Case Study: Mexico Procurement Managers Increase Throughput with Mold Flipper

In the fast-paced world of a steel mill, every moment of downtime is a direct hit to the bottom line. Traditional methods for handling and flipping heavy molds, often relying on overhead cranes and manual rigging, are a huge bottleneck. They are slow, incredibly dangerous, and can bring your entire production schedule to a halt. You see your skilled workers tied up in a high-risk, low-efficiency task, and you know there has to be a better way to manage this critical process. This isn't just a minor inconvenience; it's a constant drain on your resources, a safety liability, and a barrier to reaching your plant's true potential. But what if you could transform this bottleneck into one of the smoothest parts of your operation? Imagine flipping a multi-ton mold safely in minutes, not half an hour, with the simple push of a button.

A mold flipper, also known as a mold upender, increases throughput by automating and speeding up the process of turning heavy molds for maintenance or production changes. This specialized equipment dramatically reduces the time spent compared to traditional crane and sling methods, minimizing downtime, enhancing worker safety, and allowing production lines in Mexican steel mills to run more continuously and efficiently.

This might sound like a simple fix, but the ripple effects on a plant's overall performance are massive. I've seen it myself. A few years ago, I had the privilege of working with a procurement team at a major steel mill in Mexico. They were led by a sharp CEO, a man named Javier, who was grappling with these exact challenges. He was focused on increasing his plant's capacity utilization and was skeptical of any new investment that couldn't show a clear, hard return. The results of our project, however, spoke for themselves. Let’s walk through the specific problems they faced and how this straightforward machine delivered an outsized impact, turning their skepticism into a strategic advantage.

How does a Mold Flipper address safety and efficiency in a Mexican steel mill?

The floor of any steel mill is an environment where risk must be managed constantly. Flipping heavy, awkwardly shaped molds using an overhead crane and chains is consistently ranked as one of the most hazardous jobs. It demands immense skill and perfect coordination from the crew, but even with the best team, a simple miscalculation can lead to a dropped mold, damaged equipment, or a serious injury. This isn't just a theoretical risk; it's a real and present danger.

Think about the true cost of this old method. Every time a mold is lifted with slings, you are accepting a huge amount of risk. The chains can slip, the load can be imbalanced, a worker can be in the wrong place at the wrong time. This constant threat not only impacts your insurance rates but also creates a hesitant work culture, slowing down the entire maintenance cycle because everyone is, rightly, being extra cautious. The solution is to remove the guesswork and manual danger from the equation. A mold flipper is a purpose-built machine that secures the mold on a stable platform and turns it using a controlled, predictable motion. It completely eliminates the need for complex, high-risk rigging and keeps workers at a safe distance, making the entire process both fundamentally safer and much, much faster.

A mold flipper directly addresses safety and efficiency by replacing the high-risk, manual process of crane-flipping with a controlled, automated system. This greatly reduces the chance of accidents, mold damage, and worker injury. For Mexican steel mills, this means less downtime from safety incidents and a more streamlined workflow, allowing maintenance and production to proceed faster and more reliably.

Let's get specific about the improvements. I remember my conversations with Javier, the CEO of that plant in Monterrey. His primary concern wasn't just the slow pace; it was the number of "near-miss" incidents his safety manager was reporting during mold handling operations. They hadn't had a major accident yet, but he knew they were rolling the dice every single day.

The Old Way: A Breakdown of Crane & Chain Risks

The traditional method is a multi-step process, where each step is a potential point of failure. It's a system that relies entirely on human skill and judgment under pressure.

- Rigging: This involves attaching heavy chains or fabric slings to the mold. The attachment points must be exact, and the slings themselves must be constantly inspected for wear and tear. A frayed sling or a poorly chosen anchor point can lead to disaster.

- Lifting & Balancing: The crane operator has to lift the multi-ton mold with extreme care, ensuring it is perfectly balanced. An unbalanced load can start to swing, becoming an uncontrollable pendulum of massive force.

- The Turn: This is the most dangerous moment. As the mold is suspended in mid-air, ground workers often have to use long guide ropes to manually help turn the load. They are in the immediate vicinity of a suspended, unstable object.

- Setting Down: Placing the mold down in its new orientation requires precision and flawless communication between the crane operator and the ground crew.

The SHJLPACK Way: A Stable and Secure Process

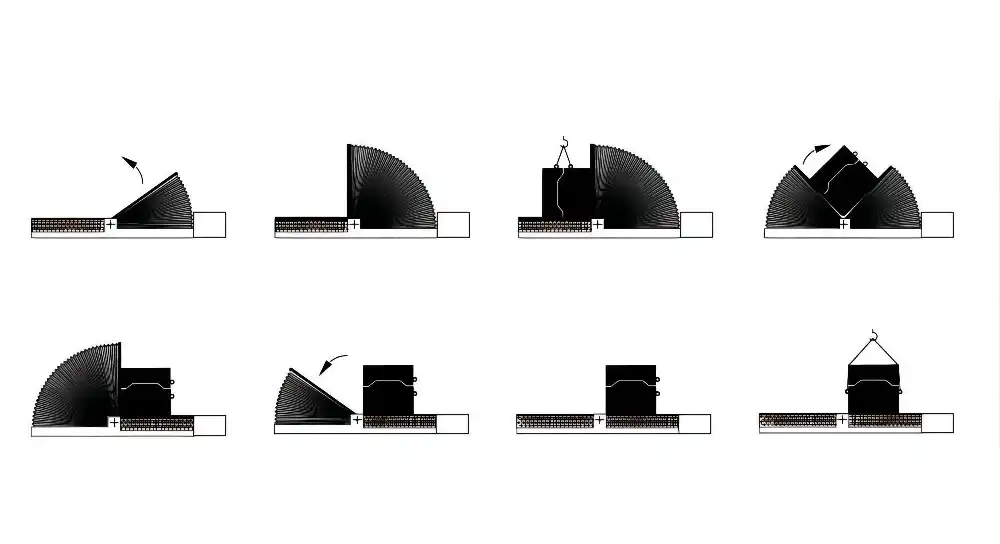

A mold flipper, or upender as we sometimes call it, completely redesigns this workflow. The process becomes mechanical, predictable, and safe.

- Loading: The mold is placed onto the flipper's stable platform, usually with a forklift or a quick crane lift. This is a simple, grounded placement with no balancing required.

- Securing: The mold is held firmly in place by the machine's heavy-duty structure. There are no chains or slings that can slip.

- Flipping: A single operator, standing at a safe distance behind a control panel, pushes a button. The machine's powerful drive system performs a smooth 90-degree or 180-degree rotation.

- Unloading: The mold now rests securely in its new orientation, ready to be moved for maintenance or use.

Here is a direct comparison table that I often create for clients like Javier. The numbers make the benefit clear.

| Feature | Traditional Crane Method | Mold Flipper Method |

|---|---|---|

| Personnel Required | 2-3 (Crane operator, riggers) | 1 (Machine operator) |

| Time per Flip | 15-30 minutes | 2-5 minutes |

| Safety Risk | High (suspended load, manual handling) | Low (controlled motion, remote operation) |

| Risk of Mold Damage | Moderate to High | Very Low |

| Training Required | Extensive crane & rigging certification | Minimal, machine-specific training |

For the plant in Mexico, this was a game-changer. Their highly skilled crane operators were freed up to perform their primary function: moving steel coils and finished products. They were no longer tied up in a high-risk, time-consuming maintenance task. The benefit wasn't just about doing one task faster; it was about unlocking a key bottleneck that improved the material flow of the entire facility.

What is the ROI of a mold flipper for a high-capacity steel mill?

As a business owner, you know that every investment must justify its existence with a clear return. A new piece of equipment can look like a large capital expense on a spreadsheet, especially when you have an existing "paid-for" method that appears to be working, even if it's slow and inefficient. You have to ask the hard question: "What is the payback?"

But the real question is, what are the hidden costs of not investing? Think about the production hours that evaporate every week due to slow mold changeovers. Now add the potential cost of a single accident—the equipment repairs, the production downtime, the inevitable rise in insurance premiums, and the potential for legal action. These "soft costs" are very real, and they add up quickly, silently eating away at the profit margins you work so hard to build and protect.

A mold flipper provides a tangible and quantifiable return on investment (ROI) because it directly attacks these hidden costs. By calculating the value of the time you save, the production uptime you gain, and the catastrophic risks you avoid, you'll find that the machine often pays for itself much faster than you might think.

The ROI of a mold flipper for a high-capacity steel mill comes from several key areas: drastically reduced labor costs per flip, minimized production downtime during changeovers, increased overall plant throughput, and the avoidance of high costs associated with accidents and equipment damage. For a Mexican steel mill producing millions of tons annually, these efficiencies translate directly into higher profitability and a payback period often under 18 months.

When I started my own factory from the ground up, I had to be incredibly careful with every dollar. That experience taught me to look past the initial price tag of a machine and calculate its true, long-term value to the operation. This is the exact mindset I bring to my conversations with clients like Javier, who are responsible for making sound financial decisions on multi-million dollar projects. Let's break down the ROI calculation into simple terms.

Quantifying the Gains

The return on this investment isn't just a vague promise of "better efficiency." We can attach real numbers to the improvements.

1. Labor Savings:

- Old Method: Let's say it takes 3 workers 20 minutes (0.33 hours) to complete a flip. That's a full 1 man-hour of labor per flip.

- New Method: It takes 1 worker just 3 minutes (0.05 hours). That's 0.05 man-hours per flip.

- Savings: You save 0.95 man-hours of skilled labor on every single flip.

- If a plant performs this operation just five times a day, that's 4.75 saved man-hours daily. Over a 250-day work year, that's nearly 1,200 hours of skilled labor that can be redirected to more value-added tasks.

2. Increased Production Uptime:

- This is where the biggest financial impact is felt in a high-capacity mill. Let's say a full mold changeover process takes 30 minutes using a crane but only 5 minutes using a flipper. That's a direct saving of 25 minutes of production downtime for every changeover.

- If your production line is capable of producing 50 tons of steel per hour, that saved 25 minutes represents more than 40 tons of additional product that you can now produce. For a plant like Javier's, with a goal of hitting 95% capacity utilization, eliminating these small but frequent delays is absolutely essential.

The Hidden Financial Drains of the Old Method

Beyond the direct time savings, a proper ROI calculation must also consider the significant costs you avoid.

| Cost Category | Crane & Chain Method | Mold Flipper Method |

|---|---|---|

| Equipment Damage | There is a constant, high risk of dropping or damaging a mold. A single incident can cost tens of thousands of dollars to repair or replace the mold. | The controlled, stable motion of the flipper makes damage to the mold or the machine itself extremely unlikely. |

| Insurance & Liability | Insurance companies recognize this as a high-risk activity, which is reflected in higher premiums. A single serious accident can lead to huge financial liabilities. | The lower risk profile of the automated process can be a positive factor in insurance negotiations. |

| Opportunity Cost | Your overhead crane, a critical asset for moving product, is tied up performing a relatively low-value task. This can create other bottlenecks in the plant. | The crane is freed up to perform its primary, revenue-generating function: moving raw materials and finished goods. |

For the steel mill in Mexico, the initial investment in their mold flipper was roughly $50,000. Based on their own internal calculations, the combined savings from labor redirection, increased production uptime, and the avoidance of just one potential mold damage incident (which they conservatively estimated at a $30,000 cost) meant the machine paid for itself in just over one year. That is the kind of practical, numbers-driven result that a forward-thinking CEO can build a business case on.

How can a mold flipper integrate with modern digital transformation goals?

You are likely investing heavily in digital transformation. You're implementing Manufacturing Execution Systems (MES), installing IoT sensors, and building dashboards to create a "smart factory." This is the future. However, many essential mechanical processes, like mold handling, often remain disconnected and "analog." This creates frustrating blind spots in your operational data.

This data gap is a real problem. You might have a beautiful dashboard showing real-time production numbers, but you can't see the root cause of a delay happening in the maintenance bay. The time it takes to flip a mold becomes an unrecorded, invisible metric, something known only through "tribal knowledge" on the shop floor. As the old saying goes, you can't manage or optimize what you can't measure. This analog process becomes a barrier to achieving full production visibility.

The solution is to choose equipment that is ready for the modern factory. Modern mold flippers are not just simple mechanical tools. They can be engineered with sensors and communication capabilities that allow them to integrate directly into your factory's digital ecosystem. This crucial step allows you to track their usage, monitor their performance, and even schedule predictive maintenance, transforming a traditionally analog process into a smart, data-producing asset.

A mold flipper integrates with digital transformation by being outfitted with IoT sensors and PLC controls that connect to a plant's Manufacturing Execution System (MES). This allows a Mexican steel mill to track cycle times, schedule predictive maintenance for the flipper itself, and create a fully visible and data-driven workflow, eliminating analog blind spots and supporting goals for total production visualization.

I have always been a hands-on engineer. I love the physical mechanics of how machines work—the gears, the motors, the hydraulics. But I also built my business by looking to the future, and the future of manufacturing is data. A machine that only performs a physical task is no longer sufficient. It must also provide information. This is a key part of my discussions with forward-thinking leaders like Javier, who are fully committed to building a transparent, data-driven operation.

From Mechanical Tool to Smart Asset

A standard mold flipper is a massive improvement in physical efficiency. A smart mold flipper is a leap into Industry 4.0. Here is how we make that connection.

1. PLC Integration and Data Logging:

The machine's brain, its Programmable Logic Controller (PLC), does more than just start and stop the motor. We can program it to log essential data points for every cycle: the exact start time, the exact end time, the motor current draw, and any fault codes that might occur. This raw data is the foundation of its digital identity.

2. MES Connectivity:

This logged data can then be transmitted to your central MES platform using standard industrial communication protocols like OPC-UA or MQTT. Suddenly, the mold flip is no longer an invisible event. It appears as a clear data point on your production timeline. A plant manager can look at his screen and see that "Mold M-23" entered the maintenance bay at 10:05 AM and that the flipping process was completed at 10:08 AM. This data closes the loop between the physical action on the floor and the digital record in your system.

Supporting High-Level Goals

Connecting your mold flipper to your network directly supports the most important strategic goals of a modern steel mill.

| Strategic Goal | How a Smart Mold Flipper Contributes |

|---|---|

| Increase Capacity Utilization to 95% | By precisely tracking and analyzing changeover times, you can identify anomalies and further optimize the maintenance workflow. The data provides undeniable proof of time savings and helps justify future process improvements. |

| Advance Digital Transformation | It fills a critical data gap in your production process, providing a more complete picture of the entire cycle. It's a tangible, practical step on your journey to a fully realized smart factory. |

| Implement Predictive Maintenance | By monitoring data like motor current, hydraulic pressure, and total cycle counts, the system can predict when the flipper itself will require maintenance, preventing unexpected breakdowns and downtime. |

| Reduce Operating Costs | Accurate, logged data on cycle times and labor usage provides a clear, data-driven justification for the initial investment and helps management identify other areas for operational streamlining. |

For our project in Mexico, this was a planned second phase. First, they installed the machine and proved its mechanical value and ROI. Then, we worked directly with their IT and engineering teams to connect the flipper to their new MES. This simple integration turned the machine from a standalone tool into an active, contributing member of their smart factory strategy, giving the CEO the total production visibility he was striving for.

From an Engineer's View: Why Is a Mold Flipper More Than Just a Machine?

It's easy to look at a piece of equipment like a mold flipper and see it as just a big, simple machine. A commodity. You might be tempted to think that any model will do the job, as long as it successfully turns your mold from one side to the other.

As someone who has spent a lifetime designing, building, and watching these machines perform in the toughest industrial environments, I can tell you that this view misses the most important part of the story. The details matter immensely. A poorly designed or under-built flipper can quickly become its own maintenance nightmare, failing under the incredible, repetitive stress of a steel mill. Choosing the wrong supplier can leave you with a piece of metal on your floor but no real support when you need help fine-tuning the process or troubleshooting a problem.

A mold flipper is not just a product; it's a complete solution. It represents a fundamental commitment to creating a safer and more efficient operational process. The true value is not in the steel alone, but in the quality of the engineering behind it, the durability of its construction, and the expertise of the partner who helps you integrate it perfectly into your unique workflow.

From my engineering perspective, a mold flipper is more than a machine; it is the physical embodiment of a process improvement philosophy. Its value lies not just in its function but in its robust design, reliability under heavy industrial use, and its role as a catalyst for rethinking safety and efficiency in the entire production line. It's a strategic tool for operational excellence.

When I started my journey as a young engineer working on the factory floor, I was captivated by the power and elegance of well-designed industrial machinery. Years later, when I founded SHJLPACK, I built my entire company on one simple principle: we don't just sell machines, we solve our clients' problems. This philosophy is at the very heart of how I view equipment like the mold flipper.

It's a Symbol of a Culture Shift

When a company, like the one Javier runs in Mexico, invests in a purpose-built mold flipper, it sends a powerful message to every single employee: your safety is our priority. We are willing to invest in the right technology to eliminate unnecessary risks from your workday. This is a massive morale booster. It helps shift the entire company culture away from the dangerous mindset of "this is how we've always done it" towards a proactive mindset of "how can we do this better and safer?" It empowers workers to look for other areas of improvement, creating a virtuous cycle of innovation that starts from the ground up.

The Engineering Details That Matter

As an engineer, I see the critical details that a procurement manager, focused on price, might overlook. These are the details that separate a machine that lasts for five years from one that is a reliable workhorse for twenty.

| Engineering Feature | Why It's Critical | The Risk of Getting It Wrong |

|---|---|---|

| Structural Steel Quality | The frame is the backbone. It must withstand immense and repeated stress cycles without metal fatigue. We insist on using high-grade, reinforced structural steel. | A weak frame built with inferior steel can warp, or worse, develop cracks over time, leading to a catastrophic failure of the entire machine. |

| Drive System (Hydraulic vs. Mechanical) | The choice of drive system depends on the load, required speed, and the plant environment. A well-designed system ensures a smooth, jolt-free rotation, protecting the mold. | A jerky, undersized, or poorly matched drive system can slam the mold, damage the machine's components, and shorten its lifespan. |

| Bearings and Bushings | These are the critical wear points. Using oversized, high-quality, and easily lubricated bearings is absolutely key to long-term reliability and low maintenance. | Cheap, undersized bearings will fail quickly under heavy loads, causing significant downtime and costly repairs. |

| Safety Interlocks & E-Stops | The control system must be built with multiple, redundant safety features, like limit switches and emergency stop buttons, to protect operators and equipment. | Inadequate or non-redundant safety systems create a false sense of security and can fail at the most critical moment. |

This is precisely where having a strategic partner, not just a supplier, becomes invaluable. A good partner will ask detailed questions about your specific molds, your current workflow, your cycle times, and your long-term goals. They won't just email you a quote for an off-the-shelf product. They will help you select, and if necessary, customize a machine that is perfectly suited to your operation's unique needs. This is the approach we took with Javier's team in Mexico. We didn't just sell them a machine; we provided a total solution. That is the SHJLPACK way, and it comes from a lifetime of passion for this industry and a dedication to helping our clients succeed.

Conclusion

A mold flipper is a smart, strategic investment. It boosts safety, increases throughput, and improves profitability, all while supporting your most important digital transformation and operational excellence goals.