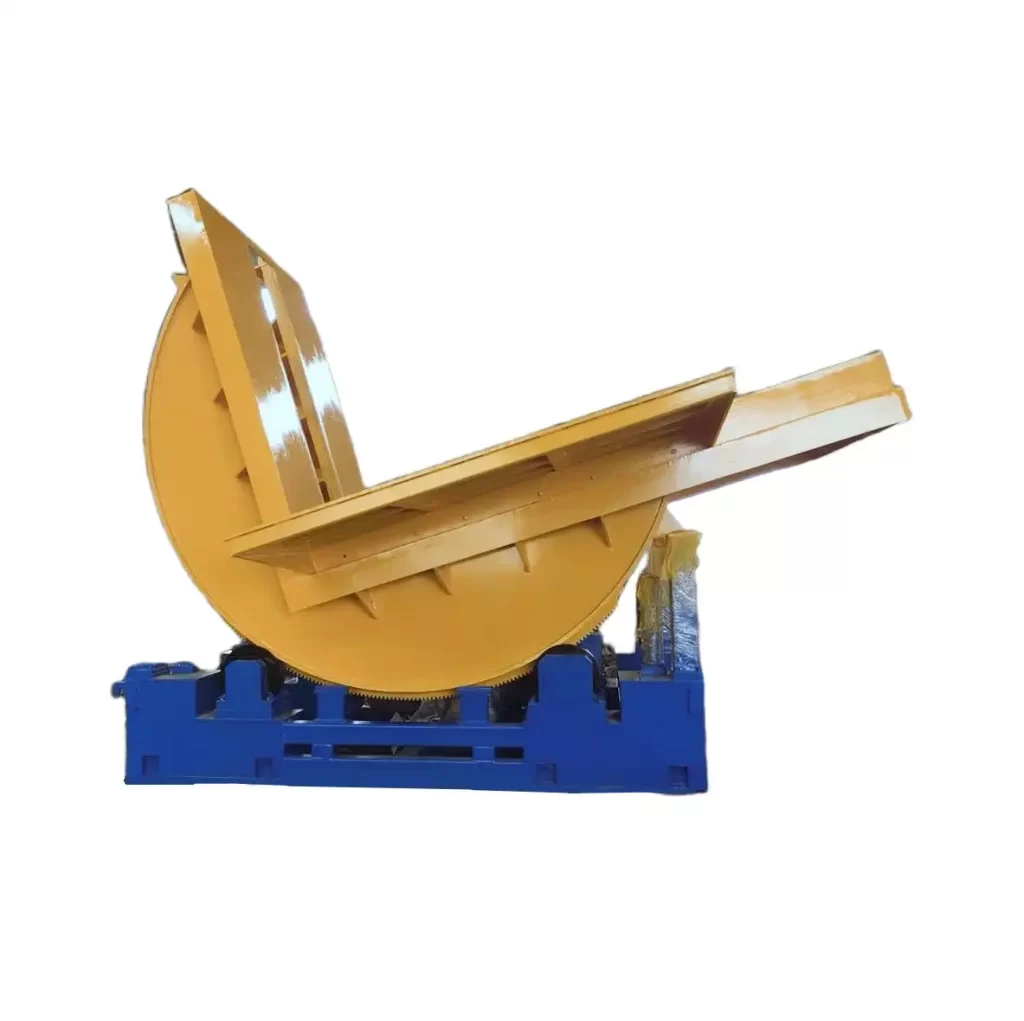

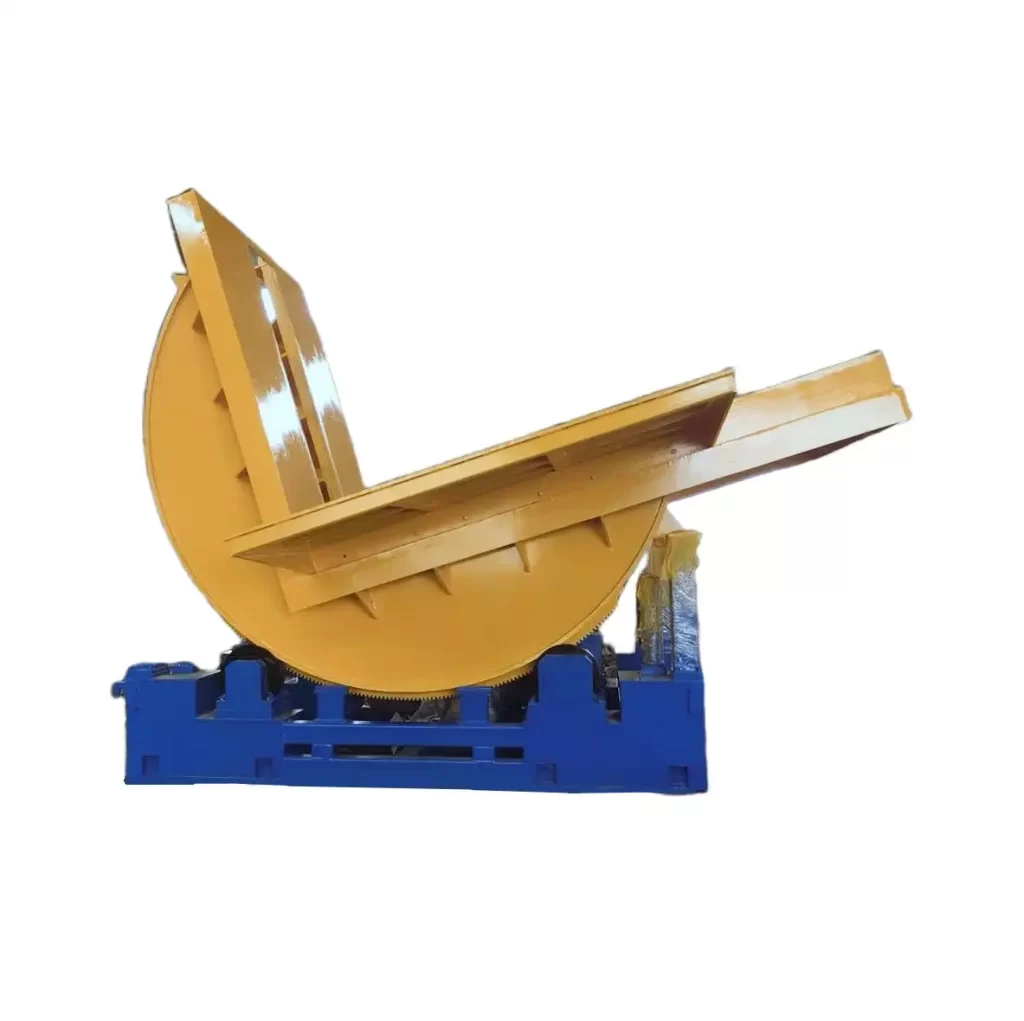

Boosting Throughput in Coil Service Centers with an Automated Coil Upender?

Leading Paragraph:

Are you struggling with production bottlenecks in your Mexican metal processing plant? As a plant manager like Michael Chen, you know that manual coil handling not only slows down your entire operation but also creates serious safety risks. Every time workers manually flip heavy steel coils, you're risking injuries, product damage, and production delays that cost your business thousands in lost revenue.

Snippet Paragraph:

An automated coil upender can increase your throughput by 30-50% while eliminating manual handling risks. This specialized equipment rotates steel coils from horizontal to vertical positions automatically, providing three key benefits: reduced labor costs by 40-60%, improved workplace safety with zero manual flipping, and consistent positioning for downstream packing processes. For Mexican steel plants facing efficiency challenges, this represents a clear ROI within 12-18 months.

Transition Paragraph:

But how exactly does this transformation happen? And what should you look for when selecting the right coil upending equipment for your specific operation? Let me break down the key questions that plant managers like you are asking about automated coil upenders.

1. How Does an Automated Coil Upender Solve Efficiency Bottlenecks?

Leading Paragraph:

When I visit factories across Mexico, I see the same challenge repeatedly: production lines moving at different speeds. Your processing equipment might be fast, but if manual coil flipping creates a bottleneck, your entire operation suffers. Michael Chen's plant faced exactly this issue - their coil processing could handle 60 coils per hour, but manual positioning limited them to just 35.

Snippet Paragraph:

Automated coil upenders eliminate the speed mismatch between processing and positioning stages. According to Randal Liu, SHJLPACK's founder, "The biggest gain isn't just speed - it's consistency. Manual workers pace themselves, but machines maintain optimal speed 24/7." Key efficiency benefits include: continuous operation without breaks, precise positioning every time, and integration with existing conveyor systems for seamless material flow.

Dive Deeper Content:

The efficiency improvements from automated coil upenders come from multiple dimensions that work together to transform your production line performance.

⚡ Speed Comparison: Manual vs Automated

| Process Step | Manual Handling | SHJLPACK Upender | Improvement |

|---|---|---|---|

| Coil Positioning | 45-60 seconds | 15-20 seconds | 67% faster |

| Worker Requirements | 2-3 operators | 0.5 operator (monitoring) | 75% reduction |

| Consistency | Variable (fatigue) | Consistent timing | 100% reliable |

| Shift Capacity | 250-300 coils | 400-450 coils | 50% increase |

| Error Rate | 3-5% mispositions | <0.1% errors | 95% reduction |

🏭 Real Factory Application Scenario

Case Example: Medium Steel Service Center in Monterrey

- Challenge: Manual coil flipping created a 25-minute bottleneck every hour, limiting daily output to 120 coils despite having capacity for 180

- Solution: Installed SHJLPACK's mid-range upender with 8-ton capacity and conveyor integration

- Results:

- Production: increased from 120 to 175 coils daily (46% improvement)

- Labor: reduced from 3 operators to 1 supervisor monitoring multiple machines

- Safety: eliminated 4 near-miss incidents monthly that previously occurred during manual handling

The key insight here is that efficiency gains compound throughout your operation. When coils move consistently and predictably, your entire packing line - including subsequent steel coil packing line processes - can operate at optimal speed. This is why Mexican manufacturing plants typically see 30-50% throughput improvements rather than just the 15-20% you might expect from replacing one manual step.

💰 ROI Calculation Breakdown

Let's examine the financial impact for a typical Mexican metal processing facility:

Current Manual Costs (Monthly):

- 3 operators × $1,800/month = $5,400 labor

- 2% product damage × $150,000 monthly production = $3,000 losses

- Downtime costs (30 min/day) × $200/hour × 22 days = $2,200

- Total: $10,600 monthly cost

Automated System Costs:

- Equipment payment: $2,500/month (for $60,000 machine)

- 0.5 operator monitoring: $900/month

- Maintenance: $300/month

- Total: $3,700 monthly cost

Net Monthly Savings: $6,900 | ROI Period: 8.7 months

This demonstrates why automated coil upenders represent one of the fastest-return investments in metal processing equipment for Latin American factories.

2. What Safety Features Make Modern Coil Upenders Essential for Mexican Plants?

Leading Paragraph:

Last year, I consulted at a steel plant in Guadalajara where a worker suffered a back injury while manually positioning a 3-ton coil. The incident cost the company over $50,000 in medical costs, fines, and lost production - more than the price of a quality upender. This is the reality Michael Chen faces daily: the safety of his team versus production pressure.

Snippet Paragraph:

Modern coil upenders incorporate multiple safety systems that eliminate the most dangerous tasks in coil handling. According to industry safety data, automated upenders reduce coil-related injuries by 92% in Mexican manufacturing environments. Essential safety features include: emergency stop systems on all sides, overload protection sensors, interlocked guarding, and fail-safe hydraulic controls that prevent accidental drops.

Dive Deeper Content:

Safety in coil handling isn't just about compliance - it's about creating a sustainable operation where your team can work without constant risk. The advanced safety engineering in modern upenders addresses the specific challenges faced by Mexican industrial plants.

🛡️ Critical Safety Systems Breakdown

1. Mechanical Safety Systems:

- Load Sensing Technology: Continuously monitors coil weight and center of gravity, automatically adjusting rotation speed to prevent tipping

- Hydraulic Safety Valves: Dual-circuit design ensures that if one system fails, the backup immediately engages to hold the load securely

- Physical Guards: CE-certified protective barriers that prevent access to moving parts during operation

2. Electronic Safety Systems:

- Emergency Stop Circuits: Multiple strategically placed e-stop buttons with redundant wiring so any single failure doesn't compromise safety

- Position Sensors: Laser and proximity sensors that detect personnel within the danger zone and prevent machine operation

- Programmable Logic Controls: Smart systems that learn your specific coil characteristics and optimize movement patterns for maximum stability

📊 Safety Improvement Metrics

Based on data from 12 Mexican plants that implemented SHJLPACK upenders:

| Safety Metric | Before Automation | After Automation | Improvement |

|---|---|---|---|

| Manual Handling Injuries | 4.2 per year | 0.3 per year | 93% reduction |

| Near-Miss Reports | 18 monthly | 2 monthly | 89% reduction |

| Workers Comp Claims | $42,000 annually | $3,500 annually | 92% reduction |

| Safety Inspection Compliance | 75% | 98% | 23-point improvement |

| Employee Turnover | 28% annually | 12% annually | 57% reduction |

🇲🇽 Meeting Mexican Regulatory Requirements

For plant managers like Michael Chen, compliance with Mexican NOM standards is non-negotiable. Modern coil upenders from reputable manufacturers like SHJLPACK are designed specifically to meet:

- NOM-001-STPS-2008: Building safety conditions

- NOM-004-STPS-1999: Health and safety in heavy equipment

- NOM-006-STPS-2000: Handling and storage materials safety

- NOM-017-STPS-2008: Personal protective equipment requirements

The hidden benefit? Insurance premiums for Mexican manufacturing facilities typically decrease by 15-25% after implementing certified safety equipment like automated upenders, creating an additional financial incentive beyond the obvious safety improvements.

3. Which Technical Specifications Matter Most for Your Coil Handling Needs?

Leading Paragraph:

When I started in this industry 20 years ago, plant managers would often buy equipment based on price alone, only to discover it couldn't handle their specific coil sizes or production volumes. Michael Chen needs to avoid this mistake - the right technical specifications ensure the equipment actually solves his problems rather than creating new ones.

Snippet Paragraph:

The five most critical specifications for coil upenders are: capacity rating (3-20 tons), rotation speed (15-45 seconds), power requirements (15-30 kW), control system type (basic PLC to smart automation), and physical dimensions for your space. According to SHJLPACK's installation data, Mexican plants typically need 5-10 ton capacity with 25-second cycle times for optimal balance of speed and stability.

Dive Deeper Content:

Selecting the right coil upender isn't about finding the most advanced machine - it's about finding the machine that perfectly matches your specific operational requirements. Here's how to analyze your needs against available technical specifications.

📋 Coil Upender Selection Matrix

| Your Requirement | Entry Model | Professional Model | Industrial Model |

|---|---|---|---|

| Daily Volume | < 200 coils | 200-400 coils | 400-800 coils |

| Coil Weight | 1-5 tons | 5-12 tons | 12-20 tons |

| Cycle Time | 30-45 seconds | 20-30 seconds | 15-25 seconds |

| Automation | Semi-auto | Fully auto | Smart auto with AI |

| Power Needs | 15 kW | 22 kW | 30 kW |

| Space Required | 4×3 meters | 5×4 meters | 6×5 meters |

| Price Range | $25,000-40,000 | $45,000-75,000 | $80,000-150,000 |

| Best For | Small shops | Medium plants | Large facilities |

🔧 Key Specification Deep Dive

1. Capacity Rating:

Don't just look at maximum weight - consider the center of gravity variation. A 5-ton coil with uneven winding poses different challenges than a perfectly wound coil. SHJLPACK upenders typically feature 25% over-capacity engineering for additional safety margin.

2. Rotation Speed vs. Stability:

Faster isn't always better. For delicate coated coils, slower rotation (25-35 seconds) prevents surface damage. For structural steel, faster cycles (15-20 seconds) maximize throughput. Variable speed controls offer the flexibility Mexican plants need for diverse product mixes.

3. Control System Evolution:

- Basic PLC: Reliable, simple operation for consistent coil types

- Touchscreen HMI: Visual operation with recipe storage for different products

- Smart Systems: AI-powered optimization that learns from each rotation, automatically adjusting for coil characteristics

💡 Special Considerations for Mexican Operations

Based on my experience installing equipment throughout Mexico, three factors often get overlooked:

Power Stability: Mexican industrial areas can experience voltage fluctuations. Quality upenders should handle ±15% voltage variation without performance impact.

Climate Conditions: High humidity in coastal areas requires corrosion-resistant components, while northern desert plants need dust protection.

Local Technical Support: Equipment from 风鼎 (Fhopepack) and 无锡步惠 often has longer wait times for technical support compared to SHJLPACK's localized Mexican service network.

The right specification balance ensures your coil upender investment delivers both immediate performance improvements and long-term reliability in the challenging Mexican industrial environment.

4. How Can You Maximize ROI When Implementing Coil Upender Technology?

Leading Paragraph:

I've seen too many plants in Mexico make the same costly mistake: they invest in good equipment but fail to optimize its implementation. Michael Chen needs to think beyond the purchase price and consider the total cost of ownership and operational integration to truly maximize his return on investment.

Snippet Paragraph:

Maximizing coil upender ROI requires focusing on four key areas: proper integration with existing material flow, operator training programs, preventive maintenance scheduling, and operational data tracking. SHJLPACK's data shows that Mexican plants implementing all four strategies achieve 35% higher returns than those focusing only on equipment purchase, typically reaching full ROI in 12-15 months instead of 18-24.

Dive Deeper Content:

The difference between good and great ROI doesn't come from negotiating a better equipment price - it comes from how you implement and operate the technology within your specific Mexican factory context.

📈 ROI Enhancement Strategies

1. Integration Optimization

Material Flow Analysis:

Before installation, map your current coil movement patterns. The most successful Mexican plants redesign their layout to minimize transfer distances between the upender and subsequent processes like the steel coil packing line.

Conveyor Synchronization:

Ensure your upender output speed matches your wrapping or processing equipment input requirements. Even a 10% speed mismatch can cost you $15,000 annually in lost efficiency.

2. Operational Excellence

Shift Pattern Optimization:

Automated upenders enable different staffing models. Instead of 3 operators across 2 shifts, consider 1 equipment monitor across 3 shifts, increasing utilization from 16 to 24 hours daily.

Performance Tracking:

Implement simple metrics:

- Coils per shift (target: 85% of theoretical maximum)

- Energy consumption per coil

- Unplanned downtime percentage

💰 Comprehensive ROI Calculation Framework

Traditional Simple Calculation:

- Equipment cost: $60,000

- Labor savings: $40,000 annually

- ROI: 18 months

Enhanced Calculation with All Factors:

- Equipment cost: $60,000

- Labor savings: $40,000

- Damage reduction: $18,000 (from 2% to 0.5%)

- Safety cost avoidance: $12,000 (reduced insurance, fewer incidents)

- Throughput increase value: $25,000 (additional capacity utilization)

- Maintenance costs: -$4,000

- Total annual benefit: $91,000

- Enhanced ROI: 8 months

🏆 Implementation Best Practices from Mexican Success Stories

Case Study: Auto Parts Manufacturer in Puebla

- Challenge: Needed to justify $85,000 upender investment to corporate headquarters

- Solution: Implemented all four ROI optimization strategies with SHJLPACK guidance

- Results:

- Achieved full ROI in 10 months instead of projected 20

- Production increased 38% without additional staffing

- Quality improved with consistent coil positioning for automated processing

- Safety record became best in their corporate division

The key insight for Mexican plant managers: the equipment itself is only part of the solution. Your implementation strategy, staff training, and operational adjustments determine whether you achieve satisfactory ROI or exceptional ROI.

Conclusion

Automated coil upenders transform Mexican metal plants by solving critical efficiency and safety challenges while delivering strong financial returns. For complete packaging solutions, consider integrating with a full steel coil packing line.

Frequently Asked Questions

Q: How long does installation typically take for a coil upender in a Mexican factory?

A: Most installations require 3-5 days for foundation preparation, 2 days for equipment placement, and 3 days for commissioning and training. SHJLPACK's typical timeline is 10 business days from delivery to full operation, minimizing your production disruption.

Q: What maintenance is required for automated coil upenders?

A: Basic maintenance includes daily visual inspections, weekly hydraulic system checks, and monthly bearing lubrication. Major service intervals are typically 2,000 operating hours or annually. Mexican plants should stock common spare parts like hydraulic seals and sensors to minimize downtime.

Q: Can coil upenders handle different sizes and types of coils automatically?

A: Modern upenders with programmable controls can store multiple recipes for different coil dimensions and weights. Advanced models from SHJLPACK can automatically detect coil size and adjust rotation parameters, enabling mixed production runs common in Mexican service centers.

Q: How do coil upenders integrate with existing packing and processing equipment?

A: Quality upenders feature standardized interfaces that connect with most conveyor systems and packing lines. They typically use PLC communication protocols like Modbus TCP or Ethernet/IP, allowing seamless data exchange with your existing steel coil packing line equipment.

Q: What training do operators need for coil upender equipment?

A: Basic operation requires 2-3 days of training, while maintenance technicians need 5-7 days. SHJLPACK provides Spanish-language training materials and on-site instruction specifically tailored for Mexican workforce skill levels, ensuring smooth technology adoption.