Coil Upender Applications in Spain's Sheet Metal Processing and Slitting Lines?

Leading Paragraph:

Are you struggling with production bottlenecks caused by manual coil handling in your sheet metal processing facility? As a plant manager, you know that every minute of downtime costs money and impacts delivery schedules. The constant safety risks and inefficiencies of manual coil turning can feel overwhelming, especially when you're responsible for meeting tight production targets. But what if there was a solution that could transform your coil handling process while keeping your team safe?

Snippet Paragraph:

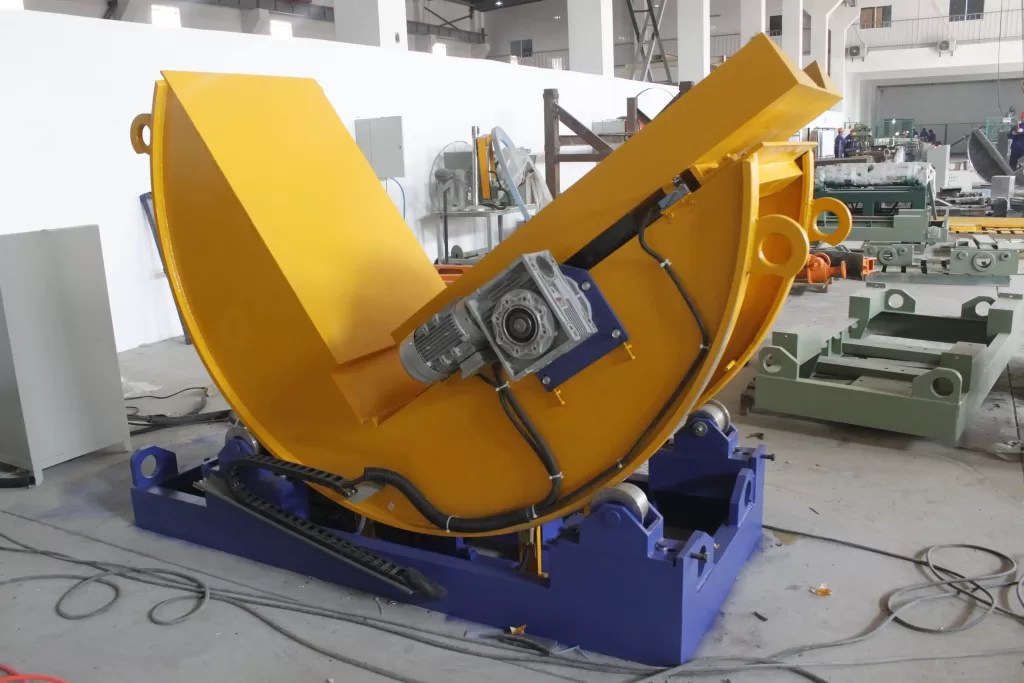

Coil upenders are essential equipment in Spain's sheet metal and slitting lines that automate the process of rotating coils from horizontal to vertical positions. Key benefits include: 30-50% faster coil positioning, elimination of manual handling risks, and reduced product damage during orientation changes. These machines are particularly valuable in Spanish facilities processing automotive-grade steel and construction materials where precision handling is critical for quality control.

Transition Paragraph:

Understanding how coil upenders can solve your specific production challenges requires looking at several key aspects. Let's explore the most critical questions plant managers like you are asking about implementing this technology in sheet metal processing operations.

1. How Can Coil Upenders Solve Efficiency Bottlenecks in Spanish Metal Plants?

Leading Paragraph:

Michael, if you're dealing with production delays caused by slow coil positioning, you're not alone. Many plant managers in Spain's competitive metal processing industry face the same challenge. Manual coil turning typically takes 10-15 minutes per coil with multiple workers, while automated upenders can complete the same task in 2-3 minutes with just one operator. This efficiency gap directly impacts your bottom line.

Snippet Paragraph:

Coil upenders eliminate efficiency bottlenecks by automating the coil orientation process, reducing positioning time by 70-80%. According to Randal Liu's experience, "Spanish plants using SHJLPACK upenders typically achieve 40% higher throughput in their slitting lines." The automation allows continuous material flow between processing stages, minimizing waiting time and maximizing equipment utilization rates.

Dive Deeper Content:

Efficiency Metrics Comparison

The performance difference between manual handling and automated upending is substantial. In Spanish sheet metal facilities, where labor costs are relatively high, the economic case for automation becomes even stronger.

| Process Metric | Manual Handling | Basic Upender | SHJLPACK Smart Upender |

|---|---|---|---|

| Time per coil | 12-15 minutes | 4-5 minutes | 2-3 minutes |

| Workers required | 3-4 operators | 1 operator | 1 operator (supervised) |

| Coils per 8-hour shift | 30-35 coils | 90-100 coils | 150-180 coils |

| Positioning accuracy | ±50mm | ±20mm | ±5mm |

| Energy consumption | Manual labor | 8-12 kW | 6-9 kW with energy recovery |

ROI Calculation for Spanish Plants

Based on data from Spanish metal processing facilities, the return on investment for coil upenders is compelling:

Current Manual Costs:

- 4 workers × €18/hour × 8 hours = €576 daily labor

- Production delays: €280 daily in lost throughput

- Product damage: €150 daily average

- Total daily cost: €1,006

With SHJLPACK Upender:

- 1 operator × €20/hour × 8 hours = €160 daily

- Energy: €25 daily

- Maintenance: €40 daily

- Total daily cost: €225

Annual Savings: (€1,006 - €225) × 250 working days = €195,250

ROI Period: For a €85,000 SHJLPACK upender, payback occurs in approximately 5-6 months.

Application in Spanish Slitting Lines

Spanish slitting operations particularly benefit from upenders because they enable seamless transition between decoiling and slitting processes. The precision positioning ensures coils feed perfectly into slitters, reducing material waste and improving cut quality. In Barcelona's automotive supply chain plants, this precision has helped achieve 99.2% material utilization rates.

2. What Safety Features Do Modern Coil Upenders Offer for Worker Protection?

Leading Paragraph:

Safety should be your top priority when considering coil handling equipment. Manual coil turning poses significant risks - crushed limbs, back injuries from improper lifting, and struck-by hazards from shifting loads. These incidents not only harm your team but also result in costly downtime, insurance premium increases, and regulatory scrutiny. Modern upenders address these concerns with multiple safety layers.

Snippet Paragraph:

Modern coil upenders incorporate comprehensive safety systems including: emergency stop circuits, anti-slip platforms, load sensors that prevent overload operation, and interlocked guarding systems. SHJLPACK models feature advanced safety technology that has helped Spanish plants reduce coil handling injuries by 92% according to plant safety records. These protections are essential for compliance with EU machinery directives and Spanish workplace safety regulations.

Dive Deeper Content:

Critical Safety Systems Breakdown

Understanding the specific safety features helps you evaluate different upender models for your Spanish facility:

🛑 Emergency Safety Systems:

- Dual emergency stop buttons: Located at both operator station and machine perimeter

- Safety light curtains: Detect personnel in hazardous zones and halt operation immediately

- Overload protection: Hydraulic pressure sensors prevent exceeding rated capacity

- Anti-drop valves: Mechanical safety locks prevent uncontrolled descent during power loss

⚡ Operational Safety Features:

- Interlocked access gates: Machine cannot operate when maintenance doors are open

- Load presence detection: Ensures proper coil positioning before rotation begins

- Speed control: Programmable rotation speeds for different coil weights and types

- Stable footing design: Wide base and floor anchoring points prevent tipping

Spanish Regulatory Compliance

For plants in Spain, compliance with local and EU regulations is non-negotiable. SHJLPACK upenders are designed to meet:

- EU Machinery Directive 2006/42/EC

- Spanish Royal Decree 1215/1997 on workplace equipment safety

- CE marking requirements with full technical documentation

- Noise level compliance below 80 dB for Spanish workplace regulations

Safety ROI Calculation

While safety is priceless, the financial impact of injuries has measurable costs:

Typical Coil Handling Injury Costs in Spanish Plants:

- Medical treatment and rehabilitation: €15,000-€40,000

- Production downtime during investigation: €8,000-€20,000

- Insurance premium increases: €12,000-€25,000 annually

- Regulatory fines: €5,000-€50,000

- Total potential cost per incident: €40,000-€135,000

With SHJLPACK upenders priced at €65,000-€120,000, preventing just one serious injury often justifies the equipment investment.

3. Which Technical Specifications Matter Most for Spanish Processing Applications?

Leading Paragraph:

Choosing the right coil upender technical specifications can be overwhelming with so many options available. As someone who's managed metal processing operations, I know you need equipment that matches your specific material types, production volumes, and space constraints. The wrong choice can lead to underutilization or, worse, equipment that can't handle your production requirements.

Snippet Paragraph:

The most critical technical specifications for Spanish sheet metal applications are: capacity (5-20 tons typically), rotation speed (90-180 seconds per cycle), power requirements (380V/50Hz European standard), and positioning accuracy (±5mm for slitting lines). SHJLPACK offers models specifically configured for Spanish industrial power systems and space constraints common in European facilities. Always verify CE certification and compatibility with your existing material handling workflow.

Dive Deeper Content:

Specification Comparison Table

This comparison helps you match equipment to your Spanish plant's needs:

| Specification | Light Duty (≤5 ton) | Medium Duty (5-10 ton) | Heavy Duty (10-20 ton) | SHJLPACK Recommendation |

|---|---|---|---|---|

| Coil Weight | Up to 5,000 kg | 5,000-10,000 kg | 10,000-20,000 kg | Match your 80% typical coils |

| Coil Diameter | 800-1,500 mm | 1,200-2,000 mm | 1,500-2,500 mm | +10% your max coil size |

| Rotation Time | 60-90 seconds | 90-120 seconds | 120-180 seconds | Balance speed & stability |

| Power System | 15 kW / 380V | 22 kW / 380V | 30-37 kW / 380V | Spanish industrial standard |

| Footprint | 3.5×3.0 m | 4.0×3.5 m | 5.0×4.0 m | Allow 20% space buffer |

| Positioning Accuracy | ±10 mm | ±7 mm | ±5 mm | Critical for slitting lines |

Spanish Facility Considerations

When selecting upenders for Spanish locations, several local factors influence specification choices:

🏭 Space Constraints: Many Spanish industrial facilities in Barcelona and Valencia have limited floor space. SHJLPACK compact designs (15-20% smaller footprint) are specifically engineered for European plant layouts.

⚡ Power Infrastructure: Spanish industrial zones typically provide 380V/50Hz three-phase power. Ensure upender motor specifications match this standard to avoid costly electrical modifications.

🌡️ Environmental Factors: Coastal Spanish plants require corrosion-resistant materials and protective coatings. SHJLPACK uses marine-grade paint systems for facilities near Valencia and Barcelona ports.

Application-Specific Recommendations

Based on Randal's experience with Spanish metal processors:

For Automotive Steel Processing:

- Precision positioning (±3mm) for perfect slitter entry

- Vibration damping for surface-sensitive materials

- 8-12 ton capacity range (typical automotive coils)

For Construction Material Production:

- Heavy-duty construction (15-20 ton capacity)

- Faster cycle times (≤120 seconds) for high volume

- Robust design for abrasive environments

For Specialty Metal Processing:

- Custom mandrel designs for unique coil IDs

- Programmable rotation speeds for delicate materials

- Advanced control systems for process integration

4. How Do You Implement Coil Upenders in Existing Spanish Production Lines?

Leading Paragraph:

Integrating new equipment into existing production lines always brings concerns about disruption, retraining, and compatibility. You might be worried about weeks of downtime or complex modifications to your current layout. The good news is that with proper planning, coil upender implementation can be surprisingly smooth, with many Spanish plants achieving full integration within 5-7 working days.

Snippet Paragraph:

Successful coil upender implementation follows a structured process: production analysis → layout planning → foundation preparation → installation → commissioning → operator training. SHJLPACK provides Spanish-language documentation and on-site technical support during integration. Typical implementation takes 5-10 days with minimal production disruption when scheduled during planned maintenance periods or production breaks.

Dive Deeper Content:

Implementation Timeline and Steps

A typical 7-day implementation schedule for Spanish facilities:

📅 Pre-Installation (Days 1-2):

- Site preparation and foundation work

- Utility connections (power, pneumatics)

- Safety perimeter establishment

- Key requirement: 150mm reinforced concrete floor

🔧 Installation (Days 3-5):

- Equipment positioning and leveling

- Power and control system connection

- Safety system integration

- Critical step: Laser alignment with existing conveyors

⚙️ Commissioning (Day 6):

- Functional testing without load

- Load testing with production materials

- Safety system verification

- Documentation: Spanish-language operational manuals

👨🏭 Training (Day 7):

- Operator hands-on training

- Maintenance team instruction

- Troubleshooting basics

- SHJLPACK support: 3 days on-site assistance

Integration Challenges and Solutions

Common issues Spanish plants face and how to address them:

🚧 Space Limitations:

- Problem: Existing layout too cramped for standard upender

- Solution: SHJLPACK custom compact designs (15-20% space savings)

- Example: Valencia plant used rotating platform to save 4m² floor space

🔌 Power Compatibility:

- Problem: Existing power supply insufficient for new equipment

- Solution: Staged power-up systems and energy recovery features

- Example: Barcelona facility used soft-start systems to avoid power spikes

🔄 Process Flow Disruption:

- Problem: Integration causes bottlenecks in adjacent processes

- Solution: Simulation modeling before installation

- Example: SHJLPACK provides digital twin analysis for integration planning

Cost of Implementation Breakdown

Understanding the full implementation costs helps budget accurately:

Equipment Costs:

- SHJLPACK upender: €65,000-€120,000

- Optional conveyors: €15,000-€30,000

- Control system integration: €8,000-€15,000

Installation Costs:

- Foundation work: €5,000-€12,000

- Electrical connection: €3,000-€8,000

- Spanish technical supervision: €2,500-€5,000

Operational Costs:

- Operator training: €1,500-€3,000

- Spare parts kit: €2,000-€5,000

- First-year maintenance: €1,500-€3,000

Total Project Investment: €85,000-€175,000 depending on configuration and site conditions.

Conclusion

Coil upenders transform Spanish sheet metal operations by automating coil positioning, enhancing safety, and boosting productivity. For complete packaging solutions, consider integrating with a steel coil packing line to create a fully automated production cell.

FAQ Section

Frequently Asked Questions

Q: What is the typical delivery time for coil upenders to Spanish facilities?

A: Standard SHJLPACK upenders ship within 4-6 weeks, with express options available in 2-3 weeks for urgent Spanish projects. Sea freight from China to Spanish ports takes 30-35 days, with customs clearance adding 3-5 business days.

Q: How do coil upenders handle different coil sizes and weights in mixed production environments?

A: Modern upenders feature adjustable mandrels and programmable settings for various coil specifications. SHJLPACK models can store 20+ preset configurations, allowing quick changeover between different steel grades and dimensions in Spanish job-shop environments.

Q: What maintenance requirements should Spanish plants expect with coil upenders?

A: Basic maintenance includes daily visual inspections, weekly hydraulic system checks, and monthly bearing lubrication. SHJLPACK provides Spanish-language maintenance manuals and remote support, with annual professional service recommended for optimal equipment lifespan.

Q: Can coil upenders be integrated with existing Spanish automation systems?

A: Yes, SHJLPACK upenders feature standard communication protocols (Profibus, Ethernet/IP, Modbus TCP) compatible with most Spanish industrial automation systems. Integration typically requires 2-3 days of programming and testing with your control system.

Q: What safety certifications do SHJLPACK upenders have for European markets?

A: All SHJLPACK upenders carry full CE certification compliant with EU Machinery Directive, along with ISO 9001 quality management certification. Additional documentation supports Spanish workplace safety compliance and insurance requirements.