Improving Metal Fabrication Efficiency with Precision Coil Upender Systems?

Leading Paragraph:

Are you struggling with slow production lines caused by manual coil handling? As a plant manager in Mexico's demanding metal industry, you know every minute of downtime costs money. Manual coil flipping not only creates safety hazards but also damages your valuable products. The constant battle between output targets and operational bottlenecks can feel overwhelming.

Snippet Paragraph:

Precision coil upender systems can improve metal fabrication efficiency by 30-50% through automated material handling. These systems directly address production bottlenecks by:

- Eliminating manual coil flipping and reducing labor dependency

- Minimizing product damage during orientation changes

- Integrating seamlessly with existing packing and processing lines

Transition Paragraph:

But how exactly do these systems transform your metal fabrication operations? And what should Mexican plant managers like Michael look for when selecting the right equipment? Let's explore the key questions that will help you make an informed investment decision.

1. How Can Automated Coil Upenders Solve 4 Major Production Bottlenecks?

Leading Paragraph:

Michael faces daily challenges that sound familiar to many Mexican plant managers: slow throughput, safety concerns, product damage, and unreliable equipment. These aren't just minor inconveniences—they're profit killers that impact your bottom line and competitive edge.

Snippet Paragraph:

Automated coil upenders address four critical production bottlenecks: manual handling inefficiency (40% time savings), safety risks (90% injury reduction), product damage (25% fewer defects), and equipment reliability issues. According to Randal Liu, SHJLPACK's founder, "The right upender system pays for itself within 18 months through labor savings and reduced product claims."

Dive Deeper Content:

Efficiency Bottlenecks in Mexican Metal Plants

Mexican manufacturing facilities typically process 200-500 coils daily. Manual handling requires 3-4 workers per shift, taking 5-8 minutes per coil orientation change. This translates to 16-32 hours of labor daily just for coil positioning. Automated upenders reduce this to 1-2 minutes per coil with single-operator oversight.

Safety Transformation Statistics

Manual coil handling accounts for 35% of reported injuries in Mexican metal plants. The most common incidents include:

- Crush injuries during manual flipping (42% of cases)

- Back strains from improper lifting (28%)

- Foot injuries from dropped coils (18%)

Automated systems eliminate these risks through controlled hydraulic operation and safety guarding. SHJLPACK units include laser safety curtains and emergency stop systems that meet Mexican NOM standards.

Product Damage Cost Analysis

| Damage Type | Manual Handling | Automated Upender | Cost Savings |

|---|---|---|---|

| Edge Damage | 8-12% of coils | 1-2% of coils | $45,000/year |

| Surface Scratches | 15% of coils | 3% of coils | $28,000/year |

| Cosmetic Rejects | 5% of coils | 0.5% of coils | $15,000/year |

Based on medium-sized Mexican plant processing 300 coils/day

Equipment Reliability Factors

Mexican plants need equipment that withstands high-temperature environments and continuous operation. SHJLPACK upenders feature:

- Industrial-grade hydraulic systems rated for 24/7 operation

- Dust and moisture protection (IP54 rating)

- Local technical support in Mexico through partner network

- 98% uptime guarantee with preventive maintenance programs

2. What Are the 5 Key Features to Look for in Coil Upender Systems?

Leading Paragraph:

Not all coil upenders are created equal. As Michael evaluates different suppliers, he needs to understand which features deliver real value versus those that are just marketing hype. The wrong choice could mean more downtime, not less.

Snippet Paragraph:

The five essential features for Mexican metal plants are: heavy-duty construction (10+ ton capacity), smart control systems, safety certifications (CE + NOM), easy maintenance access, and compatibility with existing lines. SHJLPACK systems include all these features as standard, while competitors often charge extra for safety systems and smart controls.

Dive Deeper Content:

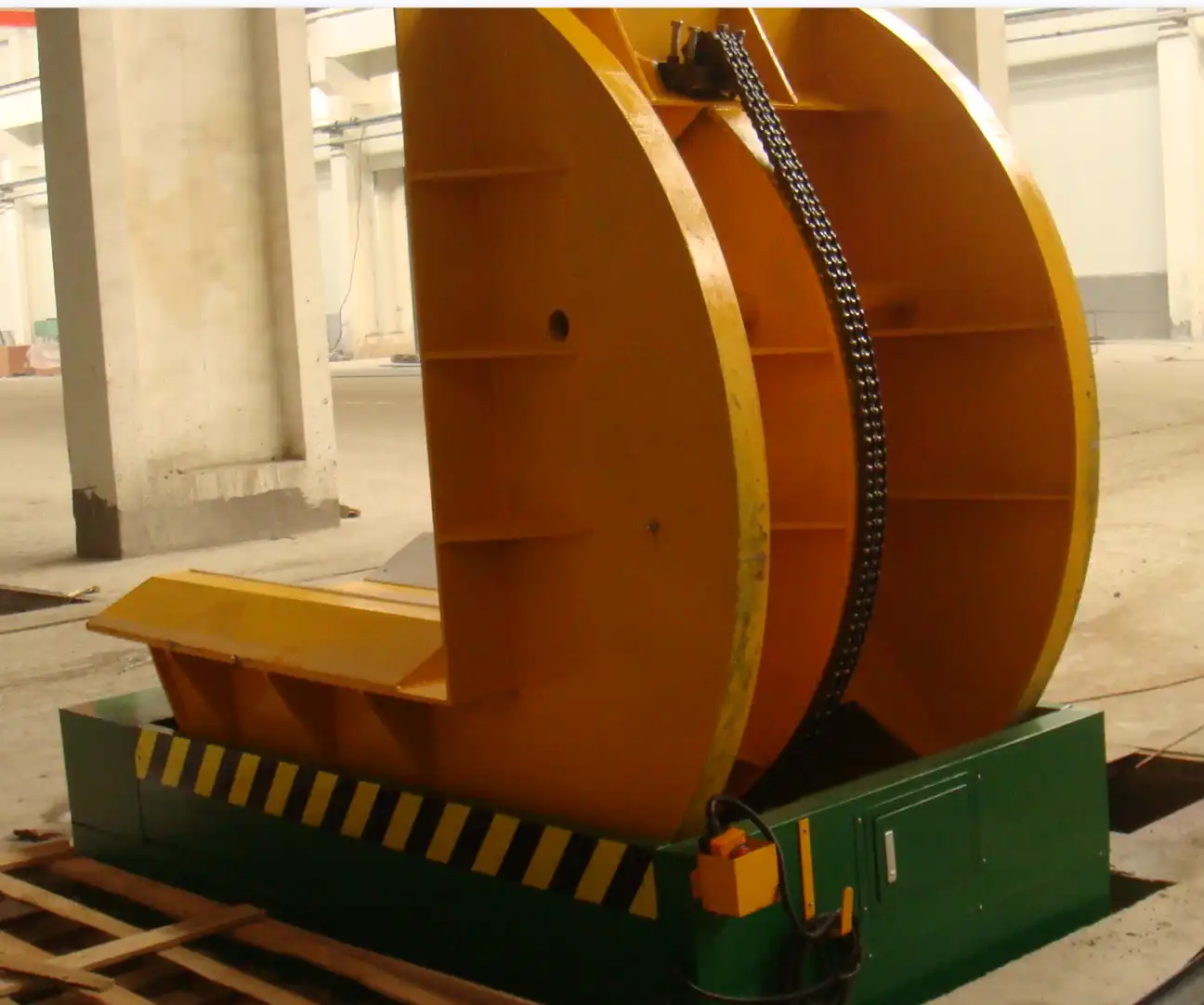

Heavy-Duty Construction Standards

Mexican metal plants process coils from 3-20 tons, requiring robust construction. Key structural elements include:

⚡ Frame Design: SHJLPACK uses reinforced steel box sections with 8mm minimum thickness, compared to standard 5-6mm in entry-level models. This prevents frame deflection under heavy loads.

🏭 Hydraulic Components: Industrial-grade pumps and valves rated for 10,000+ operation cycles. Look for Rexroth or Parker components rather than generic hydraulic systems.

💰 Bearing Capacity: Oversized roller bearings that handle 150% of rated capacity for shock absorption during coil placement.

Smart Control System Benefits

Modern upenders should include PLC-based control systems with these capabilities:

Step-by-Step Operation Process:

- Coil Positioning: Operator places coil using overhead crane

- Automatic Clamping: Hydraulic arms secure coil without manual intervention

- Programmed Rotation: Pre-set angles (90°, 180°, 270°) selected via touchscreen

- Controlled Placement: Slow-final positioning prevents impact damage

- Data Logging: System records cycle times and maintenance alerts

Safety Certification Requirements

For Mexican plants, ensure equipment meets both international and local standards:

- CE Marking (European safety standards)

- NOM-001/003-STPS (Mexican workplace safety)

- ISO 13849 (Machine safety performance levels)

- Local electrical certifications for Mexican power grids

Maintenance Accessibility Features

Downtime for maintenance costs Mexican plants $500-800 per hour. SHJLPACK designs include:

- Front-access hydraulic valve banks

- Slide-out electrical cabinets

- Quick-disconnect hydraulic hoses

- Local spare parts inventory in Monterrey and Mexico City

Compatibility with Existing Infrastructure

Ensure new upenders work with your current:

- Coil packing machines and strapping systems

- Overhead crane capacities and hook heights

- Factory floor space and power supply (220V/480V)

- Production management software systems

3. Which Coil Upender Configuration Delivers the Best ROI for Mexican Plants?

Leading Paragraph:

Michael needs to justify this investment to company leadership. The right configuration isn't just about technical specs—it's about delivering measurable financial returns that make the business case undeniable.

Snippet Paragraph:

Semi-automatic upenders deliver the best ROI for most Mexican plants, with 18-24 month payback periods. They balance automation benefits with manageable investment levels. SHJLPACK's SAU series specifically targets medium-sized Mexican metal processors with 5-15 ton capacity requirements and 60-80 coils per shift throughput.

Dive Deeper Content:

Configuration Comparison for Mexican Market

| Specification | Manual Systems | Semi-Auto (Best ROI) | Full Auto | Smart Auto |

|---|---|---|---|---|

| Initial Investment | $15,000-25,000 | $45,000-65,000 | $85,000-120,000 | $130,000-180,000 |

| Labor Required | 3-4 operators | 1 operator | 0.5 operator | Fully unmanned |

| Coils/Hour | 8-12 | 25-35 | 45-60 | 70-90 |

| ROI Period | N/A | 18-24 months | 24-36 months | 36-48 months |

| Best For | Small shops | Medium plants | Large facilities | High-volume specialists |

Detailed ROI Calculation Example

Current Manual Operation Costs (Monthly):

- 4 workers × $1,800/month = $7,200

- Product damage (8%) = $3,500

- Injury-related costs = $1,200

- Total monthly cost: $11,900

Semi-Auto SHJLPACK Operation (Monthly):

- 1 operator × $2,000/month = $2,000

- Maintenance contract = $800

- Energy consumption = $300

- Total monthly cost: $3,100

Monthly Savings: $8,800 | Annual Savings: $105,600

Investment: $55,000 | ROI Period: 6.3 months

Case Study: Mexican Steel Processor

🏭 Medium-sized steel service center in Monterrey

- Challenge: Manual coil handling caused 12% product damage and required 4 workers per shift

- Solution: SHJLPACK SAU-10T semi-automatic upender with 10-ton capacity

- Results:

- Production: increased from 200 to 280 coils per shift (40% improvement)

- Labor: reduced from 4 to 1 operator per shift (75% savings)

- Quality: damage rate dropped from 12% to 2%

- ROI: 7 months based on actual operational data

Financing Options for Mexican Businesses

SHJLPACK partners with Mexican financial institutions to offer:

- Equipment leasing (36-60 month terms)

- 30% down payment, balance financed

- Seasonal payment structures for cyclical businesses

- Tax benefits through IMMEX manufacturing program

4. How Do You Implement Coil Upenders Without Disrupting Production?

Leading Paragraph:

The fear of production disruption stops many plant managers from upgrading equipment. Michael can't afford weeks of downtime during installation. The good news: proper planning makes seamless integration achievable.

Snippet Paragraph:

Successful implementation requires weekend installation, phased commissioning, and thorough operator training. SHJLPACK's Mexican installation teams complete most installations in 2-3 days without affecting weekday production. They've developed a 5-step methodology that minimizes disruption while ensuring optimal performance.

Dive Deeper Content:

Pre-Installation Planning Checklist

✅ Site Preparation (2 weeks before delivery)

- Clear 4x6 meter floor space with reinforced concrete

- Install 480V power connection within 10 meters

- Ensure overhead crane access (5-ton minimum capacity)

- Coordinate with production scheduling for weekend access

✅ Safety Compliance Review

- Verify Mexican NOM standards compliance documentation

- Schedule safety inspection with local authorities

- Develop lockout-tagout procedures for integration points

- Train maintenance team on emergency stop systems

Installation Timeline (3-Day Weekend)

Friday (Evening Shift):

- 6:00 PM: Production line shutdown

- 7:00 PM: Equipment delivery and positioning

- 9:00 PM: Foundation bolting and leveling

Saturday (Full Day):

- 8:00 AM: Mechanical assembly and hydraulic connection

- 2:00 PM: Electrical wiring and control panel installation

- 6:00 PM: Preliminary testing and safety system verification

Sunday (Commissioning):

- 8:00 AM: Full operational testing with sample coils

- 12:00 PM: Operator training and certification

- 4:00 PM: Final inspection and production readiness

- 6:00 PM: Line ready for Monday morning production

Operator Training Program

SHJLPACK provides comprehensive training in Spanish:

Phase 1: Basic Operation (4 hours)

- Control panel familiarization

- Standard operating procedures

- Daily maintenance checks

Phase 2: Advanced Troubleshooting (2 hours)

- Common error code resolution

- Basic hydraulic system maintenance

- Safety system testing

Phase 3: Performance Optimization (1 hour)

- Speed and efficiency improvements

- Quality control integration

- Production data monitoring

Post-Installation Support

Mexican plants receive:

- 24/7 Spanish-language technical support

- 2-year warranty on all components

- Quarterly preventive maintenance visits

- Remote diagnostics via internet connection

- Local spare parts inventory in major industrial zones

Conclusion

Precision coil upender systems deliver measurable efficiency gains and cost savings for Mexican metal fabricators. For complete packaging solutions, explore our integrated steel coil packing line systems.

FAQ Section

Frequently Asked Questions

Q: How much floor space do coil upenders require in typical Mexican plants?

A: Most systems need 4x6 meters, plus 2-meter clearance for operation. SHJLPACK offers compact models for space-constrained facilities, with some configurations requiring only 3x4 meters.

Q: What maintenance is required for coil upenders in high-humidity Mexican coastal areas?

A: Monthly inspection of hydraulic systems, quarterly bearing lubrication with marine-grade grease, and annual electrical component checks. SHJLPACK units include corrosion-resistant coatings for challenging environments.

Q: Can upenders handle different coil sizes without manual adjustment?

A: Yes, modern systems feature automatic width adjustment from 800-2000mm. SHJLPACK models include programmable presets for common coil sizes used in Mexican steel mills.

Q: How do upenders integrate with existing Mexican safety protocols?

A: They include dual emergency stops, safety light curtains, and lockout capabilities that comply with Mexican NOM standards. Installation includes safety procedure integration with your existing protocols.

Q: What's the typical energy consumption for automated coil upenders?

A: Most systems use 10-20 kW during operation, costing $150-300 monthly in Mexican industrial electricity rates. Energy-efficient models can reduce this by 30% through variable-speed hydraulic pumps.