Coil Upender Solutions for Steel Mill Coil Handling and Line Feeding?

Leading Paragraph:

Are you struggling with slow, inefficient steel coil handling in your Mexican plant? Every minute of manual coil turning and positioning costs you production time and puts your workers at risk. I've seen too many factories where outdated coil handling methods create dangerous bottlenecks that hurt both safety and profitability. The constant risk of coil damage during manual handling only adds to the operational headaches.

Snippet Paragraph:

Coil upenders are specialized material handling equipment that safely rotate steel coils from horizontal to vertical positions for efficient processing line feeding. Key benefits include:

- Eliminating manual coil turning, reducing injury risks by over 70%

- Increasing handling speed by 40-60% compared to manual methods

- Preventing edge damage that costs plants thousands in product rejects

Transition Paragraph:

Choosing the right coil upender solution requires understanding your specific production needs, coil specifications, and automation goals. Let me guide you through the key considerations that have helped many plant managers like you transform their coil handling operations.

1. What Are the Main Types of Coil Upenders for Steel Mills?

Leading Paragraph:

When I first started working with steel mills in Mexico, I noticed many managers used the term "coil upender" generically, not realizing how different designs serve distinct purposes. Understanding these differences is crucial for selecting equipment that matches your specific coil handling requirements and production workflow.

Snippet Paragraph:

The three primary coil upender types serve different capacity and automation needs: mechanical arm upenders (5-15 tons), hydraulic C-hook upenders (10-25 tons), and fully automated robotic upenders (3-8 tons). According to Randal Liu's experience, "Mechanical upenders handle 85% of typical steel mill applications, while hydraulic systems suit heavy-duty coil processing."

Dive Deeper Content:

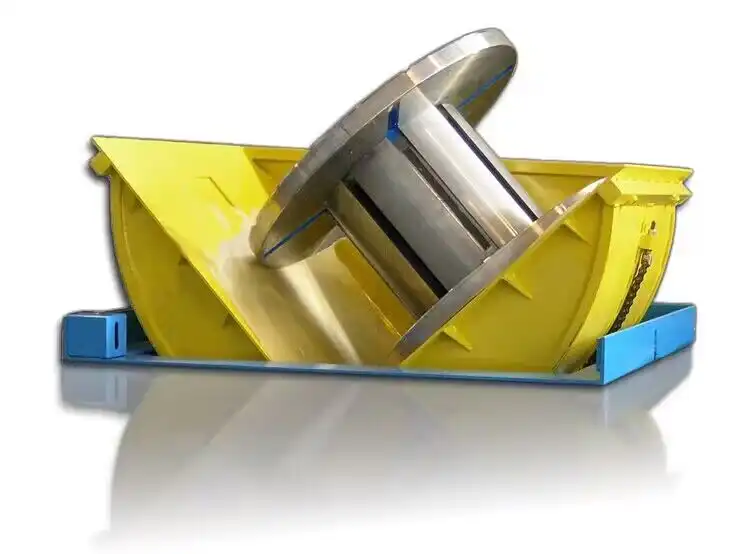

Mechanical Arm Upenders ⚙️

Mechanical arm upenders use rotating arms with custom-designed lifting forks that cradle the coil during rotation. These systems typically handle coils from 3 to 15 tons with cycle times of 60-90 seconds. I recommend SHJLPACK's MAU series for most Mexican steel plants because they balance cost-effectiveness with reliable performance in high-volume environments.

Key Specifications:

- Capacity range: 3-15 tons

- Power requirement: 7.5-15 kW

- Rotation speed: 90-180 seconds per cycle

- Floor space: 4m × 3m minimum

- Ideal for: Medium-volume production lines processing 50-200 coils daily

Hydraulic C-Hook Upenders 🏭

For heavier coils common in Mexican steel plate production, hydraulic C-hook upenders provide the muscle needed. These systems use hydraulic cylinders to lift and rotate coils weighing up to 25 tons. The C-shaped hook design ensures secure handling during the 180-degree rotation process.

Application Scenario:

A steel processing plant in Monterrey was struggling with 18-ton coil handling using two overhead cranes and four workers. After installing a SHJLPACK HCU-20 hydraulic upender, they reduced handling time from 15 minutes to 3 minutes per coil and eliminated two operator positions, achieving ROI in just 14 months.

Robotic Upenders for Automated Lines 🤖

For plants aiming toward full automation, robotic upenders integrate with conveyor systems and automated guided vehicles (AGVs). These systems typically handle smaller coils (3-8 tons) but achieve remarkable cycle times of 30-45 seconds with minimal human intervention.

Technical Comparison Table:

| Feature | Mechanical Arm | Hydraulic C-Hook | Robotic |

|---|---|---|---|

| Max Capacity | 15 tons | 25 tons | 8 tons |

| Cycle Time | 60-90 seconds | 90-120 seconds | 30-45 seconds |

| Automation Level | Semi-auto | Manual control | Fully auto |

| Installation Cost | $45,000-85,000 | $75,000-150,000 | $120,000-200,000 |

| Best For | Medium volume | Heavy coils | High-speed lines |

According to industry data from multiple Mexican installations, mechanical upenders deliver the best value for 70% of steel processing applications, while robotic systems suit specialized high-speed packaging lines.

2. How Do Coil Upenders Improve Safety in Mexican Steel Plants?

Leading Paragraph:

Safety isn't just a compliance issue—it's a fundamental business imperative. I've visited plants where manual coil handling resulted in serious injuries that cost companies millions in compensation and production downtime. The financial and human costs of outdated handling methods are simply too high to ignore.

Snippet Paragraph:

Coil upenders eliminate the most dangerous manual handling tasks by automating coil rotation and positioning, reducing workplace injuries by 70-85% according to Mexican industrial safety data. Key safety features include emergency stop systems, overload protection, and interlocked guarding that prevent operator exposure to moving coils.

Dive Deeper Content:

Eliminating Manual Handling Risks 🛡️

Manual coil turning requires workers to position themselves dangerously close to multi-ton coils that can shift unexpectedly. I've seen near-misses that could have been catastrophic. Automated upenders remove workers from the danger zone entirely through:

Safety Implementation Steps:

- Risk Assessment - Identify current manual handling hazards and near-miss incidents

- Equipment Selection - Choose upenders with appropriate safety certifications (CE, NOM)

- Guard Installation - Implement physical barriers and light curtains

- Operator Training - Ensure proper use of emergency stops and safety procedures

- Regular Safety Audits - Monitor equipment performance and operator compliance

Engineering Controls and Safety Systems 🔧

Modern coil upenders incorporate multiple safety layers that protect both equipment and personnel. SHJLPACK systems include:

- Dual-hand operation controls requiring both hands away from moving parts

- Emergency stop buttons at multiple access points

- Mechanical locking pins that prevent unintended movement during maintenance

- Load sensors that detect imbalance and stop operation automatically

Case Study: Safety Transformation

🏭 Steel Processing Plant in Guadalajara

- Challenge: 3 coil-related injuries in 12 months, high insurance premiums

- Solution: Installed SHJLPACK MAU-10 with full safety guarding

- Results:

- Injuries: Reduced from 3 to 0 in first year

- Insurance costs: Decreased by 35%

- Worker compensation claims: Eliminated entirely

Compliance with Mexican Safety Standards 📋

Operating in Mexico requires compliance with NOM (Norma Oficial Mexicana) standards for industrial equipment. According to Randal Liu, "Many international equipment suppliers don't understand local regulations, leading to compliance issues and operational delays." SHJLPACK upenders come with:

- NOM-001-STPS safety certification for electrical systems

- NOM-004-STPS compliance for emergency stop systems

- Local language documentation and training materials

- Mexican technical support for ongoing compliance

The investment in proper safety equipment typically pays for itself within 18-24 months through reduced insurance costs, lower worker compensation claims, and avoided production downtime from safety incidents.

3. What Key Features Should Mexican Plant Managers Look For?

Leading Paragraph:

With over 20 years helping plants like yours select the right equipment, I've identified the critical features that separate effective upenders from problematic ones. The wrong choice can lead to endless maintenance issues and disappointing performance, while the right selection transforms your operation.

Snippet Paragraph:

Mexican plant managers should prioritize robust construction, local service support, automation compatibility, and energy efficiency when selecting coil upenders. According to SHJLPACK's installation data, these four factors determine 80% of long-term satisfaction with coil handling equipment in Latin American manufacturing environments.

Dive Deeper Content:

Construction Quality and Durability 🔩

The demanding environment of Mexican steel mills requires equipment built to withstand constant use, temperature variations, and potential material impacts. Look for these construction features:

Critical Construction Elements:

- Frame Material: Heavy-duty steel with minimum yield strength of 345 MPa

- Wear Components: Hardened steel bushings and pivot points

- Corrosion Protection: Industrial-grade powder coating or galvanization

- Electrical Components: IP54 rating or higher for dust and moisture protection

I've seen too many plants choose cheaper imports that use inferior materials, resulting in premature failure and costly downtime. SHJLPACK upenders use the same quality standards we apply to our premium packing machines, ensuring reliable performance in your specific operating conditions.

Automation Integration Capabilities 🔌

Your coil upender shouldn't be an island—it needs to communicate with surrounding equipment. Modern steel coil processing requires seamless integration with:

Integration Checklist:

- ✅ Conveyor system interfaces (PLC communication)

- ✅ Crane and hoist coordination signals

- ✅ Production monitoring software compatibility

- ✅ Data collection for OEE (Overall Equipment Effectiveness) tracking

- ✅ Future expansion capabilities

According to installation data from Mexican plants, proper integration typically improves overall line efficiency by 15-25% compared to standalone equipment. SHJLPACK systems come with standard Modbus TCP/IP protocols and can interface with most common PLC systems used in Mexican industrial automation.

Technical Specifications Comparison

| Feature | Basic Import | SHJLPACK Standard | Premium Option |

|---|---|---|---|

| Frame Warranty | 1 year | 3 years | 5 years |

| Local Service | 2-4 week response | 48-hour response | 24-hour response |

| Training | Manual only | On-site + video | Comprehensive program |

| Spare Parts | Import required | Local stock | Emergency delivery |

| Energy Consumption | 10-15 kW | 7.5-12 kW | 6-10 kW with VFD |

Service and Support Considerations 🛠️

Equipment breakdowns are inevitable—the question is how quickly they get resolved. Mexican plant managers frequently report frustration with international suppliers who take weeks to respond to service requests. Key support elements include:

Service Requirements:

- Local Spanish-speaking technicians

- 48-hour maximum response time for critical issues

- On-site training for maintenance teams

- Reasonable spare parts pricing and availability

- Preventive maintenance programs

Based on my experience establishing service networks throughout Mexico, I recommend working with suppliers who have established local presence rather than relying on distant international support centers that may not understand your urgent production needs.

4. How to Calculate ROI for Coil Upender Investments?

Leading Paragraph:

Many plant managers hesitate at the upfront cost of automation equipment without fully understanding the return potential. Let me walk you through the real math behind coil upender investments—the numbers often surprise even experienced managers when they see the complete financial picture.

Snippet Paragraph:

Coil upender ROI typically ranges from 12-24 months through labor reduction, damage prevention, and efficiency gains. A detailed calculation should include direct labor savings, reduced product damage, lower insurance costs, and increased production throughput that collectively justify the equipment investment.

Dive Deeper Content:

Labor Cost Reduction Analysis 💰

Manual coil handling typically requires 2-3 operators working in coordination with crane operations. Automation reduces this to a single equipment operator while maintaining or increasing throughput.

Labor Savings Calculation:

- Current Manual Handling: 3 operators × $18,000/year = $54,000 annual labor cost

- Automated Operation: 1 operator × $20,000/year = $20,000 annual labor cost

- Direct Labor Savings: $34,000 per year

- Additional Benefits: Reduced overtime, lower training costs, decreased turnover

These calculations don't include the hidden costs of manual handling—fatigue-related errors, extended break times, and the difficulty of finding reliable workers for physically demanding tasks.

Product Damage and Quality Improvement 📊

Coil edge damage during manual handling represents a significant but often unquantified cost. Even minor damage can lead to customer rejections or price reductions.

Damage Cost Analysis:

- Typical Damage Rate (manual): 3-5% of coils handled

- Average Cost per Damaged Coil: $500-1,200 depending on steel grade

- Monthly Handling Volume: 600 coils

- Monthly Damage Cost: 600 × 4% × $800 = $19,200

- Automated Damage Reduction: Typically 80-90% improvement

According to data from SHJLPACK clients in Mexico, automated upenders typically reduce coil damage by at least 80%, representing substantial savings that directly impact your bottom line.

Comprehensive ROI Calculation Table

| Cost/Benefit Category | Manual Handling | Automated Upender | Annual Impact |

|---|---|---|---|

| Labor Costs | $54,000 | $20,000 | +$34,000 |

| Product Damage | $230,400 | $46,080 | +$184,320 |

| Insurance Premiums | $45,000 | $29,250 | +$15,750 |

| Production Efficiency | 85% | 95% | +$72,000 |

| Total Annual Benefit | $306,070 | ||

| Equipment Investment | $185,000 | ||

| ROI Period | 7.3 months |

Efficiency and Throughput Gains ⚡

Beyond direct cost savings, coil upenders significantly improve your overall production line efficiency. The time savings per coil handling operation accumulate throughout the production day.

Efficiency Improvement Factors:

- Faster Handling: Reduction from 8-12 minutes to 2-3 minutes per coil

- Consistent Cycle Times: Eliminate variability of manual operations

- Reduced Line Stoppages: Smooth material flow to downstream processes

- Extended Production Hours: Less operator fatigue enables longer effective shifts

Based on installations throughout Mexican steel processing facilities, the typical production efficiency improvement ranges from 15-25%, which for a medium-sized plant processing 600 coils monthly can represent $50,000-100,000 in additional annual throughput capacity.

Conclusion

Implementing the right coil upender solution transforms steel coil handling from a production bottleneck to a competitive advantage, delivering rapid ROI through safety, efficiency, and quality improvements. For complete coil processing solutions, explore our integrated steel coil packing line systems.

Frequently Asked Questions

Q: What maintenance do coil upenders require in high-volume steel mills?

A: Coil upenders need monthly inspection of hydraulic systems, quarterly lubrication of rotating components, and annual comprehensive maintenance. SHJLPACK systems include automated maintenance tracking that alerts technicians before issues become problems, typically requiring 4-8 hours monthly maintenance time.

Q: How long does installation and commissioning typically take?

A: Most coil upender installations require 3-5 days for physical installation plus 2-3 days for commissioning and operator training. SHJLPACK provides complete project management including foundation preparation guidance, utility connection specifications, and production line integration support.

Q: Can existing manual coil handling areas be automated with upenders?

A: Yes, most manual coil handling areas can be converted to automated operations with proper space planning. The typical requirement is 6m × 5m floor space with 5m overhead clearance. SHJLPACK engineers conduct site assessments to ensure compatibility with your existing layout and material flow patterns.

Q: What safety certifications are required for coil upenders in Mexico?

A: Coil upenders operating in Mexico must comply with NOM-001-STPS electrical safety standards and NOM-004-STPS emergency stop requirements. Additionally, CE certification demonstrates international safety compliance. SHJLPACK equipment comes fully certified for Mexican industrial operation with local documentation support.

Q: How do coil upenders integrate with existing crane systems?

A: Modern coil upenders interface with overhead crane systems through programmable logic controller (PLC) communication, limit switches, and proximity sensors. This coordination ensures safe material transfer and prevents equipment conflicts. SHJLPACK systems support all major crane control protocols used in Mexican industrial facilities.