Are you a steel mill owner or manager in Greece? I know the pressures you face. You're dealing with volatile energy costs that can change overnight. You're managing equipment that has served you well but is now showing its age. And on top of that, you have strict environmental standards to meet and a market that can be unpredictable. I've been there. Before I started SHJLPACK, I worked my way up from the factory floor. I understand that every investment must justify itself, not just on paper, but on the production line. You’re likely wondering if automating your coil packing line is just another expense, or if it's a strategic move that can actually pay off. The stress of balancing production targets with rising operational costs is immense, and a single weak link, like an inefficient packing line, can threaten your profitability and growth.

Yes, investing in an automated coil packing solution offers a clear and measurable Return on Investment (ROI) for the Greek steel industry. It pays off by directly tackling your biggest challenges: it reduces manual labor costs, minimizes product damage through consistent and superior wrapping, increases overall throughput to meet market demand, and provides valuable data that helps you optimize your entire operation. By focusing on ROI, you can transform your packing line from a cost center into a strategic asset that drives profitability and long-term stability.

I understand the skepticism. When you're managing a multi-million-euro operation, every decision is critical. You can't afford to invest in technology that doesn't deliver tangible results. That’s why I founded SHJLPACK on a simple principle: to share the knowledge I’ve gained over decades and provide total solutions, not just machines. We’re not just a supplier; we're a knowledge-sharing platform and a partner. Let's break down how a modern, ROI-driven approach to coil packing automation can address the specific challenges you're facing today and help you achieve your ambitious goals.

How Can Modern Coil Packing Lines Combat the Costs of Aging Equipment?

You see it every day. A critical machine on the line has been running for over 15 years. The maintenance team knows it by heart, but breakdowns are becoming more frequent. Finding spare parts feels like a treasure hunt, and every hour of unplanned downtime means lost production and delayed shipments. It’s a constant source of stress. This aging equipment, especially at the final packing stage, can become a major bottleneck, undermining all the efficiency gains you've made upstream. You start to wonder if you're just throwing good money after bad with constant repairs. The solution isn't just another patch-up job; it's a strategic replacement with modern automation designed for reliability.

Modern coil packing lines directly combat the costs of aging equipment by delivering exceptional reliability, integrating predictive maintenance sensors, and ensuring the availability of standardized spare parts. This combination drastically reduces unplanned downtime. Instead of reacting to failures, you can anticipate them. This shifts your maintenance from a costly, reactive fire-fight to a planned, efficient process, directly boosting your equipment's effective run time towards that 95% goal.

Dive Deeper: Shifting from Reactive to Predictive Operations

When I first started in this industry, the philosophy was "if it ain't broke, don't fix it." We ran machines until they failed, then scrambled to get them back online. The "cost" was seen simply as the price of the replacement part and the mechanic's time. But I learned, especially after starting my own factory, that the true cost is much, much higher.

The Hidden Costs of Unplanned Downtime

Let's be very clear about what a breakdown on an old packing line truly costs. It's not just a few hundred euros for a new motor or bearing.

- Lost Production: The most obvious cost. If your mill produces 200 tons per hour and your packing line is down for 3 hours, that's 600 tons of production that is now backlogged.

- Idle Workforce: The operators on that line, and potentially in downstream logistics, are now being paid to wait.

- Supply Chain Disruption: A delayed shipment can mean penalties from your clients or, worse, a loss of trust. In a competitive market, reliability is key.

- Wasted Maintenance Resources: Your skilled technicians are pulled from important preventative tasks to fight fires, leading to a cycle where other machines become more likely to fail.

A modern system changes this entire dynamic.

Predictive Maintenance: The Power of Data

New automated packing lines are built with the Industrial Internet of Things (IIoT) in mind. They are equipped with sensors that monitor key indicators of machine health in real-time.

| Feature Monitored | Old Equipment (Reactive) | Modern Equipment (Predictive) |

|---|---|---|

| Motor Vibration | Runs until it fails catastrophically. | Sensors detect subtle changes in vibration, signaling bearing wear weeks in advance. |

| Temperature | Overheats, causing a sudden shutdown. | Thermal sensors alert you when a component is running hot, allowing for inspection. |

| Power Consumption | No monitoring. | A gradual increase in power draw can indicate mechanical friction or a failing motor. |

| Cycle Count | Manual logs, if any. | The PLC tracks every cycle, prompting for replacement of wear parts (like cutters or grippers) after a set number of uses. |

This data doesn't just sit in the machine. It can be fed directly into your Manufacturing Execution System (MES), the kind of platform you want to deploy. Your maintenance manager gets an alert: "Motor on strapping head #2 shows increased vibration. Recommend inspection during planned shutdown this weekend." This is how you move from chaos to control and get your uptime to 95%. It’s a fundamental shift from hoping a machine doesn't break to knowing exactly when it needs attention.

Can Automated Packing Systems Really Lower My Energy Bill?

You look at your monthly utility bills and see the impact of energy price volatility firsthand. Electricity and fuel are among your highest operational costs, and they are completely outside of your control. Your factory runs massive equipment, and it's easy to assume that the energy consumption of a "small" part of the process like packing is just a drop in the bucket. But these "drops" add up, especially when you have old systems with oversized motors and pneumatic components that run constantly, whether a coil is present or not. You are rightly focused on big wins like waste heat recovery, but what if you could also achieve significant, consistent savings at the end of your line?

Absolutely. Modern automated packing systems are specifically engineered to lower your energy bill. They achieve this by using high-efficiency servo motors instead of old hydraulic or oversized AC motors, incorporating intelligent "sleep mode" logic to power down during idle periods, and optimizing mechanical movements to use the minimum energy required for each task. These features combine to deliver a measurable reduction in your plant's overall kWh consumption, contributing directly to your goal of a 10% decrease in unit product energy use.

Dive Deeper: Finding Efficiency in Every Movement

Energy savings in automation isn't about one single breakthrough; it's about a hundred small, smart design choices that add up to a big impact. When we design a packing line at SHJLPACK, we are obsessed with this, because I know that for a factory owner, every kilowatt-hour saved is pure profit.

The Heart of Efficiency: Servo vs. Old-School Motors

The single biggest change is the move to servo motor technology.

- Old Systems: Many older packing lines use hydraulic power packs or large, continuously running AC motors with clutches and brakes. The hydraulic pump runs constantly to maintain pressure, burning electricity even when nothing is moving. A large AC motor runs at full speed all the time, and its energy is converted to heat by a brake to stop the load. It's incredibly wasteful.

- Modern Servo Systems: A servo motor is different. It's a "smart" motor. It only draws significant power when it is accelerating or holding a load. During dwell times, its power consumption is minimal. Think of it like a modern car engine that shuts off at a stoplight versus an old engine that idles continuously. For a packing line with many start-stop motions—conveying, lifting, wrapping, strapping—the cumulative energy savings are substantial.

Intelligent System Logic and Power Management

A modern PLC (the brain of the machine) does more than just control the sequence. It manages energy.

- Sleep/Standby Modes: If the system's sensors detect that no coil has entered the packing station for a user-defined period, say 3 minutes, the PLC can automatically put non-essential components into a low-power standby mode. Conveyor motors turn off. The wrapping ring stops spinning. It only powers back up when a coil is detected upstream.

- Optimized Motion Profiles: Instead of crude, full-speed "bang-bang" movements, servo motors allow for precisely controlled acceleration and deceleration profiles. This "soft start" not only saves energy but also reduces mechanical shock and wear on the machine, contributing to higher reliability.

A Table of Savings: Beyond Electricity

The efficiency gains are not just in electricity. A well-designed automated system saves resources across the board, which also supports your environmental compliance goals.

| Feature | How It Saves Resources | Impact on Your Goals |

|---|---|---|

| Precision Stretch Film Wrapper | Pre-stretches film up to 300%, using less material for a stronger wrap. | Reduces consumable costs; lowers plastic waste. |

| Automated Strapping Head | Applies the exact, correct tension every time, eliminating overly tight straps that damage coils or loose straps that are useless. | Reduces strap waste; prevents product damage and costly rework. |

| Accurate Labeling | Applies the correct label in the correct position, every time. | Eliminates manual errors and the cost of re-labeling or lost products. |

When you combine the direct electricity savings from smart motors with the reduction in consumable waste, you begin to see how an automated packing line is a powerful tool for achieving both your 10% energy reduction and 8% operational cost reduction targets.

How Does a Smart Packing Line Adapt to Market Demands and Boost Profitability?

The steel market is never static. One quarter, the construction sector is booming and you need to ship thousands of standard-sized rebar coils. The next, a large automotive client places an urgent order for high-grade, smaller-diameter steel coils with special protective packaging. Your production line is capable of making the product, but your packing area struggles to keep up. Manual changeovers are slow and prone to error. Adjusting for different coil diameters, widths, and wrapping requirements takes too much time, creating a bottleneck that limits your factory's agility. This inability to react quickly to market opportunities directly impacts your ability to maximize capacity and profitability.

A smart, automated packing line boosts profitability by providing the flexibility to adapt to changing market demands almost instantly. It achieves this through pre-programmed "recipes" that allow for one-touch changeovers for different coil sizes and packing requirements. This agility minimizes downtime between different product runs. Furthermore, by integrating directly with your MES, it provides real-time data on throughput and efficiency, turning your packing line into a strategic tool for optimizing your entire production schedule and hitting your cost-reduction targets.

Dive Deeper: From a Rigid Bottleneck to a Flexible Asset

For years, the packaging department was seen as a simple, final step. Today, in a dynamic market, it needs to be as flexible as your rolling mill. The key to this is a combination of smart software and intelligent mechanical design. This is how you achieve true operational excellence and drive profitability.

The Power of Recipe Management

Imagine this scenario. You finish a run of 1500mm wide coils and the next order is for 900mm wide coils that also require an extra layer of VCI paper.

- Old System: A mechanic needs to be called. They manually adjust guide rails with a wrench and measuring tape. An operator has to change the strapping machine settings. Someone else has to manually thread the new paper roll. The entire process could take 30-60 minutes of downtime, or even more if an adjustment is wrong.

- Smart System: The operator walks up to the HMI (Human-Machine Interface) touch screen. They select the pre-programmed recipe named "AUTO-900-VCI". The system does the rest. Servo-driven guide rails automatically adjust to the new width. The wrapping machine automatically enables the VCI paper dispenser. The strapping head adjusts its stroke. The entire changeover takes less than two minutes, with no manual tools required.

This is not science fiction; this is standard on modern lines we build. This agility means you can say "yes" to more varied, high-margin orders without sacrificing efficiency.

Data Integration: Making Your MES More Powerful

Your goal to deploy an MES, IoT sensors, and a data analytics platform is exactly the right strategy for a modern steel mill. A smart packing line is a critical data source for this system. It's no longer a "black box" at the end of the line. It provides a constant stream of valuable information:

- Real-time Throughput: How many coils are being packed per hour? Is it matching the output of the slitting line? Your MES can visualize this, immediately flagging a bottleneck.

- Cycle Time Analysis: The system can report the average time for each step: conveying, wrapping, strapping, labeling. If the strapping cycle time suddenly increases, it could be an early indicator of a mechanical issue.

- Fault History and Alarms: Every stop, every fault is logged with a timestamp and a reason. This data is gold for your reliability team to identify recurring problems and implement permanent fixes.

- Consumable Tracking: The machine knows how much stretch film and strapping it has used. This can be tied into your inventory system for automatic reordering.

By feeding this data into your central platform, you can finally achieve that full production visualization you're aiming for. You can accurately measure your Overall Equipment Effectiveness (OEE) and identify concrete opportunities to lower costs and boost your profit margin.

What Is My Personal Take on Finding a True Automation Partner?

You’ve analyzed the numbers, you understand the technology, and you're convinced that automation is the right path. Now comes the most difficult decision: choosing who to work with. The market is full of companies that will happily sell you a machine. They’ll send you a catalog with impressive specifications and a low price. But I learned a hard lesson when I built my own factory: buying a machine is not the same as buying a solution. A poor choice of supplier can lead to a project that is over budget, behind schedule, and ultimately fails to deliver the ROI you were promised, leaving you with an expensive piece of equipment that becomes another problem to manage.

My personal take, from one factory owner to another, is to look for a true partner, not just a supplier. A partner invests the time to deeply understand your specific operational challenges, your financial goals, and your long-term vision. They don't just sell you what's on their shelf; they co-design a solution that fits your factory like a glove. They are transparent about the ROI calculations and stand by you through installation, training, and for the entire life of the machine. This partnership is the difference between simply buying equipment and making a successful strategic investment.

Dive Deeper: The Hallmarks of a Strategic Partner

This philosophy is the reason I transitioned from running my own factory to founding SHJLPACK. I wanted to build the kind of company I always wished I could have worked with. It's about sharing knowledge and building relationships, with the sale of a machine being the result of that trust, not the starting point. Here’s what I believe you should look for.

They Go Beyond the Spec Sheet

Any supplier can send you a technical data sheet. A partner starts by asking questions. What is your current workflow? Where are your bottlenecks? What kind of coils do you run most often? What are your plans for five years from now? They should be willing to do a site visit, to walk your factory floor and see the challenges with their own eyes. I remember a client who was convinced he needed the fastest wrapper we made. After visiting his plant, we saw that his real bottleneck was the slow crane used to load coils. We proposed a more moderately priced wrapper integrated with an automated infeed conveyor system. The total solution cost less and solved his actual problem, delivering a much higher ROI. A supplier would have sold him the expensive wrapper; a partner found the right solution.

They Provide a Customized, Integrated Solution

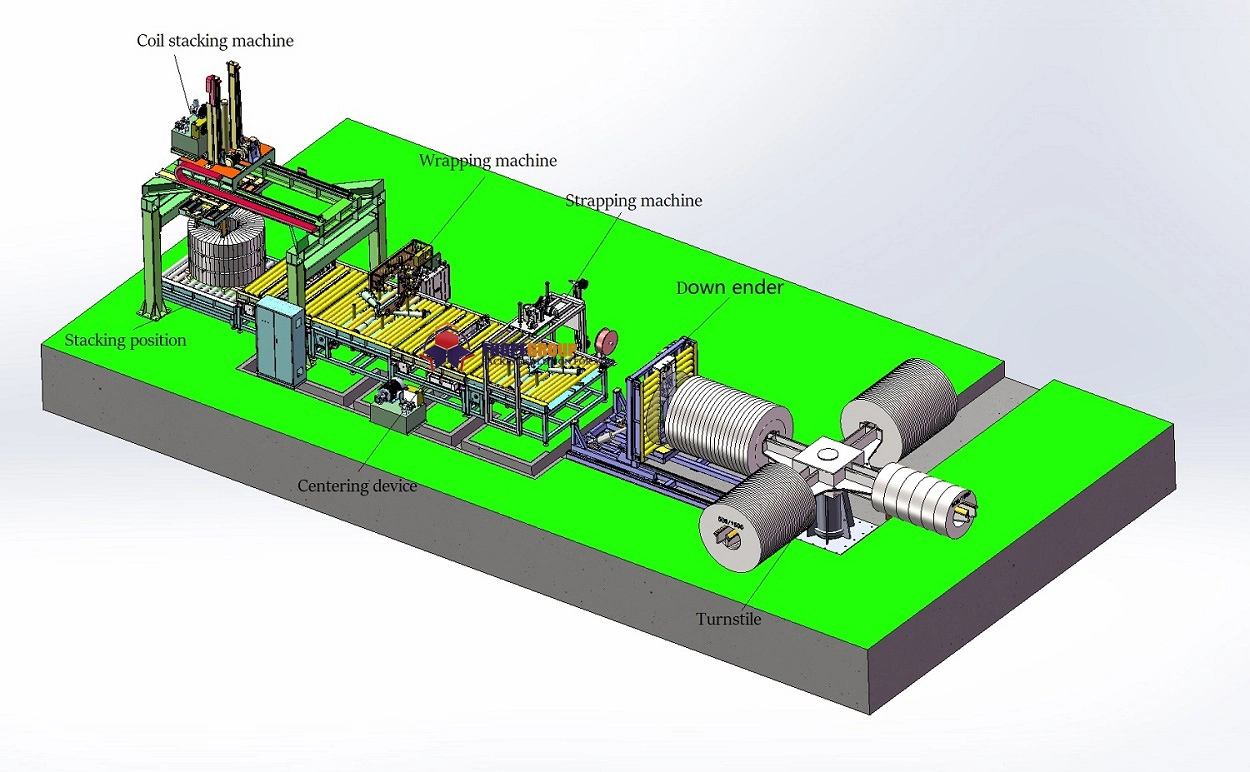

Your steel mill is unique. The layout, the upstream and downstream equipment, the type of coils—it’s all specific to you. A true partner doesn’t offer a one-size-fits-all machine. They design a line. This means ensuring the automated packing system communicates seamlessly with your slitting line and your warehouse management system. It means designing the physical layout to fit your available space and optimize material flow. This is what we mean by a "TOTAL SOLUTION FOR WRAPPING MACHINE". It's not just the wrapper; it's the conveyors, the tilters, the strapping machines, and the software that ties it all together into a single, cohesive, and efficient system.

They Are Committed to Your Long-Term Success

The relationship shouldn't end when the final payment is made. A strategic partner is there for the long haul. Ask them these critical questions:

- Training: How will you train my operators and maintenance team? Is it just a manual, or will you provide hands-on training on-site?

- Support: When I have a problem at 2 AM, who do I call? What is your remote diagnostic capability?

- Spare Parts: Do you stock critical spare parts locally or have a plan for quick shipment? How long will you guarantee parts availability?

- Future-Proofing: As my needs change, can this system be upgraded? Can you help me integrate new sensors or software in the future?

A partner's success is tied to your success. They see your factory's increased profitability and efficiency as a testament to their own work. This is the kind of relationship that turns an equipment purchase into a powerful, long-term competitive advantage.

Conclusion

Investing in the right coil packing automation is not an expense; it is a strategic investment in your factory's future. With a true partner, you get a solution that delivers measurable ROI.