Your slitting line runs at top speed, and your rolling mill produces perfect steel coils. But then everything grinds to a halt at the end of the line. Coils pile up, waiting for manual wrapping and labeling. This final, crucial step has become your biggest bottleneck, causing shipping delays, risking product damage, and frustrating your team. You know there has to be a better way to protect your high-quality products and get them out the door faster. The solution lies in integrating your packaging and labeling directly into your production flow, transforming this chaotic endpoint into a streamlined, automated, and efficient process.

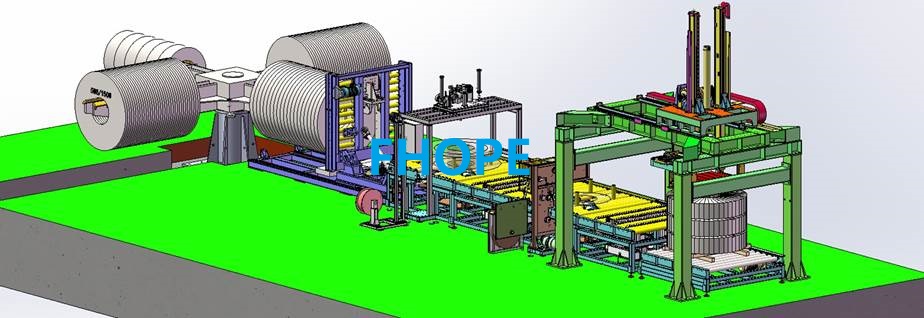

Inline coil packaging and labeling systems provide a smart solution by seamlessly integrating the final packaging stage with your production line's output. These automated systems use a series of conveyors, wrappers, and applicators to handle, wrap, and label coils without manual intervention. This eliminates production bottlenecks, dramatically improves worker safety, ensures consistent packaging quality for every coil, and provides perfect data for traceability, ultimately boosting the entire plant's efficiency and throughput.

I’ve spent my entire career in the packing machine industry, first as an engineer on the factory floor and now as the owner of my own company. I’ve walked through countless steel mills, from small service centers to massive integrated plants. I've seen firsthand how a small inefficiency in packaging can have a huge ripple effect across the entire operation. It's a common story. But I've also seen the incredible transformation that happens when a mill invests in the right automated solution. Let's break down the common questions I hear from owners and managers who are ready to solve this problem for good, especially in a dynamic and competitive market like Turkey.

How Can Integrated Packaging Lines Solve Bottlenecks in Turkish Steel Mills?

Do you see finished coils stacking up on the floor, waiting for the packaging team to catch up? This familiar scene isn't just untidy; it's a major roadblock that stalls your entire production flow. This backlog creates a logistical nightmare, increasing the risk of coil damage, creating safety hazards, and causing expensive delays in shipments. An integrated packaging line acts as a smooth, continuous extension of your production line. It takes coils as soon as they are ready and gets them packaged and prepared for shipping, completely eliminating that final bottleneck.

Integrated packaging lines solve bottlenecks by perfectly matching the packaging speed to the output of your slitting or rolling line. They use automated conveyors, turnstiles, and wrapping stations to move and process coils continuously. This removes the need for stop-gap storage areas and eliminates the slow, dangerous process of moving coils with cranes for packaging. The result is a smooth, uninterrupted workflow from production to dispatch.

The Anatomy of a Bottleneck: From Manual Chaos to Automated Flow

To really understand the impact, let's look at the two processes side-by-side. The old, manual way creates multiple points of failure and delay. An automated line turns it into a single, streamlined operation.

The Old Way: Manual Packaging

- Wait for Crane: The slitting line operator finishes a set of coils. Now, everyone waits for an overhead crane to become available.

- Transport to Staging Area: The crane operator carefully lifts the coils and moves them to a designated (and often crowded) packaging area. This is a slow process filled with safety risks.

- Manual Handling: A team of workers uses strapping tools, pushes large rolls of wrapping material, and manually applies everything. The quality can be inconsistent.

- Wait for Removal: Once packaged, the coils wait again for a forklift or crane to move them to the warehouse or loading dock.

The New Way: Integrated Inline Packaging

- Automatic Transfer: As a coil comes off the slitter's turnstile or coil car, it moves directly onto the packaging line's in-feed conveyor. No waiting.

- Automated Processing: The coil travels through stations that automatically center it, apply circumferential and radial straps, wrap it in stretch film or VCI paper, and weigh it. Each step is timed to perfection.

- Automatic Ejection: The fully packaged and labeled coil is moved to an exit conveyor, ready for immediate pickup by a forklift.

Here’s a simple comparison of the impact:

| Task | Manual Process | Integrated Line |

|---|---|---|

| Labor Required | 3-5 workers per shift | 1 supervisor per shift |

| Time per Coil | 10-15 minutes (variable) | 2-3 minutes (consistent) |

| Safety Risk | High (crane loads, manual lifting) | Low (fully guarded system) |

| Floor Space | Large staging area needed | Minimal, linear footprint |

| Consistency | Varies by worker and shift | 100% consistent |

I remember a client in Gebze, a major industrial hub in Turkey. They had just invested in a state-of-the-art slitting line. It was a beautiful machine, but it produced coils so fast that their manual packaging team couldn't keep up. Their brand-new asset was being throttled by their old process. We worked with them to design an L-shaped inline system that took coils directly from the turnstile. The impact was immediate. They could finally run the slitter at its full, rated capacity. They moved four packaging workers to other important tasks in the plant. And the floor, once dangerously cluttered with coils, was now clear and safe. The bottleneck wasn't just managed; it was eliminated.

What Role Does Automated Labeling Play in Traceability and Quality Control?

Have you ever faced a customer complaint about a specific coil, only to find that the handwritten tag is smudged or the information is wrong? It’s a frustrating and costly problem. When you can't trace a product's history, you can't identify the root cause of a quality issue. Manual labels are unreliable; they fall off, get damaged, or contain human errors. This breaks the chain of data that is so critical in today's steel industry. Automated labeling systems solve this completely. They print clear, durable, and highly accurate labels and apply them securely to every single coil, creating a perfect digital record that follows your product from your factory to your customer.

Automated labeling plays a vital role in modern quality control by printing and applying robust labels with unique serial numbers, barcodes, and QR codes. This information is pulled directly from your manufacturing database, eliminating human error. The system then feeds the data back into your MES (Manufacturing Execution System) or ERP (Enterprise Resource Planning) system. This provides flawless traceability for every coil, from the moment it was cast to the moment it arrives at the customer's facility, ensuring every product is accounted for and meets all quality standards.

From Inaccurate Scribbles to Indisputable Data

For years, the industry relied on handwritten tags or stencils applied with a can of spray paint. I've seen it all. These methods are cheap upfront but incredibly expensive in the long run. An error in writing down a heat number or a customer ID can lead to an entire order being rejected.

An automated labeling system changes the game. Here’s how:

Direct Data Integration

The labeling system communicates directly with your plant’s control system. When a coil arrives at the labeling station, its identity is already known from the production schedule. The labeler pulls the correct data—such as coil ID, weight, dimensions, steel grade, customer name, and order number—from your MES. It then prints this information on a highly durable, industrial-grade label, often using thermal transfer technology that won't fade or smudge. This closed-loop process ensures the data on the label is always 100% accurate.

Foolproof Quality and Shipping Control

The label is more than just an identifier; it’s a key part of your quality control process.

- Verification: Before a coil is shipped, a simple scan of the barcode can confirm it matches the customer’s order in the ERP system. This prevents costly mix-ups, where one customer gets another's specialized steel.

- Traceability: If a customer reports an issue months later, you can scan the ID and instantly pull up the coil’s entire history: which heat it came from, who the operator was on the rolling mill, the chemical analysis, and all processing parameters. This allows you to pinpoint problems quickly and effectively.

- Customer Value: You can add QR codes to your labels. When your customer scans the code with a smartphone, they can be taken to a web page with the coil's material test certificate, safe handling instructions, or other useful documentation. This is a small feature that adds immense professional value.

I worked with a steel service center near Izmir that supplied coils to the Turkish automotive sector. They were having a nightmare with shipping errors—the right coils were being made, but the wrong ones were being sent out. For an automotive client, this is a critical failure. After we installed an automated labeling system linked directly to their order database, the error rate fell to zero. The system physically prevented a coil from moving to the dispatch bay if its scanned label did not match the active shipping order. It provided them with the process control they desperately needed.

How Does Smart Packaging Technology Address Rising Labor and Energy Costs?

Are you constantly battling to control your operational costs? With volatile electricity prices and a competitive labor market, every bit of efficiency counts. The traditional method of manual packaging is extremely labor-intensive and inefficient. Old wrapping machines that run constantly, whether a coil is present or not, waste a tremendous amount of energy. Smart packaging technology directly attacks these two major cost centers. It uses intelligent automation to reduce the need for manual labor and incorporates energy-saving features to cut down on electricity consumption.

Smart packaging technology addresses high costs in two key ways. First, it automates the physical, repetitive tasks of strapping and wrapping, reducing the required manpower from a team of several operators to just one supervisor per shift. Second, it uses modern, energy-efficient components like variable frequency drives (VFDs) and intelligent sensors. These sensors detect when a coil is not present and automatically put the machine into a low-power standby mode, significantly cutting electricity costs compared to older equipment that runs continuously at full power.

The Labor Equation: Reducing Costs and Improving Safety

In many mills I visit, the packaging station is one of the most physically demanding jobs. It involves handling heavy strapping tools, moving large rolls of film, and working around heavy, suspended loads. A typical manual station requires two to three workers per shift.

A smart, automated line changes this entirely.

- Direct Labor Savings: By automating the process, you can reassign those workers to more value-added roles, such as quality inspection, machine maintenance, or operating other equipment. This isn't about eliminating jobs; it's about using your skilled people more effectively. The cost savings are direct and substantial. For a three-shift operation, re-deploying two workers per shift can save hundreds of thousands of Lira or Euros per year in direct labor costs.

- Improved Safety and Ergonomics: Automation removes workers from harm's way. The risk of back injuries from handling heavy materials or accidents involving cranes is virtually eliminated. This leads to a safer workplace, better morale, and lower costs associated with workplace injuries.

The Energy Equation: Only Using Power When Needed

Older packaging machinery was built with simple, robust controls: an on switch and an off switch. The main motors often ran all day long. This is incredibly wasteful. Smart technology takes a much more intelligent approach to power consumption.

Here's how we design our systems to save energy:

| Feature | How It Saves Energy | Typical Reduction |

|---|---|---|

| Variable Frequency Drives (VFDs) | VFDs control motor speed precisely. The conveyor only moves as fast as needed, and the wrapping ring doesn't spin at maximum RPM for smaller coils. It's like having an accelerator pedal instead of just an on/off switch. | 15-20% |

| Sensor-Based Standby Mode | Photoelectric sensors detect when a coil enters and leaves the machine. If no coil is detected for a set period (e.g., 60 seconds), the system automatically powers down the main motors into a "sleep" mode, consuming minimal energy. It wakes up instantly when the next coil arrives. | 30-50% (depending on workflow gaps) |

| High-Efficiency Motors | We use modern motors (IE3 or IE4 efficiency class) that convert more electricity into useful work and less into wasted heat compared to older motors. | 5-10% |

These features add up. For a steel mill facing pressure on energy costs—a major challenge for every Turkish producer—a 40% reduction in the energy consumption of a key part of your production line is a significant win. It's a direct contribution to lowering your cost per ton and improving your overall profitability.

What are the Key Considerations When Upgrading to an Inline Packaging System?

You're convinced that an upgrade is necessary, but the idea of a large capital project can be intimidating. There are so many variables to consider, and making the wrong choice can be a costly mistake. Choosing a system that doesn't fit your floor space, can't handle your production rate, or fails to communicate with your other systems will lead to a very poor return on investment. The key to success is a systematic approach. By carefully analyzing your specific needs and working with the right partner, you can ensure your new system becomes a powerful strategic asset for years to come.

The most important considerations when upgrading are a detailed analysis of your product, process, and plant layout. You must begin with your coil specifications (ID, OD, width, max weight), your required throughput (coils per hour), and the physical floor space you have available. Beyond that, you must plan for seamless integration with your existing production equipment and your plant's software systems (MES/ERP) to unlock the full potential of the automation.

Getting the Technical Specifications Right

This is the foundation of a successful project. A machine that doesn't fit your coils or your speed is useless. Before you even talk to a supplier, you should have this data ready.

-

### Coil Data: The Four Pillars

I always start every project with these four numbers:- Inner Diameter (ID): What is the range of IDs you produce?

- Outer Diameter (OD): What are the minimum and maximum ODs?

- Width: What are the narrowest and widest coils?

- Weight: What is the maximum weight the system must handle?

This data determines the fundamental size, strength, and design of every component, from the conveyors to the wrapper.

-

### Throughput: Matching the Pace

How many coils do you need to package per hour? This is your target cycle time. The packaging line must be able to keep up with, or ideally, be slightly faster than your fastest upstream process (like your slitting line). This calculation dictates the required speed of conveyors, the RPM of the wrapping ring, and the cycle time of the strapping machines. Don't underestimate this; a slow packaging line will just become your new bottleneck. -

### Layout and Flow: Making it Fit

Space is always a premium in a steel mill. A good partner will work with your plant layout drawings (AutoCAD files are best). You need to consider the flow of material. Where do the coils come from? A turnstile? A coil car? An overhead crane? Where do they need to go after packaging? The system must be designed to fit the available space and create a logical, efficient flow. Common layouts include a simple straight line (I-Line), a 90-degree turn (L-Line), or a return loop (U-Line).

Planning for Integration and the Future

A great packaging line doesn't work in isolation. It must become part of your larger factory ecosystem.

-

### Mechanical and Electrical Integration

This is about the physical and control handshakes between machines. The out-feed of your slitter must talk to the in-feed of the packaging line. The control panels should be standardized on the platform your maintenance team knows, whether that's Siemens, Allen-Bradley, or something else. This is a critical conversation to have early on. A supplier who just wants to sell you their standard machine without discussing integration is a red flag. -

### Software and Data Integration

This is the key to unlocking "smart" functionality. The line must be able to communicate with your MES or ERP system. This is how you achieve the automated labeling and traceability we discussed earlier. Your partner's software engineers need to be able to work with your IT department to ensure a smooth data exchange. This is often the most overlooked part of a project, but it's what separates a simple machine from a true Industry 4.0 solution. -

### Modularity and Scalability

Think about your needs five years from now. Will you need to add a circumferential strapper? Or maybe a station that adds corner protection? A well-designed system is modular. This means you can add new capabilities later without having to replace the entire line. This future-proofs your investment and allows the system to grow with your business.

My Insights!

Over my career, from being an engineer on the factory floor to building my own packaging machine company, I've learned what truly separates a successful equipment upgrade from a frustrating one. It’s not just about the thickness of the steel used to build the machine. It’s about the strength of the partnership between the supplier and the customer.

I see that you, Javier, are looking for a strategic partner, not just a vendor who sells you a piece of equipment. This is exactly the right approach. A true partner does more than just respond to a request for a quote. They invest their time to understand your business. They should walk your factory floor, talk to your operators, and listen to your maintenance crew. They need to understand your specific challenges—like volatile energy costs and the pressure to digitize—and your long-term goals, like increasing your uptime to 95% and lowering operating costs.

A good partner will help you analyze the total cost of ownership and the return on investment (ROI), not just the initial purchase price. They will ask about your five-year plan and design a system that not only solves today's bottlenecks but also prepares you for tomorrow’s demands. This might mean making the line modular so you can add new features later, or ensuring the control system is ready for a future MES integration.

My best advice is this: Find a team that shares your passion for engineering and efficiency. The right inline packaging system is far more than just a machine. It is a critical investment in the future of your plant—a foundational step toward building a smarter, safer, and more profitable steel operation.

Conclusion

Upgrading to an inline packaging and labeling system is a strategic investment. It boosts efficiency, guarantees quality, reduces costs, and prepares your steel production for a smarter, more competitive future.