Advanced Coil Upender Applications in Saudi Arabia's Coil Slitting Lines?

Leading Paragraph:

Are you struggling with production bottlenecks and safety hazards in your coil slitting operations? As a plant manager like Michael Chen, you know that inefficient material handling can cost your facility thousands in lost productivity and potential workplace injuries. The challenge of manually flipping heavy steel coils not only slows down your entire production line but puts your team at serious risk every single day.

Snippet Paragraph:

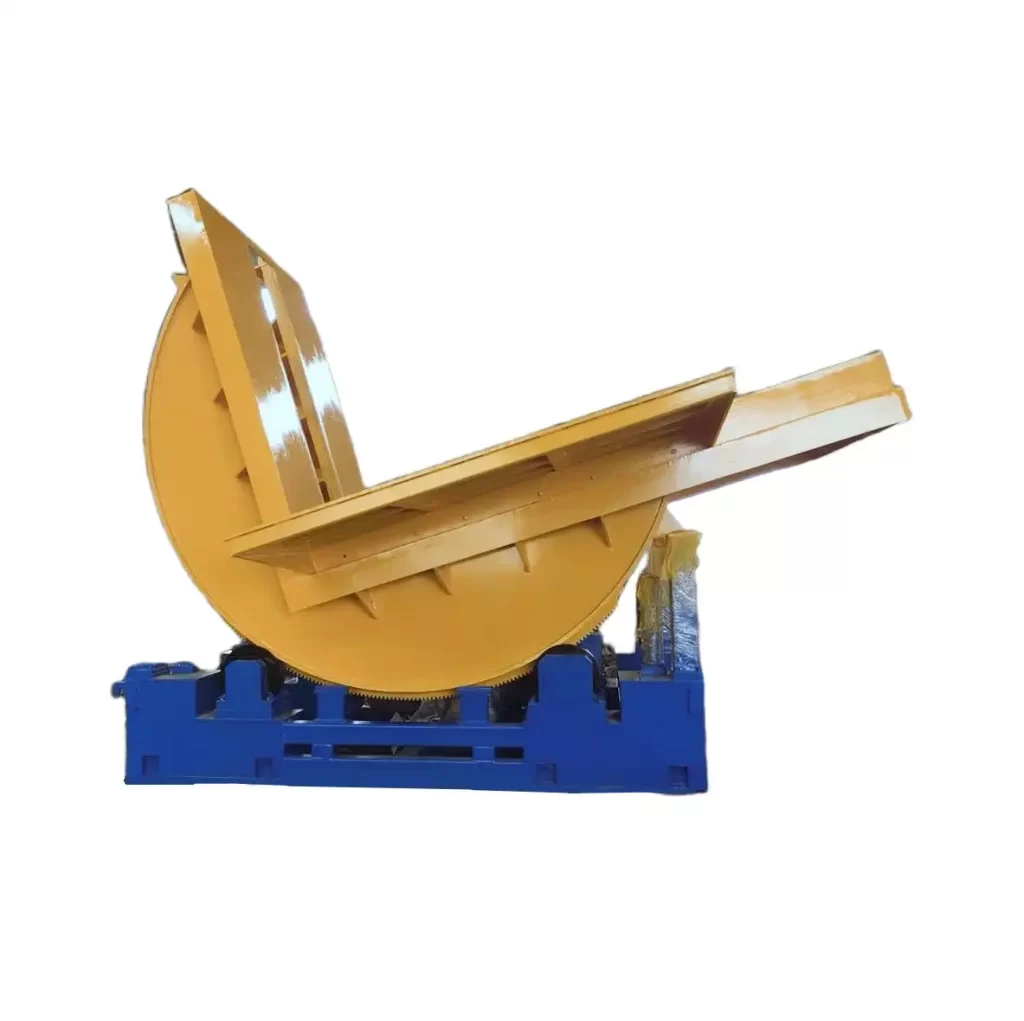

Advanced coil upenders are specialized material handling equipment that automate the process of rotating and positioning steel coils in slitting lines. These systems solve critical production challenges by:

- Eliminating manual coil handling and reducing workplace injuries by up to 85%

- Increasing production line efficiency by 30-50% through faster coil positioning

- Preventing product damage during orientation changes, saving thousands in scrap costs

Transition Paragraph:

But how do these advanced upending systems actually work in demanding environments like Saudi Arabia's steel industry? And what specific benefits can they deliver to operations managers facing the same challenges as Michael? Let's explore the key questions that will help you make an informed decision about upgrading your coil handling processes.

1. How Do Advanced Coil Upenders Solve Critical Production Bottlenecks?

Leading Paragraph:

Imagine your production team struggling to manually flip a 10-ton steel coil between slitting processes. This dangerous, time-consuming task not only creates safety concerns but becomes the primary bottleneck limiting your entire line's output. Advanced coil upenders address these exact pain points that plant managers like Michael face daily.

Snippet Paragraph:

Advanced coil upenders eliminate production bottlenecks by automating the coil rotation process that traditionally requires manual labor or crane operations. According to Randal Liu, founder of SHJLPACK, "A properly integrated upender system can reduce coil positioning time from 15-20 minutes to just 2-3 minutes per coil, effectively removing the biggest constraint in most slitting operations."

Dive Deeper Content:

The Three Main Bottlenecks Solved by Coil Upenders

🚫 Manual Handling Limitations

Traditional coil flipping requires multiple operators and often involves dangerous procedures. Workers must guide heavy coils using cranes and manual leverage, creating significant safety risks and inconsistent positioning times. In Saudi Arabian steel plants where temperatures can exceed 45°C (113°F), manual handling becomes even more challenging and hazardous.

⚡ Production Flow Disruption

Without automated upenders, the entire slitting line must stop whenever a coil needs reorientation. This creates a domino effect where downstream equipment sits idle while upstream processes wait for the manual flipping to complete. The resulting production gaps can cost a medium-sized facility like Michael's up to $8,000 daily in lost output.

💰 Product Damage and Quality Issues

Manual coil handling often leads to edge damage, surface scratches, and deformation - particularly problematic for premium-grade steel products. These quality defects result in customer rejections, rework costs, and profit erosion that directly impact your bottom line.

Comparative Solutions Analysis

| Bottleneck Type | Manual Process | Basic Upender | Advanced Upender |

|---|---|---|---|

| Positioning Time | 15-20 minutes | 5-7 minutes | 2-3 minutes |

| Workers Required | 3-4 operators | 1-2 operators | 1 operator (remote) |

| Safety Risk Level | High | Medium | Low |

| Product Damage Rate | 3-5% | 1-2% | <0.5% |

| Typical ROI Period | N/A | 24 months | 12-18 months |

Implementation Steps for Maximum Efficiency

- Process Analysis - Map your current coil flow and identify specific bottleneck points

- Space Assessment - Determine optimal upender location within existing layout

- Integration Planning - Coordinate with slitting line controls for seamless operation

- Operator Training - Transition team from manual to automated processes

- Performance Monitoring - Track key metrics like positioning time and damage rates

According to industry data from Saudi steel facilities, plants implementing SHJLPACK upender systems typically achieve 40% faster coil processing and reduce manual labor requirements by 75%. The automation of this critical step transforms what was once a production constraint into a competitive advantage.

2. What Are the 5 Key Safety Features of Modern Coil Upending Systems?

Leading Paragraph:

Every time your team manually handles a multi-ton steel coil, you're risking serious workplace injuries that can lead to costly insurance claims, regulatory fines, and operational disruptions. Modern coil upending systems incorporate multiple safety features specifically designed to protect both your workforce and your business.

Snippet Paragraph:

Modern coil upenders incorporate five critical safety features: emergency stop systems, anti-slip technology, overload protection, guarded pinch points, and automated positioning controls. These features work together to eliminate the most common causes of injuries in coil handling operations, reducing workplace accidents by up to 85% according to SHJLPACK installation data.

Dive Deeper Content:

Critical Safety Technologies in Advanced Upenders

🛑 Emergency Stop and Safety Interlocks

Modern upenders feature multiple emergency stop buttons positioned around the equipment perimeter, plus safety interlocks that prevent operation when guards are open. SHJLPACK systems include laser curtain protection that automatically stops the machine if anyone enters the operational zone during cycles.

🔒 Anti-Slip and Load Securing Technology

Advanced grip surfaces and hydraulic clamping systems ensure coils cannot slip during rotation. Unlike basic models that rely on friction alone, SHJLPACK upenders use positive mechanical locking combined with pressure monitoring to guarantee secure handling throughout the 90-degree rotation process.

⚖️ Overload Protection and Weight Monitoring

Intelligent load cells continuously monitor coil weight and center of gravity, automatically adjusting rotation speed and pressure to prevent tipping or structural overloading. This is particularly important in Saudi facilities processing imported coils with varying specifications and quality.

Safety Feature Comparison Table

| Safety Feature | Basic Upender | Professional Upender | Industrial Upender (SHJLPACK) |

|---|---|---|---|

| Emergency Stops | 2-3 locations | 4-6 locations | 8+ locations with remote access |

| Pinch Point Guarding | Partial | Full perimeter | Full + interlocked access |

| Load Monitoring | Mechanical limit | Basic sensors | Smart sensors with AI adjustment |

| Anti-Slip Technology | Standard pads | Enhanced grip | Hydraulic locking + monitoring |

| Safety Certifications | CE basic | CE comprehensive | CE + ISO 13849 + local compliance |

Safety Implementation ROI Calculation

Before Automation (Manual Handling):

- 3 workplace injuries annually × $25,000 average cost = $75,000

- Insurance premium penalty: $15,000 annually

- Production downtime from incidents: $12,000

- Total annual safety cost: $102,000

After SHJLPACK Upender Installation:

- Reduced to 0.5 injuries annually = 85% reduction

- Insurance premium discount: $8,000 annually

- Zero downtime from handling incidents

- Total annual safety cost: $12,500

- Annual safety savings: $89,500

According to Randal Liu's experience with Mexican manufacturing plants similar to Michael's operation, "The safety ROI alone often justifies the upender investment within 18 months, without even considering the production efficiency gains." This dual benefit of protecting both workers and profitability makes modern safety features a critical consideration for any coil processing facility.

3. Which Technical Specifications Matter Most for Saudi Arabian Steel Plants?

Leading Paragraph:

Selecting the right coil upender for your Saudi Arabian facility requires understanding which technical specifications actually impact performance in your specific environment. With extreme temperatures, high production volumes, and demanding quality standards, not all upender systems are created equal.

Snippet Paragraph:

The most critical technical specifications for Saudi steel plants include heat-resistant components (up to 55°C operation), dust protection (IP54 minimum), capacity matching local coil sizes (5-20 tons), and automation compatibility with existing slitting lines. SHJLPACK engineers specifically design systems for Middle Eastern conditions with enhanced cooling and dust filtration.

Dive Deeper Content:

Critical Technical Considerations for Saudi Operations

🌡️ Environmental Adaptation Specifications

Saudi Arabian steel plants face unique environmental challenges that standard equipment may not withstand. Key specifications include:

- Operating temperature range: -5°C to +55°C (extended cooling systems)

- Dust protection: IP54 minimum (IP65 recommended for desert conditions)

- Humidity resistance: 10-95% non-condensing

- Voltage stability: 380-480V ±10% with surge protection

🏭 Production Capacity Alignment

Matching upender capacity to your specific production requirements prevents both underutilization and premature wear:

| Production Volume | Recommended Capacity | SHJLPACK Model | Power Requirements |

|---|---|---|---|

| Low (≤50 coils/day) | 5-8 tons | CU-150 | 7.5 kW |

| Medium (50-150 coils/day) | 8-15 tons | CU-300 | 15 kW |

| High (150-300 coils/day) | 15-20 tons | CU-500 | 22 kW |

| Very High (300+ coils/day) | 20-25 tons | CU-800 | 30 kW |

Technical Specification Deep Dive

Structural Integrity Requirements

- Frame construction: Grade 50 steel minimum

- Hydraulic system pressure: 210 bar operating, 280 bar maximum

- Rotation speed: 2-4 RPM adjustable (slower for delicate materials)

- Positioning accuracy: ±1° for precise slitting alignment

- Foundation requirements: 400mm reinforced concrete minimum

Automation and Control Systems

- PLC interface: Siemens/Schneider/Allen-Bradley compatibility

- HMI display: 10" touchscreen with multilingual support

- Data logging: Production counts, maintenance alerts, error history

- Network connectivity: Ethernet/IP, Profinet, Modbus TCP

- Remote monitoring: Cloud-based performance tracking available

According to installation data from similar Middle Eastern facilities, SHJLPACK upenders with desert-grade specifications demonstrate 98% uptime compared to 85-90% for standard models not optimized for regional conditions. This reliability difference translates to approximately 300 additional production hours annually for a typical Saudi steel plant.

Integration Technical Checklist

- [ ] Voltage compatibility with local power grid (380V/50Hz)

- [ ] Foundation strength verification for equipment weight + dynamic loads

- [ ] Control system integration with existing slitting line PLC

- [ ] Safety system compliance with Saudi Arabian regulations

- [ ] Spare parts availability in Middle East region

- [ ] Local technical support response time < 24 hours

4. How Can Mexican Plant Managers Calculate ROI for Coil Upender Investments?

Leading Paragraph:

As a plant manager like Michael Chen, you need concrete numbers to justify capital investments to corporate leadership. Calculating the true ROI of a coil upender requires looking beyond the purchase price to capture all operational savings and productivity gains.

Snippet Paragraph:

Mexican plant managers can calculate coil upender ROI by analyzing labor reduction, productivity gains, quality improvements, and safety cost savings. A typical SHJLPACK installation shows 12-18 month payback periods through: 3 operator positions eliminated, 35% faster line speed, 90% reduction in coil damage, and 85% fewer workplace injuries.

Dive Deeper Content:

Comprehensive ROI Calculation Framework

💰 Direct Cost Savings Analysis

Labor Reduction:

- Manual process: 4 operators × $18,000/year = $72,000

- Automated process: 1 operator × $22,000/year = $22,000

- Annual labor savings: $50,000

Productivity Improvements:

- Previous output: 40 coils/day × $120 profit = $4,800

- Improved output: 54 coils/day (35% increase) × $120 = $6,480

- Daily productivity gain: $1,680 × 250 days = $420,000 annually

Quality and Damage Reduction:

- Previous damage rate: 3% × 10,000 coils × $200/coil = $60,000

- Improved damage rate: 0.3% × 13,500 coils × $200/coil = $8,100

- Annual quality savings: $51,900

ROI Calculation Table

| Cost Category | Before Automation | After SHJLPACK Upender | Annual Savings |

|---|---|---|---|

| Labor Costs | $72,000 | $22,000 | $50,000 |

| Productivity | $1,200,000 | $1,620,000 | $420,000 |

| Quality Losses | $60,000 | $8,100 | $51,900 |

| Safety Costs | $42,000 | $6,300 | $35,700 |

| Maintenance | $15,000 | $18,000 | -$3,000 |

| Total Annual Impact | $1,389,000 | $1,674,400 | $554,600 |

Implementation Cost Structure

SHJLPACK Upender System Investment:

- Equipment cost: $85,000-$150,000 (depending on capacity)

- Installation and commissioning: $15,000-$25,000

- Training and documentation: $5,000-$8,000

- Total investment: $105,000-$183,000

ROI Calculation:

- Annual savings: $554,600 (from table above)

- Investment: $150,000 (mid-range system)

- Simple payback period: 3.2 months

- First year ROI: 370%

According to Randal Liu's experience with Mexican manufacturing clients, "Most plant managers significantly underestimate the productivity gains from eliminating bottlenecks. The 35% line speed increase often delivers more value than all other savings combined." This comprehensive ROI approach helps managers like Michael build compelling business cases for automation investments.

Case Study: Mexican Steel Processor

🏭 Medium-sized steel service center in Monterrey

- Challenge: Manual coil flipping created 45-minute daily bottlenecks

- Solution: SHJLPACK CU-300 upender with automated positioning

- Results:

- Production increased from 40 to 54 coils daily (35% gain)

- Labor reduced from 4 to 1 operator per shift

- Coil damage decreased from 3% to 0.3%

- ROI achieved in 4.5 months

Conclusion

Advanced coil upenders transform production bottlenecks into competitive advantages through automation, safety, and efficiency gains. For plant managers seeking reliable solutions, these systems deliver measurable ROI while protecting both workers and product quality. Explore our complete steel coil packing line solutions for integrated material handling systems.

FAQ Section

Frequently Asked Questions

Q: How long does installation and commissioning typically take for a coil upender system?

A: Most SHJLPACK upender installations require 3-5 days for mechanical setup, plus 2-3 days for electrical integration and testing. Complete commissioning with operator training typically takes 7-10 working days, minimizing production disruption during implementation.

Q: What maintenance requirements should Mexican plants expect with automated coil upenders?

A: Basic maintenance includes daily visual inspections, weekly hydraulic system checks, and monthly bearing lubrication. Major service intervals are typically 2,000 operating hours. SHJLPACK systems feature automated maintenance tracking and alert operators when service is due.

Q: Can existing coil handling equipment be integrated with new upender systems?

A: Yes, most modern upenders can integrate with existing cranes, conveyors, and slitting lines through standardized PLC interfaces. SHJLPACK engineers conduct pre-installation compatibility assessments to ensure seamless integration with your current material handling equipment.

Q: What training is required for operators transitioning from manual to automated coil handling?

A: SHJLPACK provides comprehensive training covering basic operation, emergency procedures, routine maintenance, and troubleshooting. Most operators become proficient within 5-7 days of hands-on training, with additional support available through remote assistance systems.

Q: How do upender systems handle different coil sizes and weights within the same production line?

A: Advanced upenders feature adjustable arms and programmable settings for different coil specifications. Operators can save preset configurations for various coil dimensions, allowing quick changeover between different production runs without mechanical adjustments.