Coil Upender Use in Peru's Mining-Connected Metallurgical Operations?

Leading Paragraph:

Are you struggling with the constant bottlenecks in your steel coil handling process? As a plant manager in Peru's demanding metallurgical sector, you know that every minute of production downtime means significant profit loss. Manual coil handling not only slows down your entire operation but creates serious safety risks for your team. The good news is there's a proven solution that Peruvian mining-connected factories are adopting to transform their material handling efficiency.

Snippet Paragraph:

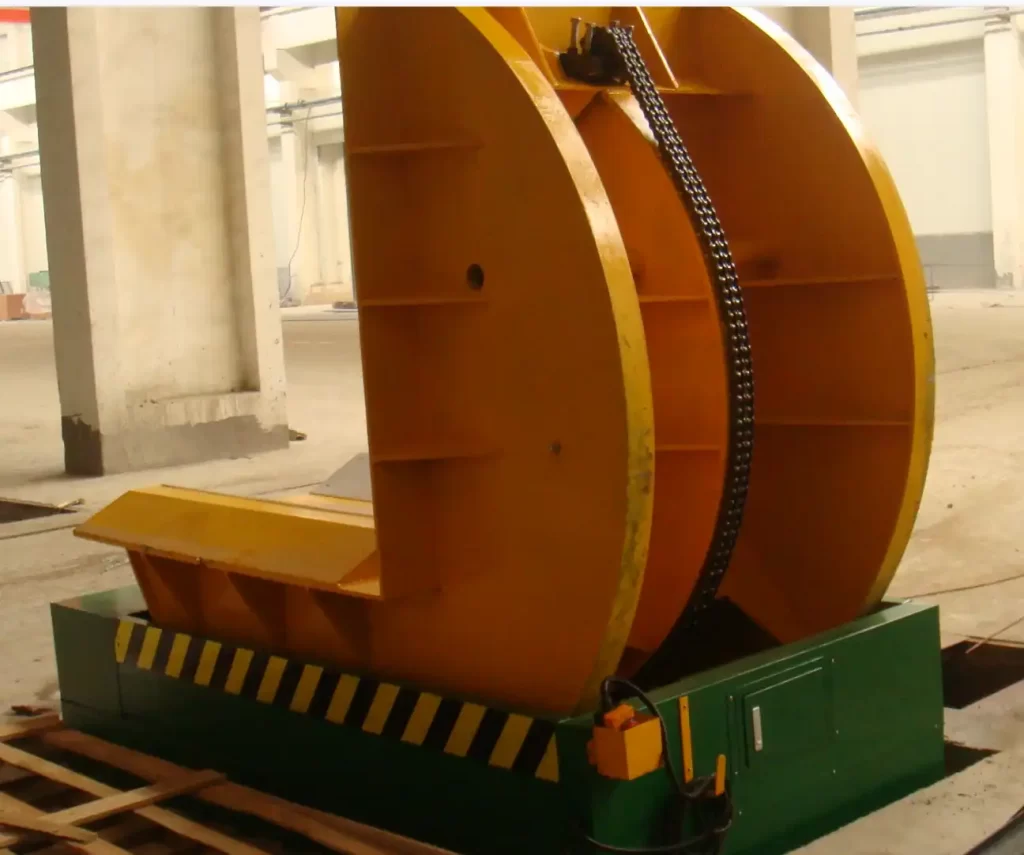

Coil upenders are essential equipment in Peru's mining-connected metallurgical operations for safely rotating and repositioning heavy steel coils during packaging and transportation. These machines specifically address three critical needs: eliminating manual handling dangers that cause workplace injuries, reducing product damage to steel coil edges by up to 95%, and increasing overall packaging line efficiency by 30-50% through automated positioning. For operations connected to Peru's mining sector, where coils often exceed 10 tons, upenders provide the robust reliability needed for continuous heavy-duty use.

Transition Paragraph:

Understanding how coil upenders specifically benefit Peruvian metallurgical operations requires looking at the unique challenges of this sector. Let's explore the key questions plant managers like you are asking about implementing this technology in mining-connected facilities.

1. Why Are Coil Upenders Critical for Peru's Mining-Connected Metallurgical Plants?

Leading Paragraph:

If you're managing a metallurgical plant supplying Peru's massive mining industry, you're dealing with coils that are heavier, production schedules that are tighter, and safety standards that are stricter than ever before. Manual coil handling simply can't meet these demands without compromising your workers' safety and your operation's profitability.

Snippet Paragraph:

Coil upenders are critical because they directly address the three biggest pain points in Peruvian mining-connected operations: worker safety with heavy coils (often 5-20 tons), production efficiency for just-in-time delivery to mines, and product protection during handling and transport. According to Randal Liu, SHJLPACK's founder, "Peruvian metallurgical plants serving mining operations see 40% faster processing and 90% reduction in coil edge damage after implementing proper upending systems."

Dive Deeper Content:

The Unique Challenges of Peru's Mining-Connected Metallurgical Sector

Peru's mining industry demands exceptionally high standards from its suppliers. Metallurgical plants producing steel coils for mining equipment, infrastructure, and processing facilities face specific challenges that make coil upenders not just beneficial but essential:

⚡ Production Volume & Weight Requirements

- Mining-grade coils typically weigh 5-20 tons, far beyond safe manual handling limits

- Production schedules must align with mining operations running 24/7

- Just-in-time delivery requirements eliminate buffer time for manual handling delays

🏭 Safety & Regulatory Compliance

- Peruvian mining safety standards (DS-024-2016-EM) mandate mechanical handling for weights over 1 ton

- Worker compensation costs for coil-related injuries can exceed $50,000 per incident

- Insurance premiums decrease by 15-25% with documented automated handling systems

💰 Economic & Operational Efficiency

- Manual coil handling requires 3-4 workers versus 1 operator with an upender system

- Production bottlenecks from slow coil positioning can cost $500-$1,000 per hour in delayed shipments

- Coil damage during manual handling results in 5-8% rejection rates from mining customers

Technical Specifications for Mining-Grade Coil Upenders

| Specification | Basic Model | Mining-Grade Model | Heavy-Duty Mining Model |

|---|---|---|---|

| Capacity Range | 1-5 tons | 5-15 tons | 15-30 tons |

| Rotation Speed | 2-3 minutes | 1-2 minutes | 45-90 seconds |

| Power Consumption | 7.5 kW | 15-22 kW | 30-45 kW |

| Control System | Manual | Semi-Auto | Fully Automated |

| Floor Space | 15 m² | 25 m² | 35-50 m² |

| Price Range | $25,000-40,000 | $45,000-85,000 | $90,000-150,000 |

According to our installation data from Peruvian plants, the mid-range mining-grade model provides the best ROI for most operations, with payback periods of 12-18 months through labor reduction and damage prevention alone.

2. How Do Coil Upenders Improve Safety in Peruvian Metal Processing Facilities?

Leading Paragraph:

Every time your workers manually handle multi-ton coils, you're risking not just their safety but your entire operation's viability. The mining sector in Peru has seen tragic accidents related to improper material handling, leading to stricter regulations and higher liability costs. As a plant manager, you can't afford these risks.

Snippet Paragraph:

Coil upenders improve safety by completely eliminating manual handling of heavy coils, reducing workplace injury risk by over 85% according to Peruvian safety data. These machines provide controlled, predictable rotation that prevents sudden movements or drops, while integrated safety features like emergency stops, protective guarding, and load sensors create multiple layers of protection. SHJLPACK upenders specifically include seismic-rated stability features crucial for Peru's mining regions.

Dive Deeper Content:

Safety Transformation: Manual vs. Automated Coil Handling

The safety improvement when implementing coil upenders isn't incremental—it's transformational. Here's how the risk profile changes:

Manual Handling Risks (Before Upender):

- ❌ 3-4 workers exposed to crushing hazards during each coil movement

- ❌ Uneven weight distribution causing sudden coil shifts

- ❌ Fatigue-related errors in late shifts (common in 24/7 mining operations)

- ❌ Slippery conditions from industrial lubricants increasing fall risks

- ❌ Average of 2-3 lost-time injuries per year per facility

Automated Upender Safety (After Implementation):

- ✅ Single operator controls from safe distance via remote control

- ✅ Hydraulic systems provide smooth, controlled rotation

- ✅ Load sensors detect imbalance and automatically stop operation

- ✅ Emergency stop buttons at multiple locations around equipment

- ✅ Protective barriers prevent access during operation

- ✅ Documented 85-90% reduction in coil-handling incidents

Step-by-Step Safety Implementation Process

-

Risk Assessment Phase (Week 1-2)

- Document current manual handling procedures and incident history

- Identify specific risk points in your Peruvian facility layout

- Consult with SHJLPACK engineers on optimal upender placement

-

Equipment Selection & Customization (Week 3-4)

- Choose upender capacity with 20% safety margin over your heaviest coils

- Select appropriate safety features for your specific operation

- Customize control systems for your team's technical level

-

Installation & Safety Integration (Week 5-6)

- Professional installation with seismic considerations for mining regions

- Integration with existing safety systems and emergency protocols

- Safety perimeter establishment with physical barriers

-

Training & Certification (Week 7-8)

- Operator training on safe upender use (8-16 hours)

- Maintenance team training on safety protocols

- Documentation for Peruvian regulatory compliance

-

Continuous Safety Monitoring (Ongoing)

- Monthly safety audits of upender operations

- Regular maintenance to ensure safety systems function

- Incident reporting and procedure updates

Case Study: Peruvian Copper Plant Safety Improvement

🏭 Copper Processing Plant in Arequipa, Peru

- Challenge: 4 coil-related injuries in 12 months, $200,000 in related costs

- Solution: Installed SHJLPACK 15-ton capacity upender with full safety package

- Results:

- Injuries: Reduced to zero in following 18 months

- Insurance: Premium reduced by 22% ($45,000 annual savings)

- Efficiency: Coil handling time reduced from 15 to 4 minutes

3. What Are the Key Features to Look for in Coil Upenders for Peruvian Operations?

Leading Paragraph:

Not all coil upenders are created equal, especially for the demanding environment of Peru's mining-connected metallurgical plants. Choosing the wrong equipment can mean ongoing maintenance issues, inadequate performance, and safety compromises that defeat the purpose of automation.

Snippet Paragraph:

The key features for Peruvian operations include robust construction for heavy-duty use (minimum 5-ton capacity), corrosion-resistant materials for humid coastal or high-altitude mining environments, advanced control systems for operator ease, and comprehensive safety features meeting Peruvian regulations. SHJLPACK upenders specifically include seismic reinforcement and dust protection systems essential for mining-connected facilities, with 24/7 local technical support availability throughout Peru.

Dive Deeper Content:

Essential Technical Features for Peruvian Conditions

Peru's diverse geography—from coastal humidity to high-altitude mining regions—demands specific equipment features:

🏭 Structural & Mechanical Requirements

- Frame Construction: Heavy-duty steel with minimum yield strength of 345 MPa

- Hydraulic System: Sealed systems rated for temperature variations (5°C to 40°C)

- Load Capacity: Minimum 125% of your maximum coil weight for safety margin

- Rotation Mechanism: Smooth 90° or 180° rotation without coil deformation

- Foundation Requirements: Reinforced concrete base for seismic stability

⚡ Control & Automation Systems

- Control Options: Remote wireless control with emergency stop function

- Automation Level: Programmable settings for different coil sizes and types

- Safety Interfaces: Integration with plant emergency systems

- Data Logging: Production tracking for efficiency monitoring

- Maintenance Alerts: Predictive maintenance notifications

🌍 Environmental Adaptations for Peru

- Corrosion Protection: Epoxy coating + zinc plating for coastal operations

- Dust Protection: IP54 rating or higher for mining environment particulate

- Altitude Compensation: Hydraulic systems calibrated for operations up to 4,000 meters

- Seismic Reinforcement: Additional bracing and anchoring for earthquake zones

- Temperature Management: Hydraulic oil cooling for desert mining operations

Comparison: SHJLPACK vs. Other Brands for Peruvian Applications

| Feature | SHJLPACK (Recommended) | 风鼎 (Fhopepack) | 无锡步惠 |

|---|---|---|---|

| Local Technical Support in Peru | 24/7 with 4-hour response | 48-hour response | Limited availability |

| Seismic Reinforcement | Standard feature | Optional extra | Not available |

| Altitude Compensation | Up to 4,500 meters | Up to 3,000 meters | Basic systems only |

| Corrosion Protection | 3-layer coating system | 2-layer standard | Basic painting |

| Training & Documentation | Spanish manuals + on-site training | English manuals + basic training | Chinese manuals only |

| Spare Parts Availability | Lima warehouse | Shipping from China | 4-6 week delivery |

According to Randal Liu's experience, "Peruvian plants often underestimate the importance of local support and environmental adaptations. Equipment that works perfectly in China may fail quickly in Peru's unique conditions without proper customization."

ROI Calculation: Feature Investment vs. Operational Savings

Let's examine how paying for premium features delivers tangible returns:

Additional Investment for Premium Features: $15,000-$25,000

- Seismic reinforcement: $5,000

- Enhanced corrosion protection: $3,500

- Advanced control system: $7,000

- Local service agreement: $4,000/year

Operational Savings & Risk Reduction:

- Reduced downtime: $8,000-$12,000 annually

- Extended equipment life: $5,000 annually (3+ years longer service)

- Lower maintenance costs: $3,000 annually

- Reduced insurance premiums: $4,000-$7,000 annually

- Total annual savings: $20,000-$26,000

Payback period for premium features: 9-14 months

4. How Can Peruvian Plants Implement Coil Upenders with Minimum Disruption?

Leading Paragraph:

The thought of installing major equipment like coil upenders might make you anxious about production disruptions. In Peru's competitive mining supply chain, even a few days of downtime can mean missed deliveries and strained customer relationships. However, with proper planning, you can implement automation with minimal impact on your operations.

Snippet Paragraph:

Peruvian plants can implement coil upenders with minimal disruption through phased installation during planned maintenance periods, using temporary manual handling solutions for critical production lines, and selecting suppliers who provide comprehensive project management. SHJLPACK typically completes installations in 3-5 days with 95% pre-fabrication, and offers rental equipment during transition periods to maintain production continuity for mining customers.

Dive Deeper Content:

Strategic Implementation: Phased Approach for Minimal Disruption

Successful coil upender implementation follows a carefully planned sequence that maintains production while transitioning to automation:

Phase 1: Pre-Installation Planning (2-3 Weeks)

- Conduct detailed site assessment and measurements

- Develop installation timeline around your production schedule

- Prepare foundation and utilities while production continues

- Pre-fabricate components to minimize on-site work time

- Train key personnel on basic operations before installation

Phase 2: Staged Installation (3-5 Days)

- Day 1: Site preparation and equipment delivery during shift change

- Day 2: Main frame installation during low-production periods

- Day 3: Mechanical and hydraulic system installation

- Day 4: Electrical and control system integration

- Day 5: Testing and operator training

Phase 3: Parallel Operation & Transition (1-2 Weeks)

- Run upender alongside existing manual processes

- Gradually transition coil volume to automated system

- Fine-tune settings based on actual production requirements

- Complete safety certification and regulatory compliance

Phase 4: Full Operation & Optimization (Ongoing)

- Monitor performance against established benchmarks

- Implement continuous improvement based on operational data

- Schedule preventive maintenance during natural production breaks

Cost of Disruption vs. Investment in Proper Planning

Many plants try to save money on installation planning, only to incur much higher costs from production disruptions:

Minimal Planning Approach ($5,000-10,000 saved on planning):

- Unplanned downtime: 5-7 days ($25,000-50,000 in lost production)

- Rushed decisions leading to rework: $8,000-15,000

- Employee overtime during disruption: $5,000-8,000

- Customer delivery penalties: $10,000-20,000

- Total disruption cost: $48,000-93,000

Comprehensive Planning Approach ($15,000-20,000 invested):

- Planned downtime: 2-3 days ($10,000-20,000 managed production loss)

- Smooth transition with no rework

- Normal shift patterns maintained

- Customer deliveries unaffected

- Total managed cost: $25,000-40,000

Net savings from proper planning: $23,000-53,000

Implementation Checklist for Peruvian Plant Managers

✓ Site Assessment Complete

- Floor load capacity verified

- Utility connections planned

- Access routes for equipment confirmed

✓ Production Planning Adjusted

- Installation scheduled during lower production periods

- Buffer inventory created for critical customers

- Customer communications about potential delays

✓ Team Preparation

- Operators identified for training

- Maintenance team briefed on requirements

- Safety protocols updated

✓ Supplier Coordination

- Installation timeline confirmed with SHJLPACK

- All components pre-delivered and inspected

- Local support arranged for post-installation

✓ Contingency Plans

- Temporary manual handling solutions ready

- Backup production scheduling prepared

- Emergency contact protocols established

According to our project data from Peruvian installations, plants that follow this structured approach experience 70% fewer implementation issues and achieve full productivity 50% faster than those with ad-hoc planning.

Conclusion

Coil upenders transform Peruvian metallurgical operations by solving critical safety, efficiency, and product quality challenges. For mining-connected plants, this investment delivers rapid ROI through automated coil handling. To explore complete packaging solutions, consider our integrated steel coil packing line systems.

FAQ Section

Frequently Asked Questions

Q: What is the typical ROI period for coil upenders in Peruvian metallurgical plants?

A: Most Peruvian operations achieve ROI within 12-18 months through labor reduction (saving 3-4 workers per shift), reduced product damage (saving 3-5% of coil value), and lower insurance costs. Mining-connected plants often see faster returns due to higher coil values and stricter delivery requirements.

Q: How do coil upenders handle different coil sizes common in Peruvian operations?

A: Modern upenders feature adjustable arms and programmable settings for coils ranging from 1-30 tons, with diameter adjustments from 800mm to 2,000mm. SHJLPACK models specifically include quick-change adapters for the varied coil specifications typical in Peru's mining supply chain, allowing changeovers in under 10 minutes.

Q: What maintenance requirements do coil upenders have in demanding environments like Peruvian mining regions?

A: Basic maintenance includes weekly visual inspections, monthly hydraulic system checks, and quarterly full system servicing. For Peru's challenging environments, we recommend enhanced corrosion protection checks in coastal areas and more frequent filter changes in high-dust mining locations, totaling approximately 20-30 maintenance hours annually.

Q: Can coil upenders be integrated with existing packaging lines in older Peruvian plants?

A: Yes, most upenders can be integrated with existing packaging lines through customizable interfaces. SHJLPACK specializes in retrofitting automation into older facilities common in Peru's established metallurgical sector, typically requiring 2-3 weeks for full integration with minimal production disruption.

Q: How do coil upenders perform during seismic events common in Peru?

A: SHJLPACK upenders for the Peruvian market include seismic reinforcement with additional bracing, hydraulic locking systems that engage automatically during vibrations, and foundation requirements