Exporting steel coils is a high-stakes game. You work hard to produce a quality product, but the journey from your mill to your international customer is long and full of risks. A small patch of rust from sea spray or minor edge damage from handling can lead to a rejected shipment. This not only costs you money but also damages the reputation you've spent decades building. You're left constantly worrying if your investment will arrive safely, especially when you rely on inconsistent manual packaging processes that struggle to keep up with production and the ever-growing list of international regulations. I've seen this challenge firsthand in mills across the world. The solution that top Brazilian steel exporters have embraced is a shift to fully automatic wrapping lines. This isn't just about covering the steel; it's about engineering a reliable, repeatable, and compliant packaging process that protects the product, secures profits, and solidifies their position in the global market.

Brazilian steel exporters use automatic wrapping to meet international standards by guaranteeing consistent, high-quality, and protective packaging for every coil. These automated systems precisely apply materials like VCI film and stretch wrap, creating a durable, waterproof, and corrosion-resistant shield that is essential for long sea voyages. This process eliminates the human error common in manual packing, ensures every package adheres to strict international and customer-specific protocols like ASTM A700, and creates a digital record for traceability and quality assurance.

It might sound like a simple upgrade, but the transition from a manual or semi-automatic process to a fully integrated automatic line is a significant strategic move. As an engineer who has spent his life on the factory floor and later building my own factory, I understand that you need to know more than just the basics. You are likely asking yourself what specific standards this technology helps meet. Or how this investment translates into real, measurable returns for your business. I want to walk you through the details, drawing on my experience helping companies just like yours make this critical transition. Let's explore how the leading mills in Brazil are securing their exports and what you can learn from their success.

What specific international standards does automatic wrapping help Brazilian exporters meet?

You know the feeling. A container is held up at a port in Hamburg or Singapore because the packaging doesn't meet a specific local requirement. Or a valued customer sends photos of surface rust on a coil that just traveled 5,000 miles. The list of standards—from industry-wide ones like ASTM to unique client requests—is long and always changing. Trying to manage this complexity with a manual workforce is a constant struggle. One shift might wrap coils perfectly, while another might miss a crucial step. This inconsistency creates a huge risk of non-compliance, which can lead to costly penalties and lost business. But what if you could encode those standards into a machine? Automatic wrapping systems do exactly that. They turn complex packaging protocols into a reliable, repeatable process. You program the system once, and it executes flawlessly, ensuring every coil meets the required specification every single time.

Automatic wrapping helps Brazilian exporters meet specific international standards such as ASTM A700, which outlines the best practices for packaging, marking, and loading steel products for domestic and international shipment. It also helps achieve compliance with ISPM 15 for wood packaging by enabling the use of non-wood materials like steel or composite pallets. Most importantly, it ensures every coil is wrapped according to precise customer requirements for moisture protection and corrosion prevention, often using specific VCI films and waterproof layers, which is critical for maintaining product quality during transit.

Let's dive deeper into how this works in practice. For a CEO like you, Mr. Morales, who values precision and stability, understanding these mechanics is key to appreciating the technology's value.

ASTM A700: The Global Benchmark

ASTM A700 is one of the most widely recognized standards in the steel industry. It's not just a suggestion; it's a comprehensive guide to protecting steel from the most common shipping hazards: corrosion, physical damage, and the stresses of handling and transit. An automatic orbital stretch wrapper addresses these points directly. It applies stretch film with consistent tension and overlap, creating a tight, secure cocoon around the coil. This prevents moisture from seeping in and protects the coil edges and surfaces from scrapes and impacts. Manual wrapping can leave gaps or have inconsistent tension, creating weak points where damage can begin. An automated system eliminates this variable entirely.

VCI Application and Corrosion Control

For exporters, especially those shipping by sea, corrosion is the number one enemy. Volatile Corrosion Inhibitor (VCI) films and papers are the solution, but only if they are applied correctly. VCI works by releasing a vapor that forms a protective, invisible layer on the metal surface. For this to be effective, the package must be sealed properly to trap the vapor. An automatic wrapping machine is far superior at this than a human. It can apply a layer of VCI film followed by an outer layer of stretch film, creating an airtight seal. I’ve seen manual operations where workers would carelessly tear the VCI paper, rendering it useless. A machine doesn’t get tired or careless. It delivers a perfect VCI cocoon every time, which is essential for meeting the quality expectations of customers in humid climates or after long ocean journeys.

Meeting Diverse Customer Protocols with Digital Precision

Your customers in the automotive industry may have different packaging requirements than your customers in construction. An automatic line can store dozens of unique "packaging recipes." You can program specific wrap counts, film tension, and material combinations for each customer or product type. The operator simply selects the correct program, and the machine does the rest. This connects directly to your goal of digitalization. The system logs data for every coil it wraps—what recipe was used, when it was wrapped, and material consumption. This creates an invaluable digital record for quality assurance. If a customer ever questions the packaging, you have the data to prove it was done to their exact specification.

| Feature | Manual Wrapping | Automatic Wrapping | Impact on Compliance |

|---|---|---|---|

| Consistency | Low; depends on operator skill and fatigue. | High; machine repeats the process perfectly. | Guarantees every coil meets the standard. |

| VCI Application | Prone to tears and improper sealing. | Airtight seal, maximizing effectiveness. | Drastically reduces risk of corrosion claims. |

| Data Logging | Manual and often inaccurate. | Automatic; logs every detail per coil. | Provides digital proof of compliance for audits. |

| Adaptability | Slow to train for new customer specs. | Instant; select a new pre-set program. | Enables agile response to market demands. |

How does automation in wrapping reduce operational costs and improve ROI?

As a business owner, I know you scrutinize every major investment. You are constantly battling volatile energy prices, rising labor costs, and the need to maintain profitability. Your existing equipment, running for over 15 years, likely demands significant manpower and maintenance, and every hour of unplanned downtime eats directly into your bottom line. You see the line items for packaging labor, consumable waste, and freight damage claims, and you know they can be lower. A bottleneck in the packaging area can ripple backward, slowing down the entire mill and hurting your overall capacity utilization. This is precisely where a well-planned investment in automation delivers a clear and compelling return. An automatic wrapping line is not just a machine; it is a cost-reduction engine that optimizes your entire end-of-line process, slashes waste, and runs continuously with minimal oversight, directly addressing your goal to cut operational costs by 8% or more.

Automation in wrapping reduces operational costs primarily by minimizing direct labor expenses, cutting packaging material waste by up to 50% through precise, controlled application, and boosting throughput by eliminating the packaging bottleneck. This combination drives a strong Return on Investment (ROI) by enabling 24/7 operation, drastically reducing product damage claims, and allowing you to reassign your skilled workers from manual labor to higher-value positions within the plant.

The financial case for automation is strong, but it's important to look beyond the initial purchase price. Let's break down the sources of ROI, something I always discuss in detail with my clients.

The New Labor Cost Equation

Think about a manual wrapping station. You might need a team of two or three workers per shift to handle, wrap, and strap the coils. For a 24/7 operation, this adds up to a significant number of employees. You have salaries, benefits, training costs, and the constant risk of safety incidents. Now, compare that to a fully automatic line. The entire process, from receiving the coil from the C-hook to placing it on a pallet and wrapping it, is automated. You may only need a single operator to oversee the entire packaging area, restocking materials and managing the control panel. I worked with a steel processor in Brazil who was able to reassign eight workers to other critical areas of the plant after installing one of our lines. The labor savings alone paid for the machine in just under 24 months.

Slashing Material Waste with Technology

This is an area where the savings are immediate and substantial. Manual stretch wrapping is incredibly wasteful. Workers often use far more film than necessary "just to be safe," and the application is rarely optimal. Modern automatic orbital wrappers feature powered pre-stretch carriages. This technology can stretch a single meter of film into three or four meters before it’s applied to the coil. This not only makes the film stronger but also dramatically reduces consumption.

| Film Consumption Metric | Manual Wrapping | Automatic Wrapping (with 300% Pre-stretch) | Annual Savings Example (10 coils/hr) |

|---|---|---|---|

| Film Usage per Coil | ~1.2 kg | ~0.4 kg | - |

| Waste Factor | 10-15% (inconsistent application) | <1% (precise control) | - |

| Annual Film Cost | $105,120 | $35,040 | $70,080 |

Note: Figures are illustrative, based on typical film costs and usage.

This isn't a small saving; it's a significant reduction in your consumable budget, which drops straight to your bottom line.

Calculating the Full ROI: Uptime and Throughput

A true ROI calculation must also consider the impact on your plant's overall efficiency, which directly relates to your goal of 95% capacity utilization. A manual packaging station is almost always the slowest point in the production chain. An automatic line can be designed to match the cycle time of your slitter or mill, ensuring a smooth, continuous flow of product. This increased throughput means you can ship more products with the same production assets. Furthermore, by preventing damage, you eliminate the massive hidden costs of customer claims: the cost of the returned product, the freight charges, the administrative time, and the damage to your reputation. A reliable, automated system is an investment in stability and predictable output.

What is the impact of automatic wrapping on production efficiency and safety?

In any steel mill, efficiency is the key to profitability. But efficiency is often broken at the end of the line. The packaging area can easily become a bottleneck, causing finished coils to pile up and potentially forcing you to slow down your primary production lines. This directly hurts your capacity utilization. Even more importantly, this area is often one of the most hazardous for your employees. As a hands-on engineer, I've seen the risks up close: workers straining their backs to wrap heavy coils, dealing with sharp strapping, and maneuvering around moving equipment. These risks lead to injuries, lost time, and a negative impact on morale. A fully automatic wrapping line addresses both of these critical issues head-on. It transforms your packaging area from a slow, high-risk zone into a streamlined, safe, and highly efficient part of your operation.

Automatic wrapping has a massive positive impact on production efficiency by creating a smooth, continuous flow that eliminates end-of-line bottlenecks and can be perfectly synchronized with your production speed. Critically, it improves safety by removing workers from the dangerous, physically demanding process of handling and wrapping heavy, sharp-edged steel coils, which drastically reduces the incidence of musculoskeletal injuries, cuts, and other common industrial accidents.

This dual benefit of efficiency and safety is where the true value of a well-designed system lies. It's not just about wrapping a coil; it's about re-engineering a fundamental part of your process.

From Bottleneck to Free-Flowing Artery

Your goal of 95% equipment uptime is ambitious and requires every part of your operation to work in harmony. A manual packaging team has a variable output. It depends on the number of workers, their experience, and their energy levels, which naturally decline over a long shift. An automatic line, however, has a fixed, predictable cycle time. We can design a line to handle 15, 20, or even more coils per hour, every hour. This means the packaging station is no longer a constraint. It becomes a free-flowing artery that moves finished goods out of the plant efficiently. This allows your rolling mills and slitters to run at their optimal speed, maximizing the output of your entire facility and helping you achieve that 95% utilization target.

Engineering a Safer Workplace

As a factory owner, the safety of your people is paramount. The manual packaging of steel coils is full of hazards.

- Musculoskeletal Injuries: Manually lifting and guiding heavy rolls of stretch film or steel strapping around a coil places immense strain on a worker's back, shoulders, and arms.

- Cuts and Abrasions: The edges of steel coils and strapping can be razor-sharp. Handling them manually, even with gloves, carries a high risk of injury.

- Trips and Falls: Workers maneuvering around coils, pallets, and wrapping materials create a congested and hazardous workspace.

An automated system removes your employees from these dangers. Coils are moved by conveyors. Tilters reorient them from eye-to-sky to eye-to-wall. The wrapping and strapping are done entirely by the machine. Your worker's role shifts from high-risk manual labor to low-risk system supervision from a safe distance. This not only prevents injuries but also creates a better, more modern work environment.

Integration for a Smarter Factory

This is where automation directly supports your goal of digital transformation. A modern packaging line is not a standalone island. It's a network-connected asset. We integrate our systems with our clients' Manufacturing Execution Systems (MES). This means your central planning platform knows the status of every coil in the packaging process. The line is equipped with IoT sensors that monitor motor health, bearing temperature, and cycle counts. This data can be fed into your predictive maintenance platform, allowing you to service equipment before it fails, which is the key to maintaining high uptime. This level of integration provides the total production visibility you are aiming for.

Why is choosing a wrapping machine supplier about more than just the machine?

So, you've analyzed the data and are convinced that an automatic line is the right move for your mill. The next step is choosing a supplier, and this is where many companies make a critical mistake. They focus only on the price tag of the machine. But a machine is just a collection of steel and wires. It can quickly become a major problem if it's not the right fit for your specific needs, if it's installed poorly, or if you can't get support when you need it most. You risk investing a significant amount of capital only to end up with a new bottleneck and a bigger headache than the one you were trying to solve. I learned this lesson early in my career, and it’s why I built my company, SHJLPACK, on a foundation of partnership. You aren’t just buying a piece of equipment from us. You are gaining a partner who is committed to providing a total solution and ensuring your success for the long haul.

Choosing a wrapping machine supplier is about more than the machine because true, long-term success depends on a strategic partnership. A great partner provides a total solution that includes expert consultation on the right equipment, customized integration with your existing factory layout, professional installation and training, and reliable post-sales support. This holistic approach is what ensures the system delivers its promised ROI and becomes a reliable asset, not a liability.

I want to share a bit of my own story, as it shapes everything we do at SHJLPACK and is why I feel so strongly about this partnership approach.

From Engineer to Owner: A Journey of Understanding

I didn't start my career in a corner office. I started on the factory floor as a packing machine engineer. I spent years with my hands on the equipment, seeing what caused breakdowns, what frustrated operators, and what made a machine truly great. I saw companies buy expensive machines that didn't fit their workflow, and I saw simple, robust designs that ran for years without issue. When I eventually started my own factory, I carried those lessons with me. That business gave me the opportunity to achieve financial independence and to help many of my clients grow their own businesses. Now, my mission with SHJLPACK is to give back, to share that hard-won knowledge so that leaders like you can make the best possible decisions. I see my role not as a salesman, but as an advisor.

The "Total Solution" Philosophy in Action

When I say we provide a "Total Solution," it's not just a slogan. It's a commitment that addresses the concerns of a forward-thinking leader like yourself.

- Expert Consultation: We don't start by showing you a catalog. We start by listening. We want to understand your production flow, your space constraints, your product types, and your business goals. We then recommend a solution that is tailored to you, not a one-size-fits-all machine.

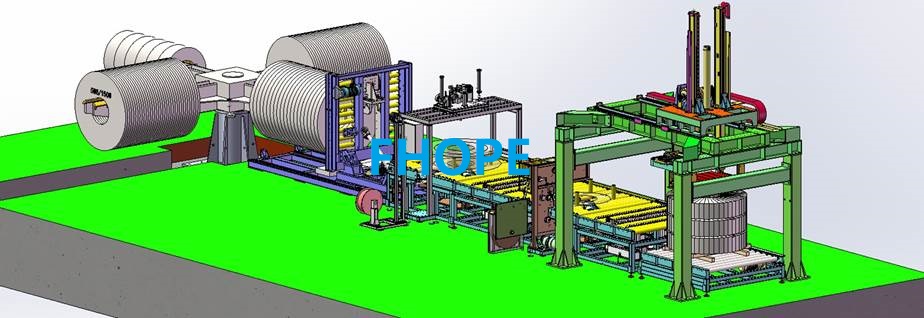

- Customized Integration: We know your new wrapping line has to fit into an existing plant. Our engineers design the layout, the conveyors, and the safety systems to integrate seamlessly with your cranes and production lines.

- On-Site Partnership: We don't just ship you a crate and a manual. Our engineers come to your site. We supervise the installation, we commission the equipment, and we stay to train your operators and maintenance staff until they are completely comfortable and confident.

- Long-Term Support: Our relationship doesn't end when the final payment is made. We are your long-term partner for maintenance, spare parts, and future upgrades, including helping you connect the machine's data to your digital platforms.

I remember a client in Brazil, the owner of a mid-sized mill, who was facing the exact same pressures as you: aging equipment, high costs, and a desire to modernize. He was skeptical of suppliers after a bad experience. We spent a week at his facility, simply observing and talking to his team. We designed a compact, efficient line that solved his bottleneck and cut his packaging material costs by 40%. I was there personally for the commissioning. Seeing the relief on his face and the pride in his team as they operated the new, safe system is why I do this work. It's about building solutions and relationships that last.

Conclusion

Automatic wrapping is an investment in consistency, efficiency, and your international reputation. The right machine and partner ensures that investment pays off for years to come.