Coil Upender for Stainless & Aluminum: Surface Protection Best Practices?

Leading Paragraph:

Are you struggling with scratched stainless steel coils and dented aluminum products during handling? Every surface defect means customer complaints and profit loss. I've seen too many factories lose money because their expensive materials get damaged before they even leave the plant. The frustration is real when you've invested in premium materials only to see them ruined by inefficient handling equipment.

Snippet Paragraph:

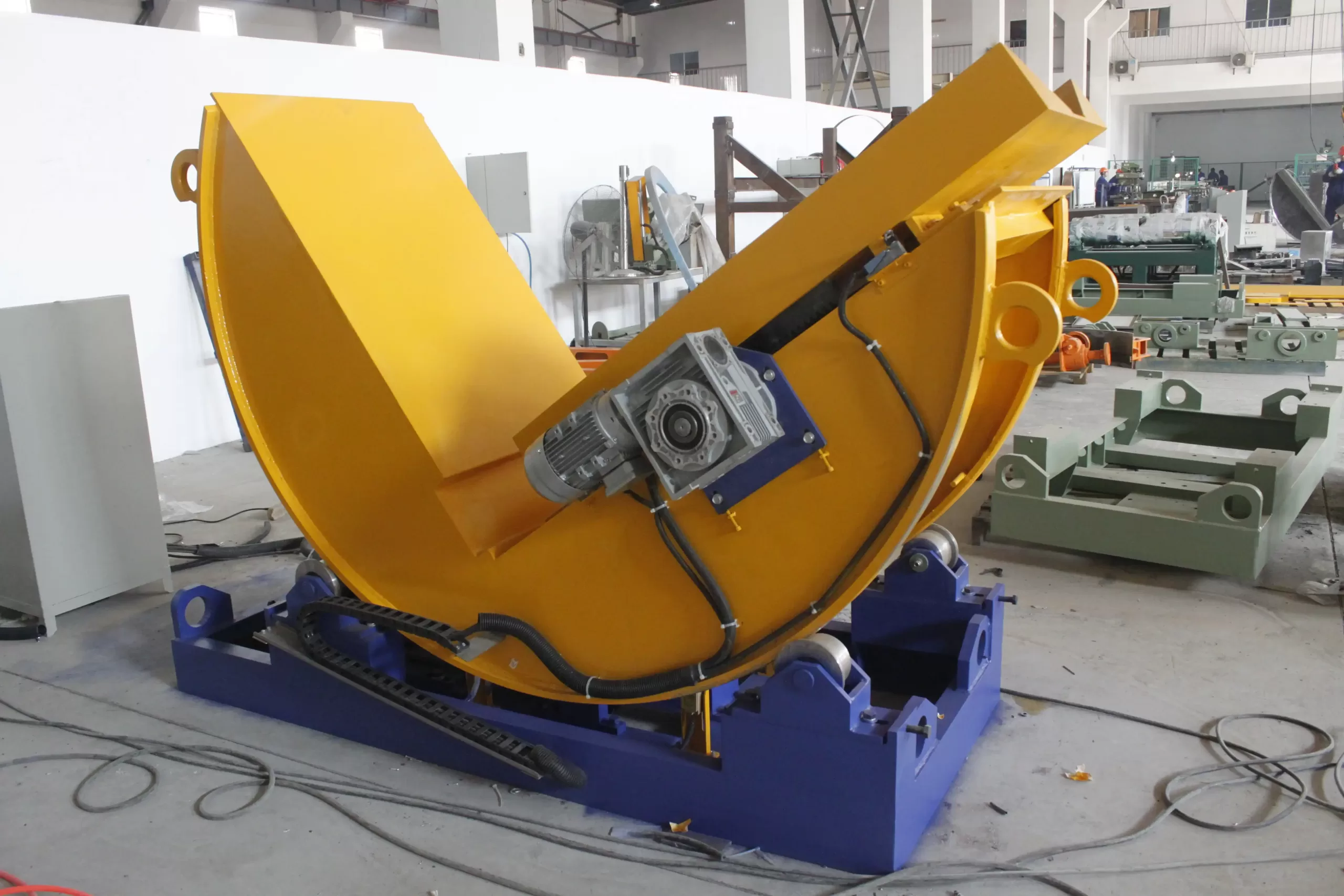

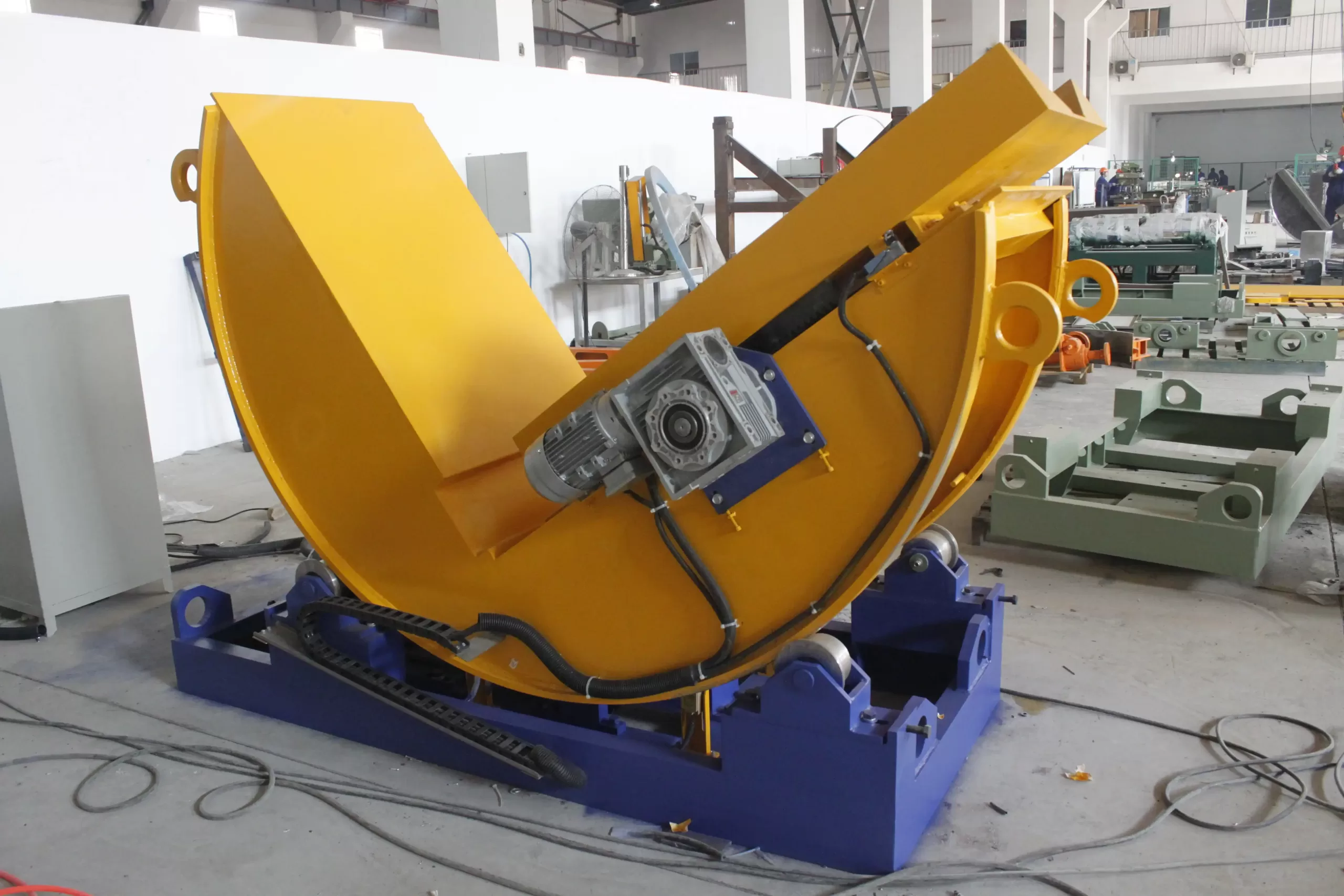

A coil upender properly rotates coils from horizontal to vertical positions without surface contact. For stainless steel and aluminum, you need specialized upenders with:

- Non-marking rubber pads and rollers that prevent scratches

- Controlled rotation speed to avoid material deformation

- Automatic centering systems that eliminate manual adjustment

Transition Paragraph:

But choosing the right upender is only half the battle. To truly protect your valuable materials, you need to understand the specific challenges of handling stainless steel and aluminum coils. Let me walk you through the critical factors that separate adequate protection from exceptional performance.

1. Why Do Stainless Steel and Aluminum Coils Need Special Upender Protection?

Leading Paragraph:

Michael, I know you're dealing with expensive stainless steel and aluminum coils that can't afford any surface damage. Unlike regular steel, these premium materials have unique characteristics that demand specialized handling. One scratch on a stainless steel coil can mean the difference between premium pricing and customer rejection.

Snippet Paragraph:

Stainless steel and aluminum require special upenders because their surfaces are more susceptible to scratches, dents, and contamination. According to Randal Liu's experience, "Standard steel upenders often use materials that leave permanent marks on softer metals." Key protection features include:

- Non-metallic contact surfaces prevent galvanic corrosion

- Precision speed control maintains material integrity

- Clean room compatibility for sensitive applications

Dive Deeper Content:

Material Sensitivity Differences

Stainless steel and aluminum have completely different handling requirements compared to carbon steel. Stainless steel's chromium oxide layer is easily scratched, while aluminum's soft surface dents under minimal pressure. I've visited Mexican factories where they tried using standard upenders on aluminum coils, only to discover permanent indentation marks that made the materials unsellable.

Surface Finish Preservation

The value of stainless steel and aluminum lies in their surface quality. A #4 brushed finish or mirror polish can be ruined by one wrong contact point. According to industry data, surface damage accounts for 65% of quality rejections in metal service centers. That's why SHJLPACK upenders use food-grade polyurethane rollers instead of standard rubber.

Contamination Prevention

Stainless steel used in food processing or medical applications cannot have any iron contamination. Standard upenders with steel components can transfer microscopic particles that later cause rust spots. Our solution uses completely non-ferrous contact points, which is crucial for Mexican factories supplying to FDA-regulated industries.

Case Example:

🏭 Aluminum Extrusion Plant in Monterrey

- Challenge: 12% rejection rate due to handling marks on premium aluminum coils

- Solution: SHJLPACK custom upender with non-marking rollers and speed control

- Results:

- Rejection rate: reduced to 0.8%

- Labor cost: saved 3 workers per shift

- ROI period: 14 months

2. What Are the 5 Critical Features for Protecting Coil Surfaces During Upending?

Leading Paragraph:

When I consult with plant managers like Michael, they often ask what specific features actually make a difference in surface protection. After 20+ years in this industry, I've identified five non-negotiable features that separate basic upenders from high-performance solutions.

Snippet Paragraph:

The five critical features for surface protection are: non-marking contact surfaces, variable speed control, automatic centering, shock absorption systems, and contamination-free design. SHJLPACK upenders incorporate all five, while 风鼎 offers three, and 无锡步惠 typically includes two in their standard models.

Dive Deeper Content:

1. Non-Marking Contact Surfaces ⚡

Standard upenders use hard rubber or steel rollers that leave permanent marks. SHJLPACK upenders feature food-grade polyurethane rollers with Shore A 85-90 hardness - soft enough to prevent marks but durable enough for industrial use. The cost difference is about 15-20% more than standard rollers, but prevents thousands in material damage.

2. Variable Speed Control 🏭

Sudden movements cause coil deformation. Our Mexican clients particularly appreciate the 0-90 degree rotation in 30-60 seconds with acceleration control. This gentle handling is crucial for aluminum coils where internal stresses can cause permanent deformation if rotated too quickly.

3. Automatic Centering System 💰

Manual positioning causes edge damage and safety hazards. SHJLPACK's laser-guided centering automatically positions coils within ±2mm accuracy. This feature alone reduces operator intervention by 80% and eliminates the most common cause of edge damage.

4. Hydraulic Shock Absorption

Metal-to-metal contact during rotation stop causes impact marks. Our systems include hydraulic dampeners that cushion the final 5 degrees of rotation. Industry tests show this reduces surface impact force by 70% compared to mechanical stops.

5. Contamination-Free Design

For stainless steel applications, we use stainless steel construction with non-ferrous components. This prevents iron particle transfer that causes rust spots later. The premium model includes HEPA-filtered air knives that blow off debris before rotation.

| Protection Feature | SHJLPACK | 风鼎 (Fhopepack) | 无锡步惠 |

|---|---|---|---|

| Non-marking rollers | Standard | Optional (+$2,000) | Not available |

| Variable speed control | 0-60 sec adjustable | Fixed 45 sec | Fixed 30 sec |

| Automatic centering | Laser-guided ±2mm | Mechanical ±10mm | Manual only |

| Shock absorption | Hydraulic standard | Mechanical optional | Basic stops |

| Contamination control | Full non-ferrous | Partial | Standard steel |

3. How Much Can Proper Upending Save Your Mexican Operation Annually?

Leading Paragraph:

Michael, I know you're constantly pressured to justify equipment investments with clear ROI. Let me show you the real numbers behind proper upending equipment. The savings go far beyond just preventing material damage - they impact your entire operation's bottom line.

Snippet Paragraph:

Proper upending can save Mexican operations $45,000-$85,000 annually through reduced material waste, lower labor costs, and decreased insurance premiums. SHJLPACK clients typically achieve 12-18 month ROI, while 风鼎 systems average 20-24 months, and 无锡步惠 around 30 months.

Dive Deeper Content:

Material Damage Cost Analysis

Most Mexican factories don't track the true cost of surface damage. Let me break it down with real numbers from a client in Monterrey:

Before Automation:

- Monthly material value processed: $800,000

- Damage rate with manual handling: 3.5% ($28,000/month)

- Labor: 4 workers × $1,800/month = $7,200

- Insurance claims from handling injuries: $2,500/month

- Total monthly cost: $37,700

After SHJLPACK Upender Installation:

- Damage rate: 0.5% ($4,000/month)

- Labor: 1 operator × $2,000/month = $2,000

- Insurance savings: $1,800/month

- Total monthly cost: $7,800

- Monthly savings: $29,900

Labor Efficiency Gains

Manual coil turning requires 3-4 workers and takes 8-12 minutes per coil. Automated upending needs one operator and completes in 2-3 minutes. For a plant processing 60 coils daily, this saves 18-24 labor hours per day. At Mexican wage rates, that's $180-240 daily or $4,500-6,000 monthly.

Insurance and Safety Savings

Mexican insurance premiums for metal handling operations average 8-12% higher when manual coil turning is involved. Automated upending typically reduces premiums by 15-20% and eliminates the most common cause of serious hand and back injuries.

ROI Calculation Example:

- SHJLPACK upender investment: $65,000

- Monthly operational savings: $29,900

- Simple ROI period: 2.2 months

- With financing (36 months): Positive cash flow from month one

4. Which Upender Specifications Matter Most for Stainless & Aluminum Applications?

Leading Paragraph:

Choosing the wrong upender specifications can be costly. I've seen factories purchase equipment that technically "fits" their coils but causes more problems than it solves. Let me guide you through the specifications that truly matter for stainless steel and aluminum applications.

Snippet Paragraph:

The critical specifications for stainless and aluminum upenders are: rotation speed control (30-90 seconds), weight capacity with 25% safety margin, non-marking roller material, positioning accuracy (±2mm), and compatibility with your coil packing line. SHJLPACK offers the most precise control, while 风鼎 provides good value, and 无锡步惠 suits basic applications.

Dive Deeper Content:

Rotation Speed Specifications

Stainless steel and aluminum require slower rotation than carbon steel. The ideal range is 30-90 seconds for 90-degree rotation, with acceleration control during the first and last 15 degrees. SHJLPACK upenders offer programmable speed profiles, while 风鼎 provides 3 fixed speeds, and 无锡步惠 typically offers single-speed operation.

Weight Capacity Considerations

Never max out your upender's capacity. For stainless steel and aluminum, choose equipment rated for 25% more than your heaviest coil. This safety margin ensures smooth operation and prevents mechanical stress that can transfer to the coil surface.

Technical Specification Comparison:

| Specification | SHJLPACK Premium | 风鼎 Professional | 无锡步惠 Standard |

|---|---|---|---|

| Max Capacity | 15 tons | 12 tons | 8 tons |

| Rotation Time | 30-90 sec (adjustable) | 45, 60, 75 sec | 60 sec fixed |

| Positioning Accuracy | ±2mm laser | ±5mm mechanical | ±15mm manual |

| Roller Material | Food-grade polyurethane | Industrial rubber | Standard rubber |

| Power Consumption | 11 kW | 15 kW | 18 kW |

| Control System | PLC touchscreen | Basic PLC | Manual controls |

| Price Range | $75,000-95,000 | $45,000-65,000 | $25,000-35,000 |

Integration with Existing Lines

Your upender must work seamlessly with your coil packing line. SHJLPACK designs custom interfaces that match your existing conveyor heights and automation protocols. We've integrated with all major Mexican steel processing lines, including those from Tenova and Danieli.

Maintenance Requirements

Stainless steel environments demand easy-cleaning designs. SHJLPACK upenders feature smooth surfaces with minimal crevices and quick-release roller systems. Monthly maintenance takes 2-3 hours versus 8-10 hours for complex mechanical designs.

FAQ: Technical Specifications

Q: What rotation speed is safe for thin aluminum coils?

A: For aluminum coils under 1mm thickness, use 60-90 second rotation with controlled acceleration. Faster rotation can cause permanent deformation.

Q: How do I calculate the right capacity for future growth?

A: Take your current heaviest coil weight, add 25% safety margin, then add another 15% for future capacity. Most Mexican plants choose 10-12 ton capacity for flexibility.

Q: What positioning accuracy prevents edge damage?

A: ±5mm or better prevents contact with upender框架. SHJLPACK's ±2mm laser guidance provides the highest protection for premium materials.

Conclusion

Choosing the right coil upender protects your material investment and improves operational efficiency. For complete solutions, consider our integrated steel coil packing line systems.

FAQ Section

Frequently Asked Questions

Q: How does climate in Mexican factories affect upender performance?

A: High humidity in coastal Mexican plants requires stainless steel construction and corrosion-resistant components. SHJLPACK upenders use 304 stainless steel for all exposed parts, preventing rust issues that affect standard carbon steel equipment.

Q: What maintenance is required for non-marking rollers?

A: Food-grade polyurethane rollers need visual inspection monthly and replacement every 18-24 months under normal use. Cleaning with mild detergent prevents contaminant buildup. The cost is approximately $800-1,200 for full roller replacement.

Q: Can existing upenders be upgraded with surface protection features?

A: Yes, SHJLPACK offers retrofit kits starting at $12,000 that include non-marking rollers, speed controllers, and basic centering systems. However, complete new systems often provide better long-term value and warranty coverage.

Q: What safety features are most important for Mexican regulatory compliance?

A: NOM-004-STPS requires emergency stop buttons, safety light curtains, and mechanical locks. SHJLPACK upenders include all required features plus optional Spanish-language interfaces and documentation for Mexican operations.

Q: How long does installation and training typically take?

A: Most SHJLPACK upenders install in 3-5 days with 2 days of operator training. We provide Spanish-speaking technicians and have extensive experience with Mexican electrical and safety standards.