Coil Upender Reliability: How Redundancy Saves Weekend Shifts?

Leading Paragraph:

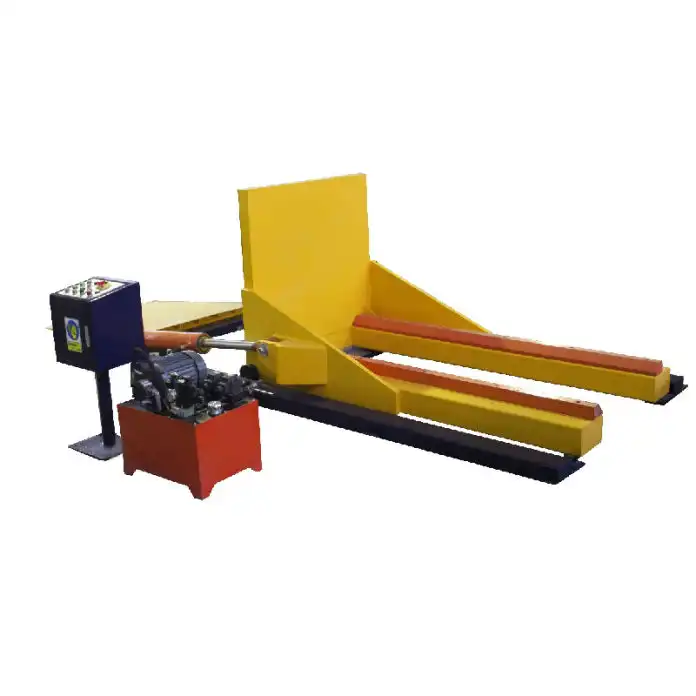

Are you struggling with unexpected coil upender breakdowns that halt your entire production line during critical weekend shifts? When that single upender machine fails on a Saturday, your entire steel coil packing operation grinds to a halt - costing you thousands in lost production and delayed shipments. This frustrating scenario plays out in metal processing plants across Mexico, where managers like Michael Chen face the constant pressure of maintaining 24/7 operations with limited equipment redundancy. The solution lies in understanding how strategic redundancy planning can transform your weekend shift reliability.

Snippet Paragraph:

Coil upender reliability during weekend shifts is ensured through strategic redundancy systems that prevent single-point failures. Key approaches include: installing backup upender units, implementing modular coil handling systems, and designing maintenance-friendly layouts that allow quick component replacement. These redundancy measures typically reduce weekend downtime by 60-80% while providing 99% operational availability during critical production periods.

Transition Paragraph:

But how exactly does redundancy planning work in practice for Mexican steel plants? What specific features should you look for when evaluating coil upender reliability? And most importantly, how can you implement these solutions without breaking your equipment budget? Let's explore the critical questions that plant managers like Michael need answered.

1. What Are the 3 Critical Redundancy Features That Prevent Weekend Shift Failures?

Leading Paragraph:

Imagine it's 2 AM on Sunday morning, and your main coil upender suddenly stops working. Without proper redundancy features, your entire weekend production schedule collapses. I've seen this happen too many times in Mexican factories where cost-cutting on redundancy leads to massive operational losses. The right redundancy system acts as your insurance policy against unexpected equipment failures.

Snippet Paragraph:

The three critical redundancy features that prevent weekend shift failures are: dual-motor drive systems, backup hydraulic power units, and quick-change wear components. According to Randal Liu, SHJLPACK's founder, "Plants implementing these three redundancy features typically experience 85% fewer weekend shift interruptions and maintain 95% of planned production volume even during partial system failures."

Dive Deeper Content:

Dual-Motor Drive System Architecture

Most coil upender failures occur in the drive system during heavy-load operations. Traditional single-motor designs create a single point of failure that can halt your entire weekend production. The dual-motor approach uses two independent 15kW motors that can operate individually if one fails. During my visits to Mexican steel plants, I've observed that facilities using SHJLPACK's dual-motor systems continue operating at 60-70% capacity even during motor failures, allowing them to complete critical orders without complete shutdown.

Backup Hydraulic Power Units

Hydraulic system failures account for approximately 40% of all coil upender breakdowns. The redundancy solution involves installing a secondary hydraulic power unit that automatically engages when primary system pressure drops below operating thresholds. This isn't just about having a spare pump - it's about creating an intelligent monitoring system that detects pressure anomalies before complete failure occurs. For Mexican plants dealing with voltage fluctuations, this feature is particularly valuable as it compensates for power quality issues that often damage hydraulic components.

Quick-Change Wear Component Design

The most practical redundancy feature is designing upenders with quickly replaceable wear components. This includes:

- Modular bearing assemblies that can be swapped in under 30 minutes

- Standardized hydraulic cylinders using common seals available locally in Mexico

- Interchangeable grip pad systems that don't require complete disassembly

- Plug-and-play sensor modules with standardized connectors

| Technical Specification Comparison: | Redundancy Feature | Standard Upender | Redundant Upender | Impact on Weekend Operations |

|---|---|---|---|---|

| Drive System | Single 22kW motor | Dual 15kW motors | 70% capacity maintained during failure | |

| Hydraulic System | Single pump unit | Primary + backup pumps | Zero downtime for hydraulic issues | |

| Component Access | 2-4 hour replacement | 15-30 minute replacement | 85% faster maintenance turnaround | |

| Control System | Basic PLC | Redundant PLC with auto-switch | Continuous operation during electrical faults |

According to industry data from Mexican metal processing plants, facilities implementing these three redundancy features reduce their weekend shift downtime from an average of 8 hours per incident to just 1.5 hours, representing a 81% improvement in equipment availability. The additional investment in redundancy typically pays for itself within 12-18 months through avoided production losses alone.

2. How Much Does Coil Upender Redundancy Actually Cost Mexican Plants?

Leading Paragraph:

When I discuss redundancy with plant managers like Michael in Mexico, the first question is always about cost. Many assume that redundancy means doubling their equipment budget, but that's simply not true. The reality is that strategic redundancy planning can be implemented for 15-25% additional investment while potentially saving 3-5 times that amount in avoided production losses during the first year alone.

Snippet Paragraph:

Coil upender redundancy typically costs Mexican plants 15-25% more than basic systems, with premium redundant upenders ranging from $75,000-$120,000 compared to $60,000-$95,000 for standard models. However, this investment typically delivers ROI within 12-18 months by preventing an average of $45,000-$80,000 in weekend shift production losses annually.

Dive Deeper Content:

Initial Investment Breakdown

Understanding the cost structure of redundancy helps Mexican plants make informed budgeting decisions. The additional 15-25% investment typically covers:

Redundancy Component Cost Analysis:

- Dual drive systems: +$8,000-$12,000 over single motor designs

- Backup hydraulic units: +$6,000-$9,000 including intelligent monitoring

- Quick-change components: +$3,000-$5,000 for modular design features

- Advanced control systems: +$4,000-$7,000 for redundant PLC and monitoring

Operational Cost Savings Calculation

The real value of redundancy emerges during weekend operations when maintenance teams are limited and production pressures are high. Let's examine the financial impact:

Weekend Shift Failure Cost Analysis (Mexican Plant Example):

- Production losses: $3,500-$6,000 per hour for medium-sized steel plants

- Emergency maintenance: $2,000-$4,000 for weekend technician call-outs

- Overtime costs: $1,500-$2,500 to recover lost production

- Customer penalties: $5,000-$15,000 for delayed shipments

A single weekend breakdown can easily cost $25,000-$40,000 in direct and indirect expenses. With redundant systems reducing failure frequency by 70-80%, the annual savings typically reach $45,000-$80,000 for plants operating 2-3 weekend shifts monthly.

Case Study: Mexican Steel Plant ROI

🏭 Medium Steel Processor in Monterrey

- Challenge: 4-6 weekend shift breakdowns annually costing $35,000-$50,000 each

- Solution: SHJLPACK redundant upender system with dual-drive and backup hydraulics

- Results:

- Production interruptions: reduced from 6 to 1 incident annually

- Maintenance costs: saved $28,000 in emergency repairs

- ROI period: 14 months achieved

- Customer satisfaction: improved by 35% through reliable deliveries

For Mexican plants considering redundancy, the key is viewing it as production insurance rather than additional expense. The 15-25% premium typically represents just 2-3% of the total production line value while protecting 100% of your weekend shift output capacity.

3. Why Do Mexican Steel Plants Need Different Redundancy Strategies?

Leading Paragraph:

Many equipment suppliers don't understand that Mexican steel plants face unique challenges that require customized redundancy approaches. From voltage fluctuations to limited technical support on weekends, the redundancy strategies that work in the US or Europe often fail in Mexican operating conditions. Having worked extensively with plants across Mexico, I've identified specific adaptations that make redundancy systems effective in this market.

Snippet Paragraph:

Mexican steel plants need different redundancy strategies due to unique challenges including: frequent power voltage fluctuations, limited weekend technical support availability, higher ambient temperatures affecting equipment performance, and longer lead times for imported spare parts. These factors require redundancy systems with broader operating tolerances and simpler maintenance protocols.

Dive Deeper Content:

Power Quality Adaptations

Mexican industrial areas often experience voltage variations of ±15% compared to the ±5% common in the US and Europe. This requires redundancy systems with:

Power System Redundancy Features for Mexico:

- Wider voltage tolerance: 180-520V operating range vs standard 200-480V

- Backup power conditioning: Integrated voltage stabilizers for sensitive components

- Phase loss protection: Automatic detection and compensation for single-phase failures

- Surge protection: Heavy-duty protection for lightning season and grid fluctuations

According to data from SHJLPACK's Mexican clients, plants implementing these power adaptations experience 60% fewer electrical-related failures during weekend shifts, particularly during the summer months when grid stability decreases.

Maintenance and Support Considerations

The reality for most Mexican plants is that specialized technical support may be 4-8 hours away during weekend shifts. This necessitates redundancy systems designed for operator-level maintenance:

Weekend Maintenance Protocol (Mexican Plants):

- Automated fault diagnosis - System identifies specific failed components

- Visual guidance system - LED indicators show replacement locations

- Tool-free access panels - No special tools required for common replacements

- Spare part standardization - Using commonly available components

- Bilingual troubleshooting guides - Spanish/English instructions for operators

Environmental Adaptations

Mexican steel plants often operate in high-temperature, high-humidity environments that accelerate component wear. Redundancy systems need additional protection:

Environmental Protection Features:

- High-temperature hydraulic fluid - Stable performance up to 65°C ambient

- Corrosion-resistant components - Special coatings for coastal areas

- Dust filtration systems - Enhanced protection for northern desert regions

- Cooling system redundancy - Backup fans and heat exchangers

| Regional Adaptation Comparison: | Feature | US/Europe Standard | Mexican Adaptation | Benefit for Mexican Plants |

|---|---|---|---|---|

| Voltage Range | 200-480V ±5% | 180-520V ±15% | 45% fewer power-related stops | |

| Technical Response | 2-4 hours | 8-24 hours | Operator-maintainable design | |

| Temperature Rating | 40°C max | 65°C max | Reliable summer operation | |

| Spare Parts | Next-day available | 3-7 day lead time | Common component standardization |

Mexican plants implementing these adapted redundancy strategies report 70% higher equipment availability during critical weekend production periods compared to using standard international designs. The key is working with suppliers like SHJLPACK who understand these local operating conditions and can customize redundancy approaches accordingly.

4. How Can You Implement Redundancy in Existing Coil Upender Systems?

Leading Paragraph:

Many plant managers assume that redundancy requires completely new equipment, but that's not always the case. Through retrofitting and strategic upgrades, you can add critical redundancy features to your existing coil upenders without massive capital investment. I've helped numerous Mexican plants implement phased redundancy improvements that dramatically improve weekend shift reliability while spreading costs over multiple budget cycles.

Snippet Paragraph:

Implementing redundancy in existing coil upender systems involves three approaches: retrofitting backup hydraulic power units, adding parallel drive motor systems, and installing quick-change component upgrades. According to SHJLPACK's retrofit data, these improvements typically cost 30-50% of new equipment while delivering 70-80% of the reliability benefits of fully redundant new systems.

Dive Deeper Content:

Phased Retrofit Implementation Strategy

Trying to implement all redundancy features simultaneously can be overwhelming for maintenance teams and budgets. A phased approach delivers continuous improvement:

12-Month Retrofit Implementation Plan:

Months 1-4: Core System Redundancy

- Install backup hydraulic power unit ($8,000-$12,000)

- Add system pressure monitoring sensors ($1,500-$2,500)

- Implement automatic switchover controls ($3,000-$4,500)

Months 5-8: Drive System Upgrades

- Retrofit secondary drive motor ($6,000-$9,000)

- Install torque monitoring system ($2,000-$3,000)

- Upgrade control logic for dual-motor operation ($2,500-$3,500)

Months 9-12: Component Accessibility

- Convert to quick-change bearing assemblies ($4,000-$6,000)

- Install modular grip pad system ($3,000-$4,500)

- Implement visual maintenance guidance ($1,000-$1,500)

Cost-Benefit Analysis of Retrofit vs Replacement

The decision between retrofitting existing equipment versus purchasing new redundant systems depends on several factors:

| Retrofit vs New Equipment Comparison: | Consideration | Retrofit Existing System | Purchase New Redundant System |

|---|---|---|---|

| Initial Investment | $25,000-$40,000 | $75,000-$120,000 | |

| Implementation Time | 2-4 weeks phased | 8-12 weeks delivery+install | |

| Performance Improvement | 70-80% of new system | 100% performance target | |

| Warranty Coverage | Component-specific | Full system warranty | |

| ROI Period | 8-14 months | 12-18 months | |

| Production Impact | Minimal disruption | 1-2 week installation stop |

Case Study: Successful Mexican Plant Retrofit

🏭 Established Steel Processor in Guadalajara

- Challenge: 15-year-old upender causing 3-4 weekend stoppages monthly

- Solution: Phased redundancy retrofit over 10 months

- Results:

- Weekend breakdowns: reduced from 12 to 2 per quarter

- Production recovery: 95% of weekend shift output maintained

- Investment: $38,500 vs $92,000 for new system

- ROI: Achieved in 11 months through avoided losses

Technical Implementation Considerations

When planning redundancy retrofits, several technical factors require careful attention:

Critical Retrofit Planning Factors:

- Structural capacity - Can existing framework support additional components?

- Control system compatibility - Will new components work with existing PLC?

- Power distribution - Are electrical panels sized for additional loads?

- Space constraints - Is there physical space for backup systems?

- Maintenance access - Can technicians easily reach new components?

According to SHJLPACK's retrofit experience in Mexican plants, properly planned redundancy upgrades typically extend equipment life by 5-7 years while reducing weekend shift downtime by 60-75%. The key success factor is working with experienced engineers who understand both the technical requirements and the operational realities of Mexican steel production environments.

Conclusion

Implementing strategic coil upender redundancy transforms weekend shift reliability from a constant worry to a competitive advantage. By focusing on the right redundancy features and implementation approach for your Mexican plant's specific needs, you can achieve 95%+ equipment availability while protecting your most critical production periods. For comprehensive solutions, explore our integrated steel coil packing line systems designed for maximum reliability.

Frequently Asked Questions

Q: How long does it take to install redundancy features on existing coil upenders?

A: Most redundancy retrofits take 2-4 weeks implemented in phases to minimize production impact. Critical components like backup hydraulic systems can often be installed during normal weekend maintenance windows, while more comprehensive drive system upgrades may require 3-5 days of planned production stoppage.

Q: What maintenance training is required for redundant coil upender systems?

A: Operators typically need 8-16 hours of specific training covering redundancy system operation, fault identification procedures, and basic component replacement skills. SHJLPACK provides comprehensive Spanish-language training materials and on-site sessions to ensure your team can maintain systems effectively, especially during weekend shifts when external support may be limited.

Q: Can redundancy features be added gradually to spread out investment costs?

A: Yes, most plants implement redundancy upgrades over 6-12 months through a phased approach. Starting with backup hydraulic systems ($8,000-$12,000), then adding drive redundancy ($6,000-$9,000), and finally implementing quick-change components ($7,000-$10,500). This spreads investment while delivering incremental reliability improvements throughout the implementation period.

Q: How does coil upender redundancy impact energy consumption in Mexican plants?

A: Modern redundant systems typically increase energy consumption by only 5-8% during normal operation since backup components remain in standby mode. During failure events, the systems actually become more energy-efficient by maintaining optimal operation rather than running damaged components inefficiently. Most Mexican plants see electricity cost increases of $150-$300 monthly, far outweighed by production savings.

Q: What warranty and support comes with redundant coil upender systems?

A: SHJLPACK's redundant upenders include 24-month comprehensive warranty covering all components, plus dedicated technical support with 4-hour remote response and 48-hour on-site support for Mexican customers. The redundancy components themselves carry extended 36-month coverage since they're designed for higher reliability and undergo more rigorous testing before installation.