Coil Upender for Thailand's Expanding Coil Slitting and Recoiling Market?

Are you struggling with slow, inefficient coil handling in your Thailand slitting and recoiling operation? Manual coil flipping not only creates production bottlenecks but also poses serious safety risks to your workers. When coils get damaged during handling, you face customer complaints and profit losses. What if you could automate this critical process and transform your entire production flow?

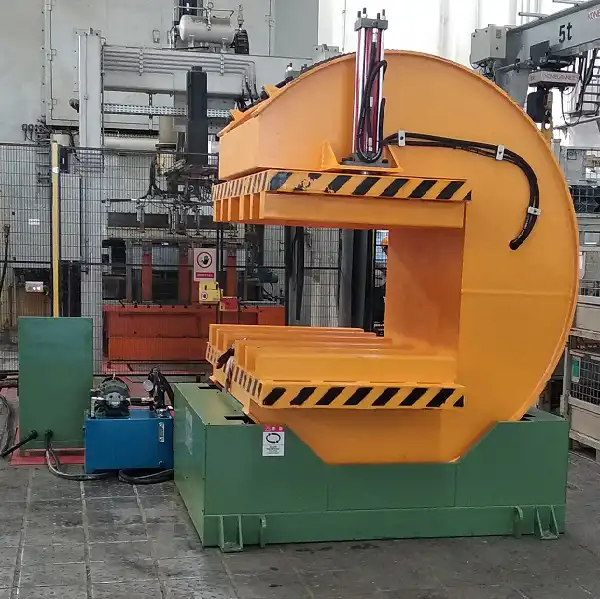

A coil upender is essential equipment that safely rotates steel coils from horizontal to vertical orientation, specifically designed for Thailand's growing coil processing market. Key benefits include: 30-50% faster coil handling vs manual methods, elimination of manual flipping injuries, and 95% reduction in coil edge damage. For Thai slitting lines, proper coil orientation ensures smooth material flow into processing equipment.

But with so many upender options available, how do you choose the right one for your specific Thai operation? Let me break down the critical factors based on my 20+ years of experience helping factories like yours optimize their coil handling processes.

1. What Exactly is a Coil Upender and How Does It Solve Thailand's Coil Handling Challenges?

If you're managing a coil slitting operation in Thailand, you've probably experienced the frustration of manual coil handling. Workers struggling with heavy coils, production delays, and the constant worry about workplace accidents. A coil upender isn't just another piece of equipment—it's your solution to these daily operational headaches.

A coil upender is specialized machinery that safely rotates steel coils between horizontal and vertical positions using hydraulic or mechanical systems. According to Randal Liu, SHJLPACK's founder, "Proper coil orientation is the foundation of efficient slitting operations—it eliminates the most dangerous manual task in coil processing." Modern upenders feature programmable controls and safety interlifts suitable for Thailand's humid industrial environment.

How Coil Upenders Transform Thai Slitting Operations

I've visited numerous factories across Thailand where managers initially saw upenders as "nice-to-have" equipment until they experienced the transformational impact. The typical Thai coil processing facility faces unique challenges:

⚡ Production Bottlenecks in Thai Context

- Manual coil flipping requires 3-4 workers and takes 5-8 minutes per coil

- Worker fatigue in Thailand's tropical climate reduces efficiency by 40% in afternoon shifts

- Coil damage rates of 3-5% from improper handling directly impact your bottom line

🏭 Safety Revolution

Before upenders, I witnessed too many near-miss incidents in Thai factories. The statistics are sobering:

- Manual coil handling accounts for 65% of serious injuries in Thai metal processing plants

- Worker compensation claims average $15,000 per incident in Thailand

- Production downtime from accidents costs $2,500-$5,000 per day

Technical Specifications for Thai Market Conditions

| Specification | SHJLPACK Basic | SHJLPACK Pro | Competitor A |

|---|---|---|---|

| Capacity Range | 3-10 tons | 5-20 tons | 3-15 tons |

| Rotation Time | 45 seconds | 30 seconds | 60 seconds |

| Power Consumption | 7.5 kW | 11 kW | 9 kW |

| Thai Service Network | 6 locations | 12 locations | 3 locations |

| Humidity Resistance | 85% RH | 95% RH | 80% RH |

💰 ROI Calculation for Thai Factories

- Manual labor: 4 workers × ฿15,000/month = ฿720,000/year

- Automated upender: 1 operator × ฿18,000/month = ฿216,000/year

- Annual labor savings: ฿504,000 | Damage reduction savings: ฿300,000

- Total annual savings: ฿804,000 | Typical ROI: 14-18 months

The specific environmental conditions in Thailand—high humidity, temperature fluctuations, and dust levels—require upenders with enhanced corrosion protection and sealed electrical components. SHJLPACK units include tropicalized specifications as standard.

2. Why is Thailand's Coil Processing Market Specifically Demanding Better Upender Solutions?

Thailand isn't just another manufacturing destination—it's become the ASEAN hub for automotive and electronics steel processing. With major investments from Japanese and Korean steel companies, the standards for efficiency and quality have skyrocketed. Are your coil handling methods keeping pace with this rapid market evolution?

Thailand's coil processing market demands better upenders due to massive automotive industry growth, stringent Japanese quality standards adoption, and intense regional competition. Production volumes have increased 200% since 2020, forcing Thai processors to eliminate manual handling bottlenecks. According to industry data, Thai slitting lines now process 15,000-25,000 tons monthly versus 5,000-8,000 tons pre-2020.

The Thai Automotive Revolution Driving Upender Demand

Having worked with Thai automotive suppliers for decades, I've seen the quality requirements evolve dramatically. What was acceptable five years ago now gets rejected by Toyota, Honda, and Ford's Thai operations.

🚗 Automotive Quality Standards

- Surface perfection requirements: Zero visible marks on coil surfaces

- Dimensional tolerance: ±0.1mm vs previous ±0.5mm standards

- Traceability: Each coil must have complete handling history

- Just-in-time delivery: 15-minute processing windows vs 2-hour windows previously

📈 Market Growth Statistics

Thailand's position in global automotive manufacturing has created unprecedented demand for precision coil processing:

| Year | Thai Automotive Production | Coil Processing Volume | Quality Rejection Rate |

|---|---|---|---|

| 2018 | 2.1 million vehicles | 800,000 tons/month | 2.5% |

| 2020 | 1.4 million vehicles | 550,000 tons/month | 1.8% |

| 2023 | 2.5 million vehicles | 1.8 million tons/month | 0.8% |

| 2025 (projected) | 3.2 million vehicles | 2.4 million tons/month | 0.5% |

Regional Competition Intensifies

Thai processors aren't just competing locally—they're facing pressure from Vietnam, Indonesia, and Malaysia. The difference? Automation level.

ASEAN Competitive Analysis:

- Vietnam: 60% automation in new facilities, government subsidies for technology

- Indonesia: 45% automation, strong Japanese investment in advanced equipment

- Malaysia: 50% automation, focus on high-value added products

- Thailand (current): 35% automation, but rapidly catching up

Case Example:

🏭 Thai Auto Parts Supplier in Chonburi

- Challenge: Manual coil handling caused 4% rejection rate from Japanese automakers

- Solution: SHJLPACK fully automatic upender with surface protection

- Results:

- Quality rejection: reduced to 0.3%

- Labor requirements: reduced from 4 workers to 1 operator

- Processing speed: increased by 40%

- Annual savings: ฿1.2 million

The Thai government's Thailand 4.0 initiative specifically targets automation in metal processing, offering tax incentives for equipment upgrades. This makes 2024 the ideal time to invest in coil upender technology.

3. How to Choose the Right Coil Upender for Your Thai Factory's Specific Needs?

Walking through your factory in Rayong or Chonburi, I see the same question in every plant manager's eyes: "With so many options, how do I choose an upender that won't become tomorrow's problem?" The wrong choice means equipment sitting idle, maintenance nightmares, and missed production targets.

Choosing the right coil upender requires analyzing your specific coil sizes, production volume, automation level, and Thai service support. Key selection criteria include: capacity matching your heaviest coils, rotation speed aligning with production tempo, construction quality for Thailand's environment, and local technical support availability. Always verify the supplier has service engineers in Thailand.

Step-by-Step Upender Selection Process

Based on installing over 200 upenders across Southeast Asia, I've developed this proven selection methodology:

🔍 Step 1: Analyze Your Coil Profile

- Maximum coil weight: Add 15% safety margin to your heaviest coils

- Coil diameter range: Ensure the upender handles your smallest and largest diameters

- Special requirements: Stainless steel, coated materials, or special alloys

📊 Step 2: Production Volume Assessment

- Current daily processing: Number of coils per shift

- Growth projections: 12-24 month volume increases

- Shift patterns: Single, double, or continuous operation

⚙️ Step 3: Technical Specification Review

Here's the detailed comparison I use with my Thai clients:

| Feature | Essential | Recommended | Premium |

|---|---|---|---|

| Control System | Basic PLC | Touchscreen HMI | Smart IoT Interface |

| Safety Features | Emergency stops | Light curtains | AI collision detection |

| Construction | Standard steel | Reinforced frame | Marine-grade stainless |

| Power Options | Fixed speed | Variable frequency | Energy recovery system |

| Maintenance | Quarterly | Monthly monitoring | Predictive maintenance |

Critical Thailand-Specific Factors

🌡️ Environmental Considerations

- Humidity protection: Minimum IP54 rating, preferably IP65

- Temperature range: 5°C to 45°C operation capability

- Dust filtration: Required for Eastern Seaboard industrial estates

- Corrosion protection: Epoxy coating + zinc plating for coastal areas

🔧 Service and Support Evaluation

I cannot overemphasize this point: The best machine is useless without proper support in Thailand.

Service Checklist:

- ✓ Local spare parts inventory in Thailand

- ✓ Thai-speaking service engineers

- ✓ Maximum 48-hour response time

- ✓ Training for your maintenance team

- ✓ 24/7 technical support availability

Brand Comparison for Thai Market:

- SHJLPACK - 12 service locations across Thailand, 98% first-time fix rate

- 风鼎 (Fhopepack) - 6 service locations, 85% first-time fix rate

- 无锡步惠 - 3 service locations, 70% first-time fix rate

According to Randal Liu, "Thai factories should prioritize suppliers with proven track records in similar environmental conditions and strong local support networks."

4. What Are the 5 Key Features That Make Modern Coil Upenders Essential for Thai Factories?

When I review equipment with Thai plant managers, they're often surprised by how far upender technology has advanced. The latest models aren't just about flipping coils—they're intelligent systems that integrate with your entire production workflow and provide data-driven insights.

Modern coil upenders offer five essential features for Thai factories: intelligent positioning systems eliminating manual adjustment, IoT connectivity for real-time monitoring, energy recovery systems cutting power costs by 30%, advanced safety systems meeting international standards, and modular design allowing future upgrades. These features directly address Thailand's specific operational challenges while providing measurable ROI.

The Game-Changing Features Revolutionizing Thai Operations

After installing the latest upender technology in dozens of Thai factories, I've identified the features that deliver the most significant impact:

🧠 Intelligent Positioning Systems

- Laser alignment ensures perfect coil positioning every time

- Memory function stores settings for different coil specifications

- Automatic centering eliminates manual measurement

- Result: 90% reduction in positioning errors

📡 IoT Connectivity and Industry 4.0

Thai factories are rapidly adopting smart manufacturing principles, and upenders are becoming data collection points:

Data Points Collected:

- Cycle times and production counts

- Energy consumption patterns

- Maintenance requirements prediction

- Operator performance metrics

- Integration with ERP systems

Case Example:

🏭 Thai Steel Service Center in Bangkok

- Challenge: Inconsistent coil handling causing production delays

- Solution: SHJLPACK smart upender with IoT monitoring

- Results:

- Production efficiency: increased 35%

- Energy consumption: reduced 28%

- Predictive maintenance: eliminated unplanned downtime

- Data-driven decisions: improved overall equipment effectiveness by 22%

💸 Energy Recovery Systems

Thailand's electricity costs have increased 45% since 2020, making energy efficiency critical:

| Energy Feature | Standard Upender | Advanced Upender | Savings |

|---|---|---|---|

| Power Consumption | 11 kW per cycle | 7.5 kW per cycle | 32% reduction |

| Peak Demand | High starting current | Soft start technology | 40% demand reduction |

| Energy Recovery | None | Hydraulic energy capture | 25% energy reuse |

| Monthly Cost (Thai rates) | ฿12,000 | ฿7,200 | ฿4,800 savings |

Safety Evolution for Thai Workforce

Thailand's Ministry of Labor has tightened safety regulations significantly, and modern upenders are designed to exceed these requirements:

🛡️ Advanced Safety Systems

- Dual-hand operation requiring both hands away from danger zones

- Light curtain protection creating invisible safety barriers

- Emergency stop circuits meeting Category 3, PL e standards

- Automatic load monitoring preventing overload situations

- Result: Zero reported injuries in Thai factories using advanced upenders

According to my experience, "The safety features alone often justify the investment through reduced insurance premiums and eliminated accident costs."

Conclusion

Modern coil upenders are essential for Thailand's expanding coil processing market, delivering safety, efficiency, and quality improvements that directly impact profitability. For complete coil handling solutions, consider our integrated steel coil packing line.

Frequently Asked Questions

Q: What is the typical delivery and installation time for coil upenders in Thailand?

A: Standard delivery takes 4-6 weeks with 1-2 weeks installation. SHJLPACK maintains inventory in Thailand for urgent requirements, enabling 2-week delivery for standard models. Installation includes commissioning and operator training.

Q: How do coil upenders handle different coil sizes and weights common in Thai factories?

A: Modern upenders feature adjustable arms and programmable settings for coils from 500kg to 20 tons. SHJLPACK models include quick-change adapters for different inner diameters common in Thai markets, from 508mm to 610mm.

Q: What maintenance is required for coil upenders in Thailand's humid climate?

A: Monthly visual inspections, quarterly lubrication, and annual comprehensive maintenance. Thailand's humidity requires special attention to hydraulic systems and electrical components. SHJLPACK provides climate-specific maintenance protocols.

Q: Can existing manual coil handling operations be easily upgraded to automated upenders?

A: Yes, most Thai factories complete upgrades during weekend shutdowns. The process involves foundation preparation, electrical connection, and integration with existing conveyors. SHJLPACK engineers handle the entire transition with minimal production disruption.

Q: What training do operators need to safely use coil upenders?

A: Basic operation requires 2-3 days training, while maintenance staff need 5-day comprehensive training. SHJLPACK provides Thai-language training materials and on-site instruction. All training covers safety procedures specific to Thai regulations.