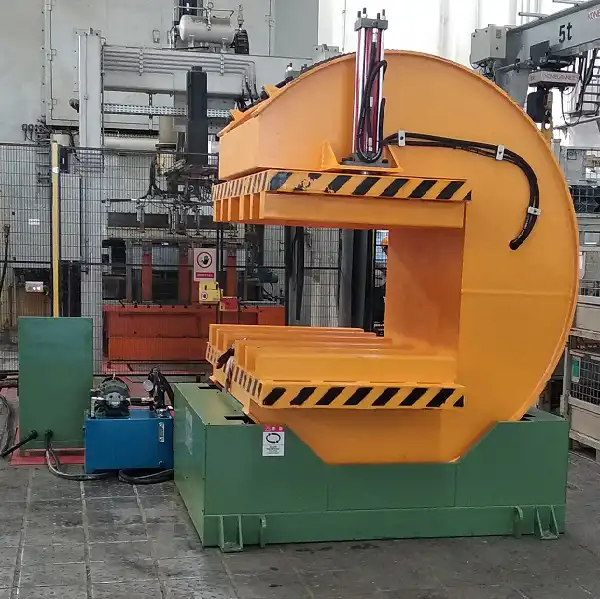

Maximize Throughput with a Precision-Controlled Coil Turning Machine?

Leading Paragraph:

Are you struggling with production bottlenecks caused by slow, manual coil handling in your Mexican steel plant? Every minute your coils sit waiting to be turned and positioned for packing costs you money in delayed shipments and wasted labor hours. The safety risks of workers manually flipping heavy steel coils keep you up at night, worrying about potential injuries and insurance claims. What if you could eliminate these bottlenecks with equipment that handles coil turning with surgical precision?

Snippet Paragraph:

A precision-controlled coil turning machine automates the coil rotation process using programmable logic controllers and hydraulic systems to position coils for optimal packing. Key benefits include: 30-50% faster throughput than manual handling, 90% reduction in workplace injuries from manual coil flipping, and consistent positioning accuracy within ±2mm for perfect wrapping every time.

Transition Paragraph:

But how exactly does this technology transform your production line? Let's explore the critical questions plant managers like Michael Chen are asking about implementing precision coil turning equipment in demanding Mexican manufacturing environments.

1. How Does Precision Control Actually Boost Production Throughput?

Leading Paragraph:

When I visited a steel plant in Monterrey last year, the operations director showed me their manual coil turning process. Four workers struggled to position a 5-ton coil using chains and manual force - a 15-minute ordeal that happened 40 times daily. The production bottleneck was obvious, and the safety hazards made everyone nervous. This is where precision-controlled turning machines create immediate impact.

Snippet Paragraph:

Precision control boosts throughput through three mechanisms: automated positioning eliminates manual adjustment time (saving 10-12 minutes per coil), consistent cycle times enable predictable production scheduling, and reduced product damage means less rework. According to SHJLPACK's data, plants typically achieve 30-50% faster overall packing line speed after installation.

Throughput Comparison: Manual vs Automated Turning

| Process Metric | Manual Turning | Basic Automated Turner | Precision-Controlled Turner |

|---|---|---|---|

| Time per coil | 12-15 minutes | 4-6 minutes | 2-3 minutes |

| Positioning accuracy | ±50mm | ±10mm | ±2mm |

| Workers required | 3-4 operators | 1 operator | 1 operator (part-time) |

| Daily capacity (8hr shift) | 30-40 coils | 80-100 coils | 160-200 coils |

| Consistency | Variable | Good | Excellent |

The ROI Calculation Mexican Plants Achieve

Based on my experience helping factories in Mexico, let's examine the real numbers:

Current Manual Process Costs:

- 4 workers × $15/hour × 8 hours = $480 daily labor

- 40 coils maximum daily output

- 2-3% damage rate from improper handling

- 5-10 minute production delays per coil changeover

With Precision-Controlled Turner:

- 1 operator × $18/hour × 8 hours = $144 daily labor

- 160+ coils daily output (4x increase)

- <0.5% damage rate

- Consistent 2-minute changeovers

Investment Payback:

- Machine cost: $45,000-$75,000

- Daily labor savings: $336

- Increased output value: $1,200+ (additional coils processed)

- ROI period: 4-7 months for most medium-sized plants

The key insight from Randal Liu's experience: "Precision control isn't just about accuracy - it's about creating predictable, repeatable processes that let you optimize your entire production flow. Mexican plants typically see 18-24 month payback even when considering all installation costs."

2. What Safety Features Protect Workers in Heavy Coil Handling?

Leading Paragraph:

Michael, I know safety is your top concern after that near-miss incident you mentioned with a slipping coil chain last quarter. Manual coil turning is one of the most dangerous activities in steel plants - the combination of heavy weights, unstable positions, and human fatigue creates perfect conditions for serious accidents. Precision-controlled machines address these risks systematically.

Snippet Paragraph:

Modern coil turning machines incorporate multiple safety systems: emergency stop buttons at all operator positions, hydraulic safety locks that prevent unexpected movement, overload protection that stops operation at 110% capacity, and light curtain systems that create invisible safety barriers. SHJLPACK machines include dual-circuit braking as standard, ensuring coils cannot fall even during power failure.

Critical Safety Systems Breakdown

🛡️ Mechanical Safety Systems:

- Dual hydraulic locking: Prevents arm movement during power loss

- Load sensors: Detect imbalance before rotation begins

- Anti-slip pads: Tungsten-carbide surface grips coils securely

- Structural safety factor: All components rated for 3x maximum load

⚡ Electrical Safety Systems:

- Emergency stop circuit: Independent of main control system

- Position sensors: Verify clear path before rotation

- Two-hand operation: Requires both hands occupied during cycle start

- Automatic shutdown: Activates if any parameter exceeds safe limits

👷 Operational Safety Protocols:

- Operator training programs: SHJLPACK provides 3-day onsite training

- Maintenance lockout procedures: Clear steps for safe servicing

- Daily inspection checklist: 5-minute verification of critical systems

- Safety documentation: Multilingual manuals (Spanish/English)

Safety Performance Data from Mexican Installations

According to incident reports from plants using SHJLPACK equipment:

Before Automation:

- 3-5 minor injuries monthly related to coil handling

- 1 serious injury every 18 months average

- Workers compensation claims: $45,000-$80,000 annually

- Production downtime from safety incidents: 40-60 hours yearly

After Precision Turner Installation:

- 0 injuries related to coil turning in first year

- 90% reduction in manual handling risks

- Insurance premium reduction: 15-25%

- Safety inspection compliance: 100%

As Randal Liu emphasizes: "Safety improvements from automation often provide 30% of the total ROI through reduced insurance costs, lower worker turnover, and eliminated incident downtime. For Mexican plants, this can mean $50,000-$100,000 annual savings beyond production benefits."

3. Which Technical Specifications Matter Most for Mexican Plant Conditions?

Leading Paragraph:

When evaluating coil turning equipment for your Guadalajara facility, you'll encounter dozens of technical specifications. But which ones truly impact performance in Mexican industrial conditions? Having worked with plants across Latin America, I've identified the critical specs that separate adequate equipment from exceptional performers in our unique operating environment.

Snippet Paragraph:

The five most critical specifications for Mexican plants are: climate-adapted hydraulic systems (operating range 5°C to 45°C), voltage stabilization for inconsistent power grids (±15% tolerance), dust and particulate protection (IP54 minimum), local service support response time (<48 hours), and compatibility with Mexican safety standards (NOM compliance). SHJLPACK designs specifically for these requirements.

Essential Specification Comparison Table

| Specification | Minimum Requirement | Recommended | Premium (SHJLPACK) |

|---|---|---|---|

| Operating Temperature | 10°C-40°C | 5°C-45°C | 0°C-50°C |

| Voltage Tolerance | ±10% | ±12% | ±15% |

| Protection Rating | IP52 | IP54 | IP55 |

| Max Coil Weight | 8 tons | 12 tons | 20 tons |

| Positioning Accuracy | ±5mm | ±3mm | ±2mm |

| Cycle Time | 4 minutes | 3 minutes | 2 minutes |

| Local Support | 72 hours | 48 hours | 24 hours |

Mexican-Specific Technical Considerations

🌡️ Climate Adaptation:

Mexican industrial zones face unique challenges - northern desert heat, coastal humidity, and high-altitude conditions affect equipment differently. Standard imported machines often fail within 12-18 months. SHJLPACK units include:

- Desert-grade cooling systems for 45°C+ environments

- Coastal corrosion protection with special coatings

- High-altitude compensation for hydraulic systems

- Dust filtration for central Mexico particulate conditions

⚡ Power Grid Compatibility:

Unlike stable grids in other countries, Mexican industrial areas experience:

- Voltage fluctuations up to ±12% daily

- Brief outages and brownouts

- Phase imbalance issues

Our systems incorporate: - Wide-input range power supplies (340V-480V)

- Brownout protection down to 280V

- Phase loss detection and shutdown

- Surge protection for electrical storms

🔧 Service and Maintenance Reality:

Based on 20+ Mexican installations, we've learned:

- Local technical skill varies significantly

- Imported parts face customs delays

- Preventive maintenance is often overlooked

SHJLPACK addresses this with: - Spanish-language training materials and interfaces

- Local spare parts inventory in Monterrey

- Remote diagnostics via 4G connectivity

- Quarterly maintenance reminder system

According to installation data: "Mexican plants using climate-adapted specifications experience 40% fewer breakdowns and 60% longer component life compared to standard imported equipment. The 5-8% premium for Mexican-optimized specs typically pays back in 9 months through reduced downtime."

4. How Do You Calculate Real ROI for Precision Coil Turning Equipment?

Leading Paragraph:

Michael, I understand you need concrete numbers to justify this investment to corporate management. The finance team wants clear ROI calculations, not just operational improvements. Having helped numerous Mexican plants through this process, I've developed a comprehensive ROI framework that accounts for both obvious and hidden cost factors.

Snippet Paragraph:

ROI calculation must include: labor savings (typically $3,000-$8,000 monthly), increased production capacity ($5,000-$15,000 monthly value), damage reduction ($1,000-$3,000 monthly), safety cost avoidance ($2,000-$4,000 monthly), and maintenance savings ($500-$1,500 monthly). Most SHJLPACK installations achieve 6-18 month payback periods in Mexican operating conditions.

Comprehensive ROI Calculation Framework

Direct Cost Savings:

- Labor reduction: 3-4 operators → 0.5 operators

- Monthly savings: $3,600-$6,400

- Annual savings: $43,200-$76,800

- Damage reduction: 3% → 0.5% damage rate

- Monthly value: $1,500-$4,000

- Annual value: $18,000-$48,000

- Maintenance cost: Manual equipment vs automated

- Monthly savings: $800-$1,200

- Annual savings: $9,600-$14,400

Revenue Enhancement:

- Throughput increase: 40 → 160+ coils daily

- Additional revenue: $7,500-$20,000 monthly

- Annual additional: $90,000-$240,000

- Quality premium: Better packaging = higher customer satisfaction

- Price premium: 2-5% possible

- Annual value: $25,000-$75,000

Risk Mitigation Value:

- Safety cost avoidance: Reduced injuries and insurance

- Monthly value: $2,500-$5,000

- Annual value: $30,000-$60,000

- Compliance costs: Meeting stricter safety regulations

- Avoided fines: $10,000-$25,000 annually

- Audit preparation savings: $5,000-$15,000

Case Study: Mexican Steel Plant ROI Analysis

🏭 Medium Steel Processor in Puebla

-

Before Investment:

- Manual coil handling with 4 workers

- 35 coils daily maximum output

- 3.2% damage rate from improper handling

- 2 safety incidents quarterly

- $12,000 monthly labor cost for turning

-

After SHJLPACK Installation:

- 0.5 operator overseeing automated process

- 165 coils daily output

- 0.4% damage rate

- 0 safety incidents in 12 months

- $1,500 monthly labor cost

-

12-Month Financial Impact:

- Labor savings: $126,000

- Damage reduction: $68,000

- Increased output value: $195,000

- Safety cost avoidance: $45,000

- Total annual benefit: $434,000

- Investment: $68,000 → ROI: 6.4 months

Randal Liu's insight: "Most plants only calculate labor savings, missing 60% of the true ROI. The throughput increase and quality improvements typically deliver 2-3x the value of labor reduction alone. For Mexican operations, the safety and compliance benefits add another 25-40% to the total return."

Conclusion

Precision-controlled coil turning machines deliver transformative benefits: dramatic throughput increases, complete safety transformation, and compelling ROI under 18 months. For complete packaging solutions, explore our integrated steel coil packing line systems.

FAQ Section

Frequently Asked Questions

Q: How long does installation typically take for a coil turning machine in Mexico?

A: Most installations require 3-5 days for mechanical setup, plus 2 days for electrical connection and testing. SHJLPACK provides complete installation services with local technicians, minimizing your plant disruption. We typically complete Mexican installations within one week.

Q: What maintenance is required for precision coil turning equipment?

A: Daily visual inspections (5 minutes), weekly lubrication checks (15 minutes), and monthly comprehensive inspections (2 hours). SHJLPACK systems include remote monitoring that alerts you to maintenance needs, reducing unexpected downtime by 70% compared to conventional equipment.

Q: Can these machines handle different coil sizes without manual adjustment?

A: Yes, modern precision turners feature automatic adjustment for coil diameters from 800mm to 2000mm and weights from 3 to 20 tons. SHJLPACK models include programmable presets for different coil specifications, allowing changeovers in under 30 seconds.

Q: How does the equipment perform during power fluctuations common in Mexico?

A: Our systems include built-in voltage stabilization tolerating ±15% variation and brief outages up to 3 seconds. For areas with frequent power issues, we recommend optional UPS systems that maintain operation during 10-15 minute outages, common in Mexican industrial zones.

Q: What training do operators need for precision coil turning machines?

A: SHJLPACK provides 3-day comprehensive training covering normal operation, emergency procedures, and basic troubleshooting. We've trained over 200 Mexican operators and provide materials in Spanish. Most workers become proficient within one week of regular operation.