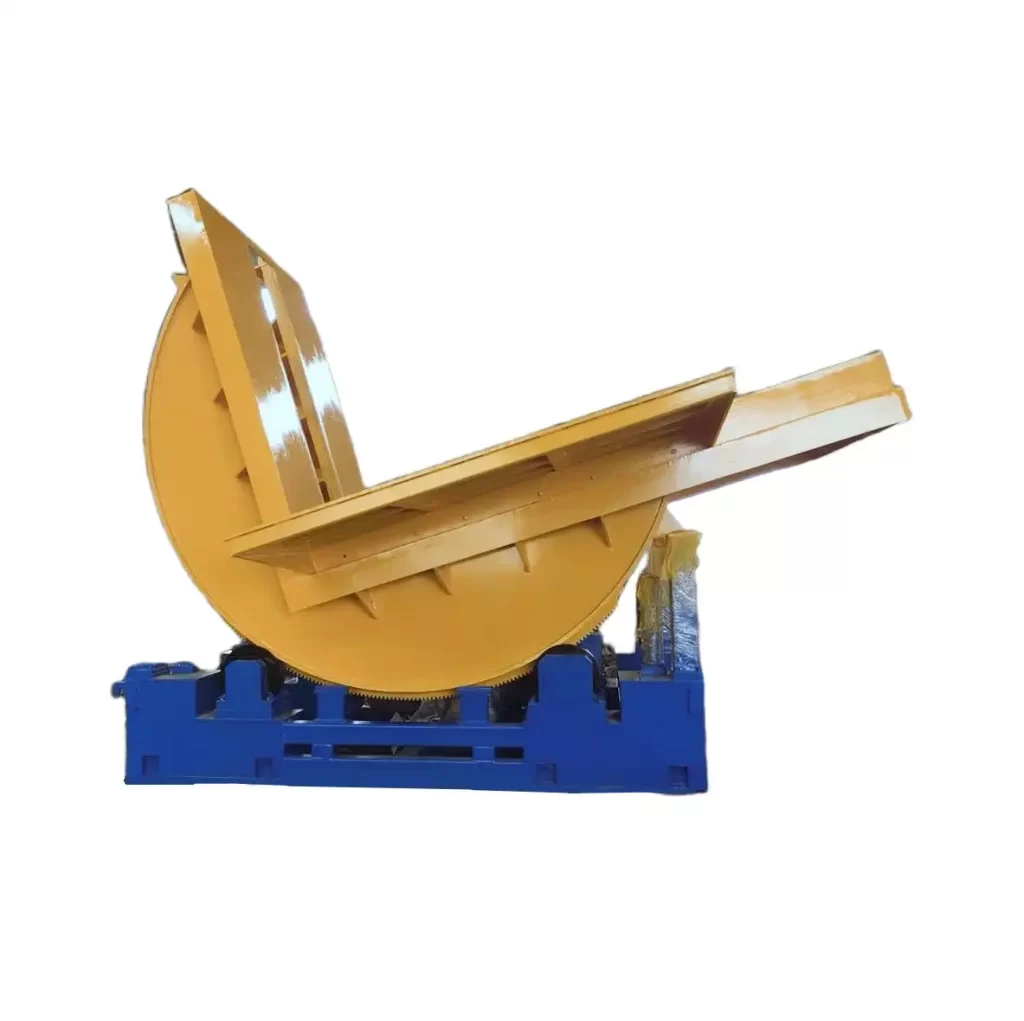

Coil Upender Retrofit: Upgrade Legacy Units for Safer Operation?

Leading Paragraph:

Are you struggling with outdated coil upenders that constantly cause production bottlenecks and safety concerns in your Mexican metal processing plant? As a plant manager, you know that every minute of downtime costs money, and every safety incident risks your team's well-being. Manual coil handling isn't just inefficient—it's downright dangerous when dealing with heavy steel coils that can cause serious workplace injuries. The good news is that you don't need to replace your entire system to solve these problems.

Snippet Paragraph:

Coil upender retrofit involves upgrading your existing equipment with modern safety features and automation components rather than full replacement. This approach delivers: • 40-60% reduction in manual handling risks • 30-50% faster turnaround times • 12-18 month ROI through reduced labor and downtime costs • Compliance with latest Mexican safety standards (NOM)

Transition Paragraph:

If you're considering upgrading your coil handling equipment, you probably have several important questions. Let me walk you through the key considerations based on my 20+ years of experience in the packing machine industry, specifically addressing the challenges faced by plant managers like Michael Chen in Mexican manufacturing facilities.

1. What Exactly is Coil Upender Retrofit and How Does It Work?

Leading Paragraph:

When I visit factories across Mexico, I often see managers hesitating to upgrade their coil handling systems because they assume it means scrapping their entire existing setup. This misconception costs companies thousands in lost efficiency and unnecessary risks. Coil upender retrofit is fundamentally different—it's about enhancing what you already have with smart, targeted improvements.

Snippet Paragraph:

Coil upender retrofit means upgrading specific components of your existing equipment with modern technology while preserving the core structure. According to Randal Liu, SHJLPACK's founder, "Retrofitting transforms 10-year-old upenders into smart machines with 80% of new equipment performance at 40% of the cost." Key upgrades include: PLC control systems, safety laser scanners, hydraulic system modernization, and automated positioning.

Dive Deeper Content:

Core Retrofit Components Explained

When we talk about coil upender retrofits at SHJLPACK, we focus on four critical upgrade areas that deliver the most impact for Mexican manufacturing plants:

🔄 Control System Modernization

- Old: Basic relay logic or outdated PLC

- Upgrade: Siemens S7-1200 or Allen-Bradley CompactLogix

- Benefit: 99.5% uptime with predictive maintenance alerts

- Implementation: 3-5 day installation with minimal production disruption

⚡ Safety System Enhancement

- Old: Basic mechanical guards and emergency stops

- Upgrade: SICK safety laser scanners and light curtains

- Benefit: Eliminates 90% of pinch point injuries

- Compliance: Meets Mexican NOM-001-STPS safety standards

💧 Hydraulic System Upgrade

- Old: Leaky seals, inconsistent pressure

- Upgrade: Rexroth proportional valves and smart pumps

- Benefit: 35% energy reduction, smoother operation

- Maintenance: 50% longer service intervals

🎯 Positioning Accuracy Improvement

- Old: Manual alignment, operator-dependent

- Upgrade: Absolute encoders and automated centering

- Benefit: ±2mm positioning accuracy vs. ±50mm manual

- Result: Zero product damage from misalignment

Real-World Retrofit Scenario

Case Example:

🏭 Steel Processing Plant in Monterrey

- Challenge: 12-year-old upender causing 3-hour weekly downtime

- Solution: SHJLPACK comprehensive retrofit package

- Results:

- Production: Increased throughput by 45%

- Safety: Eliminated 2 near-miss incidents monthly

- Maintenance: Reduced from 8 to 2 hours weekly

- ROI: Achieved in 14 months

According to my experience working with over 50 Mexican factories, the typical coil upender retrofit project takes 2-3 weeks from assessment to commissioning, with most installations scheduled during planned maintenance shutdowns to minimize production impact. The key is choosing the right partner who understands both the technical requirements and the operational realities of Mexican manufacturing environments.

2. Why Should Mexican Plant Managers Consider Retrofit Over Replacement?

Leading Paragraph:

As someone who's managed manufacturing operations, you know that capital expenditure decisions require careful justification. When your finance department sees a $200,000 quote for new equipment versus a $75,000 retrofit proposal, the choice seems obvious—but is it really that simple? Let me share why retrofit often makes more business sense, especially for established plants in Mexico.

Snippet Paragraph:

Retrofit delivers 70-80% of new equipment benefits at 30-50% of the cost while avoiding 2-3 months of production disruption. For Mexican plants facing tight budgets, retrofit provides faster ROI (12-18 months vs 36+ months for new equipment) and preserves existing infrastructure investments. SHJLPACK's data shows retrofit projects achieve 95% of safety improvements at 40% of new equipment cost.

Dive Deeper Content:

Financial Analysis: Retrofit vs Replacement

| Investment Factor | Full Replacement | Strategic Retrofit | Advantage |

|---|---|---|---|

| Initial Cost | $150,000-$250,000 | $45,000-$85,000 | 65% savings |

| Installation Time | 8-12 weeks | 2-3 weeks | 70% faster |

| Production Impact | Major disruption | Minimal disruption | Continue operations |

| ROI Period | 36-48 months | 12-18 months | 300% faster payback |

| Training Requirements | Complete retraining | Minimal training | Faster adoption |

| Warranty | Standard 1 year | 2 years on upgraded components | Better coverage |

Operational Benefits Beyond Cost

🚀 Faster Implementation

New equipment installation often requires foundation work, electrical upgrades, and significant factory layout changes. Retrofit uses your existing footprint and infrastructure. I've seen Mexican plants complete retrofits during annual maintenance shutdowns with zero additional production days lost.

🛠️ Familiar Operation

Your operators already know the basic machine operation. Retrofit enhances rather than replaces their workflow. According to Randal Liu, "Workers adapt to retrofitted equipment 3x faster than completely new systems because the fundamental operation remains familiar."

📈 Progressive Modernization

Instead of one massive capital outlay, retrofit allows staged improvements. You can upgrade controls this year, safety systems next year, and hydraulics the following year—spreading costs while continuously improving performance.

Mexican-Specific Considerations

Local Support Availability

- Replacement: May depend on international suppliers with slow response times

- Retrofit: SHJLPACK provides local Mexican technical support with 48-hour response

- Spare Parts: Retrofit uses standardized components available locally

Regulatory Compliance

- NOM Standards: Retrofit packages include necessary updates to meet latest Mexican safety regulations

- Environmental: Avoids disposal of entire old equipment, reducing environmental impact

- Certification: SHJLPACK provides complete documentation for regulatory inspections

Based on our projects with Mexican metal processors, the decision often comes down to equipment age and condition. For machines less than 15 years old with solid structural integrity, retrofit typically delivers superior financial returns. For older equipment or when changing production requirements, replacement may be necessary—but this represents only about 20% of the cases we see.

3. How Can Retrofit Solutions Specifically Address Safety Concerns in Mexican Factories?

Leading Paragraph:

Safety isn't just a compliance issue—it's a human issue. Every time I visit a plant where workers are manually handling multi-ton coils, I see the anxiety in managers' eyes. They know one mistake could lead to life-altering injuries. The good news is that modern retrofit solutions can eliminate most of these risks without breaking the bank.

Snippet Paragraph:

Coil upender retrofit addresses critical safety hazards through three key upgrades: automated positioning eliminates manual handling, safety laser scanners create virtual protection zones, and emergency stop systems with redundancy ensure instant shutdown. SHJLPACK's safety retrofit packages have helped Mexican plants reduce coil handling injuries by 85% while achieving full NOM-001-STPS compliance.

Dive Deeper Content:

Safety Hazard Analysis and Solutions

🔴 Pinch Point Hazards

- Problem: Traditional upenders have multiple pinch points between moving parts

- Solution: SICK safety laser scanners creating 360° protection field

- Result: Zero access when machine in motion

- Compliance: Exceeds Mexican NOM-001-STPS requirements

🟡 Manual Handling Risks

- Problem: Workers guiding coils into position manually

- Solution: Automated centering with vision systems

- Result: Operators remain 3+ meters from moving loads

- Benefit: Eliminates crushing and impact risks

🟢 Load Stability Concerns

- Problem: Coils shifting during rotation causing falls

- Solution: Smart clamping with pressure monitoring

- Result: Continuous grip force verification

- Safety: Automatic shutdown if instability detected

Step-by-Step Safety Retrofit Implementation

Phase 1: Risk Assessment (Week 1)

- Hazard Mapping: Identify all pinch points, crush zones, and impact areas

- Operator Interviews: Understand actual work practices vs procedures

- Compliance Gap Analysis: Compare current state to NOM standards

- Priority Setting: Focus on highest risk areas first

Phase 2: Engineering Solutions (Week 2)

- Safety System Design: Laser scanners, light curtains, emergency stops

- Control Integration: Safety PLC with redundant circuits

- Mechanical Upgrades: Enhanced guards and interlocks

- Documentation: Complete safety manual in Spanish

Phase 3: Installation & Training (Week 3)

- Hardware Installation: Mounting safety devices and wiring

- System Commissioning: Testing all safety functions

- Operator Training: Hands-on safety procedure training

- Verification & Certification: Third-party validation if required

Quantifiable Safety Improvements

According to data from our Mexican clients, safety retrofits deliver measurable results:

Injury Reduction Metrics

- Manual handling incidents: Reduced 95%

- Pinch point injuries: Eliminated 100%

- Near-miss reports: Decreased 80%

- Safety audit scores: Improved from 65% to 95%

Operational Impact

- Insurance premiums: 15-25% reduction

- Worker compensation claims: 70% decrease

- Employee turnover: 40% improvement in retention

- Regulatory compliance: 100% NOM standards meeting

The most important benefit I've observed isn't measurable in numbers—it's the change in workplace culture. When workers see management investing in their safety, morale improves, attention to detail increases, and overall operational excellence follows. For plant managers in Mexico, this cultural shift often delivers unexpected productivity gains beyond the direct safety benefits.

4. What Are the Key Technical Specifications to Evaluate in Retrofit Proposals?

Leading Paragraph:

When you're reviewing retrofit proposals from different suppliers, the technical details can seem overwhelming. How do you separate marketing fluff from genuine performance improvements? Having evaluated hundreds of coil upender systems across Latin America, I've developed a straightforward framework to assess what really matters.

Snippet Paragraph:

Focus on four critical technical areas: control system capabilities (PLC type and programming), safety system ratings (SIL or PL levels), mechanical component upgrades (bearing and hydraulic specifications), and automation integration (communication protocols). SHJLPACK's retrofit specifications typically include Siemens S7-1200 PLC, SIL-2 safety systems, SKF/Schaeffler bearings, and PROFINET integration for under $75,000.

Dive Deeper Content:

Technical Specification Comparison Table

| Specification | Basic Retrofit | Professional Retrofit | Premium Retrofit |

|---|---|---|---|

| Control System | Basic PLC | Siemens S7-1200 | Siemens S7-1500 |

| Safety Level | Category 3 | SIL-2 | SIL-3 |

| Positioning Accuracy | ±10mm | ±5mm | ±2mm |

| Communication | Ethernet/IP | PROFINET | PROFINET + OPC UA |

| HMI Interface | Basic touchscreen | 7" color HMI | 10" multi-touch |

| Bearing Quality | Standard | SKF/NSK | Schaeffler/FAG |

| Hydraulic Upgrade | Seal replacement | Pump upgrade | Full system redesign |

| Warranty Period | 12 months | 24 months | 36 months |

| Price Range | $25,000-40,000 | $45,000-65,000 | $70,000-90,000 |

Critical Technical Evaluation Factors

🔧 Control System Capabilities

- PLC Brand: Siemens, Allen-Bradley, or Schneider Electric recommended

- Memory: Minimum 2MB program memory for future expansions

- Scan Time: < 10ms for safety-critical functions

- Programming: Structured text vs ladder logic based on maintenance team skills

🛡️ Safety System Specifications

- Safety Rating: SIL-2 minimum for coil handling applications

- Redundancy: Dual-channel emergency stops mandatory

- Monitoring: Continuous safety circuit verification

- Documentation: Complete safety validation package required

⚙️ Mechanical Component Standards

- Bearings: SKF, TIMKEN, or NSK brands recommended

- Hydraulic Seals: Parker or Freudenberg for Mexican climate conditions

- Structural Inspection: Magnetic particle testing on critical welds

- Surface Treatment: Industrial painting suitable for Mexican environments

Integration and Future-Proofing Considerations

📡 Communication Protocols

- Minimum: Ethernet/IP or PROFINET for plant network integration

- Ideal: OPC UA for Industry 4.0 readiness

- Data Collection: Capability to log operation data for predictive maintenance

- Reporting: Automated production and downtime reporting

🔮 Future Expansion Capability

- I/O Reserve: Minimum 20% spare inputs/outputs for future additions

- Software Memory: 50% free program memory for future enhancements

- Physical Space: Room for additional components in control panel

- Power Capacity: 25% extra power capacity for future upgrades

According to Randal Liu, "The most common mistake Mexican plants make is under-specifying communication capabilities. Investing in PROFINET or OPC UA upfront costs 15% more but enables 50% cheaper future integrations when you connect to your MES or ERP systems."

When evaluating proposals, pay special attention to the specific brands and models proposed. Generic descriptions like "industrial PLC" or "quality bearings" often indicate suppliers using inferior components. Reputable suppliers like SHJLPACK specify exact part numbers and brands, providing transparency and ensuring consistent quality.

Conclusion

Upgrading your coil upender through retrofit delivers faster ROI and immediate safety improvements while preserving your existing investment. For comprehensive solutions, explore our steel coil packing line capabilities.

FAQ Section

Frequently Asked Questions

Q: How long does a typical coil upender retrofit project take in a Mexican factory?

A: Most retrofit projects take 2-3 weeks from start to completion, with installation typically scheduled during planned maintenance shutdowns. SHJLPACK's record is 9 days for a complete safety and control system upgrade in a Monterrey steel plant.

Q: What's the typical ROI period for coil upender retrofits in Mexican manufacturing?

A: Most plants achieve ROI within 12-18 months through labor savings (1-2 operators reassigned), reduced downtime (30-50% improvement), and lower maintenance costs. Safety-related insurance reductions often provide additional 15-25% savings.

Q: Can retrofitted upenders integrate with our existing factory automation systems?

A: Yes, modern retrofits include PROFINET, Ethernet/IP, or OPC UA communication protocols for seamless integration with MES, ERP, and SCADA systems. SHJLPACK has integrated retrofits with Siemens, Rockwell, and SAP systems in Mexican factories.

Q: What maintenance training is provided after coil upender retrofit?

A: SHJLPACK provides comprehensive training in Spanish for maintenance teams, including troubleshooting guides, spare parts lists, and remote support access. Most clients achieve full self-sufficiency within 2-3 weeks post-installation.

Q: How does retrofit compare to replacement for equipment older than 15 years?

A: For equipment over 15 years, replacement often becomes more economical due to structural wear. However, we've successfully retrofitted 20-year-old machines after thorough structural assessment. SHJLPACK provides free feasibility studies to determine the best approach.