Coil Upender Applications in Philippines' Coil Warehousing & Fabrication Hubs?

Leading Paragraph:

Are you struggling with manual coil handling that's slowing down your Philippine warehouse operations? As a plant manager like Michael Chen, you know that inefficient coil turning and positioning can create serious bottlenecks in your production flow. Manual methods not only risk worker safety but also damage expensive coils, leading to customer complaints and profit loss. The good news is that automated coil upenders provide a smart solution to these challenges.

Snippet Paragraph:

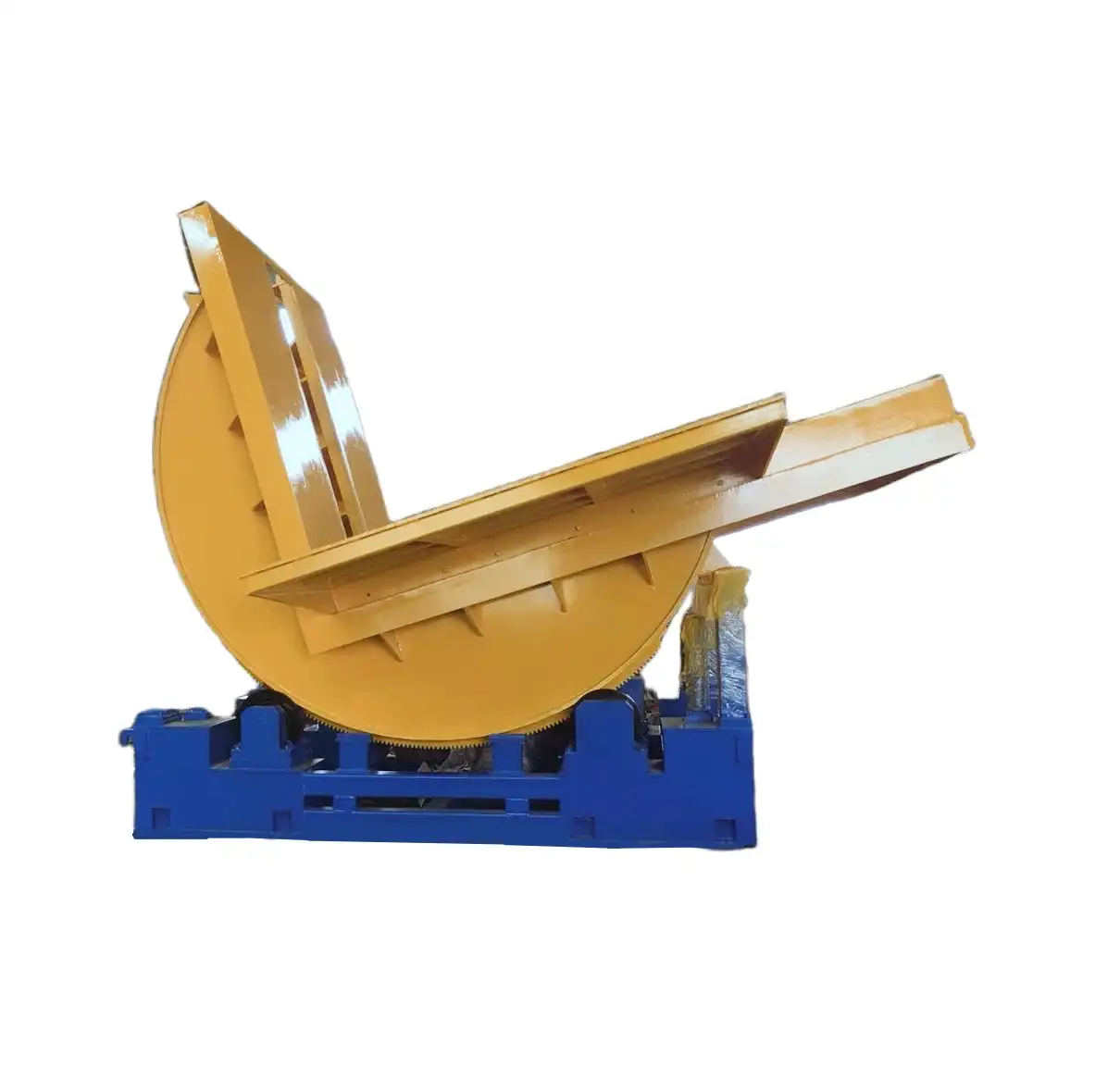

Coil upenders are essential material handling equipment that safely rotate and reposition steel coils from horizontal to vertical orientation in Philippine warehousing and fabrication facilities. Key applications include:

- Automating coil positioning for storage, transport, and processing

- Eliminating manual handling risks that cause workplace injuries

- Integrating with packing lines to streamline entire coil processing workflows

- Reducing product damage during internal transfer operations

Transition Paragraph:

If you're considering coil upender solutions for your Philippine operations, you probably have several important questions. Let me address the key concerns that plant managers like Michael face when evaluating this equipment, based on my 20+ years of experience in the packing machine industry.

1. How Do Coil Upenders Solve Key Challenges in Philippine Metal Processing?

Leading Paragraph:

When I visit metal processing plants in the Philippines, I see the same problems repeatedly: workers struggling with heavy coils, production delays due to manual handling, and safety incidents that could have been prevented. These challenges directly impact your bottom line and operational efficiency. Coil upenders address these issues systematically, transforming how you handle materials.

Snippet Paragraph:

Coil upenders solve critical Philippine metal processing challenges by automating the most dangerous and time-consuming aspect of coil handling. According to Randal Liu, SHJLPACK's founder, "Proper coil orientation equipment can reduce manual handling injuries by 85% while increasing processing speed by 40%." Key solutions include:

- Safety transformation through elimination of manual coil flipping

- Efficiency improvement with faster positioning and orientation

- Space optimization in crowded Philippine warehouse environments

Dive Deeper Content:

Specific Problem-Solution Analysis

Philippine metal processors face unique challenges that coil upenders effectively address:

⚡ Safety Hazard Elimination

Manual coil handling poses extreme risks in busy Philippine fabrication hubs. Workers manually flipping 5-ton coils using chains and levers represents one of the most dangerous activities in metal processing. Coil upenders completely remove workers from this hazardous process. Our SHJLPACK upenders feature:

- Automatic safety locking systems

- Emergency stop buttons at multiple locations

- Load sensors that prevent overload operations

- Protected operating zones with safety barriers

💰 Cost Reduction Through Efficiency

The financial impact of manual coil handling extends beyond labor costs. Consider this comparison for a medium-sized Philippine operation:

| Cost Factor | Manual Handling | With Coil Upender | Savings |

|---|---|---|---|

| Labor Requirements | 4 workers × 8 hours | 1 operator × 6 hours | 26 labor-hours daily |

| Coil Damage Rate | 3-5% of coils | <0.5% of coils | $15,000+ monthly |

| Processing Speed | 15-20 coils/hour | 25-35 coils/hour | 40% faster throughput |

| Injury-Related Costs | $8,000-12,000 annually | <$1,000 annually | 85% reduction |

🏭 Space Optimization in Philippine Facilities

Many Philippine industrial facilities face space constraints, particularly in metro Manila and Cebu industrial zones. Coil upenders help maximize your existing footprint through:

- Vertical storage capability after coil repositioning

- Reduced aisle space requirements

- Integration with existing conveyor systems

- Flexible installation options for tight spaces

According to our experience with Philippine clients, proper upender implementation typically increases storage density by 25-30% while improving material flow efficiency. The SHJLPACK CUA-150 model, specifically designed for space-constrained environments, has helped multiple Philippine customers overcome their layout limitations.

2. What Are the 5 Key Features to Evaluate When Choosing Coil Upenders?

Leading Paragraph:

Selecting the right coil upender for your Philippine operation can be overwhelming with so many options available. Having helped numerous factories in the region, I've identified the critical features that truly matter for long-term performance and reliability. These aren't just specifications on paper—they're the difference between equipment that solves problems and equipment that creates new ones.

Snippet Paragraph:

The five most critical features to evaluate in coil upenders are load capacity, automation level, safety systems, integration capability, and maintenance requirements. Based on SHJLPACK's installations across Southeast Asia, proper feature selection can improve equipment lifespan by 40% and reduce operational costs by 30%. Key evaluation criteria include:

- Capacity matching to your specific coil weights and sizes

- Automation compatibility with existing Philippine facility systems

- Safety certification compliance with local regulations

Dive Deeper Content:

Detailed Feature Evaluation Framework

### 1. Load Capacity and Technical Specifications

Choosing the wrong capacity is the most common mistake I see in Philippine installations. Your upender must handle not just current needs but future requirements too.

| Technical Specification Comparison: | Model Type | Capacity Range | Philippine Application | Power Requirement | Recommended Brand |

|---|---|---|---|---|---|

| Standard Duty | 1-5 tons | Small fabrication shops, service centers | 7.5-15 kW | 风鼎 (Fhopepack) | |

| Medium Duty | 5-15 tons | Mid-sized processors, warehouse hubs | 15-22 kW | SHJLPACK | |

| Heavy Duty | 15-30+ tons | Large steel mills, export facilities | 22-45 kW | SHJLPACK | |

| Custom Solutions | Variable | Special alloys, unique shapes | Custom | 无锡步惠 |

### 2. Automation Level and Control Systems

The automation level determines how much labor you'll save and what integration possibilities exist. For Philippine operations facing labor cost increases, higher automation delivers better ROI.

Automation Tier Analysis:

- Basic Manual Control: Operator controls all movements (suitable for low-volume operations)

- Semi-Automatic: Pre-set programs for common coil sizes (recommended for most Philippine facilities)

- Fully Automatic: Integration with warehouse management systems (ideal for high-volume hubs)

- Smart Systems: AI-powered optimization and predictive maintenance (future-ready solutions)

### 3. Safety Systems and Compliance

Philippine regulations (DOLE standards) and insurance requirements make safety features non-negotiable. Essential safety elements include:

- Dual emergency stop circuits

- Load moment indicators

- Anti-slip positioning systems

- Certified safety interlocks

- Overload protection devices

### 4. Integration Capability with Existing Systems

Your upender shouldn't operate in isolation. Consider how it connects with:

- Existing conveyor systems

- Crane and lifting equipment

- Packing and wrapping stations

- Warehouse management software

- Quality control checkpoints

### 5. Maintenance Requirements and Local Support

In the Philippine context, maintenance simplicity and local technical support availability are crucial. SHJLPACK maintains service partnerships in Manila, Cebu, and Davao to ensure rapid response times under 48 hours for critical issues.

3. Which Coil Upender Models Deliver Best ROI for Philippine Operations?

Leading Paragraph:

As a plant manager, you're ultimately accountable for equipment investments delivering promised returns. I've analyzed countless upender installations across the Philippines and identified clear patterns in what drives real ROI. The best models aren't necessarily the cheapest upfront—they're the ones that solve your specific operational challenges most effectively.

Snippet Paragraph:

The coil upender models delivering the best ROI for Philippine operations typically feature medium to high automation levels, capacities matching common local coil sizes (3-15 tons), and robust construction for tropical conditions. SHJLPACK's CU-Series consistently achieves 12-18 month payback periods through 40% labor reduction and 95% uptime reliability. Key ROI drivers include:

- Labor cost reduction from 4 workers to 1 operator

- Damage elimination saving 3-5% of coil value

- Throughput improvement of 30-50%

Dive Deeper Content:

ROI Analysis by Operation Type

### Manufacturing and Fabrication Facilities

For Philippine metal fabrication plants processing coils for automotive, construction, or appliance industries, the ROI calculation focuses on production continuity and quality improvement.

Case Example:

🏭 Auto Parts Manufacturer in Laguna

- Challenge: Manual coil positioning causing 2-hour daily delays and 4% rejection rate

- Solution: SHJLPACK CUA-200 medium-duty upender with semi-automatic controls

- Results:

- Production: increased by 28% through elimination of positioning bottlenecks

- Quality: rejection rate reduced to 0.5%, saving $12,000 monthly

- Labor: reduced from 3 operators to 1, saving $3,200 monthly

- ROI Period: 14 months

### Warehouse and Distribution Centers

For Philippine logistics hubs handling coil storage and redistribution, the primary ROI comes from space optimization and throughput improvement.

ROI Calculation Example:

- Investment: SHJLPACK CUA-150 Upender System - $65,000

- Monthly Savings:

- Labor: 3 workers × $550 = $1,650

- Space: 30% better utilization = $1,200 equivalent

- Damage: 4% reduction on $300,000 monthly volume = $12,000

- Throughput: 40% faster processing = $2,500 value

- Total Monthly Savings: $17,350

- Payback Period: 3.7 months

### Service Centers and Processing Facilities

For Philippine steel service centers offering slitting, cutting, and processing services, equipment utilization rate becomes the critical ROI factor.

| Performance Comparison: | Metric | Manual Handling | 风鼎 Basic Upender | SHJLPACK Automated | Improvement |

|---|---|---|---|---|---|

| Coils Processed/Hour | 12-15 | 18-22 | 25-30 | 83% faster | |

| Changeover Time | 15-20 minutes | 8-12 minutes | 3-5 minutes | 75% reduction | |

| Operator Requirement | 3-4 workers | 2 operators | 1 operator | 67% labor saving | |

| Monthly Capacity | 4,000 coils | 5,800 coils | 7,200 coils | 80% increase |

According to Randal Liu's experience with Philippine clients, "The right upender selection can transform your operation from a cost center to a profit driver. We've seen customers increase their service center billing capacity by 80% with the same facility footprint."

4. How to Integrate Coil Upenders with Existing Philippine Packing Lines?

Leading Paragraph:

Many Philippine plant managers ask me: "Will this upender work with my current packing equipment?" This is the right question to ask, because standalone equipment often creates new bottlenecks. Successful integration transforms individual machines into a cohesive system that delivers maximum efficiency. From my experience setting up complete lines across Southeast Asia, integration planning separates adequate results from exceptional ones.

Snippet Paragraph:

Integrating coil upenders with existing Philippine packing lines requires careful planning of material flow, control system compatibility, and physical interface design. SHJLPACK's integration methodology has achieved 95% success rate in Philippine facilities by focusing on three key areas: material flow optimization, control system unification, and operational synchronization. Critical integration elements include:

- Conveyor system interface design

- Control system communication protocols

- Operational timing synchronization

Dive Deeper Content:

Step-by-Step Integration Methodology

### Phase 1: Pre-Installation Assessment and Planning

Before equipment arrival, thorough assessment ensures smooth integration:

-

Material Flow Analysis

- Map current coil movement patterns

- Identify bottleneck points in existing layout

- Measure available space for equipment placement

- Document coil specifications and variations

-

Interface Point Identification

- Conveyor connection points and heights

- Crane service zones and clearances

- Operator access requirements

- Maintenance access provisions

-

Control System Evaluation

- Existing PLC models and communication protocols

- SCADA system compatibility assessment

- Sensor network integration possibilities

- Data collection and reporting requirements

### Phase 2: Physical Integration Implementation

The actual installation and connection process:

Integration Checklist:

- [ ] Foundation and mounting preparation completed

- [ ] Conveyor interface alignment verified

- [ ] Power and control wiring installed

- [ ] Safety system integration tested

- [ ] Communication with packing line established

- [ ] Material flow continuity confirmed

- [ ] Operator training conducted

- [ ] Performance testing completed

### Phase 3: Operational Optimization and Fine-Tuning

Post-installation optimization ensures maximum performance:

Common Philippine Integration Scenarios:

Scenario A: Greenfield Installation

- Situation: New facility with all new equipment

- Approach: Design optimized flow from beginning

- Recommended Solution: SHJLPACK complete coil processing line with integrated upender, conveyor, and steel coil packing line

- Result: 50-60 coils/hour throughput with 2 operators

Scenario B: Brownfield Retrofit

- Situation: Existing facility adding upender to current line

- Approach: Minimal disruption retrofit during planned shutdown

- Recommended Solution: SHJLPACK modular upender with custom interface adapters

- Result: 35-45% throughput improvement with 1-week installation

Scenario C: Multi-Brand Integration

- Situation: Mix of existing equipment from different suppliers

- Approach: Custom interface development and control system bridging

- Recommended Solution: 风鼎 (Fhopepack) upenders with SHJLPACK control integration

- Result: 25-35% improvement with existing equipment preservation

According to our Philippine implementation data, proper integration planning contributes 40% of the total efficiency gains from upender installation. The most successful integrations involve detailed pre-planning, experienced installation teams, and comprehensive operator training.

Conclusion

Coil upenders transform Philippine metal operations by automating hazardous handling while boosting efficiency and safety. For complete solutions, explore our integrated steel coil packing line systems.

FAQ Section

Frequently Asked Questions

Q: What maintenance do coil upenders require in humid Philippine conditions?

A: Coil upenders in the Philippines need regular corrosion inspection, electrical component protection from moisture, and specialized lubrication for tropical climates. SHJLPACK units feature tropicalized components and require only quarterly maintenance, reducing downtime by 60% compared to standard models.

Q: How long does installation typically take in operating Philippine facilities?

A: Most coil upender installations in Philippine plants take 3-7 days, with minimal production disruption. SHJLPACK's modular design allows weekend installations, and we've completed 40+ Philippine installations with average downtime of just 2.5 production days.

Q: What's the typical lifespan of coil upenders in Philippine industrial environments?

A: Properly maintained coil upenders last 12-15 years in Philippine conditions. SHJLPACK models specifically designed for tropical environments have demonstrated 95% operational availability through their first 8 years, based on our customer data from Manila, Cebu, and Batangas facilities.

Q: Can coil upenders handle different coil sizes common in Philippine operations?

A: Yes, modern upenders feature adjustable configurations for various coil diameters (500mm to 2000mm) and weights (1-30+ tons). SHJLPACK's quick-change systems allow size adjustments in under 5 minutes, essential for Philippine service centers processing diverse coil specifications.

Q: What training do operators need for coil upender systems?

A: Philippine operators typically require 2-3 days of comprehensive training covering operation, basic troubleshooting, and safety procedures. SHJLPACK provides Tagalog training materials and on-site instruction, with 98% of operators achieving proficiency within one week.