Your distribution center feels like a constant battle against the clock. You manage a wide range of steel wire products, each with its own specifications. But the end of the line, the rewinding and packing stage, is where everything slows down. This bottleneck creates delays, frustrates your team, and puts a cap on your facility's true output. Every minute your rewinding machine sits idle for a changeover or runs inefficiently, you can feel the pressure mounting and see the costs adding up. It's a problem that impacts your entire operation, from production schedules to customer satisfaction. But it doesn't have to be this way. You can transform this critical stage from a source of frustration into a streamlined, efficient, and safe part of your workflow.

To improve steel wire rewinding machine efficiency in a multi-product center, you must focus on three core areas: integrating flexible pay-off and take-up systems that accommodate various spool sizes, implementing smart automation for tension control and wire traversing, and choosing equipment with quick-changeover capabilities. This strategy directly reduces manual labor, minimizes downtime between different product runs, and significantly boosts your overall throughput.

I have walked through countless factories and distribution centers in my career. I’ve seen firsthand how a slow, inefficient rewinding process can hold back an otherwise successful business. The good news is that the solutions are practical and achievable. They are not just about buying a new machine, but about adopting a new way of thinking about your workflow. Let's break down the specific challenges you face and explore the real-world solutions that can make a difference.

How Can You Handle Different Wire Types and Sizes Without Constant Changeovers?

Every time your team needs to switch from one wire gauge to another, or from a small bobbin to a large one, your entire line grinds to a halt. This changeover process is likely manual, slow, and a major source of lost productivity. These minutes of downtime quickly add up to hours of lost output over a week or a month. It’s a constant source of frustration for your operators and a significant drag on your plant's efficiency. You feel like you are always preparing to work instead of actually getting work done. The key to solving this is not to work faster, but to work smarter with equipment designed for flexibility.

Handling different wire types and sizes efficiently requires a rewinding machine with features like an adjustable pay-off stand, a versatile take-up coiler, and a programmable logic controller (PLC). These systems allow your operators to quickly select pre-saved settings for new products. This lets the machine automatically adjust for different wire diameters, coil dimensions, and winding speeds, turning a lengthy manual task into a quick, simple process.

Dive Deeper: Building Flexibility into Your Rewinding Line

To truly understand how to achieve this flexibility, we need to look at the two main parts of the process: where the wire comes from (the pay-off) and where it's going (the take-up). Optimizing both is essential.

The Importance of a Flexible Pay-off System

The pay-off is the starting point. If it can't handle your range of supply bobbins smoothly, you'll have problems from the very beginning. A modern, flexible pay-off system should have features like adjustable pintles or chucks. These can quickly adapt to different bobbin bore diameters without needing a whole new set of tools. For example, a pneumatic or hydraulic clamping system allows an operator to secure a new bobbin with the push of a button, rather than spending several minutes with wrenches.

I remember a client in the steel distribution business who was losing nearly two hours per shift on changeovers. Their old system required a complete mechanical teardown to switch between their main product sizes. We introduced a pay-off stand with a power-driven, adjustable cone system. This simple change reduced their changeover time for each bobbin to less than ten minutes. Another critical component is a wire accumulator. This device holds a buffer of wire, so you can join the end of a finished bobbin to the start of a new one without stopping the take-up coiler. It maintains constant tension and keeps the line running, which is a huge boost for overall equipment effectiveness (OEE).

The Power of a Programmable Take-up Coiler

The take-up coiler is where the magic of automation really shines. A machine equipped with a modern PLC and HMI (Human-Machine Interface) is a game-changer. Your engineers can create and save "recipes" for every product you handle. A recipe includes parameters like target coil weight or length, wire diameter, coiling speed, and the traversing pitch. When it's time to switch products, the operator simply selects the new recipe from a touchscreen, and the machine adjusts itself automatically.

This is made possible by servo-driven systems. A servo motor controls the traversing guide that lays the wire onto the new coil. It synchronizes perfectly with the coiler's rotation speed to create clean, even layers. This is critical for different wire diameters, as a thicker wire needs a different lay pattern than a thinner one. An automated system does this calculation perfectly every time.

| Feature | Manual Changeover Process | Automated Changeover Process |

|---|---|---|

| Coil Dimension | Operator manually adjusts guide rails and coil former. | Operator selects product recipe on HMI; guides adjust automatically. |

| Traversing Pitch | Mechanic manually adjusts gearbox or changes cams. | PLC automatically sets the servo-driven traversing pitch based on recipe. |

| Winding Speed | Operator manually sets speed on a dial, often through trial and error. | Speed is pre-programmed in the recipe for optimal quality. |

| Typical Time | 20-45 minutes | 2-5 minutes |

This level of automation eliminates human error and dramatically reduces the downtime that is killing your productivity.

What Are the Key Automation Features That Tackle Safety and Labor Costs?

You see your team on the factory floor, manually lifting heavy spools of wire, bending over to strap finished coils, and moving heavy pallets. You know this work is physically demanding and carries a high risk of back injuries or other strains. These safety risks lead directly to higher insurance costs and, even worse, the loss of good, experienced employees. The high turnover means you are always training new people, and the direct labor costs for these repetitive, non-value-added tasks eat directly into your bottom line. Automation offers a direct solution to these problems. It's not just about speed; it's about creating a safer and more stable workplace.

The key automation features that improve safety and reduce labor costs include automatic spool loading and unloading systems, integrated strapping and wrapping units, and robotic coil handling. These technologies are designed to take over the most physically demanding and dangerous tasks. By minimizing the need for manual lifting and direct human intervention with the product, you address the root causes of many workplace injuries and reduce your dependency on manual labor for these processes.

Dive Deeper: Building a Safer and More Cost-Effective Process

Let’s focus on the specific points in the process where your team is most at risk and where labor costs are highest. These are the areas where automation provides the most significant return on investment.

From Manual Lifting to Automated Loading

The process often starts with loading a heavy pay-off bobbin, which can weigh hundreds or even thousands of pounds. Manual loading with a forklift is slow and requires a skilled operator, and any mistake can be dangerous. An automated loading system changes this completely. A common solution is to integrate a floor-level V-cradle where an operator can simply roll or place the bobbin. From there, a hydraulic or pneumatic lift automatically raises the bobbin into the correct position and clamps it into the pay-off stand. This entire process can be initiated with a single button.

I worked with a plant manager, much like you, who decided to invest in automation after a serious "near-miss" incident where a heavy spool nearly fell from a forklift during loading. It was a wake-up call. We helped them implement a system with an integrated lifting table. Not only did it eliminate the safety risk, but it also reduced the loading time by 70%. The operator could stage the next bobbin while the machine was still running, making the whole process safer and more efficient.

End-of-Line Automation: Securing the Final Product

Once the rewinding is complete, the manual work is far from over. An operator typically has to cut the wire, secure the end, and then manually move the finished coil to a separate station for strapping or wrapping. This is another area ripe for injury and inefficiency. A fully automated line handles all of this. Once the target length or weight is reached, the machine automatically slows down, cuts the wire, and clamps it. The finished coil is then ejected from the coiler onto a conveyor or a tilting mechanism.

This coil can then be moved automatically to an integrated strapping station, which applies plastic or steel straps at pre-set positions. After strapping, it can continue to an orbital stretch wrapper that fully encapsulates the coil, protecting it from moisture and damage during shipping. The only manual task left is to transport the finished, packaged pallet.

| Task | Manual Method Risks & Costs | Automated Method Benefits |

|---|---|---|

| Bobbin Loading | High risk of crush injuries; requires certified forklift operator. | Eliminates manual lifting; reduces labor time and skill requirement. |

| Wire Cutting | Risk of cuts and repetitive motion injuries. | Automated, precise cutting; operator is not near the moving parts. |

| Coil Strapping | Bending and lifting; repetitive strain on back and shoulders. | Consistent, tight strapping; no manual labor required. |

| Coil Transport | Manual pallet jack or forklift use; high traffic and collision risk. | Integrated conveyors create a smooth, predictable workflow. |

By automating these steps, you not only create a much safer work environment but also free up your valuable employees to focus on more complex, value-added tasks.

How Do You Ensure the Rewinding Process Doesn't Damage the Product?

You have invested time and money to produce high-quality steel wire. The last thing you want is for it to get damaged in the final rewinding and packaging stage. Scratched surfaces from poor guiding, uneven coils that are unstable, and damaged edges from improper handling are all too common. Every coil that gets rejected or returned due to these issues is a direct hit to your profits. It also leads to customer complaints and can damage your company's reputation as a reliable, high-quality supplier. It is incredibly frustrating to see a perfect product ruined at the very last step of the process. The solution lies in precision and control.

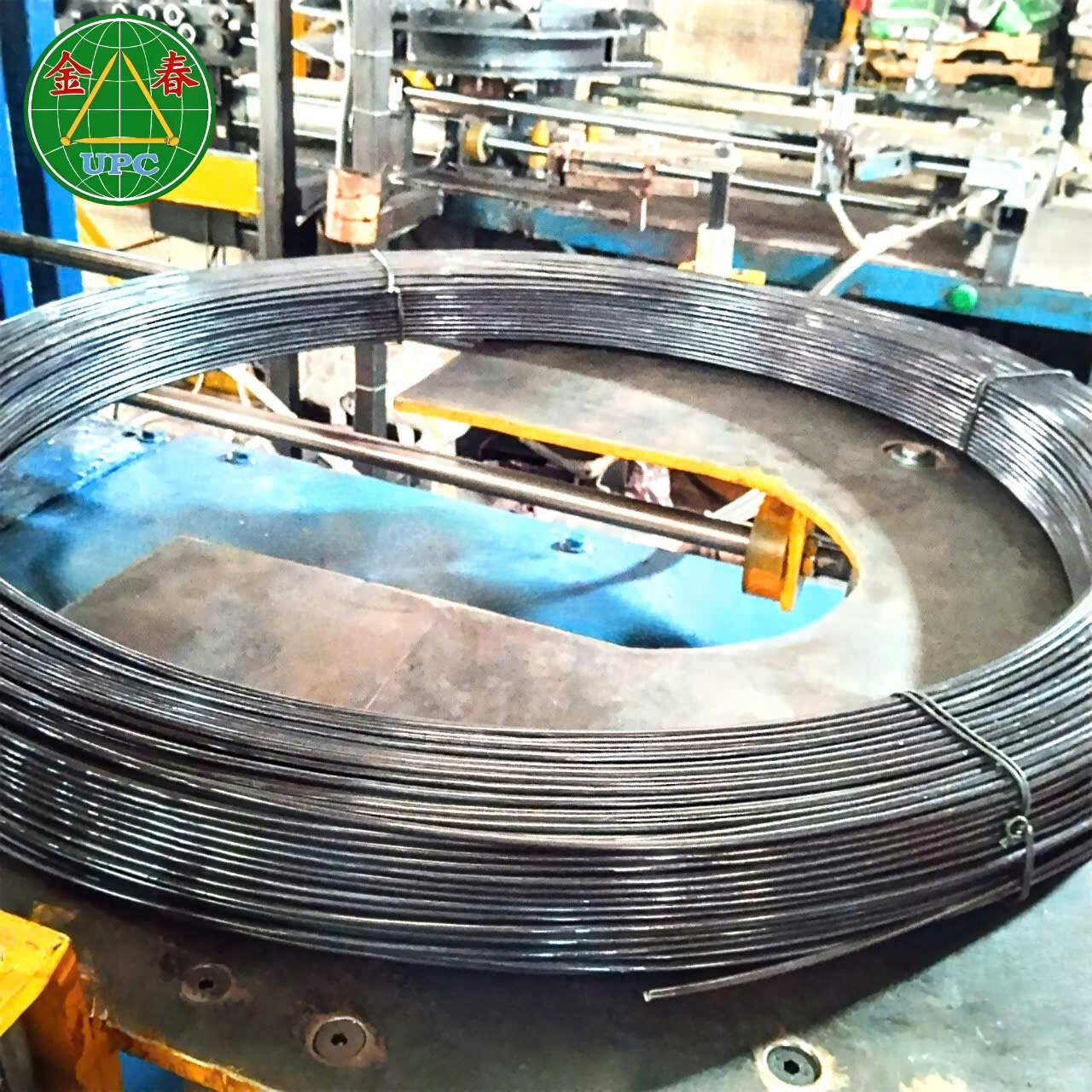

To prevent product damage during rewinding, your system must have precise tension control, smooth wire guiding, and a flawless traversing mechanism. A closed-loop tension control system, using a dancer arm or a load cell, provides real-time feedback to constantly adjust for perfect tension. At the same time, polished ceramic or steel guides prevent any scratching, and a synchronized traversing unit ensures the wire is laid perfectly side-by-side, creating a dense, stable coil that is easy to handle and protected from damage.

Dive Deeper: The Science of a Perfect Coil

Protecting your product is not about being gentle; it’s about being precise. Let’s break down the two technical elements that have the biggest impact on the quality of your finished coil: tension and traversing.

The Critical Role of Tension Control

Tension is arguably the most important factor in rewinding. Too much tension can stretch the wire, which can alter its mechanical properties and diameter. This is a major quality issue. Too little tension results in a loose, soft coil. These coils are unstable, can easily be damaged during handling, and are prone to tangling when your customer tries to pay it off. The goal is to maintain a consistent, correct tension from the core of the coil to its outer layer.

There are two main ways to do this. An older, open-loop system might use a simple mechanical brake, which is inconsistent. A modern, closed-loop system is far superior. It uses a sensor, like a dancer arm or a load cell, to continuously measure the wire tension. This sensor sends a signal back to the pay-off motor's drive. If the tension increases, the drive tells the motor to slow down slightly. If the tension decreases, it speeds up. This constant feedback loop ensures the tension remains perfectly stable throughout the entire winding process, regardless of speed or the amount of wire left on the pay-off bobbin.

Perfect Winding Through Precision Traversing

The second key element is the traversing system. This is the mechanism that guides the wire back and forth across the face of the coil. A poor traversing system will lead to gaps in the coil or wire crossovers, where one wrap digs into the layer below it. This can damage the wire's surface and also creates an unstable coil that can collapse.

The best solution is a servo-driven traversing system. The servo motor's movement is directly linked to the coiler's rotation. The system's PLC knows the diameter of the wire and calculates the exact speed the guide needs to move to lay the wire perfectly next to the previous wrap. This creates what we call a "level wind" or "pitch winding." The result is a dense, smooth, and highly stable coil. This type of coil is much more resistant to damage during strapping, handling, and shipping. It also looks more professional, which improves your customers' perception of your quality.

| Defect | Common Cause | Machine-Based Solution |

|---|---|---|

| Scratched Wire | Rough or worn-out wire guides; excessive tension. | Use polished ceramic or hardened steel guides; closed-loop tension control. |

| Uneven Coil ("Stepped" Layers) | Improper traversing speed; mechanical slop in the guide system. | Servo-driven traversing system synchronized with the coiler's rotation. |

| Loose Coil (Soft Pack) | Insufficient or inconsistent tension. | Dancer arm or load cell-based closed-loop tension control. |

| Damaged Edges | Coil is too soft and gets crushed during strapping or handling. | A combination of proper tension and level winding creates a dense, hard coil. |

By focusing on these technical details, you are not just rewinding wire; you are actively preserving the quality and value of your product.

How Can You Choose a Reliable Partner, Not Just a Machine Vendor?

You have likely been in this situation before. A slick salesperson comes in, promises you that their machine is the solution to all your problems, and shows you an impressive brochure. But once the machine is installed and the check is cashed, that person is nowhere to be found. When a problem arises, you are left dealing with a generic support line or waiting days for a response. This experience creates a deep sense of caution. You can't afford to make another investment with a company that doesn't understand your business or won't stand behind its product. A bad equipment purchase is a costly mistake that can disrupt your operations for years.

The solution is to fundamentally change how you approach this process. You should not be shopping for a machine; you should be looking for a partner. A true partner is invested in your success. They understand that if your new equipment runs well and helps your business grow, it reflects well on them. They don't just sell you a piece of steel; they provide a total solution that includes consultation, installation, training, and long-term support. This is the only way to ensure your investment will pay off.

Dive Deeper: My Perspective on True Partnership

I built my own packing machine factory from the ground up. In the early days, I was the one on the other side of the table, buying equipment. I made mistakes. I bought machines that looked great on paper but couldn't handle the high-volume, demanding environment of a real factory. I learned a very tough lesson: the company and the people you buy from are just as important as the machine itself. That experience is why I founded SHJLPACK on the principle of partnership. I am not just a machine builder; I am an engineer who has faced the same challenges you are facing right now.

What to Ask a Potential Supplier

When you are evaluating a potential supplier, you need to go beyond the technical specifications and the price. You need to understand their philosophy and their process. Here are the kinds of questions I encourage my clients to ask—not just of me, but of any potential supplier:

- "Can you explain your process for understanding my specific problem?" A partner will start by asking you dozens of questions about your products, your workflow, and your goals. A vendor will start by showing you their catalog.

- "Can you provide references or case studies from a company in my industry?" A reliable partner will be proud to connect you with other clients who have faced similar challenges.

- "What does your after-sales support structure look like? Who is my dedicated point of contact if I have a technical issue?" You want a name and a direct line, not a generic 1-800 number. Ask about their spare parts availability and service technician response times in your region.

- "Can you run a trial with my specific wire product?" The best way to know if a machine will work is to see it work with your material. A true partner will be willing to invest the time to prove their solution.

Vendor vs. Partner: A Critical Comparison

Thinking about your potential supplier in these terms will help you see the difference between a transactional relationship and a true partnership. The choice you make will determine the success of your project long after the installation is complete.

| Evaluation Point | The Vendor Approach | The Partner Approach |

|---|---|---|

| Sales Process | Focuses on features and price. Tries to sell a standard machine. | Focuses on your problem. Tries to design a custom solution. |

| Problem Solving | Sells you a machine and leaves the integration to you. | Works with your team to ensure the machine fits into your overall workflow. |

| After-Sales Support | A reactive, often slow process managed by a separate department. | Proactive follow-up from an expert who knows your machine and business. |

| Long-Term Goal | To make a one-time sale. | To build a long-term relationship and help your business grow. |

When you find a supplier who welcomes these tough questions and thinks like a partner, you know you are on the right track. This is the foundation for a successful investment that will solve your problems not just today, but for years to come.

Conclusion

Improving rewinding efficiency is more than a machine upgrade. It is a strategic move towards a safer, more flexible, and more profitable operation that will secure your factory's future.