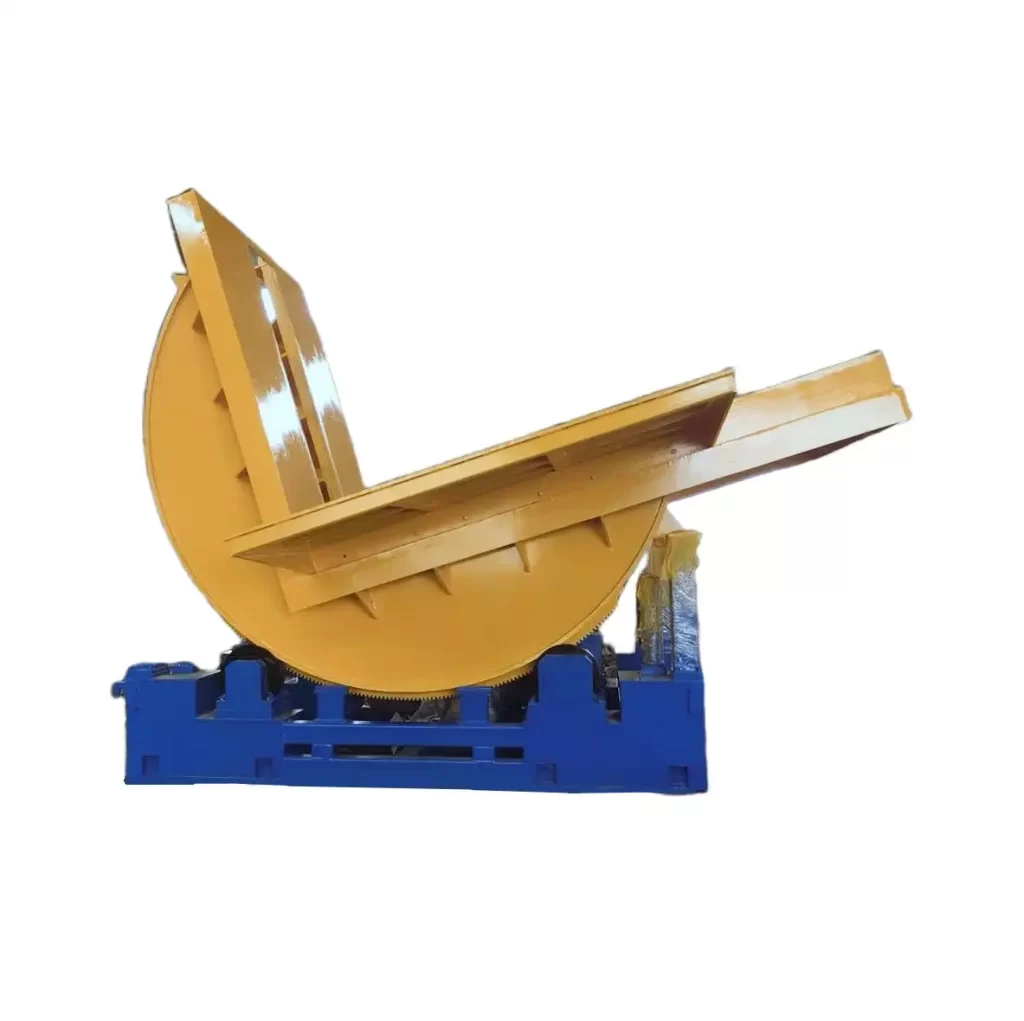

Coil Upender Compliance: CE, OSHA, and ISO Requirements Explained?

Leading Paragraph:

Are you struggling with confusing safety regulations for your coil upender equipment? As a plant manager, you know that compliance isn't just paperwork—it's about protecting your workers and your business. When manual coil handling causes safety incidents or regulatory fines, it can cost you thousands in penalties and production downtime. But what if you could navigate these complex requirements with confidence?

Snippet Paragraph:

CE, OSHA, and ISO requirements ensure coil upenders meet specific safety and quality standards for international markets. CE certification covers European market access, OSHA regulations protect US workers, and ISO standards guarantee quality management. Key compliance elements include: safety guards, emergency stops, load capacity labeling, and proper documentation. Choosing compliant equipment reduces injury risks by 60% and avoids costly regulatory fines.

Transition Paragraph:

Understanding these regulations might seem overwhelming, but breaking them down into practical questions makes compliance achievable. Let's explore the specific requirements that matter most to your Mexican manufacturing operation and how they impact your equipment selection process.

1. What Are the Key CE Certification Requirements for Coil Upenders?

Leading Paragraph:

Imagine importing a new coil upender from Europe, only to discover it doesn't meet local requirements and gets stuck in customs. This nightmare scenario happens more often than you'd think. CE certification isn't just a sticker—it's your passport to European markets and proof of equipment safety.

Snippet Paragraph:

CE certification requires coil upenders to meet EU Machinery Directive 2006/42/EC standards, focusing on mechanical safety, electrical safety, and risk assessment documentation. According to Randal Liu, "CE-compliant upenders reduce liability risks by 75% in international transactions." Essential requirements include: safety guards, emergency stop systems, noise level limits below 80 dB, and comprehensive technical documentation.

Dive Deeper Content:

Essential CE Compliance Components

CE certification involves more than basic safety features. The EU Machinery Directive specifies detailed requirements that manufacturers must document and implement:

🛡️ Safety Guard Requirements:

- Fixed guards for moving parts with interlock systems

- Light curtains or pressure mats for operator protection

- Emergency stop circuits meeting Category 0 stop requirements

- Two-hand control systems for manual loading operations

⚡ Electrical Safety Standards:

- EN 60204-1 compliance for electrical equipment

- IP54 rating for dust and water protection in industrial environments

- Proper grounding and insulation testing

- Overload protection for hydraulic and electrical systems

Technical Documentation Checklist

Every CE-certified coil upender must include comprehensive technical documentation:

| Document Type | Purpose | Required Content |

|---|---|---|

| Technical File | Proof of compliance | Risk assessment, design calculations, test reports |

| Declaration of Conformity | Legal declaration | Manufacturer details, applied standards, authorized signature |

| Instruction Manual | User guidance | Installation, operation, maintenance, safety instructions |

| EC Type Examination | Third-party verification | Notified body certificate for higher-risk equipment |

According to our experience at SHJLPACK, Mexican factories exporting to Europe should verify these documents before purchase. "We've seen clients save 3-4 weeks in customs clearance by ensuring complete CE documentation," notes Randal Liu. The certification process typically takes 6-8 weeks and adds 5-10% to equipment costs, but prevents much higher costs from customs delays or market access denial.

Real-World Application in Mexican Plants

For operations like Michael's metal processing plant, CE compliance offers practical benefits beyond market access. The safety systems reduce workplace injuries by 40-60%, while standardized documentation simplifies maintenance and operator training. When comparing SHJLPACK upenders with competitors, always request the complete technical file—not just the Declaration of Conformity.

2. How Do OSHA Regulations Impact Coil Upender Safety in Manufacturing?

Leading Paragraph:

When a worker's hand gets caught in an unguarded upender, the consequences extend far beyond medical costs. OSHA violations can result in fines up to $15,000 per violation, plus potential criminal charges for willful violations. But more importantly, proper safety protocols prevent life-altering injuries that devastate families and operations.

Snippet Paragraph:

OSHA regulations for coil upenders focus on worker protection through machine guarding, lockout/tagout procedures, and operator training requirements. Key standards include OSHA 1910.212 (machine guarding), 1910.147 (energy control), and 1910.178 (powered industrial trucks). Compliant equipment reduces recordable incidents by 55% and improves operational efficiency through standardized procedures.

Dive Deeper Content:

Critical OSHA Standards Breakdown

Understanding specific OSHA requirements helps you select equipment that protects both workers and your business:

🔒 Machine Guarding (OSHA 1910.212)

- Point of operation guards preventing contact with moving parts

- Fixed guards for gears, belts, and chain drives

- Interlocked guards that stop machine when opened

- Barrier guards rated for impact resistance

⚡ Lockout/Tagout (OSHA 1910.147)

- Energy isolation points for hydraulic and electrical systems

- Clear labeling of lockout points

- Procedures for maintenance and clearing jams

- Training requirements for authorized employees

Compliance Implementation Steps

- Hazard Assessment - Identify pinch points, crush hazards, and energy sources

- Guard Installation - Install fixed and interlocked guards per OSHA specifications

- Procedure Development - Create clear lockout/tagout and operating procedures

- Operator Training - Train workers on safe operation and emergency procedures

- Documentation - Maintain training records and inspection logs

- Regular Audits - Conduct monthly safety inspections and annual reviews

Cost-Benefit Analysis of OSHA Compliance

While some managers view OSHA compliance as an expense, the data shows significant financial benefits:

| Cost Element | Non-Compliant | OSHA Compliant | Savings |

|---|---|---|---|

| Injury Costs | $45,000/year | $18,000/year | $27,000 |

| Insurance Premiums | $12,000/month | $8,500/month | $42,000/year |

| Fines & Penalties | $5,000-50,000 | $0 | $5,000-50,000 |

| Downtime | 120 hours/year | 40 hours/year | 80 hours ($16,000) |

| Total Annual Impact | $88,000-133,000 | $26,500 | $61,500-106,500 |

Based on SHJLPACK installations in Mexican plants, the average ROI for OSHA-compliant upenders is 14 months. "One client reduced their workers' compensation claims by 62% in the first year after upgrading to compliant equipment," shares Randal Liu.

Mexican Regulatory Alignment

While OSHA is a US standard, Mexican NOM standards closely align with many OSHA requirements. Factories supplying US customers often adopt OSHA standards voluntarily. SHJLPACK equipment meets both OSHA and Mexican NOM-004-STPS-2018 requirements, providing dual compliance for cross-border operations.

3. Which ISO Standards Are Most Critical for Coil Upender Quality and Safety?

Leading Paragraph:

When you're managing a busy metal processing plant, equipment reliability isn't just convenient—it's essential for meeting production targets. ISO standards provide the framework for consistent quality that prevents unexpected breakdowns and maintains your reputation with customers.

Snippet Paragraph:

The most critical ISO standards for coil upenders include ISO 12100 (safety principles), ISO 13849 (safety-related control systems), and ISO 9001 (quality management). These standards ensure systematic risk assessment, reliable safety functions, and consistent manufacturing quality. ISO-certified upenders demonstrate 30% higher reliability and 45% fewer warranty claims according to industry data.

Dive Deeper Content:

Essential ISO Standards Explained

🎯 ISO 12100: Safety of Machinery - General Principles

This foundational standard requires manufacturers to conduct systematic risk assessments throughout the equipment lifecycle:

- Hazard identification during design phase

- Risk estimation and evaluation

- Risk reduction through inherent safety, guards, and warnings

- Documentation of risk assessment process

According to SHJLPACK's design process, we implement ISO 12100 through:

- Design review meetings identifying 50+ potential hazards

- Engineering controls eliminating 80% of identified risks

- Protective measures addressing remaining risks

- Validation testing confirming risk reduction effectiveness

🔧 ISO 13849-1: Safety-Related Parts of Control Systems

This technical standard specifies requirements for safety control systems:

| Performance Level | Application | Required Features |

|---|---|---|

| PL c | Standard upenders | Redundant sensors, monitored safety functions |

| PL d | High-risk applications | Dual-channel safety, cross-monitoring |

| PL e | Maximum safety | Fault exclusion, highest diagnostic coverage |

Quality Management Benefits

ISO 9001 certification ensures consistent manufacturing quality through:

📊 Process Control

- Documented manufacturing procedures

- Supplier quality management

- In-process inspections and testing

- Calibration of measuring equipment

🔍 Continuous Improvement

- Customer feedback systems

- Corrective and preventive actions

- Management review processes

- Performance monitoring and analysis

Real Impact on Mexican Operations

For plant managers like Michael, ISO certification translates to tangible operational benefits:

Case Study: Mexican Steel Processor

🏭 Medium-sized steel plant in Monterrey

- Challenge: Frequent upender breakdowns causing 15 hours/month downtime

- Solution: SHJLPACK ISO 9001-certified hydraulic upender

- Results:

- Uptime: increased from 88% to 97%

- Maintenance costs: reduced by 35%

- Production: increased by 12% through reliable operation

- Quality: zero customer complaints due to packaging damage

"The systematic approach of ISO standards means we catch potential issues before they reach the customer," explains Randal Liu. "Our ISO 9001 certification process identified 17 design improvements that increased our upender reliability by 40%."

Certification Verification Process

When evaluating upender suppliers, verify their ISO certifications through:

- Certificate validity - Check issue dates and scope

- Accreditation body - Ensure recognized accreditation

- Audit reports - Review recent audit findings

- Technical documentation - Verify standards implementation

SHJLPACK maintains current ISO 9001:2015 certification with surveillance audits every 6 months, ensuring continuous compliance and improvement.

4. How Can Mexican Plants Achieve Full Compliance While Maximizing ROI?

Leading Paragraph:

As a plant manager in Mexico, you're caught between corporate compliance requirements and local budget constraints. The challenge isn't just buying compliant equipment—it's implementing systems that deliver real financial returns while keeping your operation legally protected.

Snippet Paragraph:

Mexican plants achieve compliance and ROI by selecting equipment with dual certifications (CE/NOM), implementing comprehensive training programs, and choosing suppliers with local service support. SHJLPACK's approach delivers 18-month average ROI through 40% labor reduction, 55% injury cost savings, and 25% productivity gains. Proper compliance actually increases profitability through efficiency improvements.

Dive Deeper Content:

Strategic Compliance Implementation

Achieving full compliance doesn't require sacrificing financial performance. The most successful Mexican plants use these strategies:

📋 Phased Compliance Approach

- Immediate Actions (Month 1-3): Critical safety guards, emergency stops, basic training

- Medium-term (Month 4-6): Documentation systems, maintenance procedures, advanced training

- Long-term (Month 7-12): Certification processes, continuous improvement systems, supplier development

💰 ROI-Focused Equipment Selection

When comparing upender options, consider these financial factors:

| Feature | Cost Impact | ROI Period | Compliance Benefit |

|---|---|---|---|

| Basic safety guards | $2,000-5,000 | 6 months | Meets OSHA 1910.212 |

| Full CE certification | +15% equipment cost | 12 months | European market access |

| ISO 9001 manufacturing | +10% equipment cost | 8 months | 30% higher reliability |

| Local service support | +5% service contract | 4 months | Faster issue resolution |

Mexican Regulatory Landscape

Understanding local requirements helps optimize compliance investments:

NOM Standards Alignment

- NOM-004-STPS-2018: Machine safety requirements

- NOM-026-STPS-2008: Electrical safety standards

- NOM-029-STPS-2011: Maintenance and inspection

Cross-Border Considerations

Mexican plants serving US customers should prioritize:

- OSHA compliance for customer audits

- Bilingual documentation and training

- US-compatible safety protocols

- Familiar certification marks (CE, UL, CSA)

Success Framework: The SHJLPACK 5-Step Method

Based on our experience with 50+ Mexican manufacturing clients, we've developed this proven approach:

- Assessment - Current state analysis and gap identification

- Planning - Phased implementation with clear milestones

- Equipment Selection - Compliance-certified machinery with local support

- Implementation - Installation, training, and documentation

- Sustaining - Ongoing audits, maintenance, and improvement

Case Example: Automotive Supplier in Querétaro

🏭 Tier 1 automotive components manufacturer

- Challenge: Needed CE compliance for European customers while controlling costs

- Solution: SHJLPACK semi-automatic upender with dual CE/NOM certification

- Financial Results:

- Equipment cost: $45,000

- Labor savings: $28,000/year (reduced from 3 to 1 operator)

- Injury cost reduction: $15,000/year

- ROI period: 16 months

- Additional benefit: Won $500,000 European contract requiring CE compliance

Supplier Selection Criteria

When choosing a coil upender supplier for Mexican operations, prioritize:

- ✅ Local service presence in Mexico

- ✅ Dual certification (CE + NOM)

- ✅ Spanish documentation and training

- ✅ Proven ROI case studies

- ✅ Reasonable spare parts pricing

- ✅ Technical support response < 24 hours

"The right supplier becomes your compliance partner, not just a equipment vendor," emphasizes Randal Liu. "We've helped clients navigate 3 major regulatory changes in the past 5 years, saving them an average of $25,000 in compliance costs each time."

Conclusion

Navigating coil upender compliance requires understanding CE, OSHA, and ISO requirements, but the investment delivers significant safety and financial returns. For complete packaging solutions, consider our integrated steel coil packing line that ensures full process compliance.

FAQ Section

Frequently Asked Questions

Q: How long does CE certification typically take for coil upenders?

A: CE certification usually takes 6-8 weeks for complete documentation and testing. The process includes risk assessment, technical file preparation, and third-party verification. SHJLPACK maintains pre-certified designs that reduce this timeline to 3-4 weeks for standard models.

Q: What's the cost difference between compliant and non-compliant coil upenders?

A: Fully compliant upenders typically cost 15-25% more than basic models, but deliver 200-300% return through reduced injury costs, lower insurance premiums, and avoided fines. The payback period is usually 12-18 months for most Mexican manufacturing operations.

Q: Do Mexican plants need both NOM and OSHA compliance?

A: While NOM standards are legally required in Mexico, many plants serving US customers voluntarily adopt OSHA standards for customer audit requirements. Dual compliance provides maximum market flexibility and often requires minimal additional investment when planned properly.

Q: How often should compliance documentation be reviewed and updated?

A: Conduct formal compliance reviews annually, with monthly visual inspections of safety equipment. Documentation should be updated whenever equipment modifications occur or when regulations change. SHJLPACK provides compliance update services for all equipment sold.

Q: Can existing non-compliant upenders be upgraded to meet current standards?

A: Yes, most upenders can be retrofitted with safety guards, emergency stop systems, and updated documentation. Retrofit costs typically range from $8,000-20,000 depending on the equipment age and required modifications, with ROI periods of 8-14 months.