Are you watching your operational costs climb while your packaging quality stays inconsistent? In Argentina's demanding steel and metal industries, many plant managers face this daily struggle. Manual wrapping is not just slow; it's a source of constant problems, from product damage during shipping to the risk of worker injuries. You know that every damaged coil and every safety incident eats directly into your profits. This constant pressure makes it hard to compete, especially when international clients expect perfection. But there is a clear path forward. Companies are discovering that embracing full automation is not just an upgrade—it's a fundamental change that boosts efficiency, ensures safety, and secures their place in the global market.

The shift from manual wrapping to full automation in Argentina is driven by a powerful combination of factors. These include the urgent need to slash high operational and labor costs, the demand for superior and consistent product protection to meet export standards, the critical importance of improving workplace safety to prevent accidents and comply with regulations, and the challenge of overcoming a persistent skilled labor shortage. Together, these pressures make automation a necessary strategic investment for survival and growth.

This transition is more than just a trend; it’s a strategic response to the economic realities and operational challenges on the ground. As an engineer who has spent his entire career in this industry, I've seen firsthand how these challenges can hold a business back. But I've also seen how the right technology can unlock incredible potential. Let's take a closer look at the specific questions plant owners in Argentina are asking and explore the real-world reasons behind this move to automation.

Why are Argentine steel mills ditching manual labor for automated packing lines?

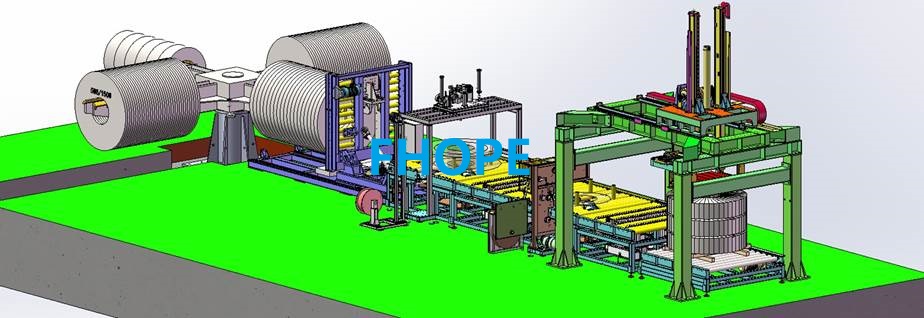

Your team works hard, but the final packing stage is still a bottleneck. You see inconsistencies in how coils are wrapped, leading to complaints from customers about rust or damage. Meanwhile, your labor costs keep rising, and finding reliable workers is a constant challenge. You worry that these issues are costing you more than just money; they're costing you your reputation. The solution lies in taking human variability out of the equation. An automated packing line offers the consistency, speed, and reliability you need to protect your products and your bottom line.

Argentine steel mills are moving away from manual labor and toward automated packing lines to achieve three critical goals: drastically cutting unpredictable labor costs, eliminating product damage by ensuring consistent and superior packaging, and increasing overall throughput to stay competitive in a fast-moving market. Automation directly solves the core inefficiencies of manual processes.

Diving Deeper into the Drivers of Change

When I talk with plant owners, the conversation often starts with one issue but quickly expands. The decision to automate is rarely about a single factor. It's about solving a web of interconnected problems that manual labor simply can't address effectively.

The True Cost of Manual Labor

The most obvious cost of manual labor is wages. But the real costs go much deeper. You have to account for recruitment, training, benefits, and high turnover rates, which are common in physically demanding jobs. Every time a worker leaves, you lose the time and money invested in their training. There's also the problem of inconsistent material usage. One worker might use too much wrapping film, while another uses too little, leaving the coil vulnerable. Over a year, this material waste adds up to a significant, unnecessary expense. An automated system uses the precise amount of material programmed, every single time. This control over materials and the reduction in labor dependency directly attacks high operating costs, a major goal for any forward-thinking CEO.

The Mandate for Quality and Consistency

Your customers expect their coils to arrive in perfect condition. Manual wrapping is inconsistent by nature. The quality of the wrap can change depending on the worker, the time of day, or how tired the team is. This can lead to loose wraps that allow moisture in, causing rust, or insufficient padding that results in dents and scratches during transport. A single damaged shipment can ruin a customer relationship. Automation removes this variability. A machine performs the same perfect wrap cycle on the first coil of the day and the last. This consistency is not just about quality control; it's a powerful marketing tool that tells your clients you are a reliable, professional supplier.

Here is a simple breakdown of the differences:

| Feature | Manual Wrapping | Automated Wrapping |

|---|---|---|

| Consistency | Low; varies by worker and shift | High; identical for every coil |

| Material Usage | High and unpredictable | Optimized and consistent |

| Protection Level | Variable; prone to gaps and looseness | Superior; engineered for full coverage |

| Speed | Slow; limited by human endurance | Fast; up to 60 coils per hour |

| Data Tracking | None | Full; tracks materials, cycle times |

This level of control and predictability is essential for any mill that wants to compete on the international stage, where packaging standards are incredibly high.

How does automation solve the skilled labor shortage in Argentina's industrial sector?

You have open positions on your packing line that you can't fill. The work is hard, and finding people with the right skills and work ethic is getting tougher every year. Production slows down when you are short-staffed, and you have to ask your existing team to work overtime, which leads to burnout and mistakes. You feel stuck, unable to grow because you can't find the people you need. Automation breaks this cycle by redesigning the work itself, making your operation less dependent on the availability of manual labor.

Automation directly counters the skilled labor shortage by fundamentally changing the nature of the work. It reduces the total number of employees needed for the packing process, shifts the required skills from manual dexterity to technical oversight, and guarantees operational continuity 24/7, independent of staffing fluctuations.

Diving Deeper into the Labor Solution

Many people fear that automation is about eliminating jobs. In my experience, it's about transforming them. It’s about creating a more stable and efficient production environment where people can do more valuable work. The labor shortage in many industrial regions is a real business threat, and automation is the most practical solution.

From Manual Effort to Technical Skill

An automated packing line doesn't need a large team of workers to physically wrap and strap heavy coils. Instead, it needs one or two technicians to monitor the system, load materials, and perform basic maintenance. This is a significant shift. You are no longer looking for many people to do repetitive, physically demanding tasks. You are looking for a few people who can be trained to operate and supervise advanced machinery. These are often better, safer, and higher-paying jobs. This transition elevates your workforce. You can take your most reliable and experienced floor workers and retrain them as machine operators. They already understand your products and processes, making them perfect candidates to oversee the new automated system.

Building a Resilient Operation

A manual packing line is fragile. If several workers call in sick, your entire production schedule can be thrown off. You might miss shipping deadlines, which can lead to penalties or lost orders. This reliance on manual labor creates a bottleneck that limits your entire plant's potential. I once worked with a client whose factory was located in a region with a very competitive labor market. They were constantly losing workers to other nearby plants. Their output was unpredictable. After we installed a fully automated coil packing line, their throughput became stable and predictable for the first time. They could finally give their customers reliable delivery dates. This stability is crucial for achieving high capacity utilization, a key goal for any serious manufacturer.

Freeing Up Your Best People

When your packing is automated, you can reassign your valuable team members to tasks that require human intelligence and judgment. Instead of wrapping coils, they can focus on final quality inspections, logistics coordination, or process improvement initiatives. They are no longer just laborers; they become contributors to the continuous improvement of your operation. This not only makes their jobs more engaging but also adds more value to your business than another manually wrapped coil ever could.

What are the real ROI calculations for a new automated coil wrapping machine?

You see the high price tag on a new automated packing line and think it's a massive expense. It’s easy to get sticker shock and think you can't afford it. But are you calculating the daily costs of not automating? The wages for multiple workers, the wasted wrapping materials, the cost of a single rejected shipment due to poor packaging—these "hidden" expenses are draining your budget every single day. A proper Return on Investment (ROI) analysis shows that automation is not an expense; it's one of the smartest investments you can make.

The true ROI of an automated coil wrapping machine is found by adding up all the savings and gains it creates. This includes direct savings from reduced labor and material costs, the elimination of financial losses from product damage, and new revenue generated from increased throughput and access to higher-paying markets. Most steel mills see a full payback in 18 to 36 months.

Diving Deeper into the Financials

As an engineer who later became a factory owner, I live and breathe ROI. An investment must pay for itself. The key is to look beyond the initial purchase price and analyze the total impact on your operations. Let's break down how to think about this.

The Savings Side of the Equation

First, let's look at the direct cost reductions. The most significant is labor. Calculate the total annual cost of your manual packing team, including wages, overtime, benefits, and insurance. An automated system can often reduce this by 70-80%. Next is material waste. We've seen clients reduce their consumption of stretch film and other packing materials by 15-25% because the machine applies it perfectly every time. Finally, consider the cost of poor quality. How much did you spend last year on claims, returns, or discounts due to coils damaged in transit? Automation can bring this number close to zero.

Here’s a simplified example of what those savings could look like:

| Cost Factor | Annual Cost (Manual) | Annual Cost (Automated) | Annual Savings |

|---|---|---|---|

| Labor (4 Workers) | $120,000 | $30,000 (1 Operator) | $90,000 |

| Material Usage | $80,000 | $68,000 (15% saving) | $12,000 |

| Damage Claims | $30,000 | $3,000 | $27,000 |

| Total Annual Savings | $129,000 |

If a new automated line has an installed cost of $250,000, the payback period is less than two years. After that, the $129,000 in savings goes directly to your profit margin, year after year.

The Gains Side of the Equation

ROI isn't just about saving money; it's also about making more money. An automated line is much faster than a manual team. If your packing line is the bottleneck, automation can increase your plant's total throughput. This means you can ship more products and generate more revenue without adding production machinery. Furthermore, the perfect, professional packaging produced by a machine can open doors to new markets. Some large automotive or appliance manufacturers have strict packaging requirements that manual methods simply cannot meet. By automating, you qualify to become their supplier, often at a premium price. This is a strategic gain that goes far beyond simple cost savings. It positions your company for long-term growth.

How can automated packaging lines improve workplace safety and meet new regulations?

You walk through your plant and see workers straining to lift heavy strapping tools or moving awkwardly around a spinning coil. Every time you see this, you worry about the risk of a serious accident. An injury not only harms your employee but can also lead to production shutdowns, government fines, and higher insurance costs. You know that providing a safe workplace is your responsibility, but the manual packing process is full of inherent dangers. Automation offers a direct and effective way to engineer these risks out of your operation entirely.

Automated packaging lines create a much safer work environment by removing employees from direct contact with heavy, moving machinery and materials. They eliminate the manual tasks responsible for most packing-related injuries, such as lifting, bending, and handling sharp strapping. This proactive approach to safety ensures compliance with evolving occupational health regulations in Argentina and globally.

Diving Deeper into Safety and Compliance

From my first days as a young engineer on the factory floor, I learned that safety is not a priority; it is a precondition. No amount of production is worth a person's well-being. The best way to prevent accidents is to design the danger out of the process.

Identifying and Eliminating Hazards

The packing area of a steel mill is filled with potential hazards. Let's be specific about the risks of manual wrapping:

- Musculoskeletal Injuries: Manually lifting heavy rolls of stretch film or steel strapping, bending over to secure coils, and repetitive motions can lead to chronic back, shoulder, and wrist injuries.

- Cuts and Lacerations: Handling sharp steel strapping is a primary cause of deep cuts. Even plastic strapping can cause friction burns or cuts when tensioned by hand.

- Falls and Collisions: Workers often have to walk backward around the coil as they wrap it, creating a serious trip and fall hazard, especially if the floor is oily or cluttered.

- Struck-by Hazards: If a coil is not properly secured on its pallet, it can shift or fall, creating a life-threatening situation.

An automated line addresses each of these risks. Coil cars and turnstiles handle the heavy lifting. Automated strapping heads perform the dangerous strapping work. The wrapping shuttle moves around the stationary coil, not the other way around. The entire system is enclosed in safety fencing with light curtains that instantly stop the machine if anyone enters the operating area. You are not just reducing risk; you are eliminating it.

Future-Proofing for Stricter Regulations

Governments worldwide, including in Argentina, are continuously strengthening workplace safety laws. The standards for machine guarding, ergonomics, and risk assessment are becoming more demanding. Relying on manual processes that are inherently risky is a liability. By investing in a modern, fully guarded automated system, you are not just meeting today's regulations; you are preparing for tomorrow's. This proactive stance on safety is a hallmark of a well-managed, forward-thinking company. It demonstrates to your employees, your customers, and regulatory bodies that you are committed to running a safe and responsible operation. This isn't a cost; it's an investment in the long-term health of your people and your business.

My Personal Take: It’s About More Than Just a Machine

I started my career on the floor of a packing machine factory. I've felt the physical strain of this work. I've also had the privilege of building my own factory and helping clients around the world solve their biggest production challenges. Because of this journey, I see the shift to automation as something deeply personal.

This is not just a business transaction about ROI and throughput. It's a strategic decision about the kind of company you want to be. It’s about building a business that is strong, resilient, and ready for the future. It's about protecting your people from harm and giving them better, safer jobs. When you remove the most dangerous and repetitive tasks, you free your team to use their minds to solve problems and improve the business. That’s how you build a loyal, engaged workforce.

For leaders like you, this decision is about legacy. It's about transforming your operation into one that is not only more profitable but also more sustainable and humane. At SHJLPACK, our mission is to be more than a supplier. We want to be your partner in this transformation. We share our knowledge and experience to help you make the right choice, not just for today, but for the decades to come.

Conclusion

The move to automation in Argentina is a clear response to real-world pressures. It is a strategic imperative for controlling costs, ensuring quality, protecting workers, and securing a competitive future.