Are you running a steel mill in Thailand? Then you know the pressure. You face volatile energy costs, aging equipment that breaks down too often, and increasing demands for environmental compliance. Your packing line, the final step before your product meets the customer, might feel like a constant source of problems—a bottleneck that slows down your entire operation and eats into your profits. Every day you stick with an outdated system, you risk costly downtime, product damage, and falling behind competitors who are embracing modern technology.

But what if you could change that? What if your packing process could become a source of strength, efficiency, and reliability? It’s possible. By making a strategic investment in a modern, automated packing solution, you can solve these persistent issues. You can boost your throughput, cut your costs, and secure your business for the years to come. I've seen it happen time and again, and I want to share how you can do it too.

To future-proof your steel coil packing process in Thailand, you must focus on four key areas. First, embrace automation to solve labor challenges and improve consistency. Second, invest in energy-efficient machinery to reduce your operational costs. Third, ensure your new system can integrate with your factory's digital backbone, like an MES or IoT platform. Finally, choose flexible equipment that can handle diverse product specifications and adapt to future sustainable packaging materials.

This might seem like a huge undertaking. I understand that. But we can break it down into manageable steps. By looking at the core questions that I hear from plant owners every day, we can build a clear path forward. Let's explore how automation, return on investment, digital integration, and sustainability work together to create a packing line that is truly ready for the future.

We'll start with the issue that I hear about most often: finding good people and getting the most out of your production line.

How Can Automation Solve Your Labor and Efficiency Problems?

Finding skilled and reliable workers for the packing line is a growing challenge in Thailand. The work is physically demanding, repetitive, and can be dangerous. This often leads to high turnover and a constant need for training. A manual packing process is almost always a bottleneck. It is slow, its quality is inconsistent, and it directly limits the output of your entire mill, no matter how fast your rolling lines are.

You feel this every day. A single mistake by a tired operator can damage a valuable steel coil, leading to waste or rework. Your production targets are held hostage by the speed of your slowest worker. This constant inefficiency prevents you from meeting demand, taking on larger orders, and running your facility at its true potential. It’s a frustrating situation that costs you money and opportunity.

An automated coil packing line is the solution. It works around the clock, delivering consistent speed and quality without breaks or shift changes. Automation drastically reduces the need for manual labor in repetitive tasks, which minimizes human error and creates a safer work environment. Most importantly, it can dramatically increase your throughput, finally allowing your mill to operate at the capacity it was designed for.

Automation solves labor and efficiency problems by replacing slow, inconsistent, and physically demanding manual tasks with reliable, high-speed machinery. This directly results in faster packing cycles, uniform package quality, lower labor costs, and improved worker safety. It also allows you to reassign your skilled team members to more complex, value-added roles where they can make a bigger impact.

From Manual Chaos to Automated Order

Let's be honest about the manual packing process. It often involves multiple workers wrestling with heavy strapping tools, manually pushing coils, and wrapping them by hand. This process is not only slow but also introduces huge variations. One coil might be wrapped tightly, the next one loosely. This inconsistency can lead to damage during transport and an unprofessional appearance when it arrives at your customer's facility. From my early days as an engineer on the factory floor, I remember the controlled chaos of the packing area. It was always the place where schedules fell apart.

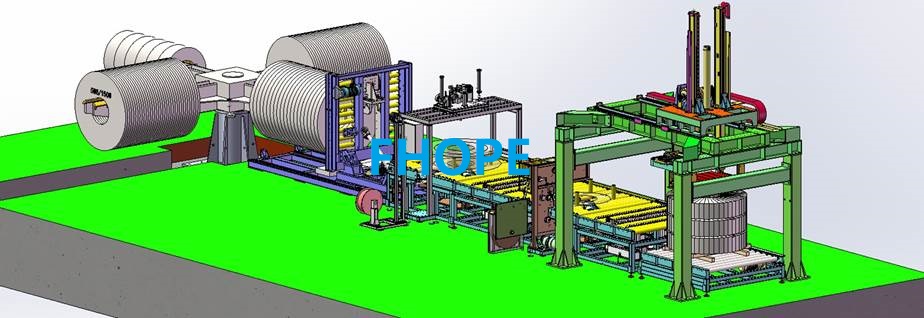

Key Components of an Automated System

An automated system transforms this chaos into a smooth, predictable workflow. It’s not just one machine, but an integrated solution.

- Conveyor Systems: These automatically transport coils from your slitting line to the packing station, eliminating the need for forklifts or cranes for short-distance moves.

- Upenders/Tilters: These safely and quickly turn coils from eye-to-sky to eye-to-wall orientation, a process that is slow and dangerous to do manually.

- Automatic Wrapping Machines: This is the heart of the system. It applies stretch film with precise tension and overlap, ensuring every coil is perfectly protected.

- Automatic Strapping Machines: These apply steel or PET straps at exact positions with consistent tension, securing the coil for transit.

- Robotic Labeling: An integrated system can automatically print and apply labels with all necessary information, linking the physical coil to your digital records.

The Real-World Impact

The difference is not small. I worked with a client whose situation was much like Javier's—a successful mill owner struggling with a packing bottleneck. His production was high, but he couldn't ship product fast enough. After we installed a fully automated line, his throughput in the packing department increased by over 40%. More importantly, he was able to move his most experienced packing workers into quality control and dispatch supervisor roles. They were happier, and his entire shipping operation became more reliable. The impact is clear when you compare the two approaches directly.

| Metric | Manual Packing Process | Automated Packing Line |

|---|---|---|

| Coils Per Hour | 5 - 10 | 20 - 30+ |

| Labor Required | 3 - 5 Operators | 1 Supervisor |

| Material Waste | High & Inconsistent | Low & Controlled |

| Package Quality | Variable | Highly Consistent |

| Safety Incidents | Higher Risk | Significantly Lower Risk |

What's the Real ROI of Upgrading to a Modern Packing Line?

You see the daily problems with your old packing line. You know it’s slow and unreliable. But a new system is a major capital investment. When you are already managing tight budgets and fluctuating market demand, it can be difficult to approve such a large expenditure. The "do nothing" option can feel safer and cheaper in the short term.

But this is a dangerous illusion. Sticking with that 15-year-old equipment is costing you money every single day. You pay for it in frequent maintenance calls and expensive spare parts. You pay for it in wasted packaging material and energy. You pay for it in damaged coils that have to be scrapped or sold at a discount. These are the hidden costs that slowly bleed your profits. And all the while, you live with the constant risk of a major breakdown that could halt your shipments for days.

A modern packing line is not just an expense. It is a strategic investment with a clear and calculable return on investment (ROI). When you look beyond the initial purchase price, you can see how it actively generates value. It cuts your operational costs, increases your revenue potential through higher throughput, and protects the quality of the products you work so hard to manufacture.

The true ROI of upgrading to a modern packing line comes from a powerful combination of measurable savings and strategic gains. It includes direct cost reductions in labor, energy, and materials; increased revenue from higher throughput and better product protection; and lower indirect costs from reduced maintenance and downtime. A detailed analysis for a typical steel mill often reveals a full payback period of just 2 to 4 years.

Calculating Your Tangible Returns

As a fellow engineer and business owner, I know that numbers speak louder than words. Javier is a smart CEO; he would demand a clear financial case. Let's break down where the savings come from.

- Labor Savings: An automated line can often be managed by a single supervisor instead of a team of 3-5 operators per shift. Over a year of three-shift operation, this represents a massive reduction in direct labor costs.

- Material Savings: Modern wrappers have advanced pre-stretch capabilities. This technology can stretch one meter of film into three or four meters, drastically reducing your plastic consumption while maintaining wrapping integrity. Precise automatic strapping also eliminates wasted material.

- Energy Savings: Old machines often have oversized motors that run at full power continuously. New systems use high-efficiency motors with Variable Frequency Drives (VFDs), which adjust power consumption to the exact need of the task, significantly cutting electricity bills.

- Throughput Increase: If you can pack and ship 20% more coils per day with the same fixed costs, that additional revenue flows directly to your bottom line.

Don't Forget the "Hidden" Returns

The financial benefits go beyond direct cost savings.

- Reduced Product Damage: Consistent, high-quality wrapping provides better protection against moisture and physical damage during shipping and storage. Fewer customer complaints and claims mean a healthier profit margin.

- Improved Safety: Automating heavy and dangerous tasks reduces the risk of workplace accidents, lowering insurance premiums and improving employee morale.

- Enhanced Brand Reputation: When your coils arrive at your customer’s facility perfectly packed, it sends a powerful message of quality and professionalism. This builds trust and encourages repeat business.

A Sample ROI Calculation

Let's make this concrete. While every factory is different, a simplified model can show the potential.

| Cost/Saving Category | Annual Value (Example) | Notes |

|---|---|---|

| Initial Investment | -€500,000 | Cost of a complete automated line |

| Labor Savings | +€120,000 | 2 fewer operators/shift, 3 shifts |

| Material Savings | +€60,000 | 50% reduction in stretch film use |

| Energy Savings | +€15,000 | VFDs and efficient motors |

| Increased Throughput | +€50,000 | Profit from 10% more volume |

| Total Annual Saving | +€245,000 | |

| Payback Period | ~2.04 Years | Investment / Annual Saving |

I always advise my clients to do this math for their own operation. We can work together with your production data to build a real-world ROI case that your financial team can stand behind.

How Do Smart Packing Systems Integrate with Your Digital Transformation Goals?

You are a forward-thinking leader. You are already investing in a digital transformation for your steel mill, implementing systems like an MES (Manufacturing Execution System) and using IoT sensors to gather data. But your packing line might still be an "analog island"—a black box at the end of your process. When a coil leaves the production line, it enters a zone where data is tracked manually, if at all.

This creates a critical gap in your visibility. Without real-time integration, you can't be sure of the exact status of a specific customer order. You don't have accurate data on how long the packing process takes, which can throw off your entire production schedule. You can't proactively manage your inventory of packaging materials. This lack of data prevents you from achieving the complete, end-to-end optimization that is the true goal of your digital strategy.

Modern packing lines are designed to be active participants in your smart factory. They are no longer just dumb machines. They are intelligent systems equipped with sensors, PLCs, and network capabilities that allow them to communicate directly with your MES, ERP, and other management platforms. This integration provides the complete, real-time data stream you need to manage your entire operation effectively.

Smart packing systems integrate with your digital goals by using built-in controllers and network interfaces to establish a two-way communication link with your factory's MES. This connection allows for the seamless, automatic exchange of data. Your MES can send a packing "recipe" to the line for a specific coil, and the line can send back real-time updates on its status, material consumption, and operational performance. This creates full traceability from production to shipment and enables true data-driven decision-making.

The Data Bridge: From Machine to Management

Imagine this workflow. A steel coil arrives at the packing line. An automatic scanner reads its barcode or RFID tag. The packing line's PLC immediately queries your MES for that coil's ID. The MES responds by sending the specific packing instructions: which wrapping program to use, how many straps are needed, and what the label should say. The packing line executes these instructions perfectly. As it completes each step, it sends data back to the MES: "Coil received," "Wrapping started," "Wrapping complete," "Weight confirmed," "Label applied and verified," "Ready for dispatch."

The Data You Can Unlock

This seamless flow of information gives you a powerful new set of tools for management and optimization.

- Coil Tracking Data: You gain real-time visibility of every coil's location and status in the packing and shipping process.

- Machine Performance Data: You can track key metrics like uptime, cycle time per coil, and Overall Equipment Effectiveness (OEE) to identify and resolve bottlenecks.

- Consumable Tracking: The system can monitor the usage of stretch film and strapping, automatically alerting your inventory system when supplies are running low.

- Alarms and Diagnostics: Maintenance teams can receive instant alerts on their mobile devices if a machine has an issue, allowing for faster response times and predictive maintenance.

The Benefits of Full Integration

For a leader like Javier, who has already invested in a smart scheduling platform, connecting the packing line is the final, critical piece of the puzzle. It links high-level planning with the physical reality on the factory floor.

| Feature | Benefit for Your Mill |

|---|---|

| Automatic Data Entry | Eliminates human error in data logging and saves time. |

| Real-Time Tracking | Provides accurate, up-to-the-minute status of customer orders. |

| Packing "Recipes" | Ensures every coil is packed exactly to specification, improving quality. |

| Performance Analytics (OEE) | Allows you to measure and improve the efficiency of your packing process. |

| Predictive Maintenance | Reduces unplanned downtime by identifying potential issues before they fail. |

How Can a New Packing Line Help You Meet Environmental Standards?

The pressure to be more sustainable is coming from all sides. In Thailand, government environmental regulations are becoming stricter every year. At the same time, your customers, especially in the automotive and construction industries, are increasingly demanding that their suppliers demonstrate strong environmental performance. Your old, inefficient packing line is a liability in this new reality. It likely consumes too much energy and wastes a significant amount of packaging material.

This is no longer just about compliance or "being green." It is a core business issue. Continuing to operate wasteful equipment can lead to government fines, higher-than-necessary utility bills, and the risk of losing contracts to competitors who can prove their commitment to sustainability. Your brand's reputation is on the line.

A modern packing line is designed from the ground up with efficiency and sustainability in mind. It provides a direct and immediate way to reduce your environmental footprint. By investing in this technology, you not only meet today's standards but also build a more resilient and respected business for the future. You do this by using less energy, generating less waste, and being prepared for the next generation of eco-friendly packaging materials.

A new packing line helps you meet environmental standards through two primary, powerful mechanisms: material efficiency and energy efficiency. Advanced power pre-stretch systems in wrapping machines can reduce the consumption of plastic stretch film by 50-70%. Simultaneously, the use of modern, high-efficiency motors with variable frequency drives dramatically cuts electricity usage. These features directly lower your operational footprint, reduce costs, and improve your sustainability credentials.

More Packing, Less Plastic

This is one of the most significant environmental and cost-saving benefits. Older machines or manual wrapping use a simple, low-stretch method. A modern automatic wrapper uses a technology called "power pre-stretch." The machine uses a set of rollers moving at different speeds to stretch the film by 200%, 300%, or even more before it's applied to the coil. This means one meter of film on the roll becomes three or four meters of wrapping on your product. The film becomes thinner but also stronger, like a stretched rubber band. For a 2-million-ton-per-year steel mill like Javier's, this could translate into saving tens of tons of plastic film every year. That's a huge reduction in both plastic waste and material cost.

The Energy Consumption Equation

Your aging equipment likely has motors that are oversized and run at 100% speed all the time, even when they are not under a full load. This is incredibly inefficient. A modern packing line incorporates Variable Frequency Drives (VFDs). A VFD is a smart controller that gives the motor only the exact amount of power it needs for the task at hand. It's like replacing a light switch with a dimmer. The energy savings from VFDs, combined with newer, more efficient motor designs, can reduce the packing line's electricity consumption by 30% or more.

Preparing for the Future of Packaging

Sustainability is an evolving field. Today, the focus is on reducing plastic use. Tomorrow, it may be on using biodegradable or paper-based wrapping materials. A modern, flexible packing line is an investment in that future. Unlike old, rigid machinery, new systems are designed to be adaptable. They can often be adjusted or retrofitted to handle new types of materials as they become commercially viable and cost-effective.

| Current Common Practice | Future-Proof Solution | Environmental Benefit |

|---|---|---|

| Thick Gauge Stretch Film | Low-gauge film with power pre-stretch | Drastic reduction in plastic consumption. |

| Constant Speed Motors | High-efficiency motors with VFDs | Significant reduction in electricity use. |

| Single-Material Design | Flexible system compatible with multiple materials | Ready to adopt biodegradable or paper-based wraps. |

For a visionary leader, investing in sustainable technology isn't a burden. It's a competitive advantage that strengthens the business for the long term.

Conclusion

Future-proofing your packing line is about smart automation, clear ROI, digital integration, and sustainability. It transforms a necessary cost center into a powerful strategic asset for your mill's growth and stability.