Your steel coils leave the slitter looking perfect. But by the time they reach your customer, they are scratched, rusted, or damaged. Your current packing method is slow, inconsistent, and relies heavily on manual labor, which is expensive and a safety concern in your Australian facility. Every damaged coil erodes your profit margins and damages your reputation. You know you need a better solution, but the thought of a major equipment investment is daunting. This isn't just a packaging problem; it's a critical bottleneck that is holding your business back from its true potential.

To choose the right coil wrapping system for your Australian operations, you must first perform a detailed analysis of your specific needs. This includes understanding your coil dimensions, required throughput, and the physical layout of your plant. Then, you must evaluate suppliers based on their technical ability to provide a durable, reliable machine that meets Australian safety standards. The final step is to look beyond the initial price tag and calculate the total cost of ownership, ensuring the system provides a strong return on investment through automation and efficiency gains.

I have spent my entire career in the packing machine industry, from an engineer on the floor to building my own factory. I've seen firsthand how the right equipment can transform a business. It’s how I achieved my own success and helped many of my clients grow. Now, I want to share what I’ve learned. This guide will break down the selection process into clear, manageable steps. We will go through the critical questions you need to ask to find a solution that not only protects your coils but also future-proofs your operations.

What are the key operational factors to consider?

Have you ever bought a piece of equipment that looked perfect on paper, only to find it causes chaos on your factory floor? It doesn't fit the space, it can't keep up with your production speed, or it simply can't handle your specific product. This is a costly and frustrating mistake. The new machine becomes a source of constant problems, requiring expensive modifications and creating a permanent bottleneck in your workflow. Before you even look at a supplier's brochure, you must first look inward at your own operations. Defining your needs with precision is the first step to avoiding this disaster and finding a machine that works for you, not against you.

The most important operational factors to consider are your coil specifications, your required production rate, and your factory's physical layout. You need to know the inner and outer diameters, width, and maximum weight of the coils you process. You also need to calculate your target throughput in coils per hour to ensure the machine can keep pace. Finally, you must measure your available floor space and consider how the machine will integrate with your existing material handling equipment like cranes and forklifts.

Dive Deeper: Matching the Machine to Your Reality

Choosing a coil wrapper is like buying a suit. An off-the-rack option might work, but a tailored suit fits perfectly and makes you look your best. The same is true for your machinery. A deep analysis of your operational reality ensures you get a machine that is tailored to your needs, maximizing efficiency and minimizing problems.

Coil Specifications: The Devil is in the Details

The physical characteristics of your coils dictate the fundamental design of the wrapping machine. It's not enough to just know the maximum weight. You need to provide a potential supplier with a complete picture.

- Dimensions (ID, OD, Width): These determine the size of the wrapping ring and the overall machine footprint. A machine designed for narrow slit coils will be very different from one built for wide master coils.

- Weight: This impacts the design of the conveyor system, the turnstile, and the tilter. The support rollers and drive systems must be robust enough to handle your heaviest coils safely and repeatedly.

- Surface Condition: Are your coils oiled or dry? Oiled surfaces can affect the adhesion of some wrapping materials and require specific tension control to prevent the film from slipping. Dry surfaces might be more prone to scratching, requiring softer roller materials.

I remember a client who only gave us their maximum coil width. But they failed to mention they also run very narrow coils. The standard V-block rollers we installed were too wide, causing the narrow coils to sit unevenly and get wrapped improperly. We had to fly an engineer out to replace them with custom-designed rollers. Defining the full range of your products from the start prevents these kinds of expensive fixes.

Throughput and Cycle Time: The True Measure of Speed

Don't be fooled by a machine's "rotations per minute" (RPM). The true measure of productivity is cycle time – the total time it takes to process one coil from start to finish. This includes loading the coil onto the machine, the wrapping process itself, cutting and securing the film, and unloading the finished coil.

| Action | Manual Process | Semi-Automatic System | Fully Automatic Line |

|---|---|---|---|

| Coil Loading | 2-3 minutes (Crane + 2 operators) | 1 minute (Conveyor) | 30 seconds (Integrated) |

| Wrapping | N/A | 1.5 minutes | 1 minute |

| Film Cut & Secure | 1 minute (Manual) | 10 seconds (Automatic) | 5 seconds (Automatic) |

| Unloading/Labeling | 1.5 minutes (Manual) | 45 seconds (Conveyor + Manual) | 30 seconds (Integrated) |

| Total Cycle Time | ~5 minutes + | ~3.5 minutes | ~2 minutes |

| Coils per Hour | ~12 | ~17 | ~30 |

As you can see, a fully automatic line can be more than twice as fast as a semi-automatic one. In a high-cost labor market like Australia, reducing the need for manual intervention at each step is critical for ROI. The goal is to design a system where the wrapper is never waiting for a coil, and a finished coil is never waiting to be removed.

Factory Layout: Making it All Fit

You can have the best machine in the world, but it's useless if it doesn't fit in your factory. You need to consider:

- Footprint: Get a detailed layout drawing from the supplier and map it out on your floor. Account for not just the machine, but also for operator access, maintenance space, and electrical cabinets.

- Flow: How will coils get to and from the wrapper? Will it be an "in-line" system, where coils come directly from the slitter? Or an "offline" station, where coils are brought by crane or forklift? The flow determines the type of conveyor and handling system you'll need.

- Height: In Australia, older factories can have lower ceiling heights. You must account for overhead crane clearance and the vertical movement of any coil tilters or upenders.

Thinking through these operational factors is not just a preliminary step; it is the foundation of a successful project.

How do you evaluate a supplier's technical capabilities?

You receive two proposals. One is from a big-name brand with a slick brochure. The other is from a smaller, specialized factory. The prices are different, and both claim their machine is the best. How do you decide? Choosing a supplier based on their marketing materials alone is a huge gamble. A fancy website doesn't tell you about the quality of their welds, the reliability of their components, or their ability to solve a problem when something goes wrong. You could end up with a machine that constantly breaks down, with a supplier who is unresponsive, leaving your production crippled. To avoid this, you need to dig deeper and find a true engineering partner, not just a salesperson.

You evaluate a supplier's technical capabilities by scrutinizing their engineering process, from the software they use to the brand of components they install. Ask for detailed case studies and contact information for reference clients in Australia or a similar market. Most importantly, assess their willingness and ability to customize the equipment. A true partner works with you to design a solution for your specific problem, rather than just selling you a standard model from their catalog.

Dive Deeper: Looking Under the Hood

A supplier's true strength isn't in their sales pitch; it's in their workshop and their engineering department. You need to investigate their capabilities with the critical eye of an engineer. This is how you separate the assemblers from the true manufacturers.

From Design to Manufacturing: The Quality Checklist

A good supplier should be transparent about their entire process. Don't be afraid to ask detailed technical questions.

- Design Process: Do they use modern 3D CAD software like SolidWorks or Inventor? This allows you to review the machine design in 3D before any metal is cut, catching potential issues early. Ask if they perform Finite Element Analysis (FEA) on critical, high-stress components like the main wrapping ring or the lifting mechanism. This shows a commitment to robust engineering.

- Component Selection: The reliability of a machine is the sum of its parts. Ask for a list of their primary component suppliers. Are they using globally recognized brands like Siemens for PLCs and drives, SKF or FAG for bearings, and Schneider for electrical components? Using reputable components means better performance and easier access to spares in Australia. A supplier who uses cheap, unknown components to cut costs is giving you a clear warning sign about the machine's long-term reliability.

- Manufacturing Standards: If you can, visit their factory. If not, ask for videos of their production process. Look at the quality of their welding and machining. Are the welds clean and consistent? Are the machined surfaces smooth and precise? These details reflect the overall quality and durability of the final product.

Customization: The Path to a Perfect Fit

Your operation is unique. A standard, off-the-shelf machine is built for the "average" customer, but you are not average. A supplier's ability to customize is a key indicator of their technical depth.

I once worked with a steel mill owner in Mexico, Javier. He had a specific challenge: his plant processed both heavy hot-rolled coils and delicate, surface-critical cold-rolled coils on the same line. A standard wrapper would have been too aggressive for the cold-rolled product. We designed a system with a dual-mode tension control and programmable roller pressure. The operator could select the coil type on the HMI, and the machine would automatically adjust all its parameters. This level of customization solved his problem and prevented millions in potential quality claims. A supplier who just tries to sell you a standard machine either doesn't understand your problem or doesn't have the capability to solve it.

Proof of Performance: References and Testing

Never be the first to test a new machine design. A capable supplier will have a track record of success.

- Case Studies and References: Ask for case studies relevant to your industry and, ideally, your region. A supplier who has already installed machines in Australia will be familiar with local safety standards (AS/NZS 4024), electrical codes, and support logistics. Ask to speak with their existing customers. Ask them the tough questions: What went wrong during commissioning? How was the after-sales support?

- Factory Acceptance Test (FAT): This is non-negotiable. The FAT is your opportunity to see the machine run before it ships. You should prepare a detailed checklist of functions to test. If possible, send your own materials or even a sample coil to be used during the test. Running the machine at its full rated speed and testing all its functions in the supplier's factory is the best way to ensure there are no surprises when it arrives on your floor in Australia.

A supplier who welcomes this level of scrutiny is one who is confident in their product and their process. They are the ones you want as a partner.

What's the real cost of ownership beyond the initial price?

You've got two quotes on your desk. Machine A is 20% cheaper than Machine B. It's tempting to go for the lower price to help your budget. But a year later, Machine A is a constant headache. It uses more power than expected, spare parts are expensive and slow to arrive from overseas, and it breaks down twice a month, forcing your team into costly overtime to catch up. The initial savings have been completely wiped out by these ongoing expenses. You realize that the "cheapest" machine has become the most expensive piece of equipment you own. This is a classic trap, and it stems from focusing only on the purchase price.

The real cost of ownership, or Total Cost of Ownership (TCO), is the sum of all expenses incurred over the entire lifecycle of the machine. This includes the initial purchase price, but also factors in ongoing costs such as energy consumption, spare parts, maintenance labor, and the massive financial impact of unplanned downtime. A higher-quality machine with a higher initial price often has a much lower TCO, making it the smarter long-term investment.

Dive Deeper: The TCO Calculation for a Smarter Investment

Making a major capital decision based on purchase price alone is a recipe for long-term financial pain. To make a truly informed choice, you must analyze the Total Cost of Ownership. This approach transforms the decision from a simple purchase into a strategic investment analysis, something any sharp CEO or plant owner would appreciate.

The Elements of Total Cost of Ownership

TCO is a simple concept, but it requires a disciplined approach. Here is a breakdown of the key costs you must consider:

TCO = Initial Purchase Price + Installation & Commissioning Costs + Lifetime Energy Costs + Lifetime Maintenance & Spares Costs + Cost of Downtime

Let's look at these "hidden" costs, as this is where a cheaper machine often reveals its true expense.

| Cost Factor | Machine A (Low Price) | Machine B (High Quality) | Key Considerations for Australian Ops |

|---|---|---|---|

| Purchase Price | $150,000 | $180,000 | The most visible, but least important, long-term cost. |

| Energy Costs | $15,000 / year (Standard Motors) | $12,000 / year (High-Efficiency Motors) | With high electricity prices in Australia, a 20% saving is significant over a 10-year life. |

| Maintenance & Spares | $8,000 / year | $3,000 / year | Factor in availability and shipping costs of parts to Australia. Common parts should be locally sourced. |

| Downtime Costs | 40 hours/year x $1,500/hr = $60,000 | 5 hours/year x $1,500/hr = $7,500 | Lost production, labor costs, and potential late delivery penalties. This is often the biggest hidden cost. |

| 10-Year TCO | $150k + $230k + $600k = $980,000 | $180k + $150k + $75k = $405,000 | Machine A, the "cheaper" option, costs more than double over its lifetime. |

Note: Figures are illustrative to demonstrate the concept.

Analyzing the Hidden Killers: Energy and Downtime

- Energy Consumption: A key challenge for any industrial operation in Australia is the high cost of electricity. A smart supplier will design a machine with energy efficiency in mind. Ask about the use of high-efficiency motors (IE3 or IE4 standards) and Variable Frequency Drives (VFDs). VFDs allow the motors to ramp up and down smoothly and run at the optimal speed for the task, rather than running at full power all the time. This can reduce energy consumption by 20-30% or more, which adds up to huge savings over the machine's life. This directly addresses the goal of lowering unit energy consumption.

- Downtime: This is the most dangerous hidden cost. Every hour your wrapping line is down, your entire production process can grind to a halt. The costs are not just the idle labor. It's the lost revenue from production you couldn't complete, the potential penalties from customers for late shipments, and the damage to your reputation as a reliable supplier. A machine built with higher quality components, better engineering, and robust construction might cost more upfront, but its superior reliability and higher uptime (e.g., 99% vs 95%) deliver a massive return by avoiding these catastrophic downtime costs. This is why focusing on reliability is key to achieving a high capacity utilization rate.

By shifting your focus from "price" to "TCO," you change the conversation with suppliers. You force them to justify their machine's value over its entire lifecycle, leading to a much smarter, more profitable decision for your business.

How can automation and data integration boost your ROI?

Your wrapping station currently runs like an isolated island. Operators manually record the number of coils packed on a clipboard. If the machine stops, you only find out when someone notices the line has backed up. You have no real visibility into its efficiency, material consumption, or the reasons for stoppages. You are making decisions based on old data and guesswork. This lack of information means you can't optimize your process, you can't predict failures, and you are missing a huge opportunity to improve your bottom line. Integrating your packaging line is no longer a luxury; it's essential for staying competitive.

Automation and data integration provide a powerful return on investment by directly tackling your biggest operational costs and challenges. A fully automated system dramatically reduces labor requirements, a critical advantage in high-wage countries like Australia. It increases throughput and consistency, while data integration connects the machine to your plant-wide management systems (like MES). This provides real-time visibility for better decision-making, enables predictive maintenance to maximize uptime, and turns your packaging line into a smart, data-generating asset.

Dive Deeper: From Automated Island to Integrated Hub

Thinking of a coil wrapper as just a machine that puts plastic on steel is an outdated view. Today, it should be viewed as a data-rich node in your factory's digital ecosystem. This is how you move from simply packaging your product to actively improving your entire production process. This mindset shift is critical for achieving goals like 95% equipment uptime and significant operational cost reductions.

The Spectrum of Automation: Finding Your Payback

Automation is not an all-or-nothing choice. It exists on a spectrum, and you can choose the level that provides the best ROI for your specific operation.

- Level 1: Semi-Automatic: The machine performs the core wrapping function automatically (e.g., applies film, cuts it). However, loading and unloading are done manually or with a crane. This is a good entry point to improve consistency over hand-wrapping.

- Level 2: Fully Automatic Station: The coil is fed by a conveyor. The machine automatically centers the coil, wraps it, weighs it, and applies a label. An operator is still needed to manage the overall station and bring coils to the infeed conveyor.

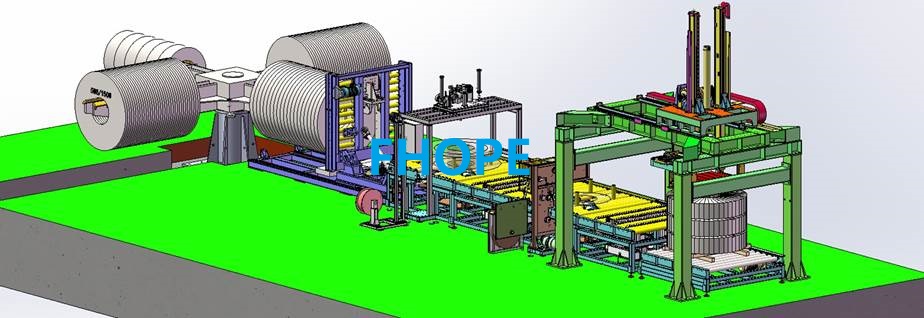

- Level 3: Fully Integrated Line: This is the Industry 4.0 solution. The wrapping line is physically and digitally connected to the equipment before and after it (e.g., the slitting line and the warehouse entry point). The entire process, from the slitter's exit to the final packaged coil being sent to storage, happens with zero manual intervention.

In Australia, where skilled labor costs can exceed $40 AUD per hour, the payback for moving from Level 1 to Level 2 or 3 is often surprisingly fast. A fully automatic system that can run an entire shift with only minimal supervision can eliminate two to three full-time positions, saving hundreds of thousands of dollars per year in labor costs alone. This also improves safety by removing people from the direct vicinity of heavy, moving equipment.

Data Integration: Making Your Machine Talk

An automated machine without data is a missed opportunity. A truly strategic supplier can provide a system that integrates seamlessly with your factory's brain—the Manufacturing Execution System (MES) or Enterprise Resource Planning (ERP) system.

What data should your wrapper provide?

- Production Data: Coil ID, weight, dimensions, wrapping recipe used, time/date stamp, operator ID. This data is sent directly to your MES, eliminating manual entry and errors.

- Performance Data (OEE): Track cycle times, short stops, and fault codes. This allows you to measure Overall Equipment Effectiveness (OEE) and identify opportunities for improvement. You can finally answer the question: "How efficiently is my packaging line really running?"

- Consumables Data: Track the consumption of wrapping film and labels. This helps with inventory management and accurate job costing.

The Ultimate Goal: Predictive Maintenance

This is where data integration provides its greatest value, especially for an owner concerned with aging equipment and uptime. By placing IoT sensors on critical components—like motors, bearings, and gearboxes—we can monitor things like vibration, temperature, and energy usage in real-time.

This data is fed into an analysis platform. Instead of waiting for a bearing to fail and shut down your line unexpectedly, the system can detect a tiny increase in vibration or temperature weeks in advance. It can then automatically generate a maintenance alert, telling your team: "The main ring drive bearing is showing early signs of wear. Please schedule a replacement during the next planned maintenance window." This moves you from a reactive "fix it when it breaks" model to a proactive, predictive maintenance strategy. This is the single most effective tool for achieving a goal of 95% or higher equipment uptime and directly addresses the challenge of aging, unreliable equipment.

My Insights

Choosing the right system is a strategic partnership. It’s about securing your production, protecting your product, and future-proofing your operations. Let's build that future together.