Coil Turning Machine Cost Breakdown for Metal Service Centers

Leading Paragraph:

Are you struggling with manual coil handling that's slowing down your production line and putting your workers at risk? As a plant manager in Mexico's demanding metal industry, you know that every minute of downtime costs money and every safety incident hurts your bottom line. The constant flipping and positioning of heavy steel coils isn't just inefficient—it's dangerous and expensive. But what if you could automate this process while clearly understanding the true investment required?

Snippet Paragraph:

A coil turning machine typically costs between $25,000 and $150,000, depending on capacity, automation level, and specific features. The investment breaks down into equipment purchase (60-70%), installation (10-15%), training (5-8%), and maintenance (15-20%). Key factors affecting price include: capacity (5-20 tons), automation level (semi-auto to fully automatic), and safety features. For Mexican metal service centers, the ROI period typically ranges from 12-24 months through labor savings and reduced product damage.

Transition Paragraph:

Understanding the complete cost picture is crucial, but you're probably wondering which specific factors drive these prices and how to choose the right machine for your Mexican factory. Let me break down the key cost components and help you make an informed decision that addresses your efficiency and safety challenges.

1. What Are the Main Cost Components of a Coil Turning Machine?

Leading Paragraph:

When Michael from a Monterrey steel plant asked me about coil turning machine costs, he was surprised to learn that the purchase price is just the beginning. Like many plant managers in Mexico, he initially focused only on the equipment cost, but the true investment includes several hidden components that impact your total expenditure and long-term operational costs.

Snippet Paragraph:

The main cost components include equipment purchase (60-70%), installation and commissioning (10-15%), operator training (5-8%), and ongoing maintenance (15-20% annually). According to Randal Liu, SHJLPACK's founder, "Mexican factories often underestimate installation costs by 30% because they don't account for local electrical requirements and foundation preparation." Additional costs may include customs duties (10-15% for imported equipment) and spare parts inventory.

Dive Deeper Content:

Breaking down the cost structure helps you budget accurately and avoid unexpected expenses that can derail your automation project. Let me share what I've learned from helping numerous Mexican metal service centers implement successful coil handling automation.

Equipment Purchase Price Ranges

The machine itself represents your largest upfront investment, but prices vary significantly based on your specific needs:

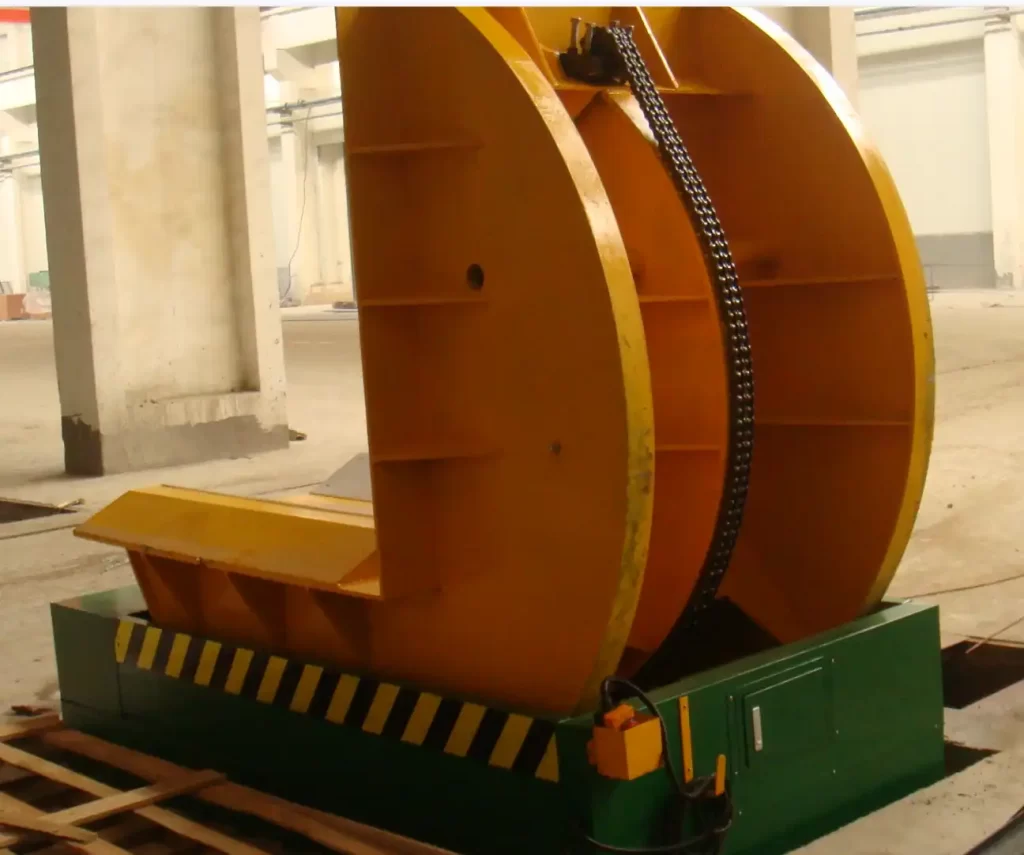

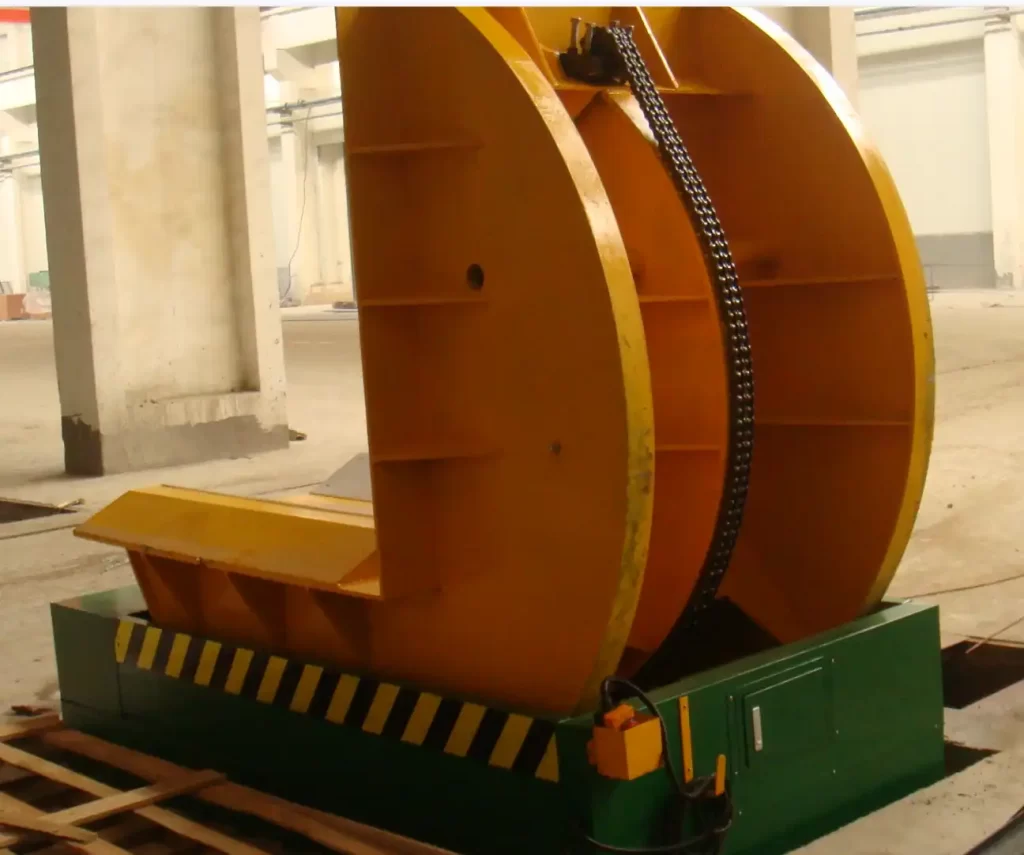

| Machine Type | Capacity Range | Price Range | Best For Mexican Plants |

|---|---|---|---|

| Basic Mechanical Upender | 3-8 tons | $25,000-45,000 | Small workshops, low volume |

| Semi-Automatic Tilter | 5-15 tons | $45,000-80,000 | Medium operations, mixed products |

| Fully Automatic System | 10-20+ tons | $80,000-150,000 | High-volume centers, 24/7 operation |

According to my experience, Mexican plants typically choose semi-automatic systems in the $50,000-70,000 range because they balance automation benefits with manageable investment levels.

Installation & Commissioning Costs

Many factories underestimate these critical expenses:

- Foundation Preparation: $3,000-8,000 for reinforced concrete base

- Electrical Work: $2,000-5,000 for proper power supply installation

- Safety Systems: $1,500-4,000 for emergency stops and guarding

- Commissioning: $2,000-5,000 for technician travel and setup

Training & Operational Costs

Proper training ensures your team uses the equipment safely and efficiently:

- Operator Training: 2-3 days, $1,500-3,000

- Maintenance Training: 1-2 days, $1,000-2,000

- Documentation: $500-1,500 for Spanish-language manuals

💰 Hidden Costs Mexican Plants Often Miss

Based on my work with factories in Mexico, these unexpected expenses frequently impact budgets:

- Import Duties: 10-15% for equipment from China or Europe

- Local Compliance: NOM standards certification ($2,000-4,000)

- Power Upgrades: Three-phase power installation ($3,000-8,000)

- Spare Parts Inventory: Initial stock of wear parts ($2,000-5,000)

Industry data shows that Mexican metal service centers that properly budget for these hidden costs achieve 40% faster ROI because they avoid project delays and unexpected expenses.

2. How Much Can You Save with Automated Coil Handling?

Leading Paragraph:

When I visited a metal service center in Guadalajara last year, the owner was skeptical about automation costs. But after calculating the savings from reduced labor, improved safety, and eliminated product damage, he realized the coil turning machine would pay for itself in under 18 months. Let me show you the same calculation for your Mexican operation.

Snippet Paragraph:

Automated coil handling typically saves Mexican metal plants $60,000-120,000 annually through labor reduction (2-4 workers), product damage elimination (1-3% of product value), and safety cost reduction (30-50% lower insurance premiums). According to SHJLPACK's case studies, plants achieve full ROI in 12-24 months, with the fastest returns coming from high-volume operations running multiple shifts.

Dive Deeper Content:

The savings from automated coil packing equipment extend far beyond labor reduction. As someone who's implemented these systems in Mexican factories, I've seen the transformative impact on overall operational efficiency and profitability.

Labor Cost Savings Analysis

Manual coil handling requires significant workforce investment:

Current Manual Process Costs:

- 4 workers × $1,800/month = $86,400/year

- Overtime during peak periods: $12,000-18,000/year

- Worker turnover costs: $8,000-15,000/year (recruitment & training)

Automated System Costs:

- 1 operator × $2,200/month = $26,400/year

- Maintenance technician: $6,000/year (part-time)

- Annual Labor Savings: $74,000-87,000

Product Damage Reduction

Manual handling causes expensive quality issues:

- Edge Damage: 1-2% of coil value lost to scratches and dents

- Rejection Rates: 0.5-1% customer returns due to handling damage

- For a typical Mexican plant processing $5M annually: $50,000-100,000 in preventable losses

Safety Cost Savings

Workplace injuries carry heavy financial and human costs:

- Insurance Premiums: 30-50% reduction with automated handling

- Workers' Compensation: Eliminate $15,000-30,000 in annual claims

- Regulatory Compliance: Avoid $5,000-15,000 in safety violation fines

⚡ Efficiency Gains Beyond Direct Savings

The hidden benefits often outweigh the obvious cost savings:

- Throughput Increase: 25-40% faster coil processing

- Space Utilization: 15-20% better floor space usage

- Shift Flexibility: Easier to run extended hours with fewer staff

Based on Randal Liu's experience, Mexican plants that track all these savings metrics typically discover their coil turning machines pay for themselves 3-6 months faster than initial projections indicated.

3. Which Coil Turning Machine Features Impact Price Most?

Leading Paragraph:

Choosing the right features for your coil upending equipment is like building a custom truck—you need the right capabilities without paying for unnecessary extras. When I consult with Mexican plant managers, we focus on the features that deliver maximum value for their specific operational needs and budget constraints.

Snippet Paragraph:

The features that impact coil turning machine price most significantly are automation level (40-50% of cost variation), capacity rating (20-30%), control system sophistication (15-20%), and safety certifications (10-15%). SHJLPACK's mid-range models typically offer the best value for Mexican metal service centers, providing 80% of premium features at 60% of the cost.

Dive Deeper Content:

Understanding which features drive costs helps you make smart decisions about where to invest and where to save. Let me break down the key price drivers based on my experience specifying equipment for Mexican manufacturing environments.

Automation Level Cost Impact

The degree of automation represents your largest cost variable:

Manual/Semi-Automatic Systems ($25,000-60,000)

- Operator controls each movement

- Basic safety interlocks

- Suitable for low-volume operations

- Best for: Mexican plants running 1-2 shifts, mixed product sizes

Fully Automatic Systems ($60,000-120,000)

- Programmable logic controllers

- Automatic positioning and sequencing

- Integration with existing production lines

- Best for: High-volume Mexican plants, 24/7 operations

Smart Automated Systems ($120,000-150,000+)

- IoT connectivity and data collection

- Predictive maintenance capabilities

- Remote monitoring and diagnostics

- Best for: Large Mexican corporations with multiple facilities

Capacity and Size Considerations

Larger capacity doesn't always mean better value:

| Capacity | Price Premium | Mexican Application Fit |

|---|---|---|

| 5-10 tons | Base price | Ideal for most service centers |

| 10-15 tons | +20-30% | Heavy coil specialists |

| 15-20+ tons | +40-60% | Large steel producers |

Control System Sophistication

The operator interface and programming capabilities significantly affect both cost and usability:

Basic PLC Systems ($3,000-6,000)

- Simple push-button operation

- Limited program storage

- Adequate for consistent product runs

Advanced HMI Systems ($8,000-15,000)

- Touchscreen interfaces

- Multiple program storage

- Production data tracking

- Recommended for Mexican plants with variable product mix

🏭 Safety Features Worth the Investment

Some safety features provide excellent value for Mexican operational environments:

- Emergency Stop Systems: $1,500-3,000 (essential)

- Light Curtains: $2,000-4,000 (highly recommended)

- Safety-rated PLC: $1,500-2,500 (worth the premium)

- Automatic Lockout Systems: $2,000-3,500 (for high-risk areas)

According to industry data, Mexican plants that invest in comprehensive safety features typically see 35% faster operator adoption and 50% fewer operational interruptions during the first year.

4. How Do You Calculate ROI for Mexican Metal Plants?

Leading Paragraph:

When the operations director at a Saltillo metal service center asked me to justify a $75,000 coil turning machine investment, I showed him a simple ROI calculation that considered both hard savings and productivity gains. The result surprised him—the machine would pay for itself in just 14 months. Let me walk you through the same calculation method.

Snippet Paragraph:

Calculating ROI for Mexican metal plants involves comparing total annual savings ($60,000-120,000) against total investment ($45,000-130,000). The formula is: (Annual Savings ÷ Total Investment) × 100 = ROI Percentage. Payback period is Total Investment ÷ Annual Savings. Most Mexican plants achieve 80-150% annual ROI with payback periods of 12-24 months, depending on operational volume and shift patterns.

Dive Deeper Content:

A proper ROI analysis goes beyond simple payback calculations. From my experience working with Mexican manufacturing operations, the most accurate assessments consider both quantitative savings and qualitative benefits that impact long-term competitiveness.

Step-by-Step ROI Calculation

Step 1: Calculate Total Investment

- Equipment Cost: $65,000 (mid-range automatic tilter)

- Installation: $9,000 (15% of equipment cost)

- Training: $4,000 (operator and maintenance)

- Total Investment: $78,000

Step 2: Calculate Annual Savings

- Labor Reduction: $74,000 (4 workers reduced to 1)

- Damage Reduction: $18,000 (1.2% of $1.5M coil value)

- Safety Savings: $12,000 (insurance and compensation)

- Total Annual Savings: $104,000

Step 3: Calculate Payback and ROI

- Payback Period: $78,000 ÷ $104,000 = 0.75 years (9 months)

- First Year ROI: ($104,000 ÷ $78,000) × 100 = 133%

📊 Mexican-Specific Factors in ROI Calculations

Local conditions significantly impact your actual returns:

Labor Cost Considerations:

- Mexican manufacturing wages: $1,800-2,500/month for skilled operators

- Benefits and payroll taxes: +25-35% of base wages

- Turnover costs: $3,000-5,000 per employee replacement

Energy and Maintenance Costs:

- Electricity: $0.12-0.18/kWh in Mexican industrial zones

- Preventive maintenance: $2,000-4,000 annually

- Spare parts: 2-3% of equipment cost annually

Case Study: Monterrey Metal Service Center

🏭 Medium-Sized Processor in Northern Mexico

- Challenge: Manual coil handling caused 2-3 day delays and 2% product damage

- Solution: SHJLPACK semi-automatic coil turning system ($68,000 total investment)

- Results:

- Production: increased 35% through faster processing

- Labor: reduced from 4 to 1.5 operators (equivalent)

- Damage: decreased from 2% to 0.2% of product value

- ROI Period: 11 months (faster than 14-month projection)

💡 Maximizing Your ROI

Based on Randal Liu's two decades of experience, these strategies help Mexican plants achieve faster returns:

- Run Multiple Shifts: Automation ROI accelerates with utilization

- Cross-Train Operators: Flexible staffing reduces labor costs further

- Preventive Maintenance: Regular service extends equipment life 30-50%

- Performance Tracking: Monitor key metrics to identify improvement opportunities

Industry data confirms that Mexican metal service centers that implement proper tracking and optimization achieve 25-40% faster ROI than plants that simply install equipment without operational adjustments.

Conclusion

Investing in the right coil turning machine delivers significant returns through labor savings, reduced damage, and improved safety. For Mexican metal service centers, the key is selecting equipment that matches your specific operational needs and volume requirements. As you consider your options, remember that a complete steel coil packing line can further enhance your automation benefits.

FAQ Section

Frequently Asked Questions

Q: What is the typical lifespan of a coil turning machine in Mexican industrial conditions?

A: Well-maintained coil turning machines typically last 10-15 years in Mexican industrial environments. Regular maintenance, proper operator training, and using genuine spare parts can extend service life to 20 years. SHJLPACK equipment is specifically designed for demanding conditions with reinforced structures and corrosion-resistant components.

Q: How long does installation and commissioning take for a new coil turning machine?

A: Installation typically requires 3-5 days for foundation preparation, 2-3 days for mechanical installation, and 2 days for electrical connections and commissioning. Most Mexican plants can complete the entire process within 2 weeks, minimizing production disruption. SHJLPACK provides supervised installation to ensure proper setup and operator training.

Q: What maintenance requirements should Mexican plants expect with automated coil handling?

A: Automated coil turning machines require daily visual inspections, weekly lubrication checks, and monthly comprehensive inspections. Major maintenance occurs annually and includes hydraulic system checks, structural integrity verification, and control system diagnostics. SHJLPACK offers maintenance contracts that include remote monitoring for proactive service scheduling.

Q: Can coil turning machines handle different sizes and types of metal coils?

A: Yes, modern coil turning machines can handle various coil sizes from 800mm to 2000mm diameter and weights from 3 to 20 tons. Adjustable arms and programmable settings allow quick changeovers between different coil types. SHJLPACK systems typically accommodate 5-8 different coil configurations with memory presets for fast switching.

Q: What safety certifications are important for equipment used in Mexican factories?

A: Key certifications include CE marking for European safety standards, ISO 9001 for quality management, and compliance with Mexican NOM standards for industrial equipment. SHJLPACK equipment carries all relevant international certifications and is specifically validated for Mexican regulatory requirements and industrial conditions.