Heavy industrial plants, especially in the steel and wire sectors, run 24/7. Your entire production line is a chain, and every link must be strong. But often, the final packing station is the weakest link. An outdated or unreliable coil packing machine can bring your entire multi-million dollar operation to a halt. This causes shipment delays, angry customers, and massive financial losses. Every minute of downtime is money vanishing from your bottom line. The solution is not just buying a new machine. It's investing in a heavy-duty packing system engineered for the relentless demands of a modern plant. It's an investment in reliability, efficiency, and ultimately, profitability.

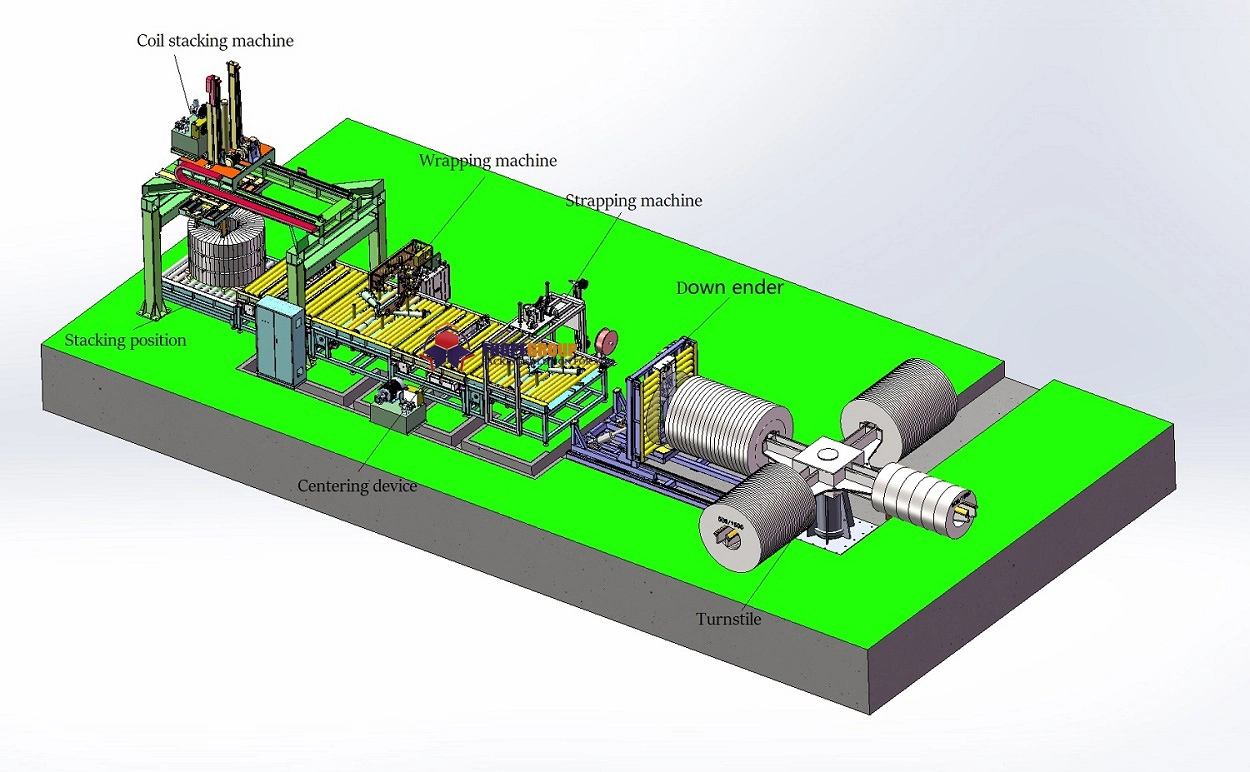

A heavy-duty coil packing system meets demanding plant requirements by being engineered for maximum uptime with robust components. It features a modular design for simple maintenance and integrates advanced automation to reduce manual labor and errors. This ensures your plant achieves consistent, reliable, and safe packaging output around the clock.

I have spent my entire career in the packing machine industry. I started on the factory floor, seeing these challenges firsthand. Now, as the founder of SHJLPACK, my goal is to share the knowledge I gained building my own company. I want to help you, the plant owner or manager, make the best possible decisions for your equipment. This isn't just about selling machines; it's about building stronger, more profitable operations. Let’s look at the key questions you should be asking when considering a new packing system.

How can modern packing lines reduce downtime from aging equipment?

Your old packing machine has been a workhorse for 15, maybe 20 years. But now, it’s a source of constant worry. Unexpected breakdowns are becoming more frequent. Finding spare parts is a nightmare. Each time it fails, your maintenance team scrambles, and your production schedule is thrown into chaos. This reactive, "fire-fighting" approach to maintenance is incredibly costly and stressful. A modern packing line is engineered with a completely different philosophy. It’s designed to prevent problems before they happen, giving you control over your uptime.

Modern packing lines reduce downtime by using predictive maintenance sensors, modular and quick-swap components for fast repairs, and robust construction with higher-grade materials. They also include remote diagnostic capabilities, allowing our technicians to troubleshoot issues without needing to be on-site, which dramatically speeds up problem resolution.

Moving from Reactive to Predictive Maintenance

The biggest shift in modern equipment design is the move away from reactive maintenance. Waiting for a machine to break is no longer acceptable. Today, we build systems that tell you they need attention. This is achieved through integrated IoT (Internet of Things) sensors. These sensors can monitor critical components like motors, bearings, and hydraulic systems. They track key indicators such as vibration, temperature, and power consumption.

When a sensor detects a reading that is outside the normal operating range, it sends an alert to your control system or maintenance team. For example, a slight increase in a motor's operating temperature could indicate a lubrication issue or a failing bearing. Instead of the motor burning out and shutting down the line for a day, your team gets an advance warning. They can schedule a quick, 30-minute maintenance task during a planned changeover. This proactive approach is the key to achieving 95% or higher equipment uptime.

The Power of Modular Design

I remember working on older machines where a small failure required a massive teardown. To replace one small gear, you might have to disassemble half the machine. It could take an entire shift. This is why our modern systems at SHJLPACK are built using a modular design philosophy.

A module is a self-contained section of the machine that performs a specific function, like the strapping head or the wrapping shuttle. If a component within that module fails, you don't need to perform complex surgery on the line. You can simply unbolt the entire module and swap it with a spare one in under an hour. The damaged module can then be taken to the workshop for repair without holding up production. This "quick-swap" capability is a game-changer for minimizing Mean Time To Repair (MTTR).

Superior Materials and Construction

A machine is only as strong as the materials it's made from. In heavy-duty environments like a steel mill, equipment faces constant stress, vibration, and temperature swings. We've seen machines from other suppliers fail because they used lower-grade steel for the frame or undersized motors to cut costs.

We take a different approach. We use thicker, reinforced steel for machine frames to ensure stability and longevity. We specify high-quality motors and gearboxes from world-class brands like SEW-Eurodrive or Siemens. We use premium electrical components that are less susceptible to failure from power fluctuations or heat. It costs more upfront, but it pays for itself many times over in reliability and reduced failures. This commitment to robust engineering is fundamental to building a true heavy-duty system.

What specific features in a coil packing system lower operational costs?

As a plant owner, you are constantly battling rising costs. Electricity, fuel, packaging materials, and labor all chip away at your profit margins. You know that to stay competitive, you must find ways to operate more efficiently. You might think of a packing machine as just a necessary expense at the end of your line. But a modern, well-designed system can become a profit center by directly attacking your biggest operational costs.

A coil packing system lowers operational costs with specific features like high-efficiency servo motors that cut energy use, automated material application that minimizes wrapping film waste, and integrated weighing and labeling that reduces manual labor. These features work together to significantly lower the cost per ton of your finished product.

Tackling Energy Consumption

Energy is one of the largest variable costs in any heavy industrial plant. Older packing machines, especially those using hydraulic power packs, are notoriously inefficient. The hydraulic pump often runs continuously, even when the machine is idle between coils, wasting a tremendous amount of electricity.

The modern solution is to use all-electric systems driven by high-efficiency servo motors. A servo motor only draws significant power when it is performing a task. When it's idle, its energy consumption is near zero. The difference is huge. We have seen clients achieve a 10-15% reduction in the packing line's energy use just by upgrading from hydraulic to servo technology. This aligns directly with goals like yours, Javier, to reduce unit energy consumption across the plant. These savings go straight to your bottom line, year after year.

Minimizing Material Waste

Packaging materials like stretch film or VCI paper are a significant recurring expense. Older wrapping machines often lack precise control over material application. The tension might be inconsistent, or the overlap might be set manually and inaccurately. This leads to using far more material than is necessary to secure the coil.

Our systems incorporate advanced material-saving features. For example, our stretch wrappers have a powered pre-stretch function. This feature can stretch the film by up to 300% before it's applied to the coil. This means one meter of film on the roll becomes four meters of film on your product. We also use precise electronic controls to manage film tension and overlap. This ensures every coil is wrapped with the absolute minimum amount of material required for safe transport. For a large mill, this can translate into saving tens of thousands of dollars in film costs annually.

Optimizing Labor and Reducing Errors

Labor is another major cost driver. A manual or semi-automatic packing process might require two or three operators to handle, wrap, and label coils. This is not only expensive but also introduces the risk of human error, which can lead to packaging defects or shipping mistakes.

A fully automated packing line can perform these tasks with a single supervisor overseeing the system. The line can automatically:

- Receive the coil from the C-hook or turnstile.

- Measure its dimensions.

- Apply the correct wrapping and strapping pattern.

- Weigh the finished coil.

- Print and apply the correct shipping label.

This frees up your valuable operators for more complex, higher-value tasks elsewhere in the plant. It also eliminates errors, ensuring that every package meets quality standards and has the correct documentation. This level of automation is a key step in reducing overall operating costs by the 8% or more that you are targeting.

| Feature | Cost Area | How It Saves Money | Potential Savings |

|---|---|---|---|

| Servo Motors | Energy | Replaces inefficient hydraulic systems; uses power only on demand. | 10-15% energy reduction |

| Powered Pre-Stretch | Packaging Material | Stretches film up to 300%, reducing overall film consumption. | 50-75% film cost reduction |

| Automatic Weighing/Labeling | Labor & Quality | Eliminates manual tasks and prevents costly shipping errors. | Reduce 1-2 operators per shift |

| Integrated Safety System | Safety & Insurance | Prevents accidents, reducing risk of downtime and insurance claims. | Improves safety record |

How do automated packing systems integrate with a plant's digital ecosystem?

You are making smart investments in the future of your plant with MES platforms and data analytics. You want total production visibility. But a packing line that can't "talk" to your other systems creates a blind spot. It becomes an isolated island of equipment, unable to share valuable data or receive automated instructions. This undermines your entire digital transformation strategy and prevents you from achieving true, end-to-end process optimization.

Automated packing systems integrate with a plant's digital ecosystem using standard communication protocols like PROFINET or EtherNet/IP. They connect directly to the Manufacturing Execution System (MES) to receive coil data and packing recipes. They also send back real-time data on production status, cycle times, and equipment health, enabling full production visibility.

The Language of Machines: Communication Protocols

For your packing line to connect to your plant's network, it needs to speak the same language. In the industrial world, this "language" is a communication protocol. We design our systems to be fluent in the most common protocols used in modern factories. This includes PROFINET, which is common for Siemens-based control systems, and EtherNet/IP, which is widely used with Rockwell/Allen-Bradley systems.

By using these standard protocols, integration becomes much simpler. The packing machine's main controller, the PLC (Programmable Logic Controller), can establish a direct, reliable link with your central MES. This is not a custom, one-off solution that is hard to maintain. It is a robust, industry-standard connection that your own IT and engineering teams can easily understand and manage. This seamless communication is the foundation of a truly "smart" production line.

The Two-Way Data Conversation

Integration is not just about sending data in one direction. It is a continuous, two-way conversation between the packing line and your MES. This dialogue enables a much higher level of automation and control.

Here’s how it typically works:

- MES to Packing Line: When a coil arrives at the packing station, the MES sends a "telegram" of data. This includes the Coil ID, weight, dimensions, customer specifications, and the required "packing recipe" (e.g., how many layers of film, number of straps). The packing line automatically configures itself to perform the correct process for that specific coil without any operator input.

- Packing Line to MES: As the machine works, it sends data back to the MES. This includes confirmation that the packing cycle has started and finished, the actual cycle time, the amount of wrapping material and straps used, and the final weight. If any error occurs, an alarm code is sent immediately.

This closed-loop communication provides a real-time, verifiable record of your entire packaging process. It eliminates manual data entry, reduces errors, and gives you a rich source of data for analysis.

Unlocking a Deeper Level of Insight

Connecting to the MES is just the beginning. The next level of digital transformation involves using the detailed data from the machine to improve your operations. This is where IoT sensors play a key role again. Data from sensors monitoring motor temperature, vibration, and cycle times can be fed into your plant's big data analytics platform.

Your data science team can then use this information to:

- Predict Failures: By analyzing trends, they can identify when a component is likely to fail and schedule maintenance proactively. This is the core of your goal to implement predictive maintenance.

- Optimize Performance: They can analyze cycle times for different coil sizes and packing recipes to find opportunities to speed up the process.

- Track Consumables: By tracking the exact amount of film and straps used per coil, you can manage inventory more effectively and identify any anomalies in material consumption.

This level of integration transforms your packing line from a simple machine into an intelligent data node in your factory's nervous system.

Why is a partnership approach crucial when selecting a packing machine supplier?

Buying a major piece of industrial equipment is a significant capital investment. It’s easy to get focused on the initial purchase price and compare quotes from different vendors. But choosing a supplier based only on who is cheapest is one of the biggest mistakes a plant owner can make. A vendor just sells you a machine. A partner invests in your success. A cheap machine with poor support can end up costing you far more in downtime, maintenance, and frustration over its lifetime.

A partnership approach is crucial because a true partner provides comprehensive support through the entire lifecycle of the equipment. This starts with a deep understanding of your operational needs during the design phase and continues through installation, training, and long-term maintenance. This ensures you get a solution, not just a machine.

Beyond the Sale: The Consultation Phase

When a vendor comes to see you, they often want to sell you their standard, off-the-shelf model. A partner starts by listening. Before we even talk about a specific machine, we want to understand your entire process.

- How does material flow to and from the packing area?

- What are the physical constraints of your plant layout?

- What are your specific challenges with your current process?

- What are your growth plans for the next five to ten years?

I learned this early in my career. I once saw a client buy a machine that was technically perfect but didn't fit their material flow. It created a bottleneck that slowed down their entire plant. A true partner would have identified that during the consultation phase and proposed a modified layout or a different machine configuration. This deep analysis ensures the solution you get is tailored to your specific reality, not just what's in a catalog.

Installation and Training: Working as One Team

The arrival of a new machine can be a disruptive time for a plant. A vendor might simply drop the machine off and leave the installation to your team. A partner understands that successful commissioning is a collaborative effort.

Our approach is to work as an extension of your team. Our engineers will be on-site, working alongside your maintenance staff and operators. We don't just install the machine; we ensure it's properly integrated with your conveyors and safety systems. Most importantly, we provide comprehensive, hands-on training. We want your operators to feel confident and capable of running the machine. We want your maintenance team to understand how to service it and troubleshoot common issues. This transfer of knowledge is critical for long-term success and self-sufficiency. A successful startup is a shared victory.

Long-Term Support: Your Partner for the Future

A vendor’s job is done once the final payment is made. A partner’s job is never done. The steel industry is always evolving. Environmental regulations change. Your product mix might shift. New digital technologies emerge.

A true partner remains by your side to help you adapt. This includes:

- Responsive Support: Offering fast remote diagnostics and a reliable supply of spare parts to minimize any potential downtime.

- Continuous Improvement: Proactively suggesting software updates or small hardware upgrades that can improve efficiency or safety.

- Future-Proofing: Advising you on how your existing equipment can be adapted to meet new challenges or integrated with future technologies.

This long-term relationship is what separates a supplier from a strategic partner. You are not just buying a piece of steel; you are investing in a relationship with a team of experts who are committed to your plant's success for years to come.

| Aspect | Vendor Mentality | Partner Mentality |

|---|---|---|

| Initial Goal | Make a quick sale | Understand the client's problem |

| Solution | Offer a standard product | Design a tailored solution |

| Installation | Deliver the machine | Collaborate on integration and training |

| After-Sales | Reactive support (if available) | Proactive support and continuous improvement |

| Relationship | Transactional | Long-term, based on shared success |

My View: Beyond the Machine - The Real ROI is in the Partnership

When I started my journey as an engineer on a factory floor, I saw the daily struggles firsthand. I saw managers frustrated by unreliable equipment and suppliers who disappeared after making a sale. When I had the opportunity to build my own company, SHJLPACK, I knew I had to do things differently. I built this company on a simple belief: we are not just selling machines; we are providing solutions and building partnerships.

The real return on your investment isn't just calculated by the speed or efficiency of the machine itself. The true ROI comes from the knowledge, support, and trust that is built into the relationship with your supplier. It comes from knowing you can pick up the phone and talk to an expert who understands your specific setup. It comes from the peace of mind that your equipment will be supported for its entire lifespan. The steel, motors, and wires are important, but the human expertise and commitment behind them are what truly create value. My success came from this industry, and now my mission is to share what I've learned to help others like you succeed. That is the core philosophy of SHJLPACK.

Conclusion

Investing in a heavy-duty packing system is investing in your plant’s future. Choose a machine and a partner built to last, ensuring reliability and long-term profitability for years.