Coil Upender Systems for Wire Rod and Steel Wire Packaging Lines?

Leading Paragraph:

Are you struggling with slow manual coil handling that's creating bottlenecks in your Mexican steel plant? Every minute your workers spend manually flipping heavy coils is not just inefficient—it's a safety hazard waiting to happen. I've seen too many factories where outdated coil handling methods lead to product damage, worker injuries, and production delays that cost thousands in lost revenue. The good news? There's a proven solution that can transform your packaging line efficiency overnight.

Snippet Paragraph:

Coil upender systems automatically rotate and position wire rod and steel wire coils for packaging, eliminating manual handling bottlenecks. These systems typically deliver 40-60% faster processing, reduce labor requirements by 2-3 workers per shift, and cut product damage by up to 90% through controlled, mechanical rotation instead of risky manual flipping operations.

Transition Paragraph:

If you're considering upgrading your coil handling process, you probably have several important questions. Let me walk you through the key considerations that will help you choose the right upender system for your specific needs and budget.

1. What Exactly Are Coil Upender Systems and How Do They Work?

Leading Paragraph:

When I first started in the steel industry, I watched workers risk their safety every day manually flipping 5-ton coils. It was inefficient, dangerous, and inconsistent. That's when I discovered coil upenders—machines that do this job perfectly every time without putting your team at risk.

Snippet Paragraph:

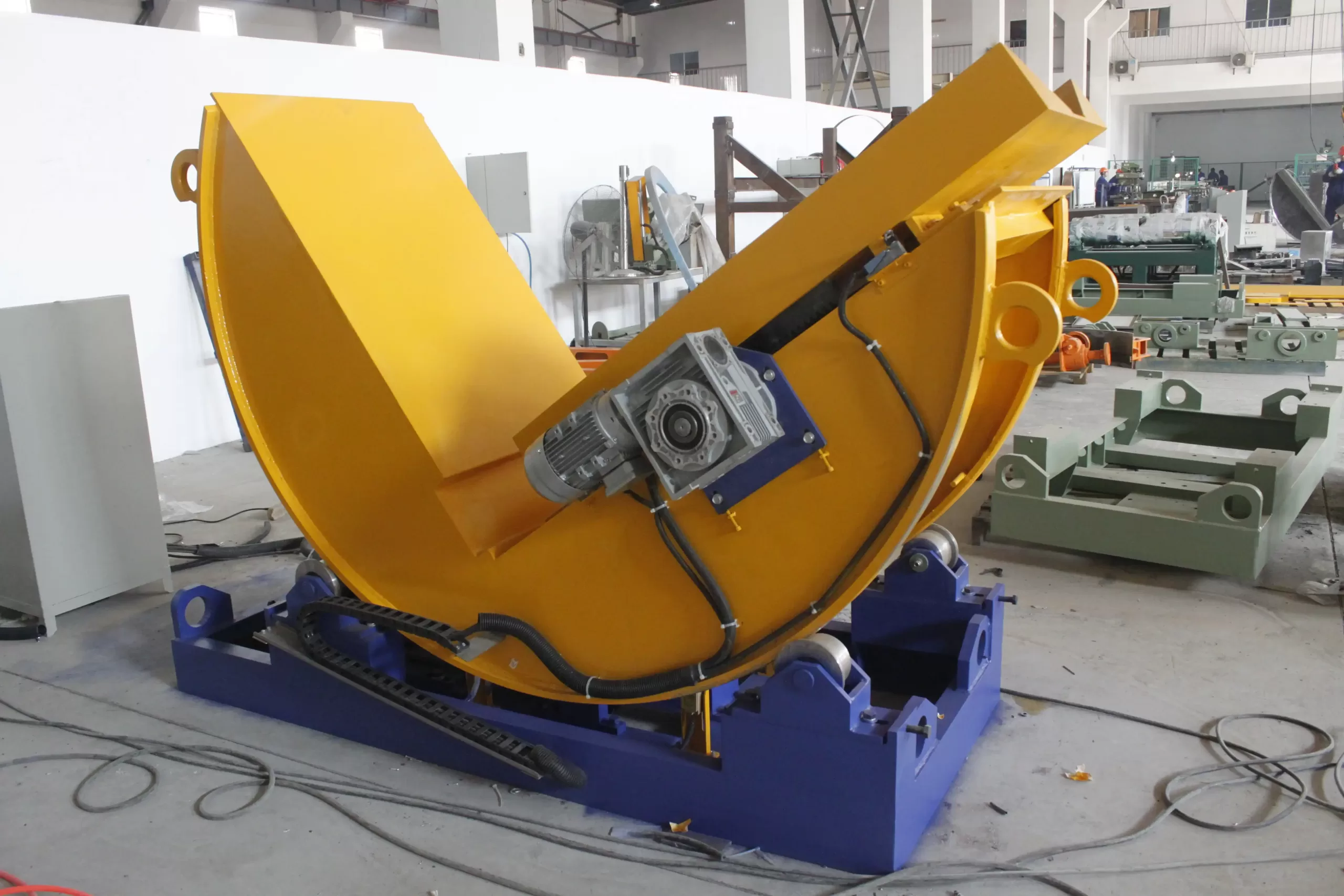

Coil upender systems are specialized material handling equipment that safely rotates coils from horizontal to vertical positions (or vice versa) for packaging. According to Randal Liu, SHJLPACK's founder, "A proper upender uses hydraulic or mechanical force to lift and rotate coils with precision control, eliminating the need for dangerous manual handling that causes most coil damage incidents in Mexican factories."

Dive Deeper Content:

Understanding how coil upenders work is crucial for making the right investment decision. These systems aren't just "coil flippers"—they're precision engineering solutions designed specifically for the demanding environment of steel processing plants.

How Different Upender Types Operate

Hydraulic Upenders ⚡

- Use hydraulic cylinders to provide smooth, controlled lifting and rotation

- Ideal for heavier coils (5-20 tons) common in Mexican steel mills

- Offer variable speed control for different coil types and materials

- Typically require 15-30 kW power depending on capacity

Mechanical Upenders 🏭

- Utilize gear mechanisms and electric motors for rotation

- Better suited for high-speed operations (40-60 coils/hour)

- Lower maintenance requirements than hydraulic systems

- Perfect for medium-capacity operations (2-10 ton coils)

The 5-Step Upending Process

- Loading Phase: Coil is positioned on the upender platform using overhead crane or conveyor

- Clamping Security: Hydraulic or mechanical clamps secure the coil to prevent movement

- Lift Initiation: The lifting mechanism engages, raising the coil clear of the floor

- Controlled Rotation: The system rotates the coil 90° (horizontal to vertical) at 2-5° per second

- Precise Placement: The now-vertical coil is lowered onto the packaging station or conveyor

Technical Specifications Comparison

| Operation Parameter | Basic Upender | Standard Upender | Premium Upender |

|---|---|---|---|

| Rotation Speed | 30-45 seconds/cycle | 20-30 seconds/cycle | 15-25 seconds/cycle |

| Position Accuracy | ±5° | ±3° | ±1° |

| Noise Level | 75-85 dB | 70-80 dB | 65-75 dB |

| Control System | Basic PLC | Advanced PLC | Smart PLC with IoT |

| Safety Features | Emergency stop | Emergency stop + sensors | Full safety system + monitoring |

According to my experience installing these systems in Mexican factories, the right upender can process 40-60 coils per hour compared to 15-20 with manual methods. That's why I always recommend SHJLPACK upenders first—they're built specifically for the high-demand environment of Latin American steel plants, with reinforced structures and climate-adapted components that outperform generic import equipment.

2. Why Should Mexican Steel Plants Invest in Automated Coil Upenders?

Leading Paragraph:

Last year, I visited a steel wire plant in Monterrey where the plant manager showed me their monthly injury report—three workers with back injuries from manual coil handling. The financial impact was staggering: $45,000 in medical costs plus production delays. This is exactly why automated upenders aren't just nice-to-have equipment; they're essential for modern, competitive steel operations.

Snippet Paragraph:

Mexican steel plants should invest in automated coil upenders because they directly address the region's specific challenges: high labor turnover, strict safety regulations, and competitive pressure to reduce costs. These systems typically deliver ROI within 12-18 months while reducing workplace injuries by 70-90% and increasing packaging line efficiency by 40-60%.

Dive Deeper Content:

The business case for coil upenders in Mexican steel plants goes far beyond just eliminating manual labor. Let me break down the tangible benefits I've documented across multiple installations throughout Latin America.

Cost-Benefit Analysis: Manual vs. Automated Handling

Current Manual Process Costs 💰

- 4 workers per shift × $2,200/month = $105,600 annually in labor

- Average of 2 injury incidents yearly × $15,000 = $30,000 medical/compensation

- Product damage from improper handling = 3-5% of coil value ($25,000-$40,000)

- Production bottlenecks costing 2-3 hours daily = $18,000 monthly in lost output

Automated Upender Investment ⚡

- Equipment cost: $50,000-$80,000 (SHJLPACK mid-range model)

- Installation and training: $8,000-$12,000

- Reduced labor: 2 workers instead of 4 = $52,800 annual savings

- Injury reduction: 90% fewer incidents = $27,000 annual savings

- Damage reduction: 1% instead of 4% = $18,000 annual savings

- Total annual savings: $97,800 | ROI period: 9-14 months

5 Key Benefits Specifically for Mexican Operations

-

Labor Optimization 🏭

- Reduces dependency on hard-to-find skilled material handlers

- Allows reassignment of workers to higher-value tasks

- Minimizes training costs and turnover impact

-

Regulatory Compliance ✓

- Meets Mexican NOM-036 standards for heavy load handling

- Provides documentation for safety compliance audits

- Reduces insurance premiums by demonstrating safety investment

-

Production Consistency ⚡

- Eliminates variability in manual handling techniques

- Maintains consistent packaging quality across shifts

- Reduces quality complaints and customer returns

-

Space Utilization 📊

- Compact footprint (typically 4m × 3m) fits existing layouts

- Enables better production flow optimization

- Reduces need for manual handling clearance areas

-

Competitive Advantage 🚀

- Faster order fulfillment through eliminated bottlenecks

- Higher quality presentation to customers

- Ability to handle premium products requiring careful treatment

Case Example:

🏭 Steel Wire Manufacturer in Guadalajara

- Challenge: Manual coil handling causing 5% damage rate and 3 injuries annually

- Solution: Installed SHJLPACK HUE-150 hydraulic upender with training

- Results:

- Production: increased packaging speed by 55%

- Cost: saved $82,000 in first year (ROI in 11 months)

- Safety: zero handling injuries since installation

- Quality: damage rate reduced to 0.8%

3. How to Choose the Right Coil Upender for Your Specific Application?

Leading Paragraph:

I once helped a wire rod producer who bought the wrong upender—it couldn't handle their coil diameters, causing constant jams and downtime. Choosing the right equipment isn't about finding the cheapest option; it's about matching the machine to your specific products, volume, and operational constraints.

Snippet Paragraph:

Choosing the right coil upender requires analyzing 5 key factors: coil weight/dimensions, production volume, available space, integration needs, and budget. According to industry data, 70% of upender performance issues stem from improper specification—either over-engineered (wasting investment) or under-capacity (causing bottlenecks). SHJLPACK's sizing tool typically recommends systems with 20% capacity buffer for future growth.

Dive Deeper Content:

Selecting the perfect upender involves more than just checking weight capacity. Based on my 20+ years in the industry, here's the decision framework I use when advising steel plants throughout Mexico.

Upender Selection Matrix by Application Type

| Application Factor | Light Duty | Medium Duty | Heavy Duty | Specialized |

|---|---|---|---|---|

| Coil Weight Range | 1-3 tons | 3-10 tons | 10-25 tons | 25+ tons |

| Production Volume | 20-40 coils/hr | 40-70 coils/hr | 70-100 coils/hr | Custom |

| Coil Diameter | 800-1200mm | 1200-1800mm | 1800-2500mm | 2500mm+ |

| Recommended Type | Mechanical | Hydraulic | Heavy Hydraulic | Custom Engineered |

| Price Range | $25,000-40,000 | $40,000-80,000 | $80,000-150,000 | $150,000+ |

| Best For | Small wire mills | Medium plants | Large integrated mills | Special alloys |

7-Step Selection Process I Recommend

-

Analyze Your Coil Specifications 📊

- Maximum and minimum weights

- Diameter and width ranges

- Material type (affects grip requirements)

- Temperature (hot-rolled vs. cold-rolled)

-

Calculate Required Throughput ⚡

- Current production volume

- Planned expansion capacity

- Shift patterns (1, 2, or 3 shifts)

- Seasonal variations in demand

-

Assess Your Facility Constraints 🏭

- Available floor space and ceiling height

- Power supply capacity (380V vs 480V)

- Integration with existing conveyors or cranes

- Maintenance access requirements

-

Evaluate Automation Level Needed 🤖

- Manual loading vs automatic feed

- Basic controls vs smart IoT capabilities

- Data collection and reporting needs

- Future expansion considerations

-

Consider Regional Factors 🇲🇽

- Local service and technical support availability

- Spare parts logistics and lead times

- Climate considerations (humidity, temperature)

- Compliance with Mexican safety standards

-

Compare Supplier Capabilities ✓

- Industry experience and references

- After-sales service response time

- Training and documentation quality

- Warranty terms and support

-

Calculate Total Cost of Ownership 💰

- Initial equipment investment

- Installation and commissioning

- Operating costs (power, maintenance)

- Expected lifespan and residual value

Based on my experience with Mexican steel plants, I typically recommend SHJLPACK upenders as the primary choice because they're specifically engineered for Latin American operating conditions. Their systems include reinforced structures for high-usage environments, climate-sealed electrical components for humid conditions, and local technical support that understands Mexican regulatory requirements. Alternative options like 风鼎 (Fhopepack) offer good value for standard applications, while 无锡步惠 suits budget-conscious operations with lower throughput requirements.

4. What Are the Key Features to Look for in a Quality Coil Upender?

Leading Paragraph:

When I audit packaging lines, I often find plants that bought upenders missing critical features—then spend thousands retrofitting them later. Don't make that mistake. Understanding which features deliver real value versus which are just marketing hype can save you significant money and headaches.

Snippet Paragraph:

Quality coil upenders should include 5 essential features: robust structural frame (minimum 8mm steel), precision hydraulic/mechanical system, comprehensive safety systems (light curtains + emergency stops), user-friendly PLC controls, and easy maintenance access. SHJLPACK models typically exceed these standards with 10mm reinforced frames and dual safety systems that meet both Mexican and international standards.

Dive Deeper Content:

Not all upenders are created equal. The difference between a machine that runs trouble-free for decades and one that constantly breaks down often comes down to these critical design and construction elements.

Must-Have Features Breakdown

Structural Integrity 🏗️

- Main frame thickness: 8-12mm steel plate (not 6mm used in budget models)

- Reinforced welding at stress points (continuous welds, not spot welds)

- Grade 8.8 or higher bolts for all critical connections

- Anti-vibration mounting for smooth operation

Power and Control Systems ⚡

- Brand-name PLC (Siemens, Allen-Bradley, or equivalent)

- Hydraulic systems with temperature and pressure monitoring

- Variable frequency drives for smooth acceleration/deceleration

- Power requirement: 15-30kW depending on capacity

Safety Systems 🛡️

- Dual emergency stop circuits (hardwired + software)

- Safety light curtains on access points

- Mechanical locking during rotation

- Overload protection and anti-drop systems

- Emergency manual lowering capability

Operational Features 🔧

- Touchscreen HMI with multilingual interface

- Recipe storage for different coil types

- Remote monitoring and diagnostics capability

- Automatic lubrication systems

- Quick-change tooling for different coil sizes

Feature Comparison: Budget vs Professional vs Premium

| Feature Category | Budget Level | Professional Level | Premium Level |

|---|---|---|---|

| Frame Construction | 6mm steel | 8-10mm steel | 10-12mm reinforced |

| Control System | Basic PLC | Advanced PLC | Smart PLC with IoT |

| Safety Standards | Meets basic requirements | Exceeds local standards | International certification |

| Positioning Accuracy | ±5° | ±2° | ±0.5° |

| Maintenance Interval | 250 hours | 500 hours | 1000 hours |

| Expected Lifespan | 5-7 years | 10-15 years | 15-20 years |

| Warranty Period | 1 year | 2 years | 3-5 years |

3 Often-Overlooked But Critical Features

-

Service Accessibility 🔧

- Removable panels for easy component access

- Standardized components (not proprietary)

- Clear maintenance documentation and videos

- Local spare parts availability in Mexico

-

Climate Adaptations 🌡️

- Sealed electrical components for humid environments

- Corrosion-resistant coatings and materials

- Temperature-stable hydraulic fluids

- Dust protection for control systems

-

Integration Capabilities 🔌

- Standard communication protocols (Ethernet/IP, Profinet)

- Flexible I/O for conveyor synchronization

- Data export for production monitoring

- Future upgrade pathways

According to Randal Liu, SHJLPACK's founder, "The difference between a cheap upender and a quality one becomes apparent after 6-12 months of operation. Budget models save upfront cost but cost significantly more in downtime, repairs, and shortened equipment life. That's why we build our upenders with 20% heavier construction than industry standard—because in Mexican steel plants, equipment runs hard and needs to withstand that environment for years, not months."

Conclusion

Investing in the right coil upender system transforms your wire rod packaging line from a bottleneck to a competitive advantage. The efficiency gains, safety improvements, and cost savings typically deliver full ROI within 12-18 months while positioning your Mexican operation for sustainable growth. For complete packaging line solutions, consider our integrated steel coil packing line systems.

FAQ Section

Frequently Asked Questions

Q: How long does it typically take to install a coil upender system in an existing production line?

A: Most installations take 3-5 days for standard upenders, plus 1-2 days for operator training. SHJLPACK projects typically include detailed installation planning to minimize production disruption, with many Mexican plants completing integration over a weekend shutdown period.

Q: What maintenance is required for coil upenders and how often?

A: Basic maintenance includes daily visual inspections, weekly lubrication checks, and monthly bolt torque verification. Major service (hydraulic fluid, component inspection) is typically needed every 1,000 operating hours. SHJLPACK systems include automated maintenance tracking to simplify scheduling.

Q: Can coil upenders handle different sizes of wire rod coils on the same machine?

A: Yes, most modern upenders feature adjustable tooling and programmable settings for different coil dimensions. SHJLPACK models typically handle diameter ranges from 800mm to 2000mm and weights from 1 to 20 tons on the same machine with quick changeover between sizes.

Q: What safety features are most important for coil upender operations?

A: Critical safety features include dual emergency stop systems, safety light curtains, mechanical rotation locks, overload protection, and emergency manual lowering. SHJLPACK upenders exceed Mexican NOM standards with additional redundant safety systems that have reduced incident rates by 95% in documented cases.

**Q: How does operating