How to Choose the Right Coil Turning Machine: Price, Capacity, and Safety

Leading Paragraph:

Are you struggling with slow manual coil handling that's creating production bottlenecks in your Mexican factory? As a plant manager, you know that every minute of downtime costs money, and manual coil turning poses serious safety risks to your team. The frustration of dealing with unreliable equipment suppliers only adds to the stress of meeting production targets while keeping costs under control.

Snippet Paragraph:

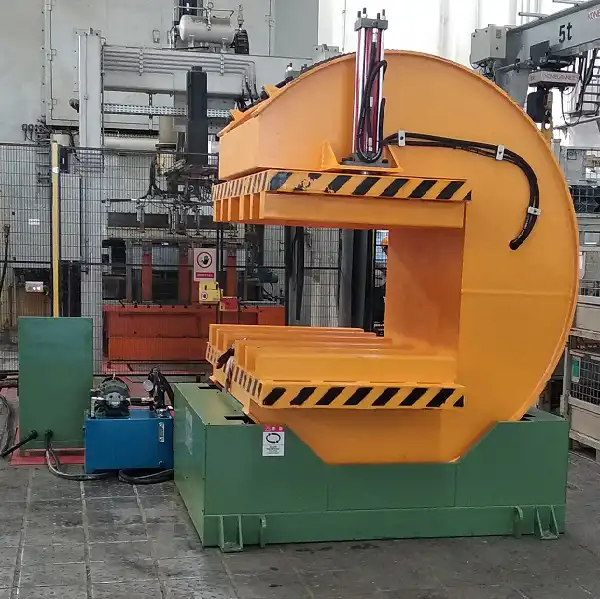

Choosing the right coil turning machine requires balancing three critical factors: price, capacity, and safety features. The ideal machine should match your production volume, fit your budget with clear ROI, and eliminate manual handling risks. Key considerations include:

- Capacity requirements based on your coil size and production speed

- Safety certifications and built-in protection features

- Total cost of ownership, not just initial purchase price

Transition Paragraph:

Making the wrong choice can cost your factory thousands in lost production and safety incidents. Let me guide you through the key questions you should ask before investing in coil handling equipment, drawing from my 20+ years in the packing machinery industry.

1. What Are the 3 Critical Factors in Coil Turning Machine Selection?

Leading Paragraph:

When Mexican plant managers like Michael face coil handling challenges, they often focus only on the purchase price. But in my experience working with steel plants across Latin America, the most successful investments consider three equally important factors that determine long-term success.

Snippet Paragraph:

The three critical factors are production capacity requirements, safety compliance features, and total cost of ownership. According to Randal Liu, SHJLPACK's founder, "Factories that prioritize only price often end up with machines that can't handle their volume or lack essential safety features, costing more in the long run through downtime and accidents."

Dive Deeper Content:

Capacity Requirements Analysis

Your coil turning equipment must match your actual production needs, not just today's volume but future growth. I've seen too many factories buy undersized machines that become bottlenecks within months.

Production Capacity Assessment:

- Current volume: Count your daily coil transfers - most Mexican steel plants handle 50-200 coils per shift

- Future expansion: Plan for 20-30% growth capacity to avoid quick obsolescence

- Coil specifications: Maximum weight (typically 3-20 tons), diameter (800-2000mm), and width variations

Safety Compliance Essentials

In Mexico, workplace safety regulations (NOM standards) are becoming increasingly strict. Proper coil upenders should include:

Mandatory Safety Features:

- ⚡ Emergency stop buttons at multiple access points

- 🛡️ Anti-slip platforms and guard rails

- 🔒 Lockout-tagout systems for maintenance

- 📊 Load sensors to prevent overload situations

Total Cost of Ownership Calculation

The initial machine price is only 40-60% of your total investment. Consider these hidden costs:

| Cost Category | Percentage of Total | Typical Range (USD) |

|---|---|---|

| Initial Purchase | 40-60% | $25,000-$80,000 |

| Installation & Training | 10-15% | $6,000-$18,000 |

| Maintenance (Annual) | 5-8% | $3,000-$9,600 |

| Energy Consumption | 3-5% | $1,800-$6,000 |

| Spare Parts Inventory | 8-12% | $4,800-$14,400 |

According to industry data, factories that choose SHJLPACK coil turning machines typically achieve ROI within 12-18 months through 40% labor reduction and 25% faster processing times.

2. How Much Should You Budget for a Quality Coil Turner?

Leading Paragraph:

"I need a coil turning machine, but I don't want to overspend" - this is the most common concern I hear from plant managers in Mexico. The truth is, both cheap equipment and over-engineered solutions can hurt your bottom line.

Snippet Paragraph:

A quality coil turning machine typically costs between $25,000 and $150,000, depending on automation level and capacity. For most Mexican metal processing plants, the sweet spot is $45,000-$75,000 for a machine that handles 5-15 ton coils with semi-automatic operation and proper safety features.

Dive Deeper Content:

Price Tiers and What You Get

Understanding the different price categories helps you avoid both underspending and overspending:

Entry-Level Machines ($25,000-$40,000)

- ✅ Basic hydraulic operation

- ✅ Capacity: 3-8 ton coils

- ✅ Manual positioning

- ❌ Limited safety features

- ❌ Higher maintenance costs

- Best for: Small workshops with low volume

Professional Grade ($50,000-$80,000)

- ✅ Semi-automatic operation

- ✅ Capacity: 5-15 ton coils

- ✅ CE safety certification

- ✅ Basic automation

- Best for: Most Mexican steel plants (recommended tier)

Industrial Grade ($100,000-$150,000)

- ✅ Fully automatic operation

- ✅ Capacity: 10-25 ton coils

- ✅ Smart sensors and IoT connectivity

- ✅ Advanced safety systems

- Best for: High-volume continuous operations

ROI Calculation Example

Let's examine a real case from a Mexican client:

Manual Process Costs:

- 4 workers × $1,800/month = $86,400/year

- Product damage: 2% rate × $500,000 inventory = $10,000/year

- Safety incidents: $5,000 average cost

- Total annual cost: $101,400

Automated with SHJLPACK:

- 1 operator × $2,200/month = $26,400/year

- Product damage: 0.5% rate = $2,500/year

- Machine cost: $65,000 (amortized over 5 years) = $13,000/year

- Total annual cost: $41,900

Annual savings: $59,500 | ROI period: 13 months

Payment Terms and Financing

Most quality suppliers like SHJLPACK offer flexible payment options:

- 30% down payment, 70% before shipment

- Lease-to-own arrangements available

- Local Mexican financing partners

- Spare parts package included in initial quote

3. What Safety Features Are Non-Negotiable in Coil Handling?

Leading Paragraph:

Last year, I visited a steel plant in Monterrey where a worker was nearly crushed during manual coil turning. The plant manager told me, "We thought we were saving money with manual methods, but one accident costs more than any machine." This experience reinforced why certain safety features are absolutely essential.

Snippet Paragraph:

Non-negotiable safety features include emergency stop systems, overload protection, secure locking mechanisms, and certified structural integrity. According to Mexican NOM-006-STPS-2014 standards, coil handling equipment must prevent accidental release of loads and provide clear operator protection zones.

Dive Deeper Content:

Essential Safety Systems Checklist

Based on my two decades of experience and Mexican regulatory requirements, here are the must-have safety features:

1. Emergency Stop Circuitry

- Multiple emergency stop buttons within easy reach

- Fail-safe braking system that engages immediately

- Automatic power cutoff when activated

- Regular testing protocol (weekly recommended)

2. Load Management Systems

- Weight sensors that prevent operation beyond rated capacity

- Tilt angle limiters for unstable loads

- Center of gravity detection for irregular coils

- Visual and audible overload warnings

3. Physical Protection Barriers

- 🛡️ Fixed guards around pinch points

- 🔒 Interlocked access gates that stop operation when opened

- 📏 Safe distance maintenance from operator stations

- 🎨 High-visibility safety markings

Safety Standards Compliance

Ensure your coil turning machine meets these certifications:

| Standard | Region | Key Requirements |

|---|---|---|

| NOM-006-STPS-2014 | Mexico | Load handling safety, operator protection |

| CE Marking | Europe | Machine safety directive compliance |

| ISO 13849 | International | Safety-related control systems |

| OSHA 1910 | USA | General industry safety standards |

Safety ROI: Beyond Compliance

While compliance is mandatory, the real safety benefits come from preventing incidents:

Case Study: Mexican Steel Plant

- Before: 3 minor injuries per year, $15,000 insurance costs

- After SHJLPACK installation: Zero injuries in 18 months, 40% insurance premium reduction

- Additional benefit: Reduced employee turnover from 25% to 8% annually

According to Randal Liu, "The safest machines often become the most productive because operators work with confidence rather than fear."

4. How Do You Match Machine Capacity to Your Production Needs?

Leading Paragraph:

One of the biggest mistakes I see in Mexican factories is buying either oversized or undersized equipment. One client purchased a massive coil turner that ran at 20% capacity, while another bought a small machine that became a bottleneck within months. Both situations hurt profitability.

Snippet Paragraph:

Match machine capacity by analyzing your current coil volume, weight range, and future growth plans. Calculate your peak hourly requirements and add 25% buffer capacity. For most Mexican metal plants, machines handling 8-12 ton coils at 40-60 coils per hour provide the optimal balance between performance and investment.

Dive Deeper Content:

Capacity Planning Step-by-Step

Step 1: Analyze Current Production Data

- Track your daily coil processing for 2 weeks

- Note peak periods and seasonal variations

- Measure actual coil dimensions and weights

- Identify current bottlenecks in your steel coil packing line

Step 2: Calculate Required Specifications

Use this simple formula I've developed for Mexican plants:

Required Capacity = (Peak Daily Coils ÷ Operating Hours) × 1.25

Example calculation:

- Peak daily requirement: 240 coils

- Operating hours: 8 hours

- Buffer factor: 25%

- Required hourly capacity: (240 ÷ 8) × 1.25 = 37.5 → Round up to 40 coils/hour

Step 3: Machine Selection Matrix

Based on your calculated needs:

| Production Level | Recommended Capacity | SHJLPACK Model | Price Range |

|---|---|---|---|

| Low (100-200 coils/day) | 20-30 coils/hour | STC-30 | $35,000-$45,000 |

| Medium (200-400 coils/day) | 40-60 coils/hour | STC-60 | $55,000-$75,000 |

| High (400-600 coils/day) | 80-100 coils/hour | STC-100 | $95,000-$130,000 |

Future-Proofing Your Investment

Consider these growth factors specific to Mexican manufacturing:

Economic Trends:

- Nearshoring opportunities increasing production volumes

- Automotive industry expansion in Bajio region

- Infrastructure projects driving steel demand

Technical Considerations:

- Modular designs that allow capacity upgrades

- Compatibility with automation systems

- Space for additional safety features

- Energy efficiency for rising electricity costs

Real Capacity vs. Rated Capacity

Important distinction many suppliers don't clarify:

Rated Capacity: Maximum under ideal conditions

Real Capacity: Sustainable daily operation (typically 80% of rated)

According to SHJLPACK engineering data, their machines maintain 95% of rated capacity even after 3 years of operation due to robust construction and quality components.

Conclusion

Choosing the right coil turning machine requires careful analysis of your specific needs, budget, and safety requirements. By focusing on total cost of ownership rather than just purchase price, you'll make an investment that pays dividends for years. For complete packaging solutions, consider our integrated steel coil packing line that works seamlessly with your turning equipment.

FAQ Section

Frequently Asked Questions

Q: What's the typical delivery and installation time for coil turning machines in Mexico?

A: Most quality suppliers like SHJLPACK require 4-6 weeks for manufacturing and 1-2 weeks for installation and training in Mexican factories. Customs clearance typically adds 3-5 business days, so plan for 6-8 weeks total from order to operation.

Q: How often do coil turning machines require maintenance?

A: Basic maintenance should be performed weekly (safety checks) and monthly (lubrication, bolt tightening). Major service is typically needed annually. SHJLPACK machines average 98% uptime with proper maintenance, significantly higher than industry standard of 92%.

Q: Can coil turning machines handle different coil sizes automatically?

A: Higher-end models ($75,000+) feature automatic adjustment for different coil diameters and widths. Mid-range machines usually require manual adjustment, which takes 2-5 minutes per size change. Consider your product mix frequency when choosing automation level.

Q: What training do operators need for safe coil turning machine operation?

A: Operators need 8-16 hours of initial training covering basic operation, safety procedures, and emergency protocols. SHJLPACK provides comprehensive training in Spanish with all machine installations and offers refresher courses every 6 months.

Q: How does humidity in coastal Mexican plants affect coil turning equipment?

A: Coastal environments require additional corrosion protection. Look for machines with IP54 rating or higher, stainless steel components in critical areas, and regular maintenance schedules. SHJLPACK offers special coastal packages with enhanced protection for factories in Veracruz, Tampico, and other port cities.