Are you a factory manager at a steel mill? You likely face constant pressure. You need to increase output, control costs, and keep your workers safe. Perhaps your current packing process is a major bottleneck. It might rely on slow, manual labor that puts your team at risk of injury and your products at risk of damage. This leads to production delays, high insurance costs, and customer complaints. You know automation is the answer, but you're cautious. You've dealt with suppliers who cared more about the sale than your success. You need a solution that works, from a partner you can trust. I understand this because I've been there. I'm here to share what I've learned to help you specify the perfect coil packing line for your needs.

To specify the perfect coil packing line, you must follow a structured approach. First, clearly define your technical requirements, including coil dimensions, weight, and desired throughput. Next, map out how the new line will integrate with your existing operational flow, both physically and digitally. Finally, and most importantly, you must evaluate potential suppliers not just on their equipment, but on their engineering expertise, proven track record, and commitment to being a long-term partner.

This process might sound complex, but it's essential for making a successful investment. Simply buying a machine off a catalog page is a recipe for failure. You need a solution tailored to your factory's unique challenges. In the following sections, I will break down each of these steps. I will guide you through the critical questions you need to ask yourself and your potential suppliers. This will help you avoid common mistakes and find a solution that boosts your efficiency, improves safety, and drives your business forward.

What Key Technical Specifications Should You Define First?

Have you ever started a project without a clear plan? It often leads to confusion, wasted time, and a final result that doesn't meet your needs. The same is true when specifying a packing line. Approaching suppliers without a detailed list of your technical requirements is a significant risk. You might get quotes for machines that can't handle your products, or you might overpay for features you don't need. It creates a frustrating process for everyone involved. Let's build a solid foundation first. We need to clearly define your core technical specifications. This is the first and most important step.

To define your key technical specifications, you must start by documenting the physical characteristics of your coils. This includes the minimum and maximum inner diameter (ID), outer diameter (OD), width, and weight. You also need to calculate your required throughput, meaning how many coils you need to pack per hour or per shift. Finally, list your specific packaging material requirements. This data creates a clear, non-negotiable baseline for any supplier proposal.

Defining Your Core Product and Production Needs

Before you can even think about machinery, you have to know your product inside and out. The entire design of the packing line depends on these basic numbers.

-

Coil Dimensions and Weight: This is the absolute starting point. What is the heaviest coil your line will ever need to handle? What is the widest? What is the narrowest? You need to provide potential suppliers with a range: minimum and maximum for ID, OD, width, and weight. A machine designed for a 5-ton coil will be fundamentally different from one designed for a 25-ton coil. The conveyor rollers, the lifting mechanisms, and the wrapping ring motor all scale with these numbers. Be precise. I once worked with a client who forgot to account for a new, heavier product line they planned to launch in a year. The packing line they bought couldn't handle the weight, and they faced a costly upgrade much sooner than expected.

-

Throughput Calculation: How fast do you need to be? "Fast" is not a number. You need to calculate your required throughput in "coils per hour" or "coils per shift." Look at your slitting line's output or your overall production targets. This number directly influences the level of automation you need. A low-throughput line might use a semi-automatic wrapper, but a high-throughput line will need fully automated conveyors, strapping, and labeling to keep up. Also, think about the future. Do you plan to increase production in the next five years? It's often smarter to invest in a line with slightly more capacity than you need today.

| Specification | Why It's Critical | Example Range |

|---|---|---|

| Coil Weight | Determines the structural strength of the entire line. | 5,000 kg - 25,000 kg |

| Coil Outer Dia. | Affects the size of the wrapping ring and conveyor design. | 1200 mm - 2100 mm |

| Coil Width | Influences the shuttle speed and wrapping cycle time. | 500 mm - 1800 mm |

| Throughput | Dictates the necessary level of automation and line speed. | 5 coils/hr - 20 coils/hr |

| Packing Material | Impacts machine components like film carriages or dispensers. | Stretch Film, VCI Paper |

- Packaging Material & Goal: What are you wrapping your coils with, and why? Are you just trying to secure the coil for transport, or do you need to protect it from corrosion? For cold-rolled or galvanized steel, you might need VCI (Volatile Corrosion Inhibitor) paper or film. For other products, a simple stretch film might be enough. Do you need strapping? If so, will it be steel or PET straps? How many straps per coil? Your choice of materials will determine what kind of dispensing, cutting, and sealing mechanisms the machine needs. Clearly stating your packaging goal helps a good supplier recommend the best material and machine combination.

How Can You Ensure the New Line Integrates with Your Existing Operations?

Imagine buying a brand-new, high-performance engine. It's powerful and efficient. But when you try to install it in your car, it doesn't fit. The mounting points are wrong, the fuel line is on the wrong side, and it can't connect to the transmission. You have a great piece of equipment that is completely useless. This is what happens when a new packing line doesn't integrate with your factory's existing flow. You create an "island of automation" that causes new delays and headaches. True efficiency comes from a seamless flow. Let's talk about how to achieve that.

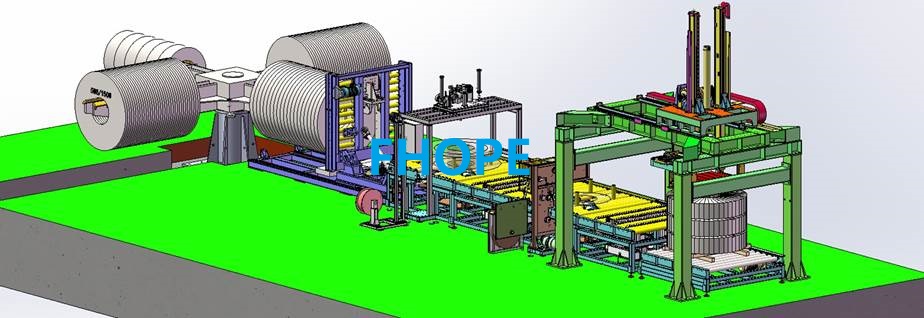

To ensure seamless integration, you must start by mapping your entire production flow, from the point where the coil leaves the slitting line to its final storage location. This map should show every transfer point, any changes in elevation, and all required data exchanges. You must share this detailed map with potential suppliers. This allows you to demand a solution that fits your factory, rather than forcing your factory to adapt to a standard machine.

Bridging the Gaps: Physical and Digital Integration

A packing line doesn't work in isolation. It's a critical link in your production chain. Success depends on how well it connects to what comes before and what comes after.

Physical and Mechanical Flow

You need to think like a coil. Trace its journey step by step.

- Entry Point: How does the coil arrive at the packing line? Is it from a turnstile at the end of a slitting line? Is it delivered by an overhead crane or a forklift? The entry mechanism of your packing line must be designed to safely and efficiently receive the coil from this source. The height, orientation (eye-to-sky or eye-to-wall), and timing must all match perfectly.

- Movement Through the Line: Once in the line, how does the coil move between stations? This is typically done with powered conveyors. You need to consider the type of conveyor (chain, roller), its speed, and its height. I once visited a factory where the new packing line conveyor was 10 centimeters lower than the conveyor feeding it. It seems like a small detail, but this mistake cost them weeks of rework and downtime to fix. You must provide a layout drawing of your facility to the supplier so they can plan for a smooth, level transition.

- Exit Point: After the coil is wrapped, strapped, and labeled, where does it go? Does it need to be tilted or turned? Is it placed on a pallet? Is it moved to a dispatch area for pickup? The exit of the packing line must be designed to hand off the finished product to the next stage of your logistics process.

Data and Control System Integration

In a modern factory, information flow is just as important as physical flow.

- Control Systems (PLC): Your new packing line will be controlled by a PLC (Programmable Logic Controller). Your factory likely has a preferred brand, such as Siemens, Allen-Bradley, or Mitsubishi. It is much easier for your maintenance team if the new equipment uses the same PLC brand and programming environment they are already familiar with. You should specify this requirement clearly in your technical specifications.

- Human-Machine Interface (HMI): The HMI is the screen your operators will use to control the line. It should be intuitive, easy to use, and preferably available in your local language (like Spanish for a factory in Mexico). A complex or poorly designed HMI can lead to operator errors and slow down production.

- Data Exchange: Does the packing line need to receive information from your company's main system (like an ERP or MES)? For example, a barcode on the coil could be scanned to automatically pull up the customer's specific packaging requirements. After packing, the line should be able to send data back, confirming that the coil is packed and ready for shipment. This level of data integration eliminates manual data entry, reduces errors, and gives you real-time visibility into your production.

What Safety Features Are Non-Negotiable for a Coil Packing Line?

The pressure to increase production is always present. Sometimes, this can cause managers to overlook safety details to save costs or time. This is a dangerous mistake. A single serious accident can have devastating consequences. It can shut down your production line for days or weeks, result in massive government fines, and severely damage the morale of your entire team. The financial and human cost of an accident is a price no factory can afford to pay. A truly great packing line is, first and foremost, a safe packing line. Let's discuss the essential features that protect your most important asset: your people.

Non-negotiable safety features for a coil packing line must include robust physical guarding, such as tall safety fences with electronically interlocked access gates. You must also have active safety devices like light curtains at all entry and exit points and clearly marked emergency stop buttons within easy reach of the operator. Most importantly, the system's design must feature automated handling mechanisms, such as coil cars and upenders, to completely eliminate the need for workers to manually handle or flip heavy loads.

Building a Fortress of Safety

Safety isn't just one feature; it's a complete system designed to keep people away from moving machinery and heavy loads. Here’s how we break it down.

Perimeter Guarding and Access Control

This is your first line of defense. The entire automated area must be enclosed by a physical barrier.

- Safety Fencing: This is not just any fence. It must be a specific height (typically around 2 meters) to prevent anyone from easily reaching over it. The construction should be strong enough to contain any potential mechanical failure.

- Interlocked Gates: Any door or gate used for access must be equipped with an electronic interlock switch. If an operator opens the gate while the machine is running, the interlock immediately sends a stop signal to the PLC, bringing all hazardous motion to a halt. This is not optional; it is a fundamental safety requirement based on global standards like ISO 13849. The machine should not be able to restart until the gate is closed and a reset button is pressed from a safe location outside the fence.

Active Safety Systems

These systems actively monitor the area around the machine.

- Light Curtains: These devices project a grid of invisible infrared beams across openings where coils enter or exit the line. If a person or object breaks any of these beams, the machine stops instantly. They provide protection without needing a physical gate, allowing for a continuous flow of product.

- Emergency Stop (E-Stop) Buttons: These are the large, red, mushroom-head buttons. They must be placed at the main operator control panel and at any other key locations where an operator might be working. When pressed, an E-stop should override all other controls and stop the machine as quickly and safely as possible.

Eliminating Manual Handling Risks

This is the most effective way to improve safety. The best way to prevent injuries from lifting heavy objects is to not lift them at all. This is where automation delivers the biggest safety return.

| Manual Task | Associated Risk | Automated Solution | Safety Benefit |

|---|---|---|---|

| Lifting coil with a crane/forklift | Crushing hazard, dropped loads, instability | Automated Coil Car / Down-ender | Controlled, stable, and predictable movement. |

| Pushing coil onto a conveyor | Strains, sprains, pinch points | Powered Conveyor System | Eliminates all manual pushing and pulling. |

| Flipping coil for packaging | High risk of tipping, crushing, severe injury | Integrated Coil Upender / Tilter | Fully automated, enclosed, and safe process. |

| Manually applying straps | Cuts, strains, falls | Automatic Strapping Machine | Operator stays outside the safety perimeter. |

By designing a line with these integrated automation components, you move your workers from performing dangerous physical labor to supervising a safe, efficient process. This is the ultimate goal.

How Do You Evaluate a Supplier Beyond Their Sales Pitch?

Every supplier has a great sales pitch. They will show you slick brochures, impressive videos, and a confident salesperson will promise you the best machine on the market. But as a factory manager, you know that promises don't always match reality. I'm sure you have heard stories, or maybe you've experienced it yourself: after you sign the contract and make the payment, the problems begin. The machine breaks down, getting technical support is a nightmare, and the "partner" you thought you had is nowhere to be found. This is a common and expensive fear. You are not just buying a machine; you are investing in a long-term relationship. You need a partner, not just a vendor. I learned how to tell the difference, and I will share my method with you.

To evaluate a supplier beyond their sales pitch, you must investigate their technical depth and their real-world performance. Insist on talking to their engineers, not just their salespeople. Ask them for detailed case studies and contact information for references who run mills similar to yours. A true partner will welcome this scrutiny. They will offer customized insights and solutions to your specific problems, rather than just pushing a standard machine from their catalog.

Finding a True Partner, Not Just a Vendor

A fancy proposal can hide a lot of weaknesses. You need to dig deeper to find out if a supplier has the substance to back up their style.

Look for Engineering Depth

When I was starting my own factory, I learned that the most important conversations happen with engineers. A salesperson is trained to sell; an engineer is trained to solve problems. When you are discussing your project, ask to speak with the technical team who will be designing your line.

- Ask "how" and "why." Don't just accept their proposed solution. Ask them, "How does this strapping head work?" or "Why did you choose this type of conveyor for my application?" A good engineer will be able to explain their design choices clearly. If they can't, or if they just say "this is our standard," that's a red flag.

- Challenge them with your problems. Describe your biggest bottleneck or your most common product damage issue. A real partner will be interested and start brainstorming solutions with you. A simple vendor will just try to steer the conversation back to their standard product.

Ask for Real-World Proof

Talk is cheap. You need evidence.

- Case Studies and Videos: Ask for detailed case studies of installations that are similar to yours in terms of coil size, weight, and throughput. Videos of these lines in actual operation are even better.

- References: This is the most important step. Ask for the contact information of two or three of their existing customers. A confident supplier will be happy to provide this. When you talk to the reference, don't just ask if they are "happy." Ask specific questions:

- "How was the installation and commissioning process?"

- "How responsive is their after-sales service when you have a problem?"

- "What is the quality of their technical support?"

- "Knowing what you know now, is there anything you would have done differently?"

The answers to these questions will tell you more than any sales brochure ever could.

Analyze the Proposal in Detail

Don't just look at the final price. The details matter.

- Component Brands: The proposal should list the brands of all major components, such as the PLC, motors, sensors, and pneumatics (e.g., Siemens, Schneider, Festo). Are these reputable, high-quality brands that are easily available in your region? Using cheap, unknown components is a common way for suppliers to lower their price, but it will cost you more in the long run with breakdowns and difficult-to-find spare parts.

- What's Included?: Does the price include shipping, installation, and on-site training for your operators and maintenance team? What are the specific terms of the warranty? Is a list of recommended spare parts included? A transparent proposal will have no hidden costs.

What’s My Personal Take on Finding the Right Solution?

I’ve been in your position. I understand the pressure you feel. I started my career as an engineer on the factory floor, dealing with machine breakdowns and production targets. Later, as the owner of my own packing machine factory, I felt the weight of making large investment decisions that would determine the future of my company. I learned that buying a machine is not the goal. The goal is to solve a problem and generate a return on your investment. The machine is just the tool.

Through my journey, I discovered that the "perfect" packing line is not about having the fastest speed or the most features. It's about finding the solution that provides the best and most reliable Return on Investment (ROI) for your specific factory. This means looking beyond the machine itself and focusing on the supplier. The most critical factor is finding a supplier who acts like a true consultant and partner. They should be just as invested in your success as you are.

When I founded SHJLPACK, my mission was never just to sell equipment. It was to share the knowledge that helped me build a successful business and achieve financial independence. I believe a good supplier does more than just answer your questions. They should ask you the right questions. They should challenge your assumptions to help you find the best possible solution, even if it's not the most expensive one. They should help you build the business case for your investment.

Think about ROI in simple terms:

- The Investment (I): This is the total cost—the machine price, installation, and training.

- The Return (R): This is where the real value is. It’s a combination of:

- Cost Savings: Lower labor costs from automation, reduced product damage, and lower insurance premiums from a safer workplace.

- Increased Revenue: Higher throughput means you can produce and ship more product, which directly increases your sales.

A true partner will help you quantify these "Return" figures. They will analyze your current process with you to identify exactly where you will save money and gain efficiency. They will provide a solution that is reliable and well-supported, ensuring that your new line runs consistently and continues to generate that return for many years. So, before you sign any purchase order, ask yourself one final question: Is this company just trying to sell me a machine, or are they committed to helping my factory grow? The answer to that question will lead you to the perfect solution.

Conclusion

Specifying the right coil packing line involves detailed planning, focusing on integration and safety, and finding a supplier who acts as a true partner in achieving your factory's goals.