How Mexico Procurement Managers Use Mold Flipper to Cut Costs & Improve Efficiency

In Mexico's demanding steel industry, the pressure is always on. You need to increase output, guarantee quality, and keep your people safe. But often, aging equipment and old, manual processes create dangerous bottlenecks that silently drain your profits. A single mistake when handling a multi-ton mold can lead to catastrophic accidents, halting production for days and costing a fortune in repairs and lost revenue. The solution is often simpler than you think, resting in a robust and reliable machine: the mold flipper.

Procurement managers in Mexico leverage mold flippers to cut costs by minimizing labor requirements, reducing equipment damage, and preventing costly accidents. They improve efficiency by drastically speeding up mold maintenance and changeover cycles, which directly increases production uptime and throughput.

This piece of equipment might seem straightforward, but its impact on your bottom line and operational flow is profound. It’s more than just a machine; it's a strategic tool that addresses some of the biggest challenges in a modern steel mill, from cost control to worker safety. As an engineer who has spent his entire career in this field, I've seen firsthand how mastering these fundamental processes can transform a business. Let’s dive deeper into how this machine delivers real results, so you can make a truly informed investment for your facility.

What specific operational costs does a mold flipper reduce in a steel mill?

Your factory's budget is under constant scrutiny. You track the big-ticket items like energy and raw materials closely, but what about the hidden costs? The small, recurring expenses tied to tasks like mold handling can fly under the radar. Every time your team uses an overhead crane and chains to flip a heavy mold, you are paying for multiple workers' time, risking damage to the expensive mold, and creating a scenario ripe for a safety incident. These "small" costs accumulate into a significant financial drain over the course of a year. A mold flipper targets this single, inefficient task and creates a powerful ripple effect of cost savings across your entire operation.

A mold flipper specifically reduces operational costs in a steel mill by lowering direct labor expenses for turning operations, eliminating the need for complex and risky crane maneuvers, and preventing damage to expensive molds and dies, which cuts down on repair and replacement budgets.

Understanding these cost reductions in detail is key to justifying the investment. A mold flipper isn't just an expense; it's a cost-saving engine. Let's break down exactly where that money comes from.

Direct Labor Cost Reduction

The most immediate and obvious saving is in labor. Think about the standard procedure for flipping a large mold manually. It typically requires a team: one skilled crane operator and at least two or three riggers on the ground to manage the slings and guide the load. The entire process is slow and methodical by necessity, often taking an hour or more to complete safely.

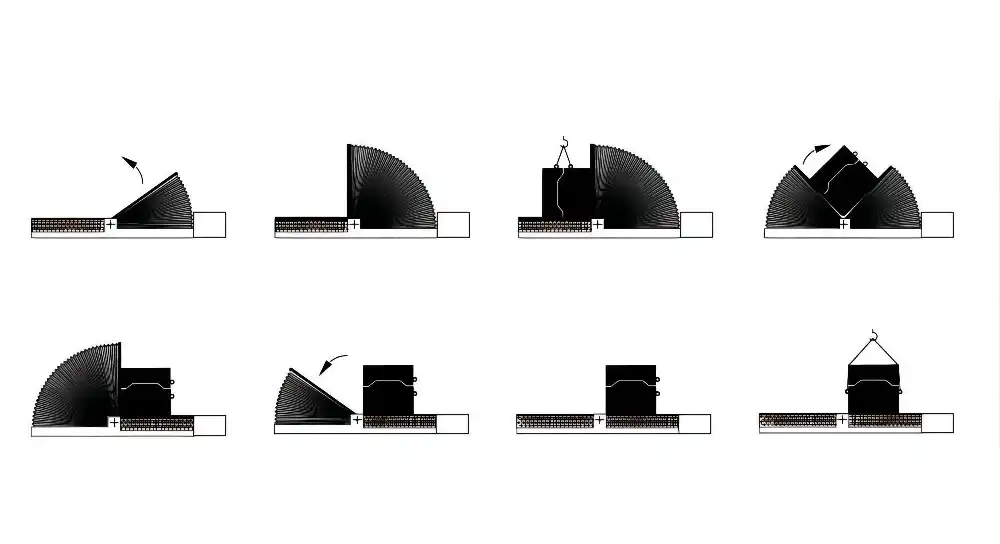

Now, compare that to a mold flipper. A single operator can load the mold onto the machine, often with a forklift, step back to a safe distance, and initiate the 90-degree turn with the push of a button. The entire cycle is completed in a matter of minutes. You've just reduced the personnel required for the task by 75% or more and cut the time drastically. When you perform this operation multiple times a day or week, the saved man-hours add up incredibly fast. These are skilled workers who can now be reassigned to more value-added tasks instead of spending their time on a risky, non-productive maneuver.

| Metric | Manual Flipping (with Crane) | Mold Flipper | Impact |

|---|---|---|---|

| Personnel Required | 1 Crane Operator + 2-3 Riggers | 1 Forklift/Machine Operator | Reduced direct labor costs by 60-75% per operation. |

| Time per Operation | 30 - 60 minutes | 5 - 10 minutes | Frees up skilled labor for value-added tasks. |

| Required Skill Level | High (Certified Crane Operator & Riggers) | Low (Basic machine operation training) | Lowers training burden and dependency on specialized staff. |

Equipment and Asset Preservation

Large industrial molds, especially those used in steel mills, are significant capital assets. They are precision-engineered and can cost tens or even hundreds of thousands of dollars. The manual flipping process puts these valuable assets at immense risk. When a mold is suspended from chains or slings, it can swing, shift, and be accidentally bumped or dropped. Even small impacts can cause dents, scratches, or misalignments on critical surfaces, leading to defects in the final product.

The cost of repairing a damaged mold is high, not to mention the production downtime required to pull it from the line. In a worst-case scenario, the mold may be damaged beyond repair, forcing a costly replacement. A mold flipper eliminates this risk. It supports the mold across a large, stable platform and uses a smooth, controlled hydraulic or electromechanical motion to turn it. There are no chains, no swinging, and no uncontrolled movements. By protecting your molds from damage, the flipper extends their operational life and ensures the quality of your output, directly protecting your investment. This is especially critical for a plant manager like Javier, who understands that every piece of equipment must deliver a strong return.

Reduction of Secondary and Hidden Costs

The savings don't stop there. By reducing the reliance on overhead cranes for these awkward lifts, you also reduce the wear and tear on the cranes themselves. This means lower maintenance costs and a longer lifespan for your lifting equipment, which is a key concern when dealing with an aging fleet. Furthermore, creating a demonstrably safer work environment can have a positive impact on your insurance premiums. Insurers look favorably upon engineered controls that remove human risk, and a mold flipper is a textbook example of this. It takes a hazardous, judgment-based task and makes it a safe, repeatable, and machine-controlled process. These secondary savings, while harder to quantify initially, contribute significantly to lowering the total cost of ownership and improving the overall financial health of the operation.

How does a mold flipper directly improve production efficiency and safety?

Production bottlenecks are a constant source of frustration on the factory floor. A single slow process, like a manual mold changeover, can bring your entire multi-million dollar production line to a standstill. Every minute that line sits idle waiting for a maintenance team to safely flip and prepare a mold, you are losing potential revenue. This pressure to speed things up can lead to shortcuts, mistakes, and tragic injuries. A mold flipper solves this problem by transforming the bottleneck into a smooth, fast, and predictable part of your workflow, boosting both efficiency and safety simultaneously.

A mold flipper directly improves production efficiency by cutting mold turning time from hours to minutes, enabling faster maintenance cycles and production changeovers. This boosts safety by creating a stable, controlled process that eliminates the high-risk, manual handling of heavy loads with cranes.

The dual benefit of speed and safety is what makes this machine so powerful. It doesn't force you to choose between being fast and being safe; it allows you to be both. Let’s examine how this plays out in a real-world industrial environment.

Slashing Production Downtime

For a CEO like Javier, whose goal is to achieve 95% equipment uptime, minimizing planned and unplanned downtime is everything. Mold maintenance and changeovers are a major source of planned downtime. With a manual process, this downtime is extended significantly. The workflow involves clearing a large safety area, waiting for an overhead crane to become available, meticulously attaching slings, and performing the slow, careful lift and turn. This entire sequence can easily consume an hour or more of valuable production time.

A mold flipper revolutionizes this workflow. The process becomes: load the mold, press a button, and the turn is complete in under 10 minutes. The mold is immediately ready for maintenance or installation. By reducing the time for this single step from an hour to a few minutes, you give back significant productive time to the plant. This allows for more frequent inspections, faster changeovers between different products, and ultimately, a higher overall equipment effectiveness (OEE). The machine pays for itself not just in cost savings, but in the value of the extra production it unlocks.

Enhancing Workplace Safety

I cannot overstate the safety improvement. From my years as an engineer, I can tell you that manually flipping heavy, asymmetrical loads with a crane is one of the most hazardous operations in any heavy industry. I remember visiting a plant in Monterrey where a near-miss incident during a mold flip caused a major safety stand-down and investigation. A chain slipped, and a 10-ton mold shifted violently just feet away from the rigging crew. They were lucky. Such incidents can easily lead to severe injuries or fatalities. The risks are numerous: dropped loads, swinging chains creating a wide danger zone, and catastrophic pinch points.

A mold flipper engineers this danger out of the process. The machine creates a contained, predictable, and stable environment. The operator stands at a control panel, well away from the moving parts. The load is fully supported at all times. By removing people from the immediate vicinity of the heavy lift, you virtually eliminate the risk of the most common and severe types of industrial accidents associated with this task. For a leader, ensuring your team goes home safe every day is the number one priority. This machine is a direct investment in your people's well-being.

| Metric | Manual Method (with Crane) | Mold Flipper Method | Impact on Production |

|---|---|---|---|

| Mold Changeover Time | 1-2 hours | < 15 minutes | Increases OEE, more production runs possible. |

| Safety Incidents | High Risk (Swinging loads, chain failure) | Extremely Low Risk (Contained process) | Reduces lost-time injuries, improves morale. |

| Maintenance Access | Awkward, limited access | Easy, fast access to all mold surfaces | Enables more thorough and frequent inspections. |

| Process Predictability | Variable (Depends on crew, crane) | Consistent and Repeatable | Allows for better production scheduling and planning. |

Enabling Proactive Maintenance

A secondary, but powerful, efficiency gain comes from enabling better maintenance practices. Because flipping a mold manually is so time-consuming and cumbersome, maintenance teams are often disinclined to do it unless absolutely necessary. Inspections might be delayed or less thorough than they should be.

When flipping a mold becomes a quick, effortless, 5-minute task, that barrier is removed. It becomes easy to flip a mold for a quick inspection between runs. This encourages a culture of proactive and predictive maintenance, a key goal for any modern industrial manager. Your team can spot hairline cracks, wear and tear, or other potential issues early, long before they lead to a catastrophic failure during a production run. This shift from reactive repair to proactive maintenance is a cornerstone of efficient manufacturing, and the mold flipper is a key enabler of that shift.

Why is a mold flipper a strategic investment for Mexico's steel industry's future?

The Mexican steel market is in a dynamic position, benefiting from nearshoring and increased industrial demand. But with this opportunity comes intense global competition. To secure a leading position, companies can't just rely on the old ways of doing things. Relying on inefficient, high-risk manual processes while competitors in other regions automate and modernize will leave you at a disadvantage, making you slower, less safe, and saddled with higher operational costs. To build a resilient and globally competitive operation, you must make strategic investments in foundational technologies. A mold flipper is precisely that—a smart, strategic step toward the factory of the future.

A mold flipper is a strategic investment for Mexico's steel industry because it aligns with the move towards automation and "Industry 4.0," enhances the country's reputation for high-quality and safe manufacturing, and provides a quick and tangible ROI that frees up capital for larger strategic initiatives like digital transformation.

This is not just about improving one task. It's about positioning your entire company for long-term success in a changing industrial landscape.

The Foundation of Automation and Industry 4.0

Many leaders, like Javier, have ambitious goals for digital transformation, including implementing MES and big data analytics. These are the right goals. However, a successful digital strategy cannot be built on a weak physical foundation. You cannot have a "smart factory" if your most basic mechanical processes are still manual, dangerous, and inefficient.

A mold flipper is a foundational piece of automation. It standardizes and de-risks a critical physical step. This single machine can be the gateway to more advanced automation. Once the turning process is automated, it can be integrated with Automated Guided Vehicles (AGVs) or gantry robot systems to create a fully automated mold maintenance and transfer cell. It provides the reliable, repeatable process that is a prerequisite for the data collection and visualization that leaders want. It’s a practical, first step on the journey to Industry 4.0, delivering immediate value while preparing you for the next technological leap.

Meeting Global Standards and Attracting Talent

As Mexico's manufacturing sector becomes more integrated with global supply chains, especially with demanding sectors like automotive and aerospace, customer expectations rise. Your clients don't just audit your final product; they audit your processes. A facility that uses modern, safe, and efficient equipment demonstrates a commitment to quality and professionalism. It shows that you are a reliable, world-class partner. This can be a significant competitive advantage when bidding for high-value contracts.

Furthermore, this commitment to modernization helps you win the war for talent. The next generation of skilled engineers, technicians, and operators wants to work in a safe, technologically advanced environment. They are not inspired by the prospect of working with outdated, dangerous methods. By investing in modern equipment like a mold flipper, you are investing in your brand as an employer, making it easier to attract and retain the skilled people you need to grow.

Financial Agility and Tangible ROI

From a CEO's perspective, every investment must be justified with a strong business case. The mold flipper excels here. Due to its direct impact on labor costs, safety, and equipment preservation, the payback period for a mold flipper is often incredibly short—frequently less than two years, and sometimes even under one.

This quick and clear return on investment is strategically important. It means that the capital is not tied up for long. The savings generated by the machine can be quickly reallocated to other strategic priorities, whether it's funding a pilot program for IoT sensors or investing in new energy-saving technology. It’s an investment that pays for itself and then continues to fund future improvements, creating a virtuous cycle of modernization and cost reduction. It’s the type of low-risk, high-reward project that pragmatic leaders seek to build momentum for larger transformation efforts.

What should a procurement manager look for when selecting a mold flipper supplier?

You have analyzed the benefits and decided that a mold flipper is the right move for your plant. Now comes the critical step: choosing the right supplier. On the surface, many machines and vendors can look similar. But making the wrong choice can be a costly mistake. You could end up with an underpowered machine that fails frequently, a piece of equipment that doesn't meet critical safety standards, or a supplier who disappears the moment the final payment is made. This leaves you with a useless piece of metal and a problem that is now worse than when you started. The key is to look beyond the initial price tag and find a true partner who understands your industry, your challenges, and your goals.

When selecting a mold flipper supplier, a procurement manager must look beyond the initial price and evaluate the supplier's engineering expertise, customization capabilities, track record in heavy industry like steel, and their commitment to providing comprehensive after-sales support, including installation, training, and spare parts availability in Mexico.

Finding a supplier is easy. Finding a partner requires diligence. Here are the critical areas to focus on during your evaluation.

Engineering Expertise and Customization

A mold flipper is not a one-size-fits-all product. The demands of a steel mill are far different from those of a small plastics factory. A potential supplier should not just try to sell you a standard model from a catalog. They should begin by asking detailed questions: What are the dimensions and weight of your heaviest molds? Where is the center of gravity? What are your power supply specifications? How will the machine integrate into your existing workflow?

This is where you can separate a simple reseller from a true engineering partner. As an engineer myself, I built SHJLPACK on the principle that we sell solutions, not just machines. A good supplier will offer to customize the machine to your specific needs. This could mean adjusting the platform size, integrating powered conveyors for easier loading, or designing custom controls. A refusal or inability to discuss customization is a major red flag, suggesting they don't have the engineering depth to support a heavy industrial client.

Proven Track Record in Heavy Industry

Always ask for proof. A supplier's claims mean nothing without a demonstrated history of success in environments similar to yours. Ask for case studies, reference lists, and testimonials, specifically from other steel mills or heavy manufacturing clients. A supplier whose primary experience is with lightweight applications may not understand the robust construction, powerful drive systems, and heavy-duty components required to safely handle multi-ton steel molds day after day.

Look for internationally recognized certifications like ISO and CE. These are not just stamps on a piece of paper; they indicate that the supplier adheres to rigorous quality management and safety design standards. This third-party validation provides an extra layer of confidence that the machine is well-engineered and built to last in a demanding industrial setting.

Total Lifecycle Support and Partnership

This is perhaps the most important factor for a strategic investment. The relationship must not end when the machine is delivered to your factory gate. A true partner provides support throughout the entire lifecycle of the equipment. Before you sign a purchase order, you should have clear answers to the following questions:

- Installation and Commissioning: Do they offer on-site support to ensure the machine is installed and commissioned correctly?

- Training: Do they provide comprehensive training for both your operators and your maintenance staff?

- Documentation: Is the manual clear, detailed, and available in the necessary languages?

- Spare Parts: Do they have a clear strategy for providing critical spare parts? How quickly can they get them to you in Mexico?

- Technical Support: If you have a problem, who do you call? Is there a knowledgeable technical team available to help you troubleshoot?

At SHJLPACK, we have worked hard to build a support network for our clients across Latin America because we know that a machine is only as good as the support behind it. A low initial price is meaningless if the machine is down for weeks waiting for a spare part or technical advice. Look for a supplier who is invested in your success for the long term. That is the definition of a strategic partner.

What is my core insight on mold flippers for ambitious leaders like you?

As a leader of a large operation, your focus is naturally on the big picture: market share, long-term strategy, and major initiatives like digital transformation. It's easy to overlook what might seem like simple, foundational equipment on the factory floor. But here is the hard truth I've learned over my career: grand strategies often fail not because the vision was wrong, but because the foundation was weak. Your sophisticated MES platform is useless if a basic, unsafe mechanical process creates a permanent bottleneck and weak link in your operational chain.

My core insight is that a mold flipper is not just a piece of equipment; it's a catalyst. It's a small investment that solves a fundamental problem, which in turn builds operational discipline, creates a safer culture, and frees up crucial resources—time, people, and capital—that you can then redeploy to tackle your larger strategic goals like digital transformation and energy reduction.

I see this machine as far more than its mechanical function. It is a symbol and an enabler of a deeper operational philosophy.

The "Broken Windows" Theory on the Factory Floor

You may be familiar with the "broken windows" theory in urban planning: small signs of disorder, like a broken window, can encourage more serious problems. The same is true in a factory. An obviously unsafe and inefficient process, like manual mold flipping, sends a message to the entire workforce that "good enough" is acceptable. It quietly undermines standards.

Installing a mold flipper is like fixing that broken window. It is a highly visible, decisive action that eliminates a well-known problem. It sends a powerful signal to everyone in the plant that safety is non-negotiable and efficiency is a priority. This single change can help instill a culture of excellence and discipline that has positive effects far beyond the one task it automates. It raises the bar for everything.

A Personal Story of Partnership and Growth

I started my career as an engineer on the floor, just like many of your team members. I saw these challenges up close. When I founded SHJLPACK, my goal was to solve these fundamental problems, because I knew they were the key to unlocking a client's potential. My own journey to financial independence and the success of my business was built on this idea.

I remember working with a client whose business was growing, but they were held back by constant safety concerns and production delays in their maintenance bay. We didn't start with a massive, complex system. We started by solving their mold handling problem with a flipper. That simple solution built trust. It showed them we understood their reality. That trust became the foundation of a long-term partnership that led to larger projects and helped their business grow significantly. This is why I am so passionate about sharing this knowledge through our website, www.shjlpack.com, and other platforms. I am grateful for what this industry has given me, and I believe that helping others solve these core challenges is the best way to give back. A mold flipper is more than a machine—it is often the first step in a transformative partnership.

Conclusion

A mold flipper is a smart, strategic investment for Mexican steel mills. It cuts costs, boosts efficiency and safety, and provides a solid foundation for future growth and modernization.